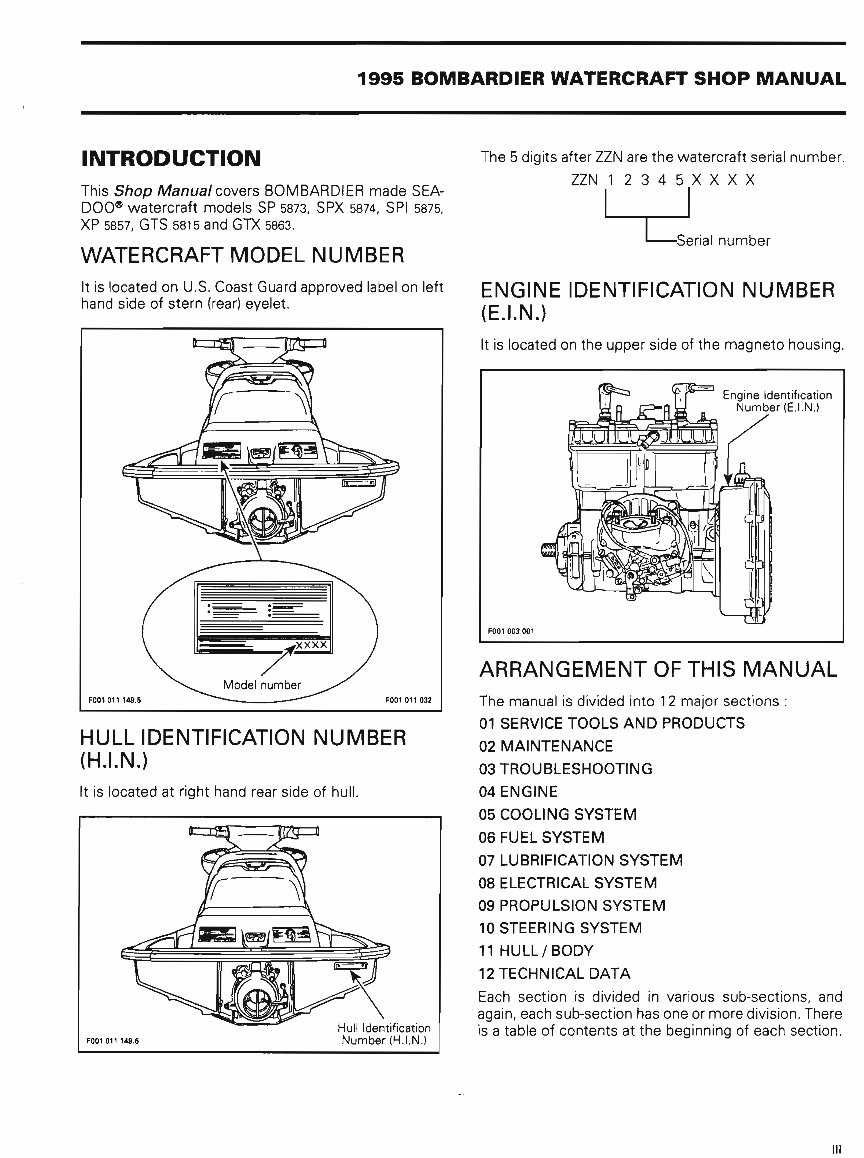

The internal structure of personal watercraft is crucial for maintaining peak performance and ensuring a smooth ride. Understanding how each element is connected and functions together can significantly improve maintenance and troubleshooting efficiency. This guide offers insights into the layout of various key elements within a popular watercraft model, helping you gain a deeper knowledge of its mechanical and electrical systems.

Key components are systematically arranged to provide optimal performance. Whether it’s the propulsion system, the electrical wiring, or the cooling mechanisms, recognizing the specific arrangement can greatly simplify any repair or upgrade processes. With clear visualization and descriptions, this section will make it easier to identify essential systems and their respective roles in keeping your machine running smoothly.

By grasping these essential configurations, you will be better equipped to maintain your vehicle, perform regular checks, and replace worn-out elements as needed. This overview serves as a reliable resource to keep your machine in top condition.

Understanding the Seadoo GTX 1995 Components

To fully comprehend how a personal watercraft operates, it’s essential to explore its individual mechanisms and how they interact. Each element plays a critical role in ensuring both performance and safety, from propulsion systems to the control mechanisms.

Key Functional Areas

- Engine System: The heart of any watercraft, driving the vessel through internal combustion and providing the necessary power for all operations.

- Cooling Mechanism: Ensures the motor remains at optimal temperature, preventing overheating and maintaining performance.

- Fuel Delivery: This component is responsible for managing the flow of fuel, ensuring efficient and stable power output.

Steering and Control

- Handlebars: These allow the rider to direct the watercraft, controlling its movement with precision.

- Throttle: The throttle adjusts the speed, giving the rider control over acceleration and deceleration.

- Braking System: A

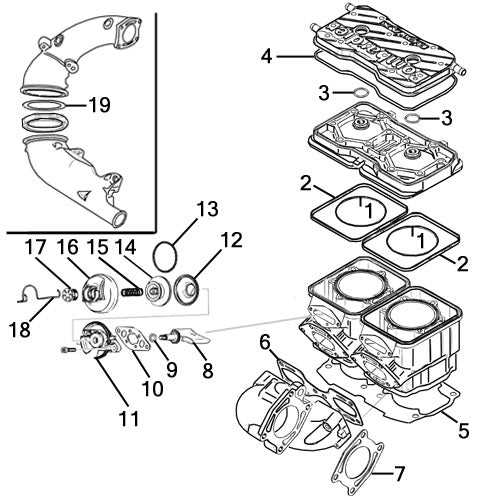

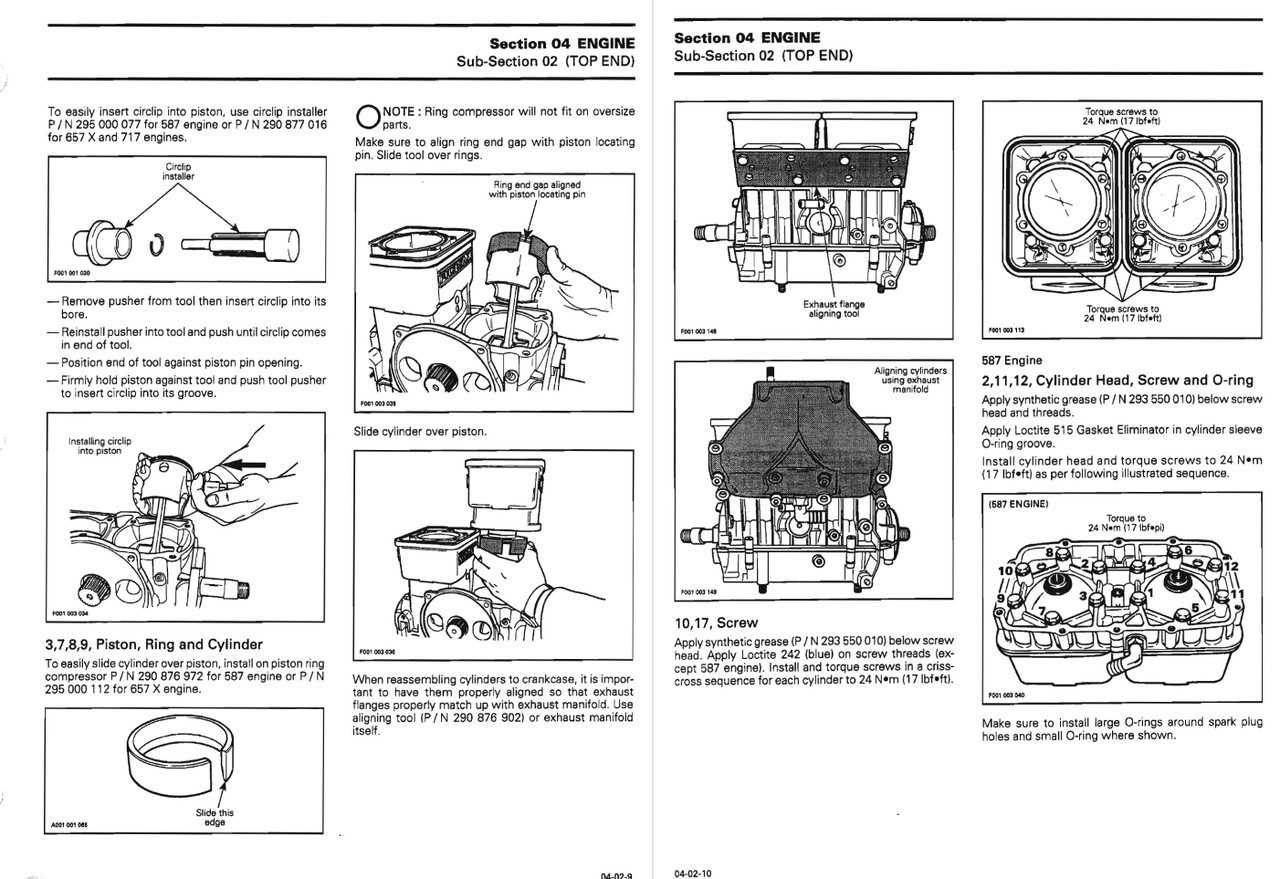

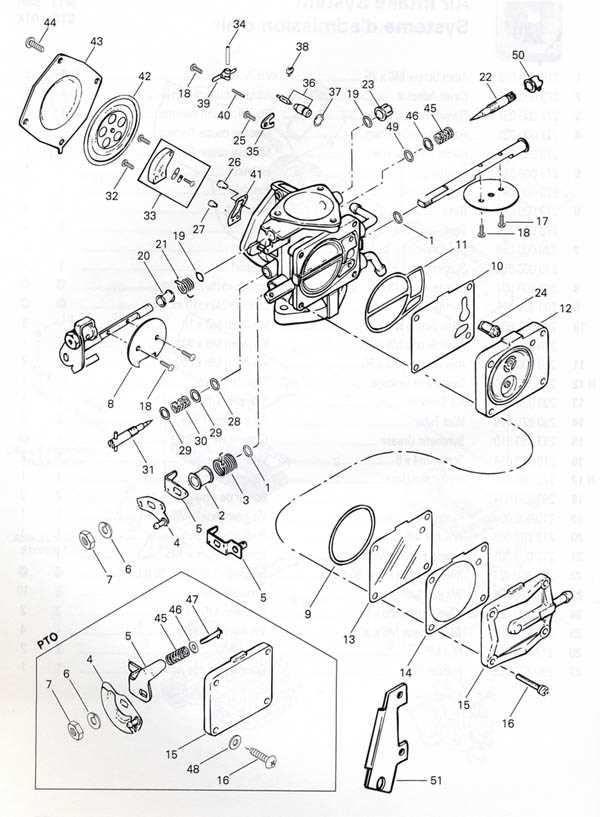

Engine Parts Overview

The engine is a critical component, consisting of various interconnected elements that work together to ensure smooth operation. Understanding the key aspects of its structure and functionality can help in maintaining and repairing the motor. Each part plays a vital role in ensuring efficiency and performance.

Cylinders are central to the engine’s power generation, converting fuel into mechanical energy. The pistons move inside them, driven by combustion, while the crankshaft translates this motion into rotational energy. Additionally, the carburetor ensures the right mixture of air and fuel is delivered for combustion, optimizing performance.

Other essential elements include the cooling system, which prevents overheating, and the ignition system, responsible for sparking combustion. By maintaining these components, the overal

Fuel System Breakdown

The fuel system is essential for ensuring the proper operation of any watercraft engine. It consists of several key components that work together to deliver the right amount of fuel to the motor, enabling smooth performance and efficiency. Understanding how these elements interact helps in maintaining the overall reliability and function of the vehicle.

The primary elements of this system include the fuel tank, lines

Electrical System Layout

The electrical network of this watercraft is a carefully arranged system designed to manage power distribution efficiently. It ensures that all components, from the ignition system to auxiliary electronics, receive stable and reliable electrical current. Understanding how this system is interconnected can simplify troubleshooting and maintenance tasks.

Main Components

The key elements within the electrical setup include the power source, control units, and connectors that facilitate communication between different parts of the vehicle. The power generation is handled by the stator and battery, while the control units regulate distribution and functionality.

Wiring and Connections

The layout of the wiring harness plays a crucial role in ensuring seamless connectivity. Every section of the system is linked by cables and connectors that transmit signals and energy to vital parts of the craft, maint

Cooling System Components

The cooling system is an essential part of any watercraft, ensuring that the engine remains at an optimal temperature during operation. By circulating water through various channels, it helps prevent overheating, which could lead to engine damage. Understanding how the individual elements work together is key to maintaining overall system efficiency.

Water Intake and Circulation

One of the primary elements is the water intake, which allows water from the surrounding environment to enter the system. Once inside, the fluid moves through pipes and passages, circulating around the engine to absorb excess heat. This process ensures that the engine stays within a safe operating range, even during extended use.

Heat Exchange and Exhaust

After the water absorbs heat, it needs to be expelled from the system. The heat exchanger plays a critical role here, transferring the absorbed heat away from the engine. The water then exits through the exhaust, completing the cooling cycle. This continuous flow of water

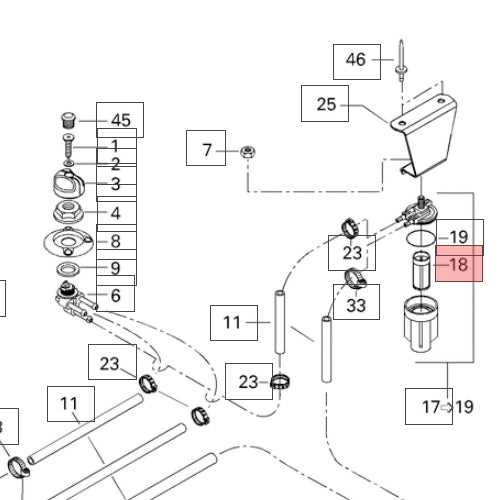

Jet Pump Assembly Details

The jet pump assembly plays a crucial role in the propulsion system of watercraft. This component is responsible for converting the engine’s power into thrust, enabling the vessel to navigate efficiently. Understanding the structure and functionality of the jet pump is essential for maintenance and performance enhancement.

Key Components: The assembly consists of several integral parts, including the impeller, stator, and housing. Each element serves a specific function, contributing to the overall effectiveness of the propulsion mechanism. The impeller, for instance, is designed to draw in water and accelerate it, while the stator ensures smooth flow direction.

Maintenance Considerations: Regular inspection of the jet pump assembly is vital to prevent performance issues. Components may wear out or become damaged over time, leading to decreased efficiency. Keeping the assembly clean and free of debris is also essential to ensure optimal operation and longevity.

Exhaust System Diagram

The exhaust system is a crucial component in any watercraft, designed to manage the flow of gases produced during combustion. Understanding its layout can help in identifying issues and maintaining optimal performance. This section provides insights into the structure and functionality of the exhaust components, ensuring an efficient operation of the vessel.

Key Components

- Muffler: Reduces noise produced by the engine.

- Exhaust Manifold: Collects gases from the engine cylinders.

- Pipes: Direct the exhaust gases away from the engine.

- Water Injection: Coolants that mix with exhaust gases to reduce temperature.

Functionality Overview

The exhaust system operates by channeling gases generated during the combustion process through various components. The muffler minimizes sound while the manifold gathers exhaust from multiple engine cylinders. Efficient piping is essential to ensure gases exit smoothly, reducing back pressure and enhancing engine performance. Water injection plays a vital role in cooling the gases, protecting components from heat damage.

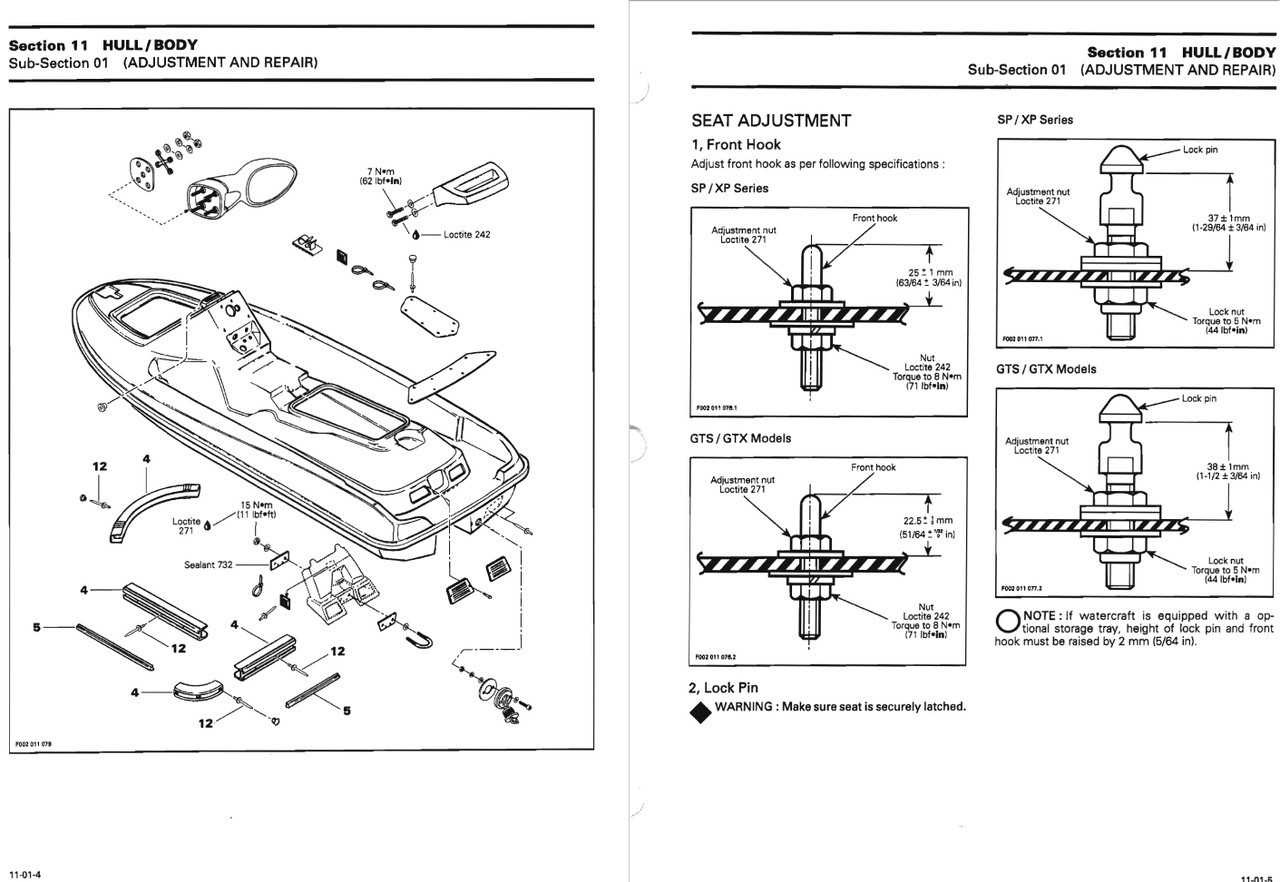

Hull Structure and Design

The hull of a personal watercraft serves as its foundation, contributing significantly to performance, stability, and safety on the water. The design of the hull involves a careful balance of materials and shape, ensuring that the craft can handle various conditions while providing comfort and control for the operator.

Various components work together to create an effective hull. Below is a table outlining the primary elements involved in hull construction and their functions:

Component Description Outer Shell The exterior layer that protects the internal components and provides a hydrodynamic shape. Reinforcements Additional materials integrated into the structure to enhance strength and durability. Keel The central structural element that runs along the bottom of the hull, providing stability and tracking. Bulkheads Vertical partitions within the hull that divide it into sections, adding structural integrity and buoyancy. Drains Channels designed to allow water to exit the hull, preventing excess accumulation and ensuring safety. A well-designed hull not only enhances the aesthetic appeal of the watercraft but also plays a crucial role in its overall performance. Understanding the various elements that constitute the hull structure can aid in effective maintenance and improvements for better functionality on the water.

Steering and Control Mechanisms

The functionality and maneuverability of watercraft heavily rely on their steering and control systems. These components play a vital role in ensuring smooth navigation and precise handling in various aquatic conditions. Understanding the mechanisms involved is essential for optimal performance and safety while operating the vessel.

Steering systems typically encompass several key elements, including the handlebars, cables, and the steering nozzle. Each part is designed to work in unison, providing the operator with the ability to direct the craft effectively. The connection between the handlebars and the steering nozzle is crucial; any wear or damage in this area can lead to compromised steering precision.

Control mechanisms also include throttle and brake systems, which allow the operator to regulate speed and stop the craft safely. These systems must be responsive and intuitive, providing a seamless interaction between the rider and the vessel. Regular maintenance and inspection of these components ensure reliability and longevity, contributing to a safe and enjoyable riding experience.

Ignition System Schematic

The ignition system is a crucial component in ensuring the proper functioning of a watercraft’s engine. It is responsible for initiating the combustion process by generating a high-voltage spark that ignites the air-fuel mixture in the engine’s cylinders. Understanding the layout and connections of this system can aid in diagnosing issues and performing maintenance effectively.

Below is a simplified representation of the ignition system components and their interconnections:

Component Description Ignition Coil Transforms battery voltage into high voltage needed to create a spark. Spark Plug Fires the spark to ignite the fuel-air mixture. CDI Unit Controls the timing of the spark and regulates the ignition coil’s firing. Trigger Sensor Detects the engine’s position and signals the CDI to fire the ignition coil. Wiring Harness Connects all components and facilitates the flow of electrical signals. Proper maintenance and understanding of this system can significantly enhance the performance and reliability of the engine, ensuring a smooth and enjoyable riding experience.

Maintenance and Replacement Guidelines

Regular upkeep and timely part substitution are crucial for ensuring optimal performance and longevity of your watercraft. Adhering to a structured maintenance schedule can help prevent unexpected failures and enhance the overall experience on the water. This section outlines essential practices and recommendations for effectively maintaining and replacing components.

Below is a summary of key maintenance tasks and the recommended intervals for each:

Task Description Frequency Oil Change Replace engine oil to ensure smooth operation and reduce wear. Every 50 hours of use Battery Check Inspect battery connections and charge levels for optimal performance. Monthly Inspection of Hoses Examine hoses for signs of wear or damage and replace if necessary. Every season Fuel System Maintenance Clean fuel filters and inspect lines to prevent clogs and leaks. Annually Propeller Condition Check propeller for dings or bends and replace if damaged. Every 100 hours of use Following these guidelines will not only extend the life of your watercraft but also ensure a safe and enjoyable experience on the water.