When working with marine engines, understanding the various systems and their interconnections is crucial for proper maintenance and repairs. Each component has a specific role, and ensuring that all elements are correctly aligned is essential for the engine’s efficiency and longevity.

In this section, we will explore the essential mechanisms and how they interact within the engine structure. From fuel delivery systems to cooling channels, it is important to grasp the organization of these elements to ensure smooth operation.

Whether you are troubleshooting or performing routine upkeep, having a clear visual representation of the engine’s internal layout is invaluable. By familiarizing yourself with the system’s structure, you will be better equipped to identify any issues that may arise

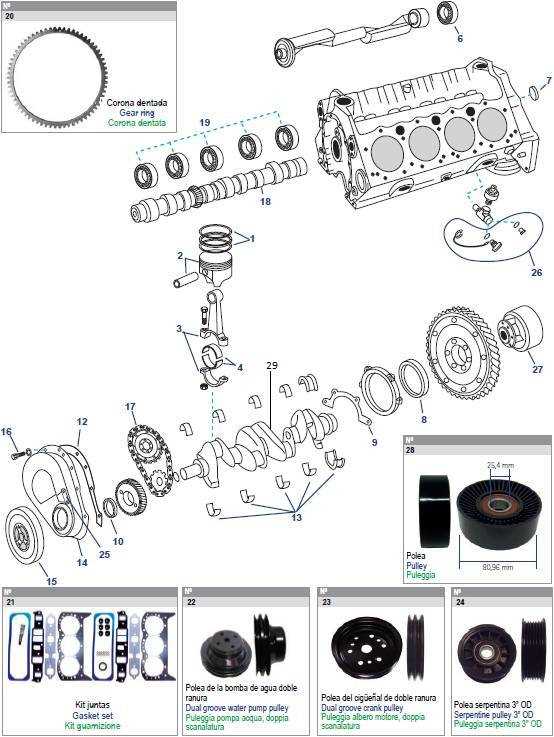

Understanding 4.3 Mercruiser Parts Diagrams

In this section, we delve into the comprehensive illustrations that elucidate the intricate components of the 4.3 Mercruiser system. These visual aids serve as detailed roadmaps, offering an in-depth exploration of the internal mechanisms and external assemblies that comprise this marine engine.

- Visual Guides: These diagrams provide a pictorial representation, guiding enthusiasts and technicians through the labyrinthine network of components without the need for verbose technical manuals.

- Component Breakdown: Each part, depicted with clarity and precision, showcases its role within the operational framework, facilitating both maintenance tasks and the identification of potential issues.

- System Integration: Beyond individual parts, the diagrams elucidate how these elements interconnect, fostering a holistic understanding crucial for troubleshooting and optimizing performance.

- Analytical Utility: By translating complex engineering concepts into visual narratives, these diagrams empower users to grasp the spatial relationships and functional dependencies of every component.

Thus, mastering these diagrams not only enhances comprehension but also augments efficiency in servicing and enhancing the longevity of the 4.3 Mercruiser engine, ensuring smooth sailing and peak performance on the water.

Exploring Fuel System Components

The fuel delivery mechanism plays a crucial role in ensuring efficient operation and performance. This section will provide an overview of essential components involved in managing fuel flow, highlighting their significance in maintaining proper engine functionality. Understanding how these elements work together allows for better diagnostics and upkeep.

Key Elements of the Fuel System

The fuel system consists of various interconnected parts responsible for transporting and regulating the flow of fuel. Key elements include pumps, filters, and injectors, each of which plays a vital role in ensuring consistent and clean fuel supply to the engine.

Fuel Flow

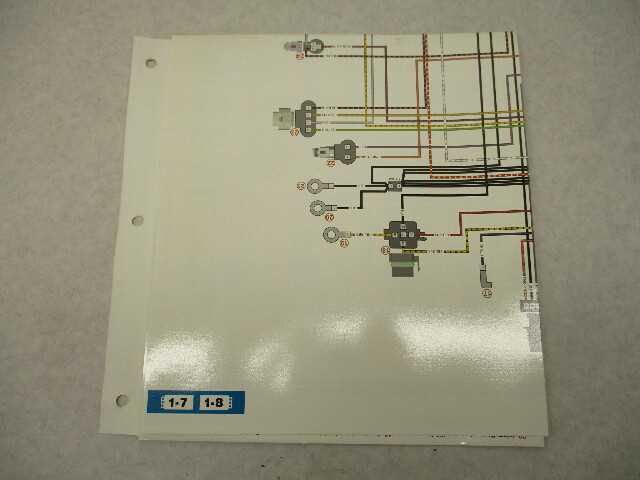

Identifying Electrical System Elements

Understanding the components of a marine electrical system is essential for proper maintenance and troubleshooting. These elements are interconnected, providing power and control to various systems on the vessel. By recognizing the different elements and their roles, you can ensure a reliable and efficient electrical setup.

Batteries are at the heart of any boat’s electrical system, providing energy to power essential systems when the engine is off. They store energy that can be used to start the engine, power lights, and run electronics.

Alternators serve as the system’s recharge mechanism, converting mechanical energy from the engine into electrical power. This helps to maintain the battery’s charge while the engine is running.

Another key element is the fuse panel, which ensures that electrical circuits are protected from overloads. Each circuit is safeguarded by a fuse that breaks

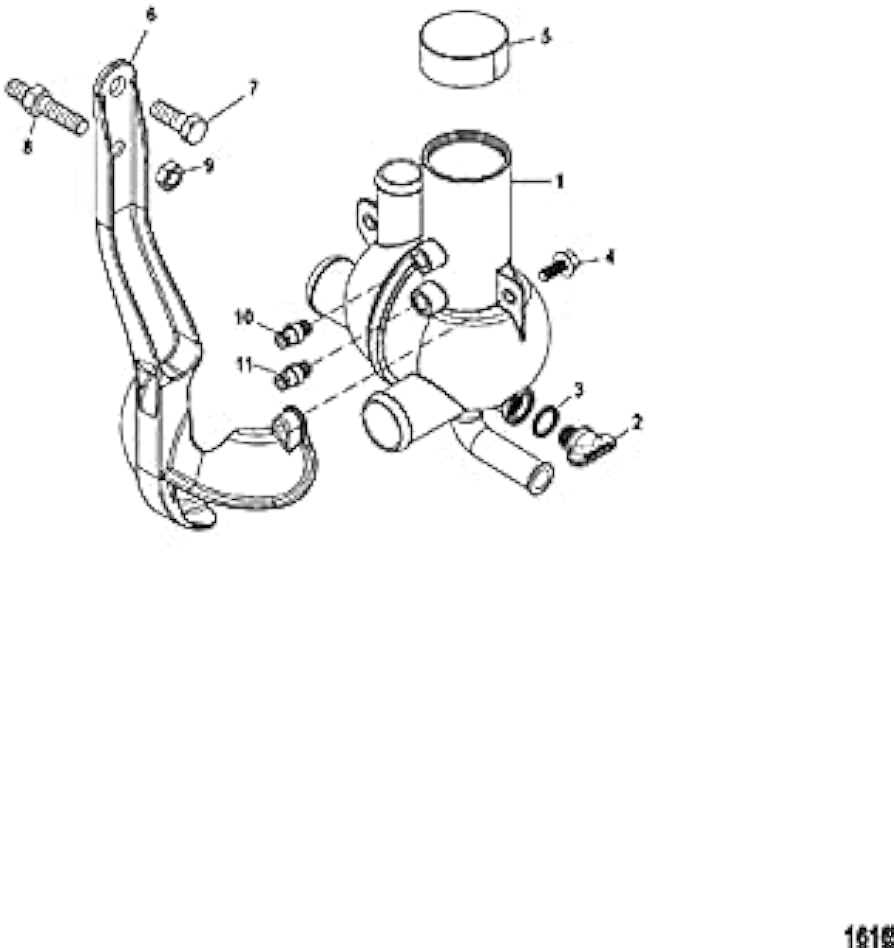

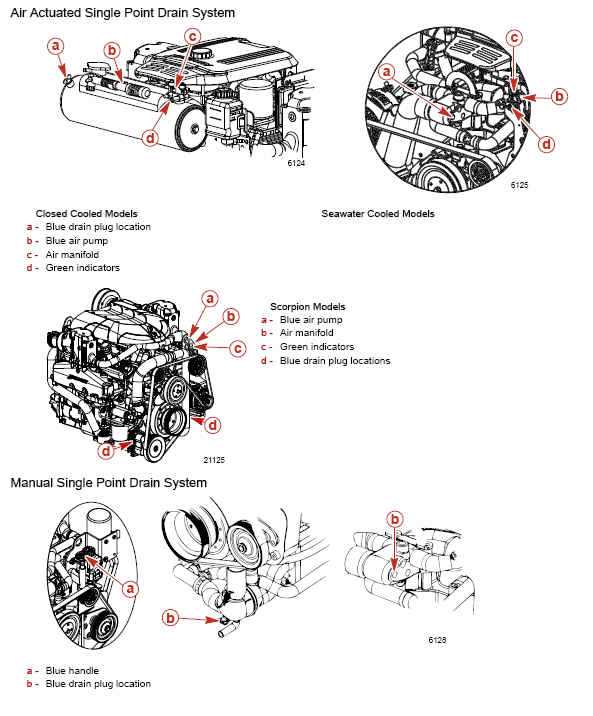

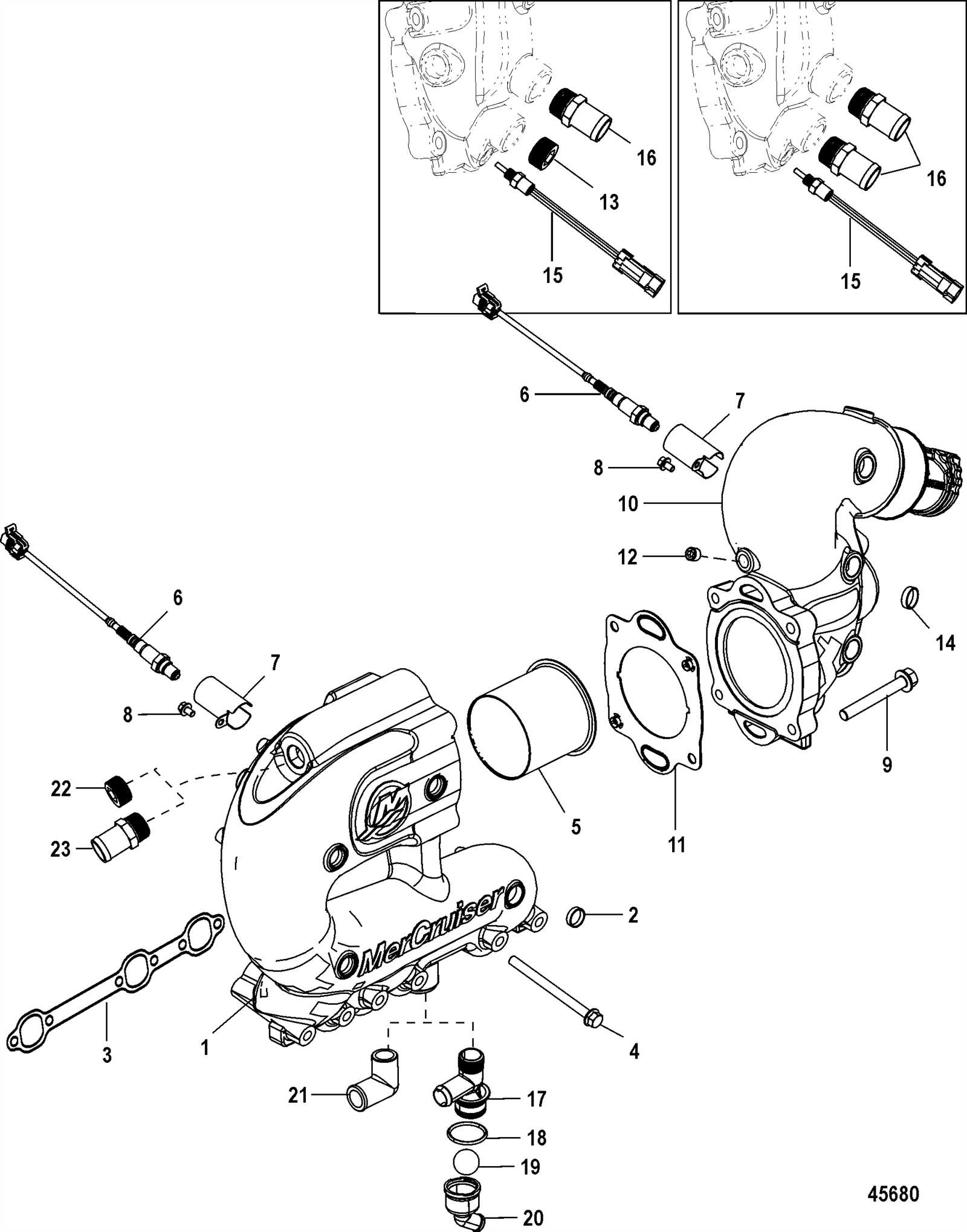

Analyzing Cooling System Components

The cooling system in an engine plays a critical role in maintaining optimal temperature, ensuring the machine operates smoothly under various conditions. Understanding the key elements that make up this system is essential for proper maintenance and troubleshooting. Each component works together to regulate temperature and prevent overheating, contributing to the overall performance and longevity of the engine.

Key elements within the cooling system include mechanisms that circulate fluid, regulate heat, and ensure efficient energy transfer. These parts must function in harmony to maintain stable operation, especially under stress or prolonged use. Improper management of any of these aspects can lead to inefficiencies or potential damage to the engine, making regular checks and timely repairs necessary.

Analyzing how these components interact is crucial for diagnosing issues. Monitoring temperature levels, inspecting fluid flow, and ensuring all mechanical parts are in good condition help identify potential problems early. Preventative care not only prolongs the system’s life but also improves engine efficiency.

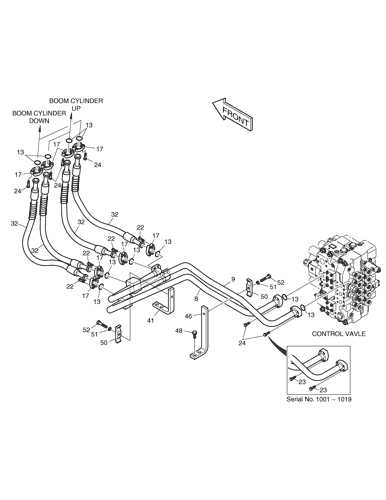

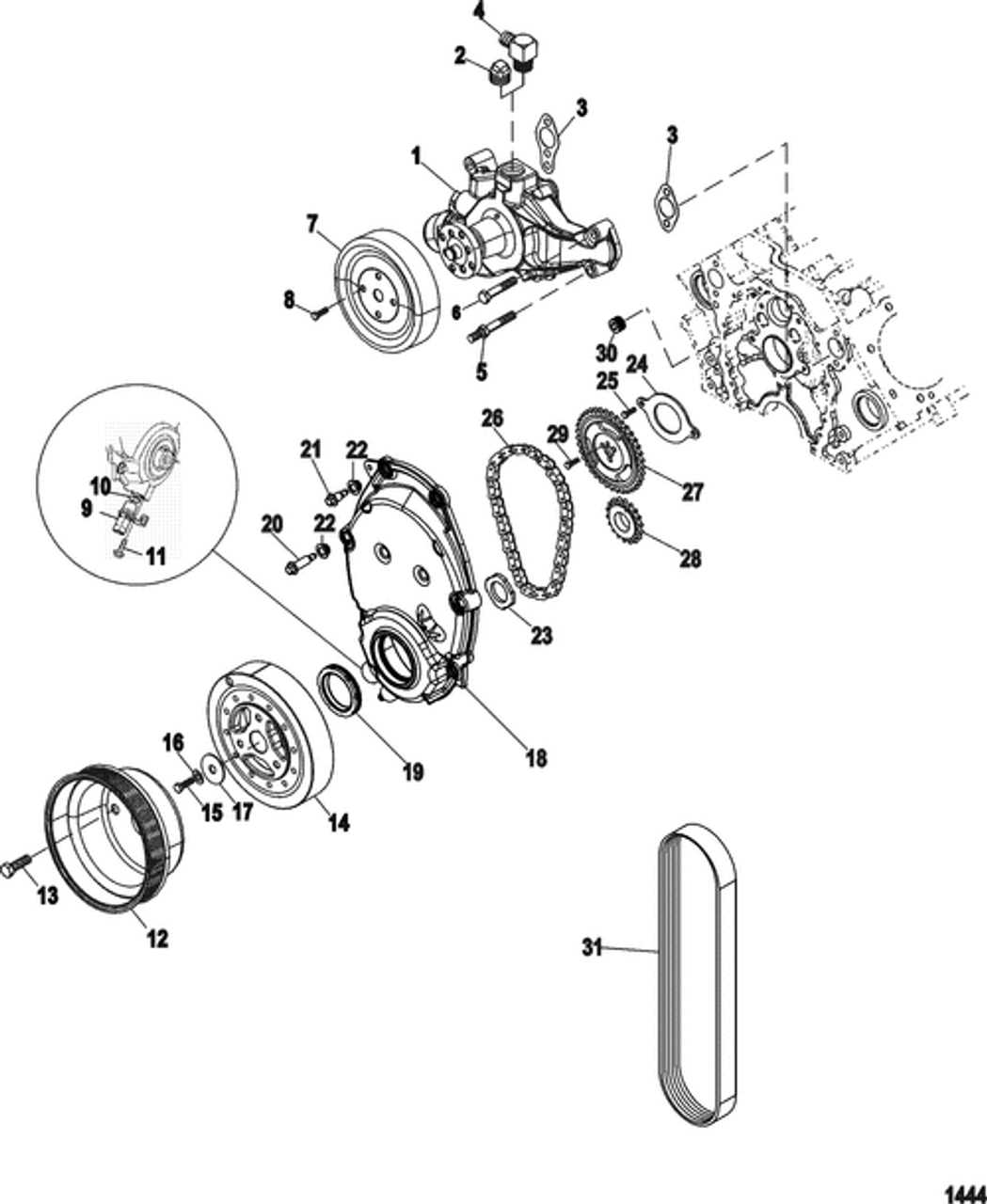

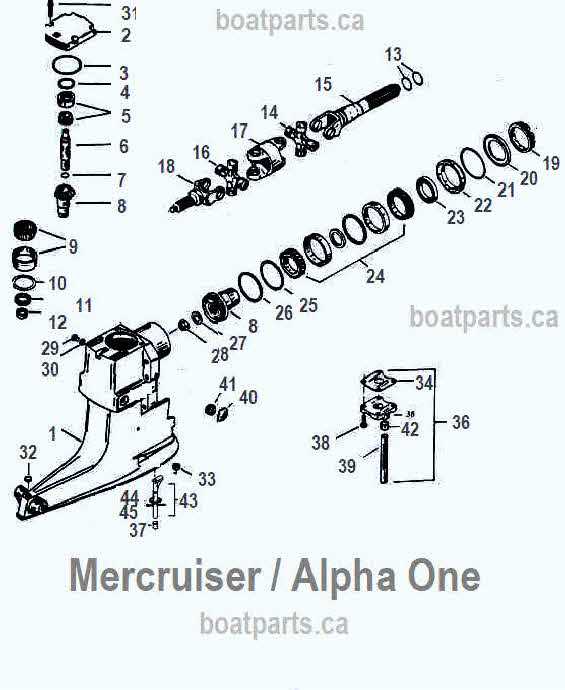

Overview of Drive System Parts

The propulsion mechanism is a crucial component in any marine engine setup, ensuring smooth and efficient transfer of power from the motor to the water. It consists of several integrated elements that work together to control speed, direction, and stability while cruising. This system is designed to enhance performance and provide durability under various conditions.

Main Components

Key elements of the drive mechanism include the propeller, shafts, and various connecting gears. These parts are engineered to handle the force generated by the engine while maintaining precision in motion. The propeller converts rotational energy into thrust, while the shafts and gears work together to ensure seamless movement and control.

Supporting Elements

Other vital components include the cooling and lubrication systems, which protect the system from overheating and excessive wear.

Examining Ignition System Elements

The ignition system plays a critical role in the overall functionality of a marine engine, ensuring efficient power delivery. Understanding its key components and how they work together is essential for maintaining optimal performance. This section explores the core elements that make up the ignition process, offering insight into their importance and functionality.

Key Components of the Ignition System

- Spark Plugs: These small but essential parts create the necessary spark to ignite the air-fuel mixture within the engine’s combustion chambers.

- Ignition Coil: Responsible for converting low voltage from the battery into the high voltage required to generate

Understanding Exhaust System Components

The exhaust system plays a crucial role in maintaining the performance and efficiency of marine engines. It ensures the proper expulsion of gases generated during combustion, helping to reduce harmful emissions while protecting engine components from excessive heat. The system is designed to enhance the overall functionality, ensuring smooth operation even under demanding conditions.

Manifold is a key element responsible for collecting exhaust gases from the engine’s cylinders. It directs these gases into the next section, maintaining consistent flow and temperature control. Made from durable materials, it is built to withstand high heat and constant pressure.

The riser is positioned between the manifold and the rest of the system. It prevents water from re-entering the engine, ensuring

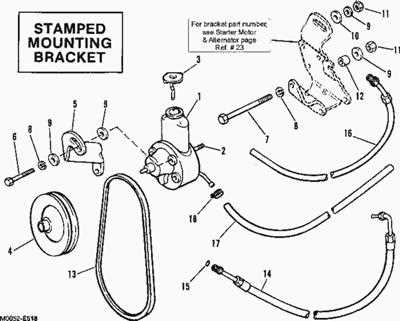

Reviewing Steering System Parts

The steering system plays a critical role in ensuring safe and smooth navigation on water. Its components work together to provide responsive control and precise handling, making it essential for effective operation. Understanding how these elements function together can help maintain stability and improve maneuverability, enhancing overall performance.

Key Elements of the Steering Mechanism

Within the steering mechanism, several integral components ensure accurate control. The steering wheel serves as the user interface, transmitting commands to the steering cable and other linked elements. These, in turn, coordinate with the rudder to adjust the direction of the boat, responding to changes with agility. Regular inspection of these elements is essential for smooth and reliable operation.

Maintaining Optimal Performance

Proper upkeep of the steering

Inspecting Propeller and Shaft Assemblies

Regular inspection of the propeller and shaft system is vital for maintaining optimal performance. These components experience significant wear due to their constant interaction with water, making it essential to identify any issues early. Monitoring for signs of damage or misalignment can help ensure smooth operation and avoid costly repairs.

Checking for Damage

When examining the propeller, look for physical damage like cracks, bends, or chipped blades. Even small imperfections can impact efficiency. The shaft should be checked for corrosion, pitting, or warping, which can affect its alignment and overall functionality.

- Examine blades for bends or chips.

- Inspect the shaft for signs

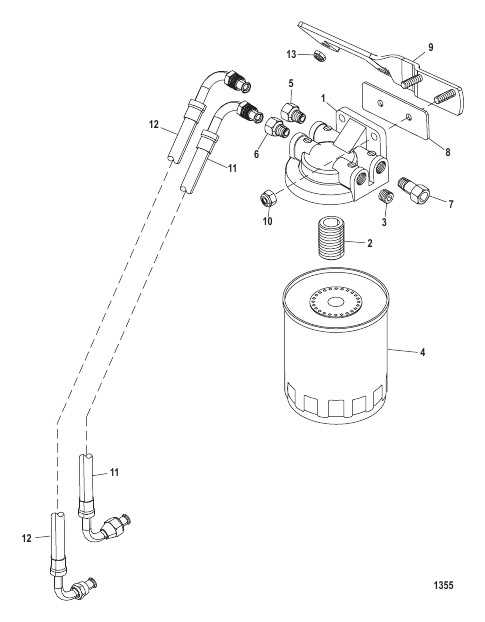

Overview of Lubrication System Elements

The lubrication system plays a vital role in ensuring the smooth operation of mechanical components by reducing friction and wear. It distributes oil to crucial parts, maintaining optimal performance and extending the lifespan of the engine. Without proper lubrication, the system would face increased heat and friction, leading to potential damage.

Key Components of the System

- Oil Pump: Responsible for circulating oil through the engine, the pump ensures that every moving part receives sufficient lubrication.

- Oil Filter: This element removes impurities from the oil, preventing contaminants from reaching sensitive parts and causing damage.

- Oil Pan: Located at the base, the oil pan serves as the reservoir where the oil is stored before being pumped through the system.

Importance of Regular Maintenance

Understanding Transmission System Components

The transmission system is a critical part of any vessel, ensuring that power from the engine is efficiently transferred to the propeller. By converting the engine’s output into usable force, it allows for smooth and controlled movement on the water. Each element of this system plays a role in optimizing performance and maintaining the overall stability of the boat during operation.

Component Function Gearbox Adjusts the engine’s output by changing speed and torque to suit different conditions.