The intricate arrangement of elements within an automotive transmission is crucial for its functionality and efficiency. A comprehensive overview of these components provides insight into their roles and interconnections, allowing for a better understanding of the system as a whole.

By examining the structure and configuration of these essential parts, one can identify how each element contributes to the overall performance of the vehicle. Knowledge of these components aids in troubleshooting issues and performing maintenance effectively.

In-depth exploration of the transmission’s assembly reveals the significance of each piece and how they work in unison to ensure smooth operation. A visual representation of this configuration serves as a valuable tool for mechanics and enthusiasts alike, enhancing comprehension and facilitating repair processes.

The configuration of a transmission system is crucial for its effective operation. A comprehensive grasp of the layout assists in diagnosing issues and facilitating repairs. Each component plays a specific role, contributing to the overall functionality of the system.

Key elements of a transmission layout include:

- Input Shaft: Engages with the engine to receive power.

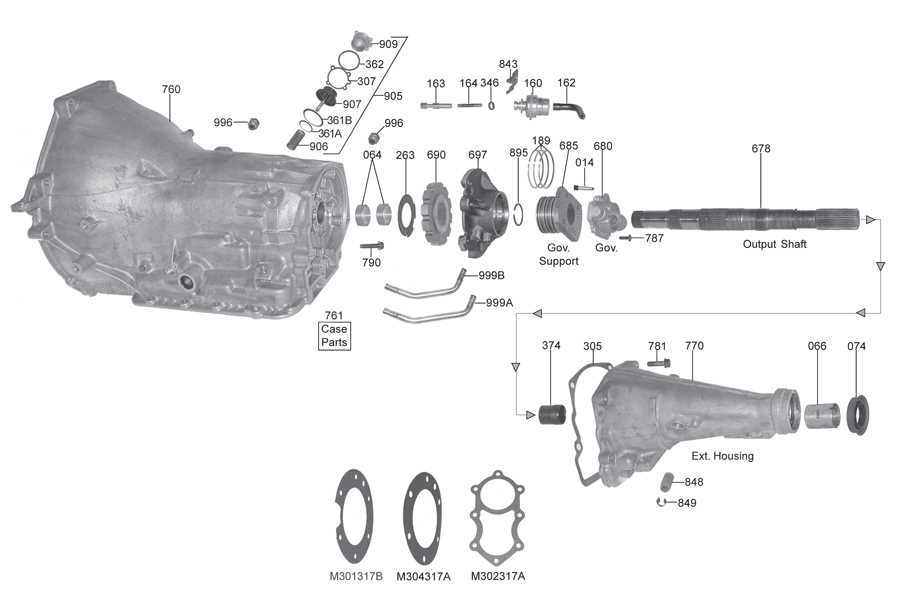

- Output Shaft: Transfers power to the drive train.

- Gear Sets: Provide various ratios for speed and torque adjustment.

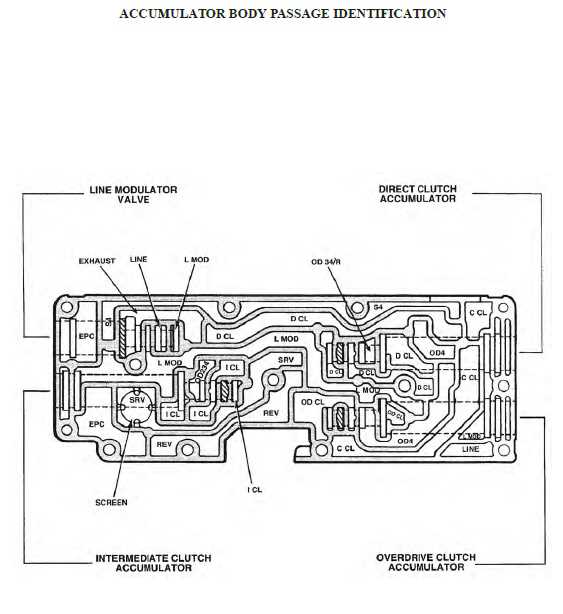

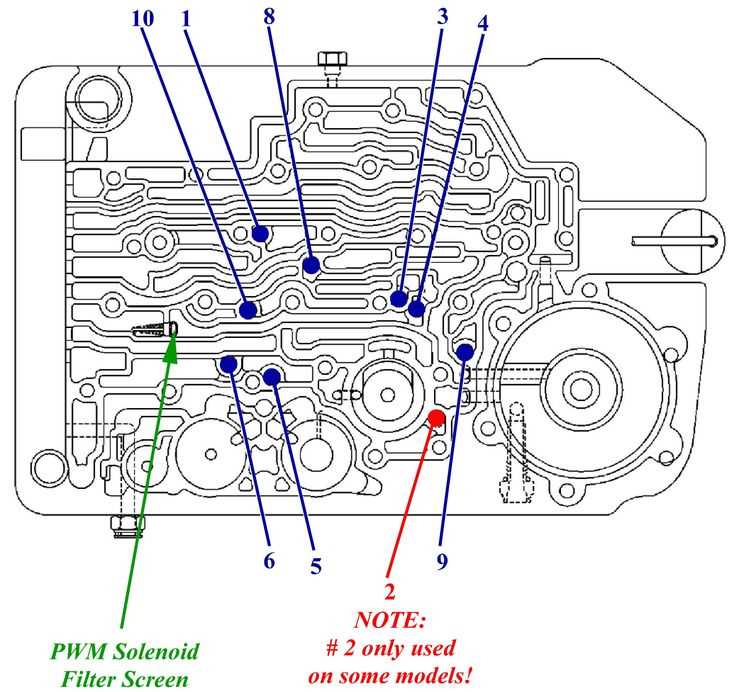

- Valve Body: Controls fluid flow and directs pressure to the appropriate channels.

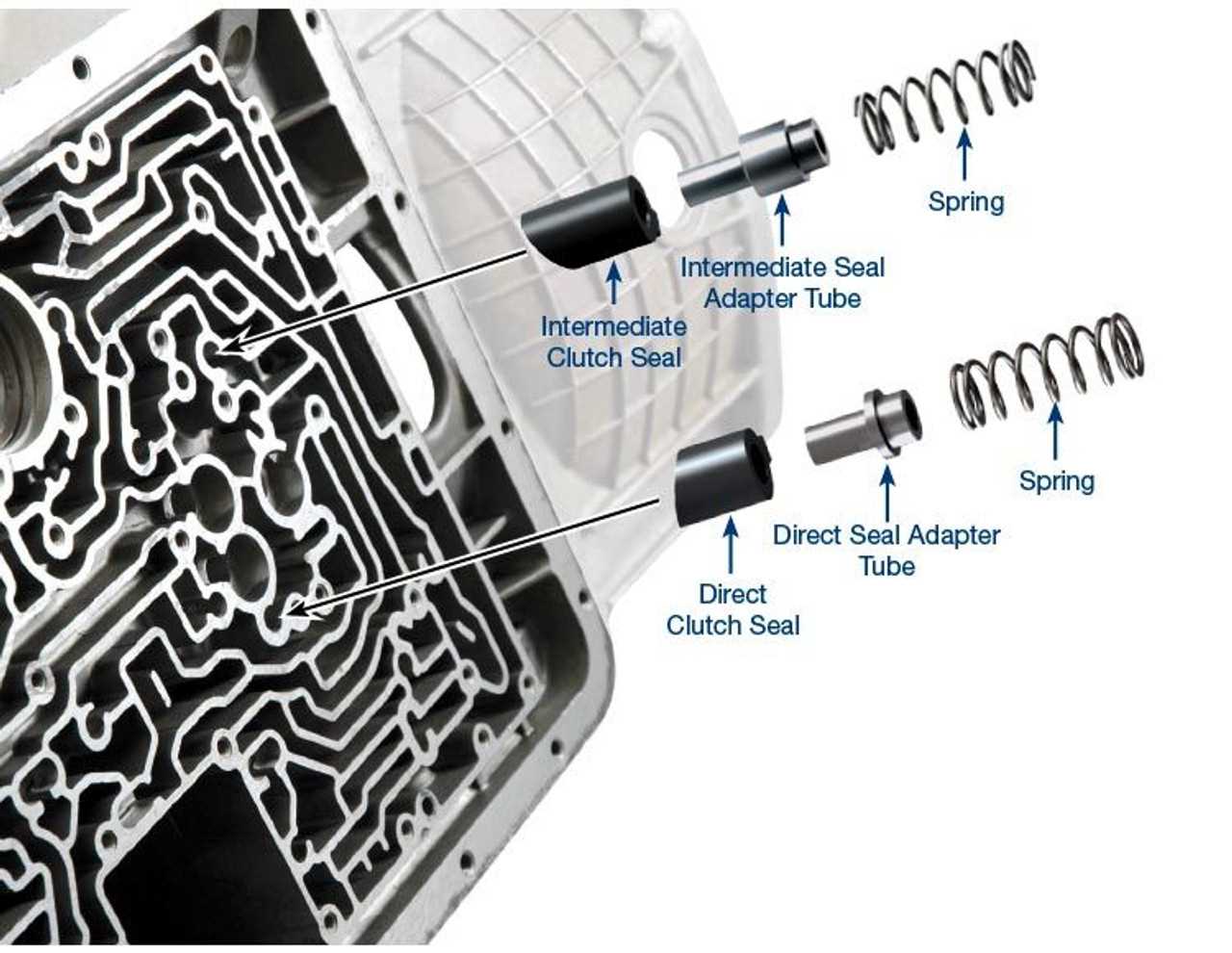

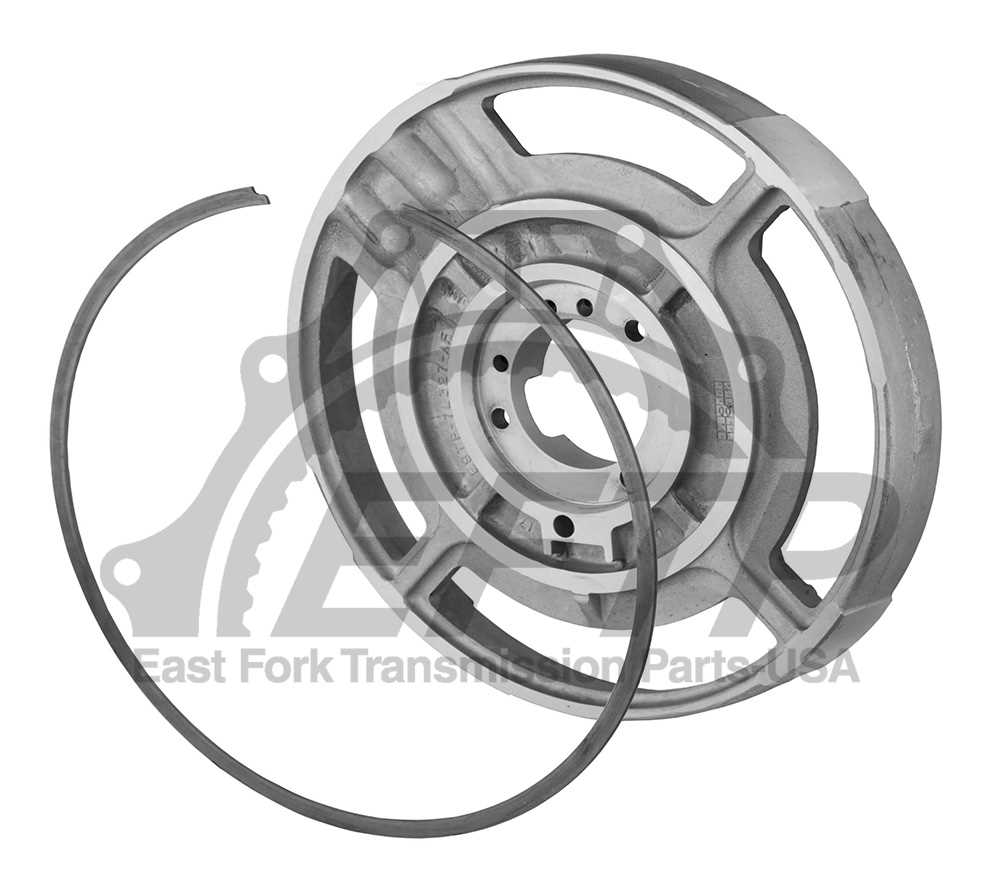

- Clutch Packs: Engage and disengage to manage gear shifts smoothly.

Understanding the positioning of these components is essential for troubleshooting and enhancing performance. Each part’s relationship to others influences the overall efficiency of the transmission, making knowledge of the arrangement invaluable for maintenance and repair efforts.

Functionality of Each Transmission Element

The efficient operation of a vehicle’s transmission relies on a variety of components, each serving a distinct purpose. Understanding how these elements interact and function can provide insight into the overall performance and reliability of the transmission system.

Main Components and Their Roles

- Torque Converter: This device is responsible for transferring power from the engine to the transmission. It amplifies engine torque and allows for smooth acceleration.

- Planetary Gear Set: A crucial component that enables various gear ratios, allowing the vehicle to adapt to different speeds and loads. It consists of gears that revolve around a central gear, providing versatility in performance.

- Clutch Packs: These components engage and disengage the transmission gears, allowing for smooth shifting and control over power delivery.

- Hydraulic System: This system uses fluid pressure to operate various transmission elements, ensuring efficient operation and response during gear changes.

Additional Elements

- Valve Body: The control center of the transmission, directing fluid flow to the appropriate clutches and bands, facilitating gear selection.

- Transmission Cooler: Helps maintain optimal operating temperatures, preventing overheating and ensuring the longevity of the transmission system.

- Output Shaft: This shaft transmits power from the transmission to the driveshaft, ultimately propelling the vehicle forward.

Each component is integral to the seamless functioning of the entire system, highlighting the complexity and engineering behind modern automotive transmissions.

Common Issues with 4R100 Parts

Various components in automatic transmission systems can experience frequent complications that affect their overall performance and reliability. Understanding these issues can help in effective troubleshooting and maintenance.

Some of the most prevalent problems include:

- Fluid Leaks: A common issue caused by worn seals or gaskets, leading to inadequate lubrication.

- Shifting Delays: Delays in gear engagement can occur due to low fluid levels or faulty solenoids.

- Overheating: Excessive heat can result from insufficient cooling, often linked to fluid degradation.

- Noise During Operation: Unusual sounds might indicate internal wear or component failure.

To address these complications, regular maintenance and inspections are essential. Keeping an eye on fluid levels, monitoring for leaks, and ensuring that components are in good working condition can prevent significant damage and costly repairs.

Visual Guide to 4R100 Assembly

This section provides a comprehensive overview of the assembly process for a specific automatic transmission model. By breaking down the components and their arrangements, it aims to enhance understanding and facilitate successful assembly.

Key aspects to consider when assembling the transmission include:

- Understanding the function of each component

- Identifying the correct orientation for assembly

- Ensuring proper alignment of parts

- Utilizing appropriate tools for installation

The following steps outline the assembly procedure:

- Gather all necessary components and tools.

- Begin by aligning the main housing with the input shaft.

- Install the gear sets, ensuring they fit securely into place.

- Attach the valve body, confirming all seals are intact.

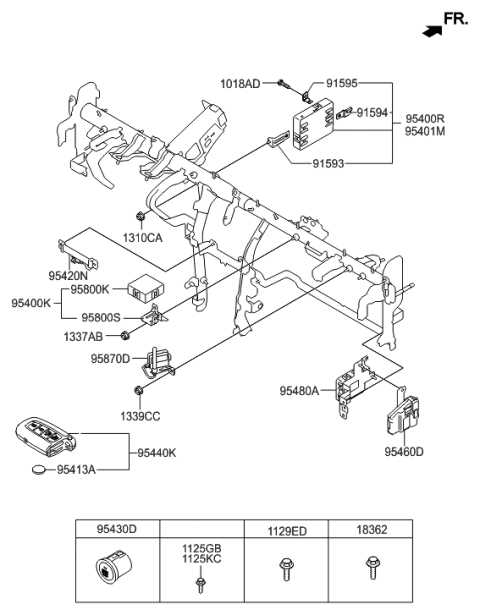

- Carefully connect the electrical components, paying attention to the wiring layout.

- Complete the assembly by securing the outer casing.

Referencing visual aids during this process can significantly improve accuracy and efficiency. Following these guidelines will help ensure a successful assembly.

Maintenance Tips for 4R100 Components

Proper upkeep of mechanical elements is crucial for ensuring optimal performance and longevity. Regular attention can prevent premature wear and potential failures, which can be costly and time-consuming. This section highlights essential maintenance strategies that contribute to the efficient functioning of these components.

1. Regular Inspection: Conduct routine examinations to identify any signs of wear, corrosion, or damage. Early detection of issues can facilitate timely repairs and minimize the risk of more significant problems down the line.

2. Fluid Checks: Ensure that lubricants and hydraulic fluids are at appropriate levels. Regularly replacing fluids can prevent contamination and reduce friction, thus extending the lifespan of the internal mechanisms.

3. Cleaning: Keep all parts clean from debris and dirt. Accumulation of contaminants can hinder performance and lead to overheating. Use appropriate cleaning agents to maintain the integrity of the surfaces.

4. Component Alignment: Verify that all elements are correctly aligned. Misalignment can cause excessive stress and lead to premature failure. Adjustments should be made whenever necessary to ensure optimal functionality.

5. Follow Manufacturer Guidelines: Adhering to the manufacturer’s recommended maintenance schedule is vital. These guidelines provide specific instructions tailored to the unique requirements of each component, enhancing reliability and performance.

Implementing these maintenance tips will help ensure that your mechanical systems operate smoothly and efficiently, ultimately prolonging their lifespan and performance.

Replacement Procedures for Key Parts

When it comes to maintaining complex machinery, ensuring the proper functioning of vital components is essential. Following systematic replacement processes not only enhances performance but also prolongs the lifespan of the equipment. This section outlines the fundamental steps for effectively substituting key elements, ensuring a smooth transition and optimal operation.

Step-by-Step Replacement Process

The replacement of essential components involves several critical steps that should be adhered to for achieving the best results. These steps include:

- Assess the condition of the component to determine if replacement is necessary.

- Gather the required tools and replacement items before beginning the process.

- Carefully remove the faulty component, ensuring that all connections and fasteners are disengaged properly.

- Install the new component, following the manufacturer’s guidelines for alignment and securing.

- Test the equipment to confirm that the replacement has been successful and that everything is functioning as expected.

Tools and Materials Needed

Utilizing the appropriate tools and materials can significantly simplify the replacement procedure. Below is a table summarizing essential items that may be required:

| Tool/Material | Description |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts. |

| Torque Wrench | Ensures bolts are tightened to the specified torque settings. |

| Replacement Component | The specific item being installed to replace the old one. |

| Lubricant | Facilitates smooth operation and prevents wear. |

Upgrades for Enhanced 4R100 Performance

Improving the capabilities of a specific transmission system can significantly enhance the overall driving experience. By focusing on various enhancements, enthusiasts can achieve greater efficiency, durability, and responsiveness. These modifications not only optimize the functionality of the system but also contribute to increased power delivery and smoother operation.

Performance Modifications

Several modifications can be implemented to elevate performance levels. Upgrading to high-performance clutches and bands can provide better grip and handling of increased torque. Additionally, installing a more efficient torque converter can facilitate quicker power transfer and improved acceleration. These enhancements are crucial for maximizing the system’s potential.

Cooling and Lubrication Enhancements

Effective cooling and lubrication are vital for maintaining optimal performance. Upgrading to a high-capacity transmission cooler can prevent overheating during demanding conditions. Furthermore, utilizing synthetic fluids can reduce friction and wear, enhancing longevity and reliability. Such improvements ensure that the system operates within its ideal temperature range, promoting consistent performance.

Parts Compatibility with Other Models

The interchangeability of components between different automotive systems can significantly enhance maintenance efficiency and reduce costs. Understanding how various elements can work together across similar models allows for more flexibility in repairs and upgrades.

Many systems share common features that enable certain components to be compatible. For instance, several models may utilize similar transmission designs, leading to the potential for cross-compatibility. Compatibility not only facilitates easier access to replacement options but also opens avenues for improving overall vehicle performance through the use of advanced components.

It is essential to verify specific model years and configurations to ensure the successful integration of these parts. By consulting detailed specifications and resources, enthusiasts and mechanics alike can identify suitable alternatives, ensuring that replacements function effectively and enhance vehicle reliability. Proper research is crucial in maximizing the benefits of using interchangeable components.

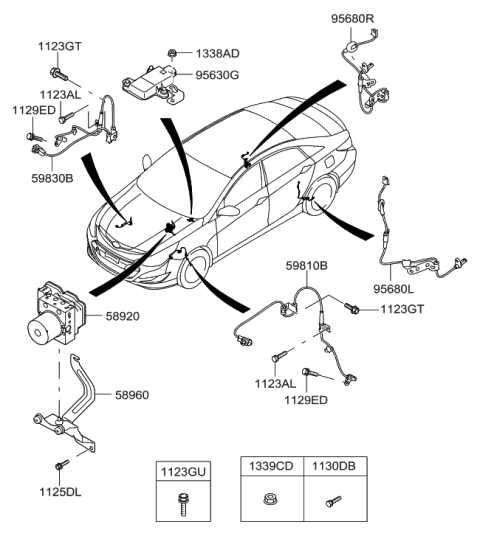

How to Read a Parts Diagram

Understanding the layout of a component schematic is essential for effective maintenance and repairs. These illustrations serve as visual guides, providing an organized representation of various elements within a system. By familiarizing yourself with these visuals, you can enhance your ability to identify components and their functions.

Begin by examining the overall layout, which often includes labeled sections that categorize different groups of elements. This segmentation helps in quickly locating specific items. Pay attention to the orientation and arrangement, as they can indicate how components interact with one another.

Next, focus on the symbols and labels used in the illustration. Each symbol corresponds to a particular element, and the accompanying labels usually provide additional details, such as part numbers or specifications. Understanding these notations is crucial for accurate identification and ordering of replacements.

Lastly, refer to any accompanying legends or notes that clarify the illustration. These can provide valuable context, such as installation instructions or troubleshooting tips. Mastering the interpretation of these visuals will significantly improve your technical skills and streamline the repair process.

Resources for 4R100 Repair Manuals

Finding reliable resources for maintenance and repair documentation is essential for any vehicle enthusiast or professional mechanic. Access to comprehensive guides can greatly facilitate the repair process, ensuring that every task is performed efficiently and accurately. Here are some valuable sources to consider when seeking repair manuals.

- Online Forums: Communities focused on automotive repairs often share manuals and helpful tips.

- Manufacturer Websites: Official sites typically provide downloadable versions of manuals or direct links to authorized service providers.

- Repair Manual Retailers: Specialized retailers offer printed and digital versions of repair guides for various vehicle models.

- Library Resources: Many public libraries provide access to databases of repair manuals, which can be accessed for free with a library card.

- YouTube Channels: Several automotive experts create video tutorials that can complement written manuals.

Utilizing these resources can significantly enhance the repair experience, ensuring that all necessary information is readily available. Proper documentation not only aids in troubleshooting but also helps maintain the overall performance and longevity of the vehicle.