The maintenance and repair of any utility vehicle require a thorough understanding of its components. Proper knowledge of the various elements that make up the machinery is crucial for efficient functioning and longevity. Whether you are a seasoned mechanic or a novice enthusiast, having access to a detailed schematic can greatly enhance your ability to identify and troubleshoot issues.

In this section, we will explore a comprehensive breakdown of the crucial elements involved in this specific model. By examining the layout of each component, you will gain insights into how they interact and contribute to the overall performance of the vehicle. This knowledge empowers you to make informed decisions regarding upgrades, replacements, and repairs.

Furthermore, familiarity with the arrangement of these components facilitates easier navigation during maintenance tasks. With a clear visual representation at hand, both routine inspections and complex repairs become significantly more manageable. Engaging with the intricacies of this model will enable you to maintain optimal functionality and reliability.

Overview of 2005 Arctic Cat 500 Parts Diagram

This section provides a comprehensive examination of the essential components and assemblies of a specific model of all-terrain vehicle. Understanding the various elements that make up this machine is crucial for maintenance, repair, and enhancement. Each segment plays a vital role in ensuring optimal performance and longevity, contributing to the overall functionality and reliability of the vehicle.

Key Components and Their Functions

Among the various parts, the engine assembly stands out as the powerhouse, delivering necessary propulsion. Additionally, the suspension system is integral for managing rough terrains, ensuring comfort and stability for the operator. Understanding how these components interact allows for better troubleshooting and efficient upgrades.

Maintenance and Replacement Considerations

Routine inspections and timely replacements of wear-prone elements are crucial for preserving the vehicle’s efficiency. Identifying the correct specifications for replacements is essential, as using incompatible parts can lead to performance issues. It is advisable to consult detailed schematics to ensure proper installation and compatibility.

Importance of Parts Diagrams

Understanding the layout and arrangement of various components in a mechanical system is crucial for effective maintenance and repairs. A visual representation helps identify individual elements and their connections, ensuring that each piece is placed correctly. Without such a resource, troubleshooting and assembly can become time-consuming and prone to errors.

Clarity in Repairs and Maintenance

When faced with complex machinery, having a clear guide to the inner workings is essential. A schematic view simplifies the process, allowing users to follow step-by-step instructions without confusion. This ensures that even minor repairs are carried out efficiently, reducing the risk of damaging other components.

Efficient Part Replacement

- Helps locate the exact component quickly

- Avoids mismatching or incorrect replacements

- The power unit is designed to offer consistent output, enabling the vehicle to handle various terrains effectively.

- Connected to the drive system, the gearbox ensures smooth gear changes and optimal speed control.

- The cooling mechanism helps regulate temperature, protecting the engine from overheating.

Key Components of the Vehicle

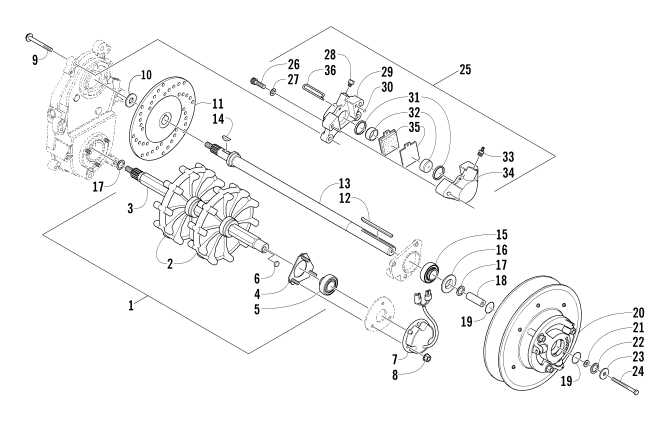

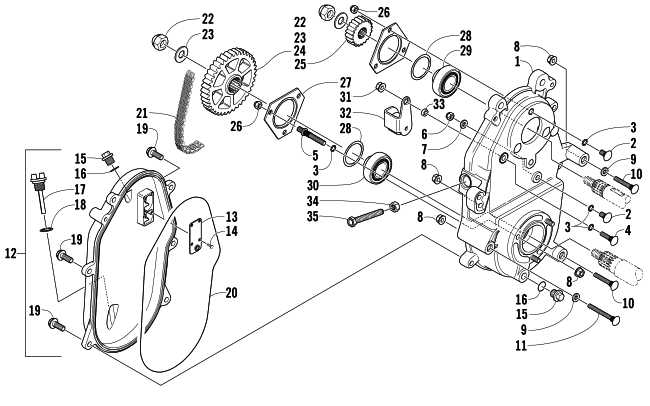

The mechanical structure of this vehicle consists of various crucial elements that ensure its efficient operation and performance. Each section plays a significant role in maintaining balance, power transmission, and overall functionality, working in harmony to deliver a smooth ride under diverse conditions.

Engine and Transmission System

Suspension and Braking System

- The suspension setup absorbs shocks, providing comfort and stability over uneven surfaces.

- The braking mechanism ensures quick and reliable stopping power, critical for both

How to Read the Diagram

Understanding visual representations of mechanical assemblies is essential for effective maintenance and repair. These illustrations offer a clear view of how components interact, providing a guide to the arrangement and structure of various elements. By interpreting these visual guides correctly, users can identify connections, alignments, and the overall placement of parts.

Symbol Meaning Dashed Lines Indicate flexible connections or potential movements between components. Solid Lines Represent fixed or permanent connections that are critical to the structure. Numbers Common Replacement Parts

Frequent maintenance often requires the replacement of certain components to ensure smooth operation and longevity. Various elements may wear down due to regular use or challenging conditions, making it essential to address these issues promptly to maintain performance and prevent further damage.

Key elements subject to regular inspection and substitution include filters, which play a vital role in keeping the engine running efficiently, as well as braking components that ensure safety during operation. Suspension parts and tires also experience considerable stress and may need attention, especially in demanding environments. Regular checks and timely updates can significantly extend the service life and ensure consistent functionality.

Maintenance Tips for Longevity

Ensuring the durability and smooth operation of your vehicle requires a consistent maintenance routine. By focusing on a few key practices, you can significantly extend the lifespan of your machine and avoid costly repairs. Below are essential steps you can follow to keep everything running in top condition.

- Regular Oil Changes: Periodically replacing the engine oil is crucial for reducing friction and preventing wear on internal components.

- Check and Replace Filters: Air and oil filters should be checked regularly and replaced when necessary to maintain optimal performance.

- Inspect Drive Belt: Examine the belt for any signs of cracking or wear. Replace it if necessary to avoid breakdowns during operation.

- Grease Moving Parts: Lubricate joints and bearings to reduce wear and

Tools Required for Repairs

When performing maintenance or restoring key components, having the right tools at hand can greatly simplify the task. A well-prepared toolkit ensures smooth and efficient work, helping to avoid potential setbacks and ensuring each step is completed properly.

Basic Hand Tools

- Wrenches of various sizes for loosening and tightening bolts

- Screwdrivers, both flathead and Phillips

- Pliers for gripping and adjusting components

- A torque wrench to ensure precise application of force

Specialized Equipment

- Socket set with a range of metric and standard sizes

- Lubrication tools for proper greasing and maintenance

- Jack or lift for raising heavy machinery during repair work

- Multimeter to check electrical circuits and

Understanding Wiring and Electrical Systems

The electrical setup of any machine plays a critical role in ensuring its smooth operation. A well-designed network of cables and circuits ensures that power is delivered where it is needed, while also protecting components from overloads or short circuits. Proper knowledge of how these connections function is essential for troubleshooting or upgrading the system.

- Power Distribution: Electrical systems typically rely on a primary power source, such as a battery, to energize the various circuits.

- Grounding: A robust grounding system is crucial for safe operation, providing a return path for excess current to avoid damaging sensitive parts.

- Fuse Protection: Fuses act as safeguards, preventing excessive current from flowing through components and avoiding potential failure or fire risks.

- Connectors and Terminals:

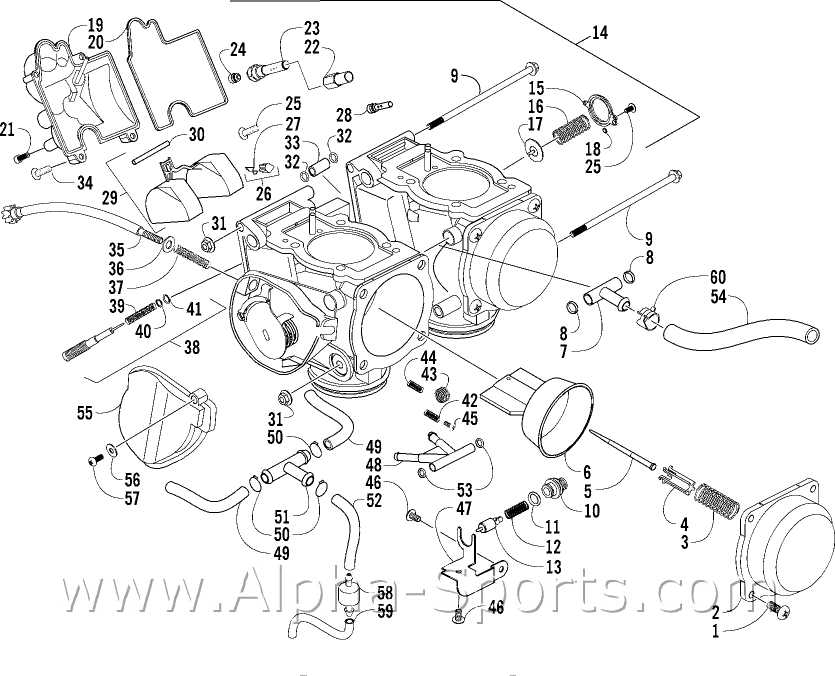

Identifying Engine Components

The engine of any off-road vehicle consists of multiple interconnected elements that work together to ensure optimal performance. Understanding how each piece functions within the overall system is crucial for effective maintenance and repair. By recognizing key elements, owners can troubleshoot issues and replace worn-out items with greater confidence.

Cylinder head plays a pivotal role in housing components responsible for combustion. Valves control the intake of air and fuel, as well as the exhaust of gases. The piston moves within the cylinder, creating the compression needed for the engine to run. Connecting these, the crankshaft converts the vertical motion of the pistons into rotational energy.

The camshaft controls the timing of valve movements, ensuring they open and close at

Suspension and Chassis Parts

When it comes to maintaining optimal performance, the frame and support mechanisms play a crucial role in ensuring smooth rides and stability over uneven terrain. Each component within this system contributes to handling, comfort, and the overall driving experience, making it essential to focus on proper upkeep and functionality.

Key Structural Components

The primary elements of the framework include various support arms, joints, and connectors, which work in harmony to provide strength and flexibility. These elements must be regularly inspected for wear and tear, as they ensure the vehicle’s ability to absorb shocks and maintain balance during operation.

Importance of Stability Systems

The stability system is crucial for maneuverability and comfort, especially when navigating challenging surfaces. Ensuring all stabilizers, bushings, and shock absorbers are in good condition helps to prevent excessive

Braking System Overview

The stopping mechanism plays a critical role in ensuring safe and reliable operation, especially during demanding conditions. Its function is to decelerate or halt movement by applying controlled friction. This section explores the key components responsible for managing the system’s efficiency and performance, highlighting their interaction and importance.

Hydraulic Mechanism: The system utilizes fluid pressure to engage the components. When the control lever is pressed, it triggers a reaction that sends force through the fluid lines, activating the deceleration process.

Disc and Caliper: The disc, connected to the wheels, is clamped by the caliper. This action converts kinetic energy into heat, ensuring effective reduction of speed or complete stoppage.

Brake Pads: Positioned within the caliper, these frictional surfaces press against the disc, creating the necessary resistance to

Finding OEM Parts Online

Locating original equipment manufacturer components on the internet has become increasingly convenient due to the growing number of online retailers and platforms. By utilizing specific keywords and understanding how to navigate various websites, enthusiasts can efficiently acquire high-quality replacements for their machinery. This approach not only ensures compatibility but also promotes longevity and optimal performance.

Utilizing Reputable Sources

When searching for authentic components, it is crucial to choose trustworthy suppliers. Websites dedicated to aftermarket and OEM items often feature customer reviews and ratings, providing insight into their reliability. Additionally, authorized dealers and manufacturer websites typically offer accurate inventory listings, ensuring that the items purchased meet the required specifications.

Exploring Online Marketplaces

Online marketplaces can also be a valuable resource for sourcing genuine components. Platforms like eBay and Amazon may host third-party sellers offering a variety of products. However, it is essential to scrutinize the seller’s credentials and product descriptions to confirm authenticity. Checking return policies and warranty options can provide extra assurance when purchasing from these sources.