When exploring the inner workings of diesel engines, it’s essential to have a clear understanding of how various elements come together. Each component plays a crucial role in ensuring smooth performance and durability, and knowing their precise arrangement can make maintenance tasks significantly easier. By grasping the overall structure, users can enhance both efficiency and longevity of the equipment.

Accurate visualization of engine layouts aids in troubleshooting and repairs, helping technicians identify specific issues more quickly. Whether it’s a minor fix or a complete overhaul, familiarizing oneself with the engine’s layout can save both time and effort. This section will provide an insightful overview, guiding you through the essential aspects of an engine’s internal setup.

Comprehensive Overview of 5.9 Cummins Engine Components

The internal structure of this widely recognized power unit is composed of various interconnected elements that work together to deliver optimal performance and efficiency. Each section of the engine plays a critical role in ensuring smooth operation, durability, and reliability under different conditions. Understanding the individual elements of this machinery can help in its maintenance and troubleshooting.

- Fuel System: Responsible for delivering the right amount of fuel into the combustion chambers for efficient energy generation.

- Turbocharger: Enhances air intake to improve combustion and overall engine power output.

- Cylinder Block: The main structure that houses the cylinders, where the core energy conversion process occurs.

- Cooling System: Maintains ideal operating temperatures by dissipating heat generated during engine function.

- Exhaust System: Channels out gases produced

Essential Parts of a 5.9 Cummins Engine

The heart of any diesel engine relies on a well-coordinated assembly of components working in unison. These crucial elements ensure smooth operation, providing both power and efficiency. Understanding how the key systems are organized and function together is vital for anyone looking to maintain or repair this type of engine.

Fuel System: The fuel delivery mechanism plays a central role in powering the engine by injecting precise amounts of fuel into the combustion chamber. Proper functioning of this system ensures optimal performance and fuel economy.

Turbocharger: This component is responsible for increasing air pressure, thereby enhancing the overall power output. By compressing the incoming air, the engine can achieve higher performance, especially under load.

Cylinder Head: A critical element in sealing the combustion chamber, the cylinder head contains intake and exhaust valves,

Detailed Breakdown of Fuel System Components

The fuel system plays a critical role in ensuring that the engine operates efficiently. It comprises several interconnected components, each with a specific function to deliver fuel from the tank to the engine. By maintaining a steady flow of fuel, this system ensures optimal combustion, contributing to both performance and efficiency. Understanding how these elements work together helps in diagnosing issues and maintaining the system properly.

Fuel injectors are key players in the process, responsible for delivering precise amounts of fuel into the combustion chamber. Their performance directly affects engine efficiency and power output. Regular cleaning and proper maintenance are essential to avoid clogging and ensure smooth operation.

The fuel pump ensures a consistent supply of fuel from the tank to the engine. It maintains the necessary pressure to allow the injectors to function correctly. If the pump fails or loses efficiency,

Understanding the Turbocharger and Its Role

The turbocharger plays a vital role in enhancing engine efficiency and performance by boosting the air intake system. It allows the engine to generate more power without increasing its size or weight, making it a crucial component for modern vehicles. This section explores how the turbocharger operates and the benefits it provides in terms of power and fuel efficiency.

A turbocharger works by utilizing exhaust gases to spin a turbine, which compresses the intake air and increases the engine’s air-to-fuel ratio. This creates a more efficient combustion process, leading to enhanced performance. The system consists of several interconnected parts that work together to ensure optimal engine output.

- Compressor side: This section draws in and compresses the air before it enters the engine.

- Turbine side: Driven by exhaust gases, this turbine powers the compressor, making the entire system function effectively.

- Intercooler: Reduces the temperature of compressed air, making it denser and more efficient for

Key Cooling System Parts and Their Function

The cooling system in an engine plays a vital role in ensuring the optimal temperature is maintained during operation. By efficiently managing heat, it prevents overheating and ensures the engine runs smoothly. Below, we will explore the main elements of this system and how they contribute to keeping the engine in peak condition.

Radiator

The radiator is essential for dissipating heat from the coolant. As the coolant passes through, the radiator transfers the heat to the air, allowing the fluid to cool down before circulating back into the engine.

Water Pump

The water pump is responsible for circulating the coolant through the engine and the radiator. By maintaining a steady flow, it ensures that heat is consistently removed from the engine.

- Thermostat: Regulates the temperature by controlling the flow of coolant. When the engine reaches the optimal temperature, the thermostat opens, allowing the

Internal Engine Components and Their Importance

Internal components of an engine play a crucial role in ensuring smooth and efficient performance. These elements work in harmony to convert fuel into power, maintain optimal operation, and ensure longevity. Understanding how these parts interact is key to recognizing the importance of proper maintenance and timely replacement of any worn elements.

Pistons are central to this process, moving inside cylinders to create the force needed for motion. Their function directly impacts power output and overall efficiency. The cylinder head and valves regulate air and fuel flow, maintaining proper combustion. Additionally, the crankshaft converts the linear motion of the pistons into rotational energy, which drives the wheels.

Each of these components must function perfectly to prevent malfunctions or loss of performance. Regular inspection and care ensure that the engine runs efficiently, maximizing its lifespan and avoiding costly repairs. Neglecting internal components can lead to

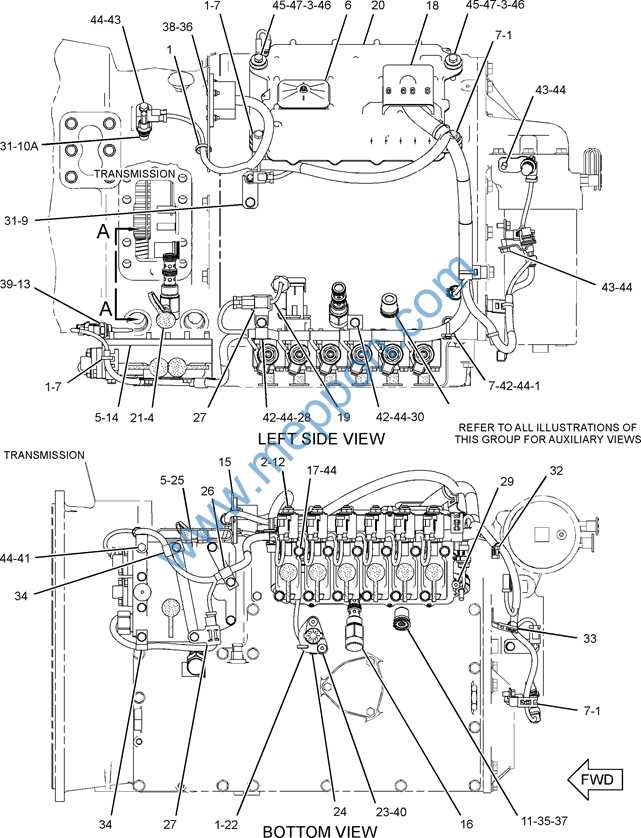

Diagram of the Air Intake System

The air intake system plays a crucial role in ensuring efficient engine performance by managing the flow of air required for combustion. This system is responsible for filtering and directing clean air into the engine, allowing optimal fuel mixture and power generation. It helps maintain the overall health of the engine, reducing the risk of contamination from external particles.

Below is a detailed breakdown of the key components that make up the air intake assembly:

Component Description Air Filter Filters dust, debris, and contaminants from the incoming air. Air Duct Connects the air filter to the intake manifold, guiding clean air to the engine. Throttle Body Regulates Oil System Parts and Lubrication Process

The lubrication mechanism within an engine plays a vital role in ensuring smooth operation and preventing wear. By distributing oil effectively throughout various components, it reduces friction and minimizes the risk of overheating. The flow of oil is essential for maintaining engine longevity and efficiency, ensuring that all moving parts function without excessive wear or damage.

Key components of this system include the oil pump, which generates the necessary pressure to circulate oil, and the filter that keeps the lubricant free from contaminants. Additionally, oil passages guide the fluid to various regions of the engine, ensuring continuous lubrication. Each component works together to ensure

Explaining the Exhaust System Configuration

The exhaust system plays a crucial role in managing the emissions and optimizing the performance of an engine. Understanding its layout and components is essential for ensuring efficient operation and compliance with environmental regulations.

This configuration typically includes several key components:

- Exhaust Manifold: This part collects exhaust gases from the engine cylinders and directs them into the exhaust system.

- Turbocharger: In many setups, a turbocharger utilizes exhaust gases to enhance engine efficiency and power output.

- Downpipe: The downpipe connects the exhaust manifold to the rest of the exhaust system, facilitating the flow of gases.

- Catalytic Converter: This component reduces harmful emissions by converting them into less harmful substances before they exit the system.

- Muffler: The muffler helps to minimize noise produced by the engine while maintaining optimal exhaust flow.

- Exhaust Tip: The exhaust tip is the visible end of the exhaust system, often designed for aesthetic purposes as well as functional exhaust flow.

Each element of the exhaust configuration contributes to the overall effectiveness of the system, affecting performance, noise levels, and emissions. Regular inspection and maintenance of these components are essential for preserving the system’s integrity and ensuring compliance with regulations.

Electronic Control System and Sensors

The electronic control system plays a crucial role in managing engine performance and efficiency. It integrates various components that monitor and adjust parameters to ensure optimal functioning. By utilizing advanced technology, this system enhances the overall reliability and responsiveness of the engine, contributing to better fuel economy and reduced emissions.

Functionality and Components

This control system relies on a network of sensors that gather data about engine conditions. These sensors monitor vital aspects such as temperature, pressure, and airflow. The information collected is processed by the control unit, which makes real-time adjustments to optimize performance. This seamless interaction between components allows for precise regulation of engine functions, ensuring smooth operation under varying conditions.

Importance of Calibration

Calibration of the electronic control system is essential for maintaining accuracy and performance. Regular checks and adjustments help ensure that the sensors provide reliable data, enabling the control unit to function effectively. Proper calibration not only improves engine performance but also extends the lifespan of components, making it a vital aspect of engine management.

Overview of the Valve Train Assembly

The valve train assembly is a crucial component in an internal combustion engine, responsible for controlling the flow of air and exhaust gases. Its design and functionality directly impact the engine’s performance, efficiency, and overall reliability.

This assembly consists of several key parts that work in unison to ensure proper valve operation:

- Valves: These elements open and close to allow air and fuel into the combustion chamber and expel exhaust gases.

- Camshaft: This rotating shaft controls the timing and movement of the valves, enabling precise coordination with the engine cycles.

- Lifters: These components transfer motion from the camshaft to the pushrods, ensuring that the valves operate smoothly.

- Pushrods: Connecting the lifters to the rocker arms, these rods transmit the motion needed to actuate the valves.

- Rocker Arms: These parts leverage the motion from the pushrods to open and close the valves, playing a pivotal role in the valve operation.

Understanding the function and arrangement of each part within the valve train assembly is essential for diagnosing issues and performing maintenance. Proper upkeep of these components is vital for sustaining engine efficiency and prolonging its lifespan.

Commonly Replaced Parts in a 5.9 Cummins

When it comes to maintaining performance and reliability in diesel engines, certain components often require regular replacement. Understanding which elements are most frequently swapped out can help in keeping the engine running smoothly and efficiently.

Key Components to Monitor

- Fuel injectors

- Water pumps

- Thermostats

- Oil filters

- Turbochargers

Common Signs of Wear

Drivers should be vigilant about specific indicators that may suggest the need for part replacement:

- Reduced engine performance

- Increased fuel consumption

- Unusual noises from the engine

- Visible leaks

Maint

This section focuses on the essential upkeep and service components necessary for optimal engine performance. Regular maintenance not only extends the life of the machinery but also ensures efficiency and reliability during operation.

Regular Maintenance Tasks

- Check and replace the oil and oil filter regularly to ensure proper lubrication.

- Inspect air filters and replace them as needed to maintain air quality and performance.

- Monitor coolant levels and check for leaks to prevent overheating.

- Examine belts and hoses for wear and tear, replacing them as necessary.

- Test the battery and electrical connections to ensure reliable starts.

Maintenance Schedule

- Daily: Check fluid levels and inspect for leaks.

- Weekly: Clean air filters and inspect belts.

- Monthly: Change the oil and inspect the fuel system.

- Quarterly: Conduct a comprehensive inspection of all components.

- Annually: Perform a full service including all filters and fluids.

- Thermostat: Regulates the temperature by controlling the flow of coolant. When the engine reaches the optimal temperature, the thermostat opens, allowing the