The intricate structure of a modern pickup vehicle is essential for ensuring optimal functionality and performance. Every element plays a significant role in the overall operation, from the engine to the electrical systems. Analyzing these configurations can help enthusiasts and mechanics alike identify the correct components and enhance their understanding of the vehicle’s mechanics.

By examining the arrangements and relationships between different parts, users can gain insights into maintenance and upgrades. This knowledge is crucial for both everyday drivers and automotive specialists who seek to improve or restore the efficiency of their trucks.

Utilizing visual representations of these layouts allows for a clearer comprehension of how each component interacts. Such illustrations serve as a valuable resource, guiding users through the complexities of their vehicle’s design and functionality.

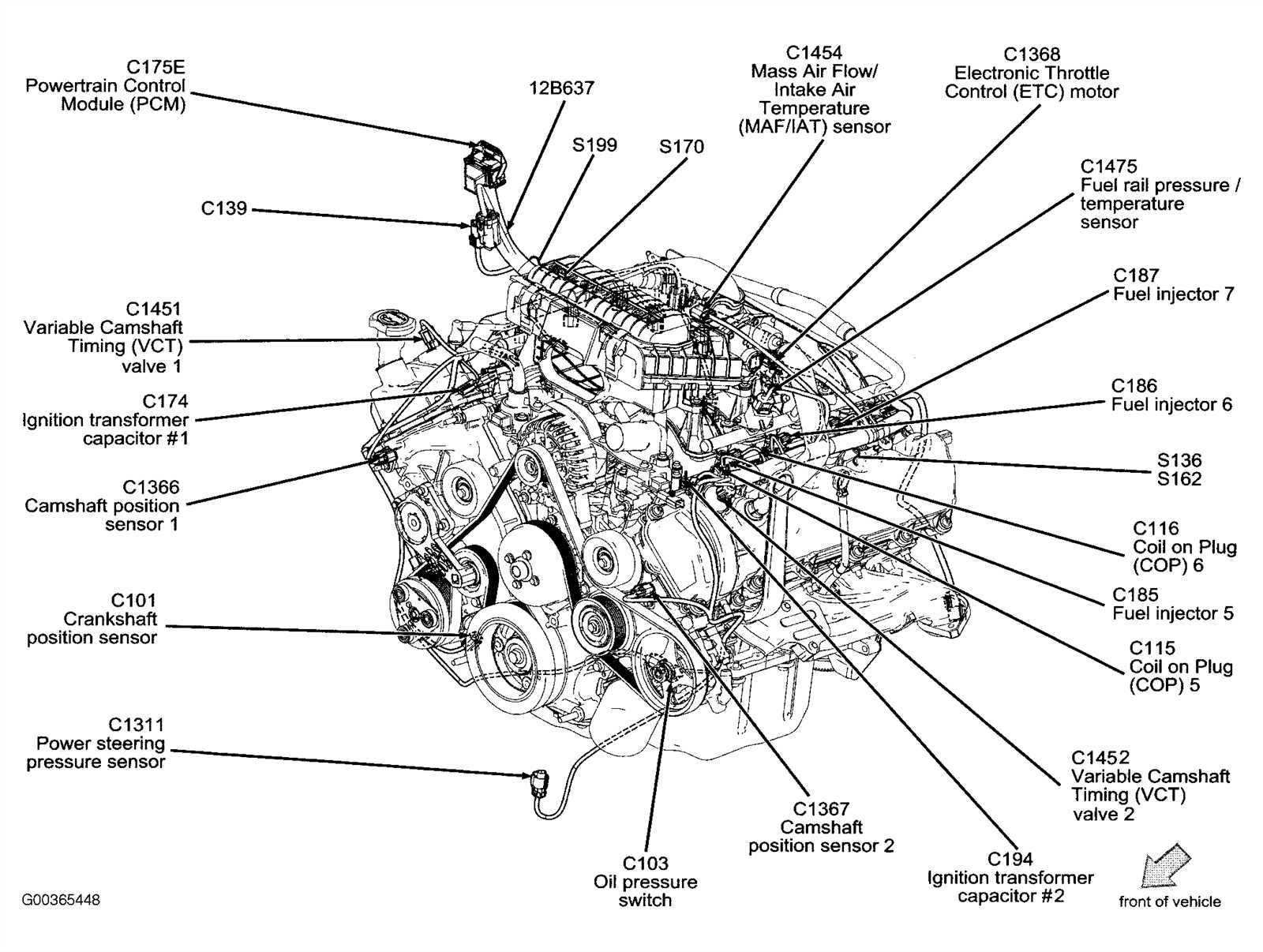

The internal combustion mechanism is composed of various components, each serving a vital role in the overall operation and efficiency of the system. Understanding these elements is essential for maintenance and troubleshooting, ensuring optimal performance over time.

- Block: The main structure housing various engine components, providing support and stability.

- Cylinder Head: Covers the upper part of the cylinders, containing valves and spark plugs, crucial for gas exchange and combustion.

- Pistons: Move up and down within the cylinders, compressing the air-fuel mixture and converting energy from combustion into mechanical power.

- Crankshaft: Transforms the linear motion of the pistons into rotational motion, driving the vehicle’s transmission.

- Camshaft: Operates the intake and exhaust valves, timing their opening and closing to synchronize with the pistons’ movement.

- Oil Pan: Holds lubrication fluid, essential for reducing friction and cooling engine components.

- Timing Belt/Chain: Ensures the synchronized operation of the crankshaft and camshaft, maintaining the correct timing of valve operations.

Each component plays a unique role, working in harmony to maximize efficiency and power output. Regular inspection and maintenance of these parts can significantly enhance performance and extend the lifespan of the mechanism.

Transmission System Breakdown

The transmission system is a crucial component of any vehicle, playing a vital role in transferring power from the engine to the wheels. Understanding the various elements that make up this system is essential for maintenance and troubleshooting. This section delves into the key components and their functions within the overall assembly.

1. Gearbox: The gearbox serves as the heart of the transmission, allowing for gear changes that adjust the vehicle’s speed and torque. Its operation is fundamental to ensuring smooth acceleration and deceleration during driving.

2. Torque Converter: This device connects the engine to the transmission, enabling the transfer of power while allowing the engine to continue running when the vehicle is stationary. It plays a significant role in enhancing fuel efficiency and improving performance.

3. Shift Linkage: The shift linkage system enables the driver to select different gears, facilitating seamless transitions between them. Proper functioning of this mechanism is crucial for the overall driving experience.

4. Clutch Assembly: In manual transmission systems, the clutch assembly is responsible for engaging and disengaging the engine from the drivetrain. This component is essential for changing gears smoothly without damaging the transmission.

5. Transmission Fluid: This lubricant is vital for the system’s operation, ensuring that all moving parts function correctly and preventing overheating. Regular checks and changes of this fluid are necessary for the longevity of the transmission.

Overall, a thorough understanding of the transmission system components contributes to effective vehicle maintenance and enhances driving performance.

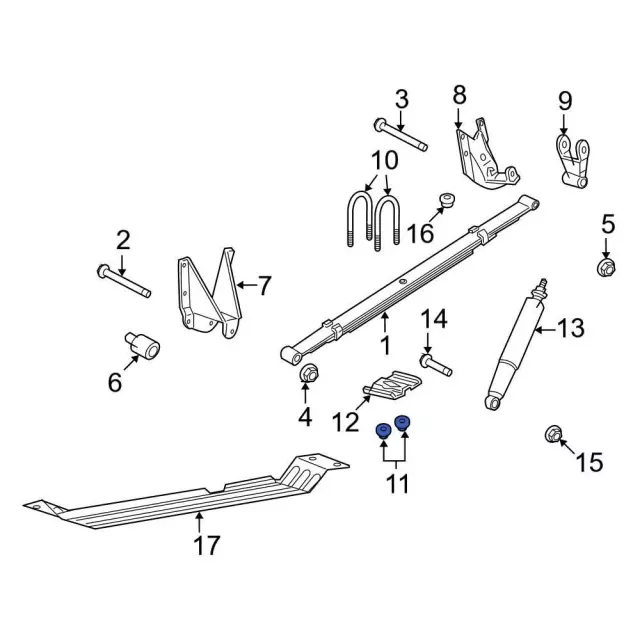

Suspension and Steering Elements

The components that facilitate the smooth operation of the vehicle’s suspension and steering systems are crucial for maintaining control and comfort. These elements work together to provide stability, enhance handling, and absorb road imperfections, ensuring a pleasant driving experience.

Key Suspension Components

The suspension system consists of various parts that contribute to the vehicle’s overall performance. Key elements include springs, dampers, and control arms. Springs support the weight of the vehicle and absorb shocks from the road, while dampers, or shock absorbers, help control the oscillation of the springs, providing a stable ride. Control arms connect the chassis to the wheel assembly, allowing for controlled movement and alignment.

Steering Mechanism Overview

The steering mechanism enables the driver to guide the vehicle with precision. Essential components include the steering wheel, column, and rack-and-pinion system. The steering wheel allows the driver to input directional changes, which are transmitted through the column to the rack-and-pinion, translating rotational motion into lateral movement of the wheels. This system ensures responsiveness and control, essential for safe navigation.

Braking System Components Explained

The braking system in a vehicle plays a crucial role in ensuring safety and control during operation. Understanding the various elements that comprise this system can help in maintaining and troubleshooting performance issues. This section delves into the key components of the braking mechanism and their respective functions.

Key Elements of the Braking System

- Brake Pedal: The interface between the driver and the braking system, allowing the driver to apply force to engage the brakes.

- Brake Booster: A device that amplifies the force applied to the brake pedal, making it easier to achieve effective stopping power.

- Master Cylinder: This component converts the mechanical force from the brake pedal into hydraulic pressure, transmitting it to the brake lines.

- Brake Lines: Tubes that carry the hydraulic fluid from the master cylinder to the brake calipers or wheel cylinders.

- Brake Calipers: Responsible for clamping the brake pads against the rotors, creating friction to slow down the vehicle.

- Brake Pads: Friction materials that press against the rotors to reduce speed and ensure safe stopping.

- Rotors: Metal discs that the brake pads grip to create the necessary friction for deceleration.

- Wheel Cylinders: Components in drum brakes that exert force on the brake shoes, leading to braking action.

Functionality and Maintenance

Each part of the braking system plays an integral role in ensuring effective operation. Regular maintenance, including checking fluid levels and inspecting components for wear, is essential to guarantee the system functions properly. Understanding these elements can empower vehicle owners to address issues promptly, enhancing overall safety.

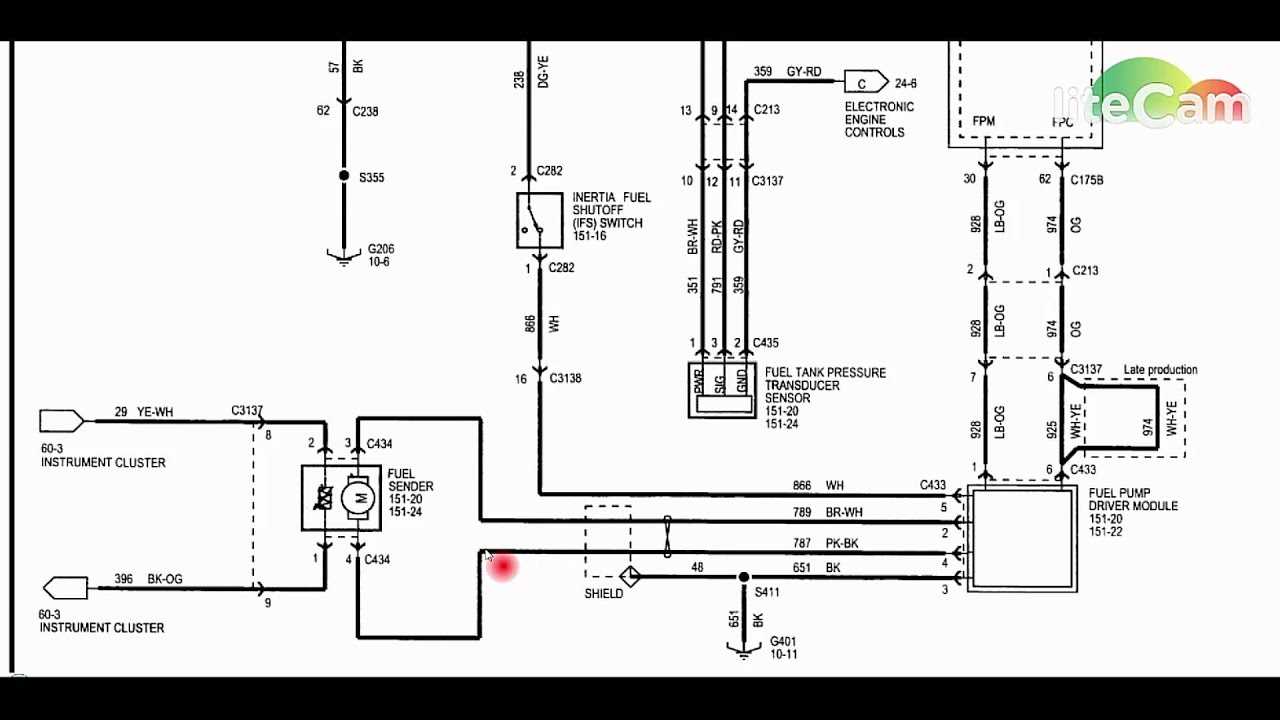

Electrical System Wiring Overview

This section provides a comprehensive look at the wiring configuration associated with the vehicle’s electrical components. Understanding the layout and connections of the electrical system is crucial for effective troubleshooting and maintenance. Proper knowledge of the wiring harnesses, connectors, and their functions can significantly enhance the efficiency of repairs and upgrades.

The electrical system in modern vehicles comprises various circuits responsible for powering essential functions such as lighting, ignition, and communication between different modules. Each circuit is meticulously designed to ensure optimal performance and safety. Below is a simplified representation of the key components and their interconnections:

| Component | Description | Function |

|---|---|---|

| Battery | Primary power source for electrical components | Stores energy for starting and operating the vehicle |

| Fuses | Protective devices within the wiring system | Prevent circuit overloads and protect components |

| Alternator | Device that generates electrical power | Charges the battery and powers electrical systems while the engine runs |

| Wiring Harness | Bundle of wires connecting various electrical components | Facilitates communication and power distribution |

| Relays | Electromechanical switches | Control high-current circuits with low-power signals |

A thorough understanding of these components and their relationships is essential for ensuring the reliability of the vehicle’s electrical system. Regular inspection and maintenance can help prevent issues and extend the lifespan of the electrical components.

Fuel Delivery System Parts

The fuel delivery mechanism is essential for ensuring optimal engine performance. This system is responsible for transporting fuel from the tank to the engine, where it is mixed with air and combusted. Understanding the components involved is crucial for maintaining efficiency and preventing issues related to fuel flow.

Key Components of the Fuel Delivery Mechanism

Several critical elements work together to facilitate fuel movement. Each part plays a unique role in ensuring that the engine receives the proper amount of fuel at the right pressure.

| Component | Function |

|---|---|

| Fuel Pump | Transfers fuel from the tank to the engine. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine. |

| Fuel Injector | Sprays the fuel into the engine’s combustion chamber. |

| Fuel Pressure Regulator | Maintains consistent fuel pressure within the system. |

Maintenance Considerations

Regular maintenance of the fuel delivery system is vital for longevity and reliability. Components such as the filter should be replaced periodically, while the fuel pump and injectors should be inspected for proper function to prevent engine performance issues.

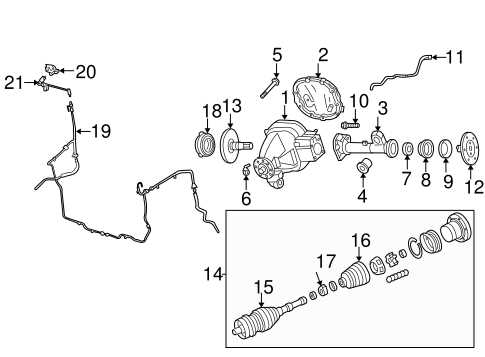

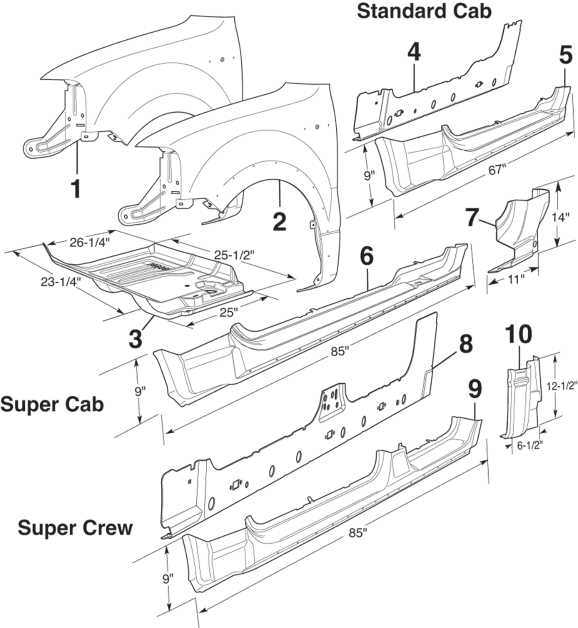

Body and Frame Assembly Insights

The assembly of the outer structure and chassis is crucial for the overall integrity and performance of any vehicle. This segment delves into the essential components and their interconnections that contribute to the vehicle’s durability and functionality. Understanding the relationships between various elements can aid in effective maintenance and enhancements.

Key Components of the Structure

- Frame: The foundational structure that supports the entire vehicle.

- Body Panels: Outer sections that provide aesthetic appeal and protect internal mechanisms.

- Mounting Points: Specific locations designed for attaching various components securely.

- Reinforcements: Added sections that enhance strength and rigidity against impacts.

Assembly Considerations

- Alignment: Proper alignment is vital to ensure that all components fit together seamlessly.

- Fastening Techniques: Utilizing appropriate methods and tools to secure connections ensures durability.

- Material Compatibility: Selecting materials that work well together can prevent corrosion and wear over time.

- Inspection: Regular checks for wear or damage are essential for maintaining structural integrity.

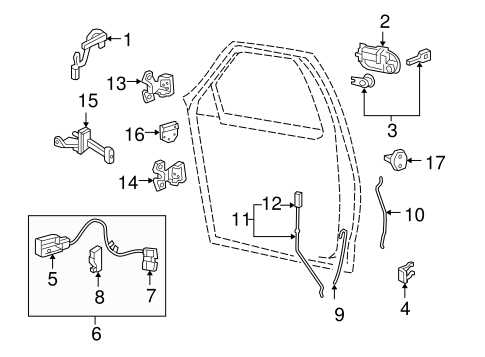

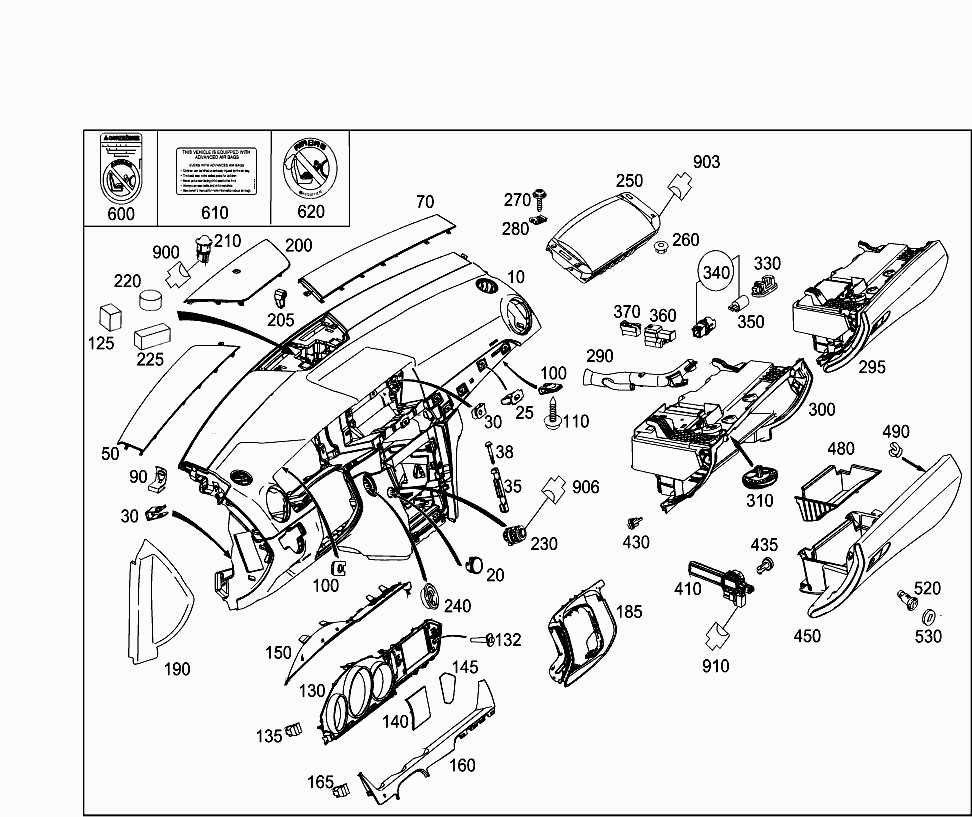

Interior Features and Controls Layout

The arrangement of interior components and control mechanisms in vehicles is designed to enhance user experience and accessibility. Understanding the layout is essential for efficient interaction with various features, ensuring comfort and convenience during every journey.

Key elements include:

- Dashboard: The central hub housing gauges, warning lights, and infotainment systems.

- Control Panels: Located on the center console, these panels provide access to climate control, audio settings, and navigation options.

- Steering Wheel Controls: Integrated buttons allow for hands-free operation of media and phone features.

- Storage Compartments: Thoughtfully placed areas for storing personal items, enhancing organization and accessibility.

Understanding the layout of these features aids in navigating the vehicle’s functionalities effectively. Key aspects include:

- Ergonomics: Placement of controls should ensure ease of reach and visibility.

- Intuitive Design: Features should be logically arranged for quick access without distraction.

- Visibility: Instrument clusters and screens should be easily readable, providing crucial information at a glance.

Familiarity with these aspects enhances user interaction and promotes a more enjoyable driving experience.

Common Replacement Parts for Maintenance

Regular upkeep is essential to ensure the longevity and performance of your vehicle. Several components may require attention over time, depending on usage and environmental conditions. Below are key items that are often exchanged during maintenance routines to keep your vehicle running smoothly.

-

Brake Components:

- Brake pads

- Rotors

- Calipers

-

Filters:

- Oil filter

- Air filter

- Fuel filter

-

Fluids:

- Engine oil

- Transmission fluid

- Coolant

-

Belts and Hoses:

- Serpentine belt

- Timing belt

- Radiator hoses

-

Battery:

- Starter battery

Staying on top of these common replacements can help prevent larger issues and ensure a safe and efficient driving experience. Regular inspections and timely replacements contribute to the overall reliability of your vehicle.

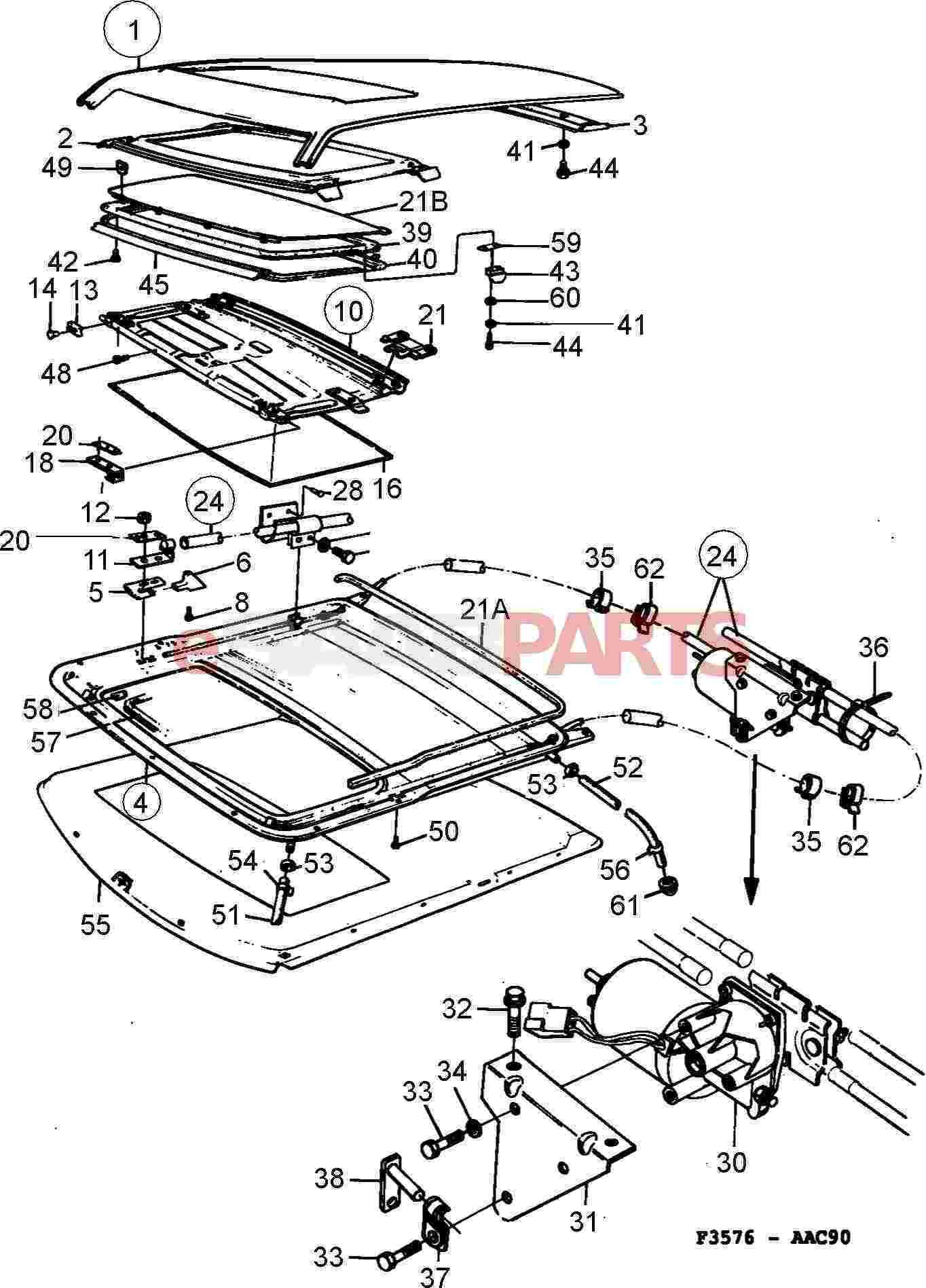

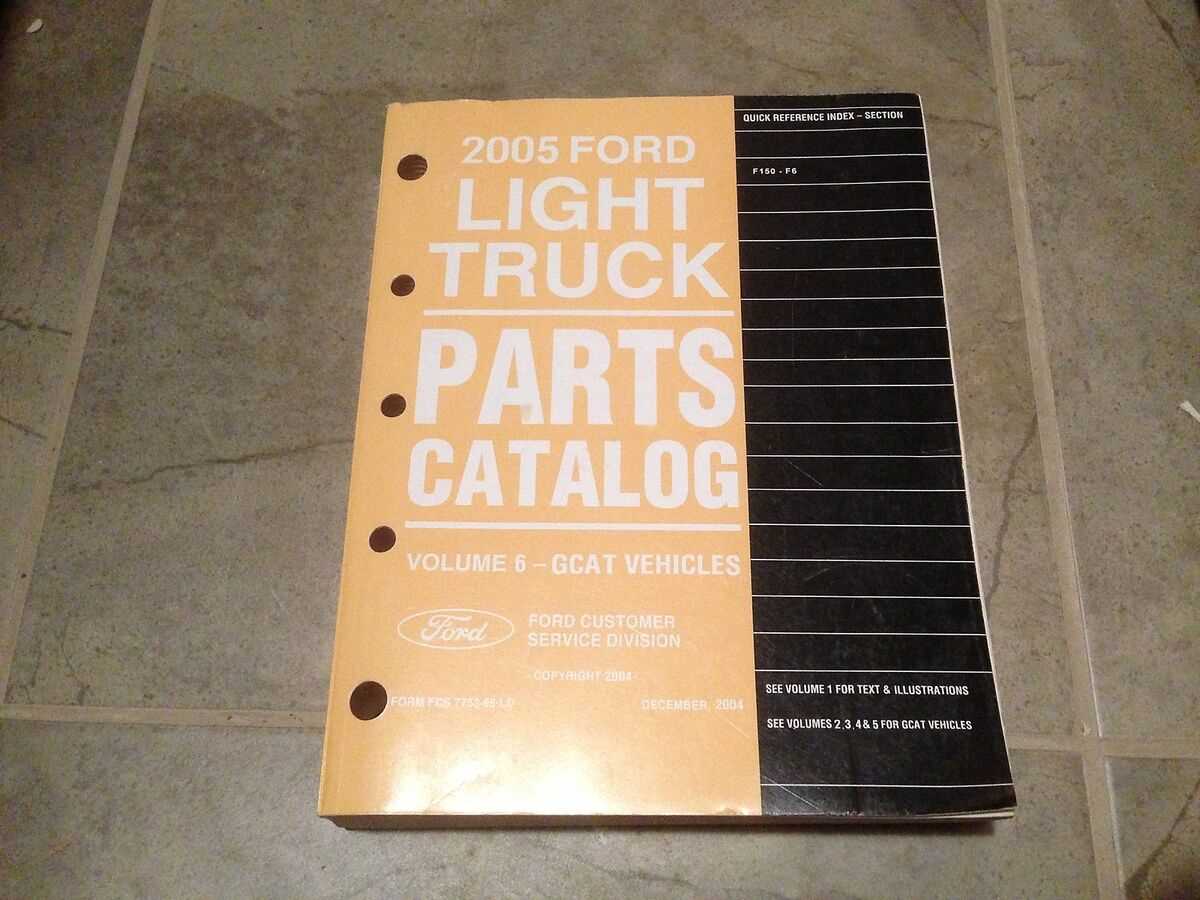

Resources for Parts and Diagrams

When seeking components for your vehicle, having access to detailed illustrations and information is essential. Numerous resources can assist you in identifying and acquiring the necessary elements for your automotive needs. Utilizing these references will enhance your understanding and streamline your maintenance or repair processes.

Online platforms, such as dedicated automotive websites and forums, provide a wealth of knowledge, including schematics and specifications. These sites often feature user-generated content, allowing enthusiasts to share their experiences and recommendations. Additionally, many retailers offer comprehensive catalogs that include visual aids and technical data, making it easier to locate the right components.

Local dealerships can also be invaluable, as they typically maintain extensive records and resources related to specific vehicles. Engaging with service departments or parts specialists can yield insights that are difficult to find elsewhere. Furthermore, many dealerships provide access to online tools for searching inventory and obtaining pricing information.

For those who prefer hands-on resources, repair manuals and workshop guides are excellent choices. These publications often contain detailed visual representations and step-by-step instructions that assist in various maintenance tasks. Whether you choose digital or printed versions, having these guides at your disposal can significantly aid your efforts.