In the world of automotive engineering, a thorough comprehension of the various elements that comprise an engine is crucial for both enthusiasts and professionals. This section delves into the intricate relationships between the components that work harmoniously to ensure optimal performance. By gaining insight into these parts, one can better appreciate the complexity of modern vehicles and their engineering marvels.

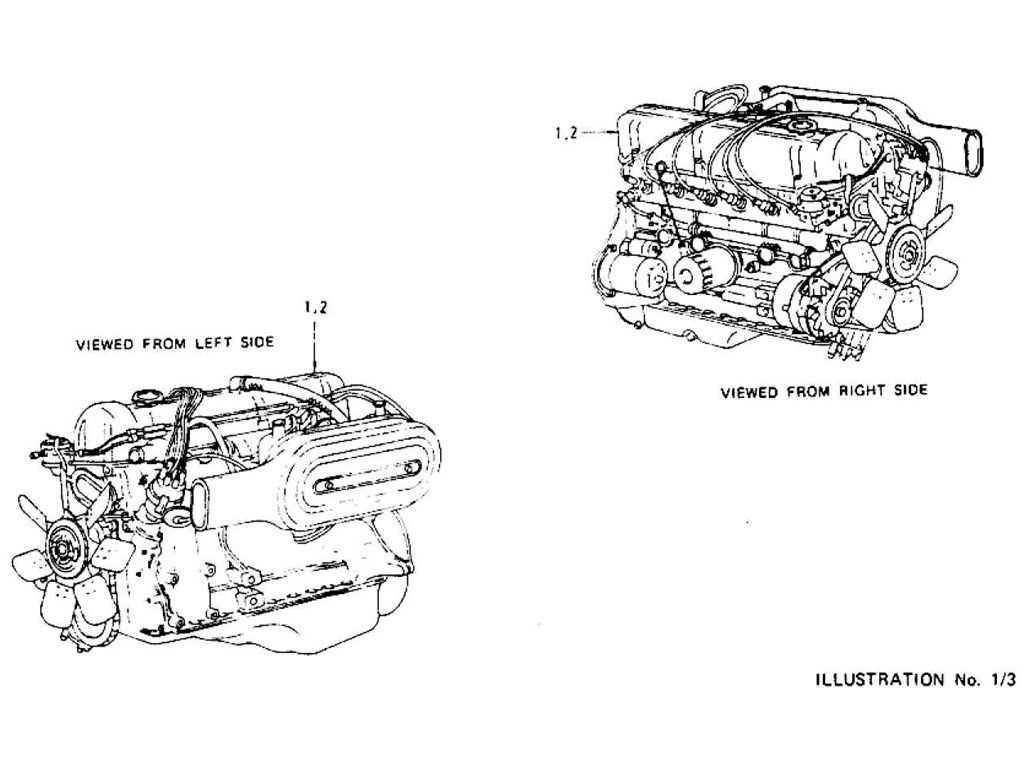

The layout and arrangement of engine components can significantly impact functionality and efficiency. Each element plays a pivotal role, whether it be in the process of combustion, power generation, or the overall operation of the vehicle. This exploration highlights the significance of understanding how these individual pieces interact, which is essential for diagnosing issues and implementing improvements.

Moreover, having a visual reference can enhance one’s ability to identify and understand the specific roles of each component. By examining illustrations that showcase the arrangement and connectivity of these engine elements, readers can cultivate a deeper knowledge of their function and importance within the broader context of vehicle mechanics. Ultimately, this information serves as a foundation for anyone looking to deepen their expertise in automotive systems.

Overview of the 351 Windsor Engine

This section provides an in-depth look at a specific V8 power unit that has earned a reputation for its robust performance and versatility. Originally designed for various vehicles, this engine combines power with efficiency, making it a favorite among enthusiasts and manufacturers alike. Its architecture allows for extensive customization, enhancing its adaptability to different applications.

Key Features

The engine is characterized by several notable attributes that contribute to its enduring popularity. Its compact design facilitates easier installation in a range of chassis, while its robust build quality ensures durability. Additionally, the engine’s configuration supports a broad spectrum of modifications, catering to both street and performance applications.

Specifications

| Specification | Details |

|---|---|

| Cylinder Configuration | V8 |

| Displacement | 5.0 liters |

| Power Output | Up to 400 HP |

| Torque | 400 lb-ft |

| Compression Ratio | 9.0:1 to 10.5:1 |

Key Components of 351 Windsor

The engine assembly consists of several essential elements that contribute to its overall functionality and performance. Understanding these crucial components allows for better maintenance and enhances the knowledge of how the system operates. Each part plays a significant role in ensuring smooth operation and efficiency.

Crankshaft and Pistons

The crankshaft transforms linear motion into rotational movement, while the pistons convert the pressure from combustion into mechanical energy. Together, they form the core of the engine’s power-generating process, influencing torque and horsepower output.

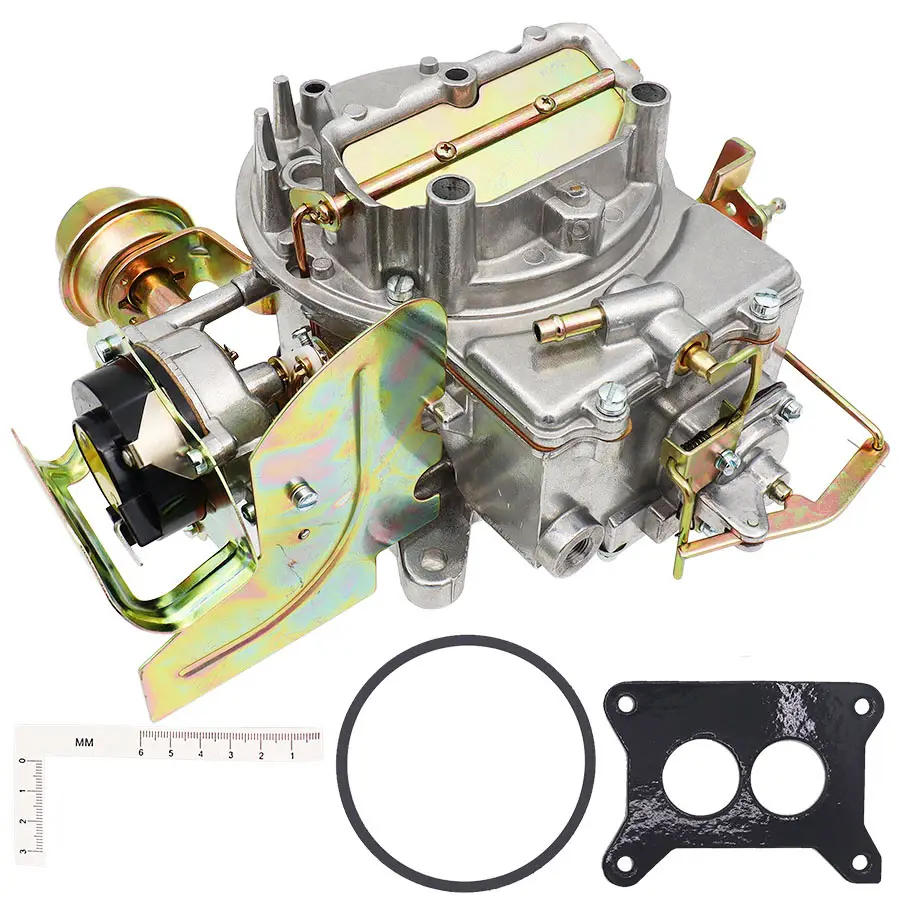

Intake and Exhaust Systems

The intake assembly draws in air for combustion, whereas the exhaust system expels the gases produced during the process. These systems are designed to optimize airflow and improve engine efficiency, contributing significantly to overall performance and fuel economy.

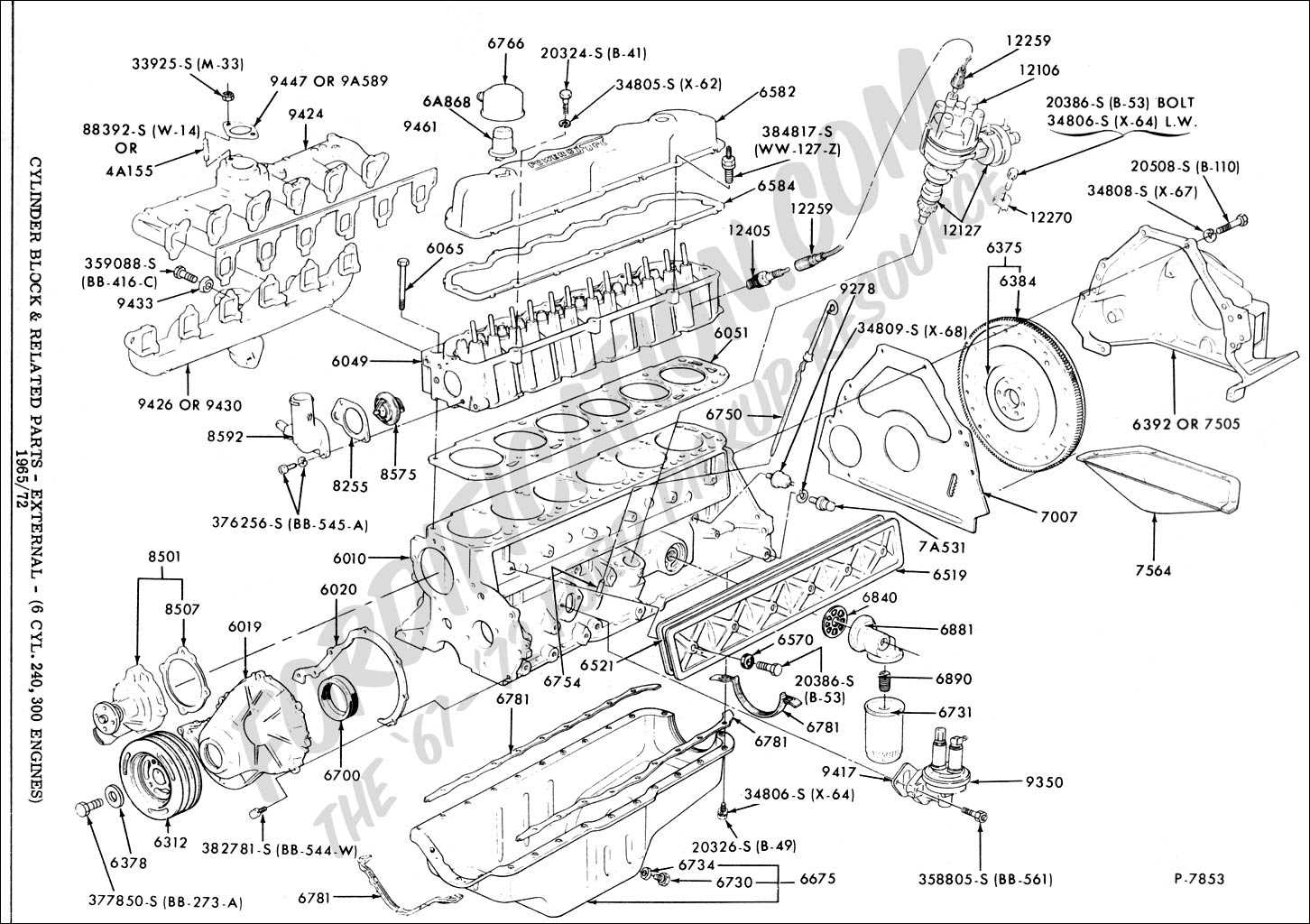

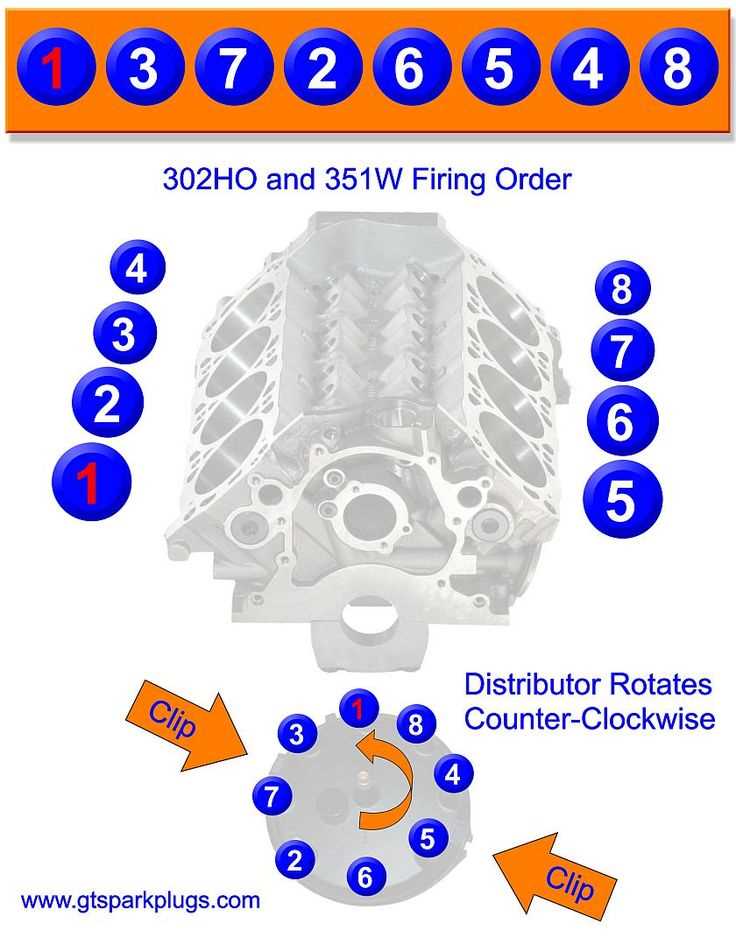

Understanding the Parts Diagram

Familiarity with the assembly layout is essential for anyone working on automotive engines. This visual representation offers insight into how various components interconnect, making it easier to comprehend the overall structure. By examining the schematic, enthusiasts can identify specific elements, their relationships, and how they contribute to the engine’s functionality.

Importance of Visual Representation

Visual aids enhance understanding by breaking down complex systems into manageable parts. A well-organized layout allows mechanics and hobbyists to pinpoint areas requiring attention, streamlining maintenance and repair tasks. This clarity fosters confidence when addressing issues or undertaking upgrades, ultimately leading to improved performance.

Components and Their Functions

Each element depicted in the layout plays a crucial role in the engine’s operation. Recognizing these parts and their specific functions helps users troubleshoot problems effectively. Understanding how each component interacts with others is vital for successful modifications, ensuring that any changes made enhance rather than hinder overall performance.

Importance of Each Engine Part

Understanding the significance of each component within an internal combustion engine is crucial for optimal performance and longevity. Each element plays a specific role in the overall function of the engine, and neglecting any part can lead to reduced efficiency or even failure.

Key Functions of Engine Components

Each section of the engine has its unique function, contributing to the smooth operation of the entire system. Here are some vital components and their roles:

- Cylinder Block: This is the foundation where other components are mounted, housing the cylinders and providing structural integrity.

- Pistons: These move up and down within the cylinders, converting combustion energy into mechanical energy.

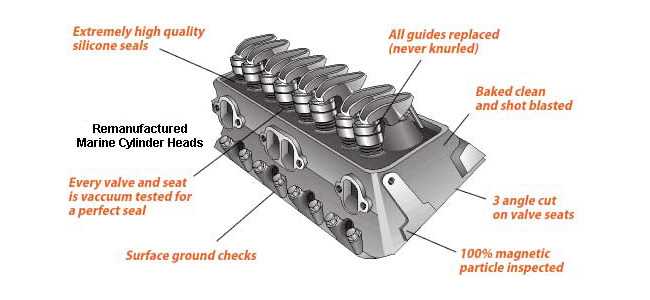

- Cylinder Head: It sits on top of the cylinder block and contains vital components such as valves and spark plugs.

- Crankshaft: This converts the linear motion of the pistons into rotational motion, driving the vehicle.

- Camshaft: This component controls the timing of the opening and closing of the valves, ensuring optimal air-fuel mixture intake and exhaust expulsion.

Consequences of Component Malfunction

Failure to maintain or replace any of these essential elements can result in severe consequences, including:

- Decreased Performance: A malfunctioning part can lead to reduced power output and efficiency.

- Increased Emissions: Problems with specific components can cause higher levels of harmful emissions.

- Potential Engine Damage: Continuing to operate with faulty parts can lead to catastrophic engine failure, resulting in costly repairs.

Regular inspection and maintenance of each engine component are vital to ensure reliability and performance. A well-functioning engine is not only more efficient but also contributes to the overall health of the vehicle.

How to Read Engine Diagrams

Understanding technical illustrations of engine components is essential for effective maintenance and repair. These representations provide a visual guide that outlines the relationships between various elements of the power unit, aiding in diagnostics and assembly. Familiarity with reading these visuals can significantly enhance your ability to work on automotive engines.

Familiarizing with Symbols and Labels

Each illustration features unique symbols and labels that denote specific components and their functions. Key components are often represented by standardized icons, while labels provide crucial information about part specifications, orientation, and interaction. Taking the time to understand these symbols can simplify the process of identifying each element within the engine.

Interpreting Relationships and Flow

Another critical aspect of these visuals is the representation of connections and flow between components. Arrows often indicate the direction of movement or the flow of fluids, such as oil or coolant. Recognizing these pathways helps in understanding how different parts work together to ensure optimal engine performance. By analyzing these relationships, one can identify potential issues and make informed decisions regarding repairs or upgrades.

Common Issues with 351 Windsor Parts

When working with a particular type of engine, enthusiasts and mechanics often encounter a variety of challenges that can affect performance and longevity. Understanding these common problems is essential for effective maintenance and repairs.

- Cooling System Failures: Overheating can occur due to radiator blockages or faulty thermostats, leading to significant engine damage.

- Oil Leaks: Gaskets and seals may degrade over time, resulting in oil seeping from various engine components, which can compromise performance.

- Fuel Delivery Issues: Problems with fuel pumps or injectors can lead to inadequate fuel supply, causing misfires or poor acceleration.

- Ignition System Malfunctions: Worn spark plugs and faulty ignition coils can lead to starting difficulties and reduced engine efficiency.

- Exhaust System Restrictions: Blockages or leaks in the exhaust can affect back pressure and overall engine performance.

Addressing these issues promptly can help maintain optimal performance and extend the lifespan of the engine. Regular inspections and preventive maintenance are crucial in avoiding these common pitfalls.

Upgrading 351 Windsor Components

Enhancing the performance of your engine can significantly improve the overall driving experience. By focusing on key elements within the system, you can achieve better efficiency, increased power, and improved reliability. This section will explore various methods to elevate the functionality of your engine, ensuring it meets your performance aspirations.

Key Areas for Enhancement

When considering upgrades, prioritize components that offer the most substantial gains. Intake systems, for instance, can drastically affect air flow, enabling the engine to breathe more efficiently. Additionally, exhaust modifications can enhance the expulsion of gases, contributing to a smoother operation and a noticeable increase in power output.

Choosing Quality Components

Investing in high-quality components is crucial for achieving optimal results. Look for reputable brands that provide performance-driven parts designed to work harmoniously with your engine. This approach not only enhances performance but also extends the longevity of your system, ensuring that your investment pays off in the long run.

Maintenance Tips for Engine Longevity

Ensuring the durability and optimal performance of your power unit requires regular attention and care. By following a few essential guidelines, you can significantly extend its lifespan and enhance efficiency. This section outlines practical recommendations for maintaining your engine.

- Regular Oil Changes: Change the lubricant at recommended intervals to keep the internal components well-lubricated and reduce wear.

- Check Fluid Levels: Regularly inspect coolant, transmission fluid, and brake fluid levels. Keeping these fluids at proper levels prevents overheating and ensures smooth operation.

- Inspect Filters: Replace air and fuel filters according to the manufacturer’s recommendations to ensure optimal airflow and fuel delivery.

- Monitor Belts and Hoses: Regularly examine drive belts and hoses for wear or cracks. Replace them as needed to prevent breakdowns.

- Clean the Cooling System: Flush the cooling system periodically to prevent corrosion and build-up that can hinder performance.

In addition to these tips, maintaining a clean engine compartment can help identify potential issues early. A proactive approach to upkeep not only enhances performance but also saves on costly repairs down the line.

- Follow the Maintenance Schedule: Adhere to the manufacturer’s maintenance schedule to keep the engine running smoothly.

- Keep the Engine Clean: Regularly wash the engine to remove dirt and debris, which can lead to overheating and component failure.

- Use Quality Parts: When replacements are necessary, opt for high-quality components to ensure reliability and longevity.

By implementing these strategies, you can help ensure that your engine remains reliable and efficient for years to come.

Tools Required for Engine Work

Performing maintenance or repairs on an engine requires a selection of essential instruments to ensure the job is done efficiently and effectively. Having the right equipment not only saves time but also helps avoid potential damage to the engine components.

Basic Hand Tools: A good set of wrenches, sockets, and screwdrivers is fundamental for any mechanical work. These tools allow for loosening and tightening various fasteners, making them indispensable for disassembly and assembly tasks.

Torque Wrench: Precision is key when working with engine components. A torque wrench ensures that bolts are tightened to the manufacturer’s specifications, preventing issues such as leaks or mechanical failure due to improper tension.

Diagnostic Tools: Utilizing diagnostic equipment, such as scanners or multimeters, can help identify issues with the engine’s electronic systems. These tools are vital for troubleshooting problems and ensuring everything functions correctly.

Fluid Transfer Equipment: When changing fluids, having the right equipment, such as oil pumps or funnels, can minimize spills and make the process smoother. Proper fluid management is crucial for maintaining engine health.

Safety Gear: Personal protective equipment, including gloves and safety goggles, is essential. Working on engines can expose you to various hazards, and taking safety precautions is necessary to prevent injuries.

Overall, equipping your workspace with these essential tools will enhance your ability to conduct engine maintenance or repairs, ensuring a successful and safe operation.

Aftermarket vs. OEM Parts Explained

The choice between replacement components can significantly impact vehicle performance and longevity. Understanding the differences between original equipment manufacturer (OEM) and alternative offerings is essential for informed decision-making. This section explores the nuances that define these two categories of components, helping you choose the best option for your vehicle.

OEM components are produced by the vehicle manufacturer or their designated suppliers, ensuring a perfect fit and adherence to the original design specifications. In contrast, alternative components are created by third-party manufacturers, which may offer a variety of options in terms of pricing, quality, and performance. Here is a comparison of some key factors:

| Criteria | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | Consistent, often superior | Varies by manufacturer |

| Cost | Typically higher | Generally more affordable |

| Warranty | Often includes a warranty | Warranty varies by brand |

| Availability | Limited to manufacturer outlets | Widely available through various retailers |

| Fitment | Perfect fit guaranteed | May require adjustments |

Ultimately, the decision between these two types of components should be guided by your specific needs, budget, and the desired outcome for your vehicle. Understanding the strengths and weaknesses of each option empowers you to make a choice that best aligns with your expectations.

Resources for Further Information

For those seeking to deepen their understanding of engine components and their functionalities, numerous resources are available. These materials offer insights into assembly, maintenance, and performance enhancements.

Online Forums and Communities: Engaging with enthusiasts on dedicated platforms can provide valuable knowledge and troubleshooting tips. Many experienced individuals share their insights, making these forums an excellent place for learning.

Technical Manuals: Comprehensive manuals often include detailed specifications and illustrations that clarify various components’ roles and interactions. Investing in a quality manual can be beneficial for both novices and seasoned mechanics.

Video Tutorials: Visual learners may find video content particularly useful. Numerous channels focus on mechanical repairs and modifications, offering step-by-step guides that simplify complex processes.

Books and Publications: Consider acquiring literature that covers engine mechanics and performance tuning. These resources typically provide in-depth analysis and can serve as a reference for ongoing projects.

Workshops and Classes: Participating in hands-on workshops can significantly enhance practical skills. Many organizations offer classes that cater to various skill levels, allowing individuals to gain firsthand experience under expert guidance.