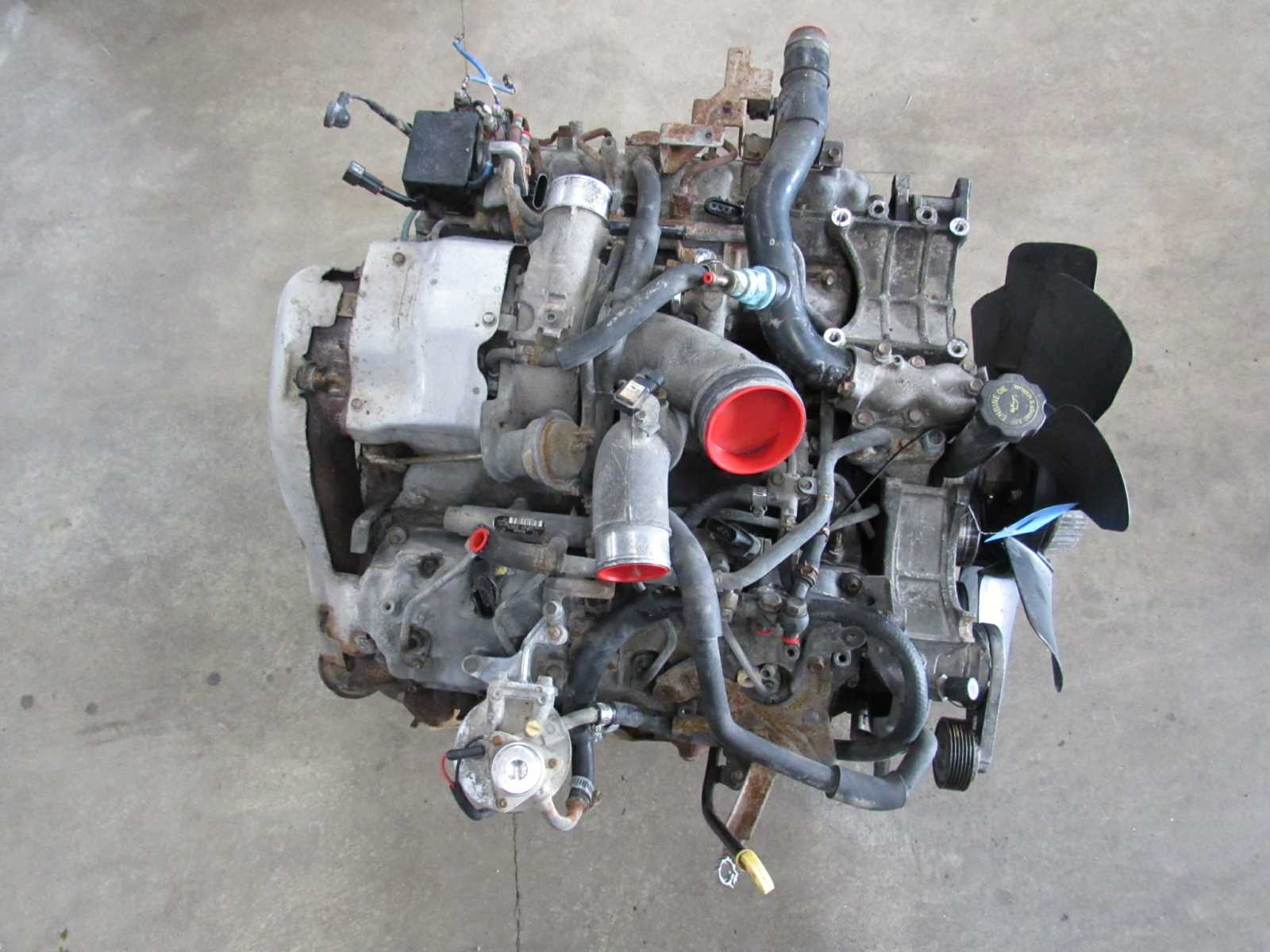

When exploring the intricacies of heavy-duty automotive machinery, it becomes essential to grasp the various elements that contribute to optimal performance. This section aims to unravel the complexities involved in understanding the relationships between components, ensuring a seamless operation.

Each segment plays a crucial role in the overall functionality of the engine, impacting not only efficiency but also longevity. By breaking down these crucial elements, enthusiasts and professionals alike can enhance their knowledge and maintain their vehicles more effectively.

Moreover, identifying the specific characteristics of each component allows for informed decisions when it comes to upgrades and repairs. A thorough comprehension of these parts leads to greater confidence in tackling maintenance tasks and improving performance.

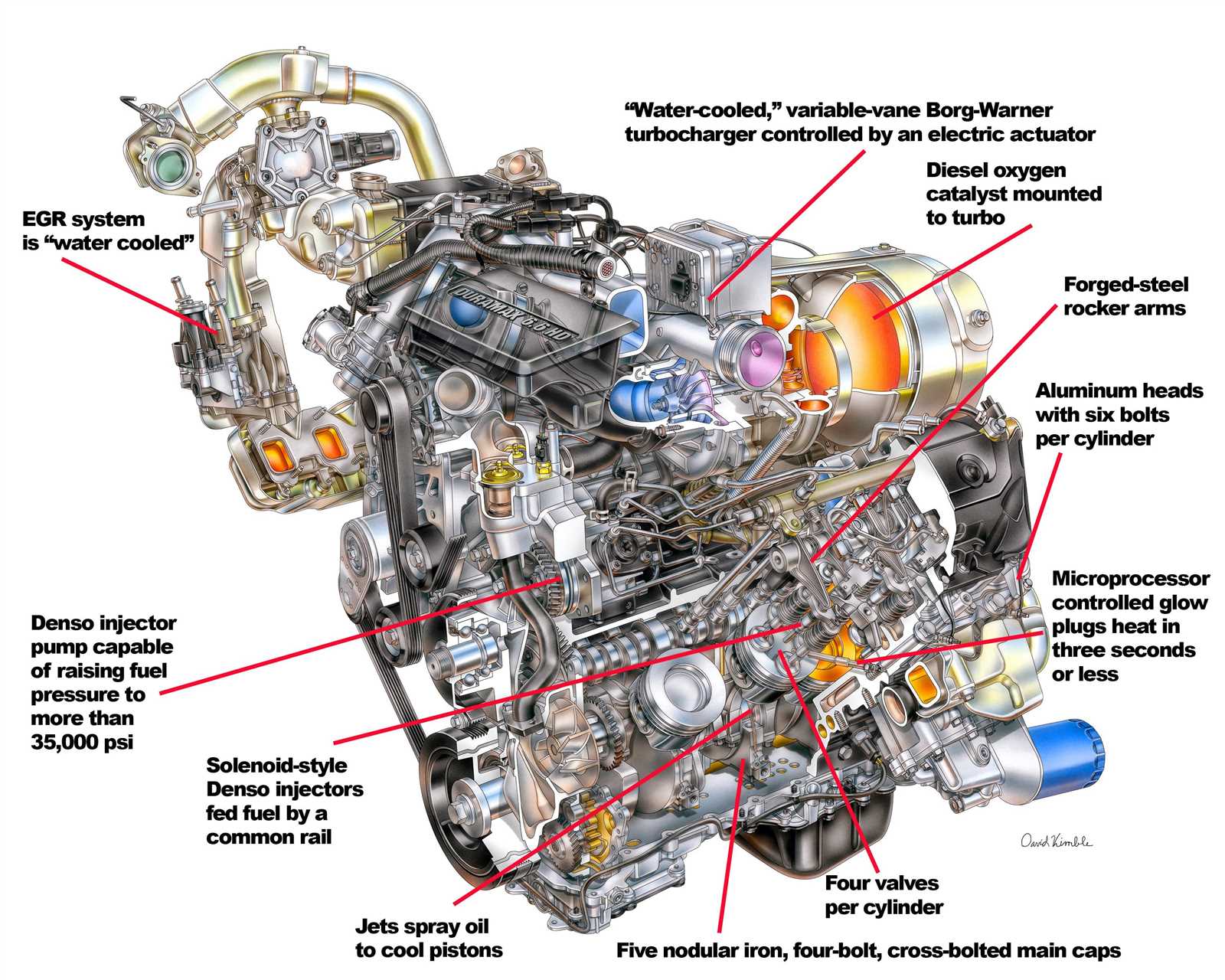

Understanding Duramax Engine Components

This section explores the intricate elements that contribute to the functionality and efficiency of a high-performance diesel engine. Grasping these components is essential for maintenance and optimization.

- Engine Block: The core structure housing critical internal parts.

- Cylinder Heads: Essential for combustion, they manage airflow and fuel injection.

- Pistons: Key players in converting fuel energy into mechanical power.

- Fuel Injectors: Precision tools ensuring optimal fuel delivery.

- Turbocharger: Enhances power output by increasing air intake.

Understanding each element’s role helps enthusiasts and technicians alike delve into engine performance and troubleshooting.

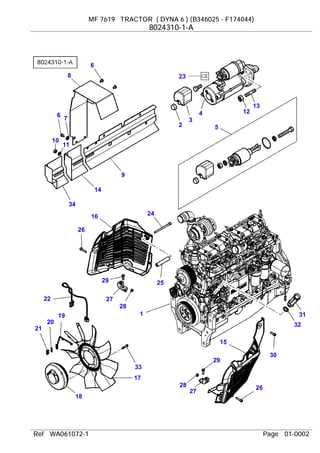

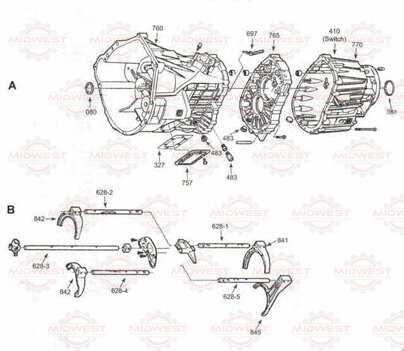

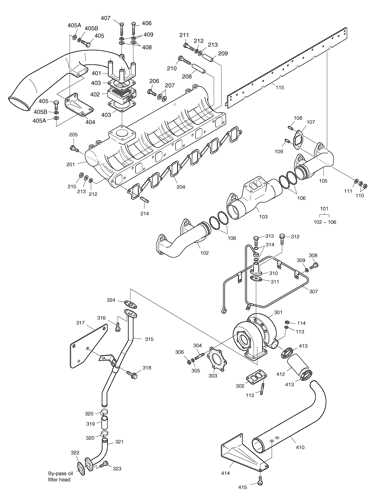

Importance of Parts Diagrams

Understanding the intricate components of any mechanical system is crucial for maintenance and repair. Visual representations of these elements provide clarity and facilitate the identification of each part’s function and location. Such resources serve as essential tools for technicians and enthusiasts alike, ensuring efficient assembly, disassembly, and troubleshooting.

Benefits of Visual Representations

- Enhanced Understanding: Diagrams simplify complex structures, allowing users to grasp how components interact within the system.

- Accurate Identification: Clearly labeled visuals help in pinpointing specific elements, reducing the chances of errors during repairs.

- Streamlined Processes: With a visual guide, technicians can follow procedures more efficiently, saving time and effort.

Role in Maintenance and Repair

- Troubleshooting: Diagrams assist in diagnosing issues by providing a roadmap of the system.

- Ordering Replacement Parts: Accurate visuals help ensure that the correct items are procured, minimizing delays.

- Training Tool: New technicians can learn quickly by referencing visual guides, improving their skills and confidence.

Common Issues with Duramax Parts

In the realm of high-performance diesel engines, certain components frequently present challenges that can impact overall functionality and longevity. Understanding these common concerns can aid in effective maintenance and troubleshooting.

Frequent Problems

- Fuel Delivery Failures

- Cooling System Leaks

- Electrical Malfunctions

- Oil Pressure Irregularities

Signs of Trouble

- Unexpected engine stalling or misfiring.

- Increased temperature readings during operation.

- Unusual noises from the engine compartment.

- Frequent warning lights on the dashboard.

Addressing these issues promptly can prevent more severe damage and ensure optimal performance of the engine over time.

Upgrading Your Duramax Engine

Enhancing the performance of your heavy-duty powertrain can significantly improve its capabilities and efficiency. Whether you’re looking to boost horsepower, optimize fuel efficiency, or enhance overall reliability, there are numerous options available. This section explores various approaches to elevate your engine’s performance, ensuring it meets your specific demands.

One effective strategy involves upgrading the intake and exhaust systems. By improving airflow, you can maximize combustion efficiency, leading to noticeable gains in power. Additionally, consider advanced tuning solutions that modify the engine’s electronic control unit. These modifications can tailor performance parameters, allowing for a more responsive driving experience.

Another vital area to focus on is the fuel delivery system. High-performance injectors can enhance fuel atomization, resulting in better combustion and reduced emissions. Coupled with a high-flow fuel pump, this upgrade can provide the necessary fuel volume for increased power output.

Furthermore, don’t overlook the importance of robust cooling systems. A more efficient radiator and intercooler can maintain optimal operating temperatures, preventing overheating during heavy loads or prolonged use. This not only prolongs engine life but also maintains performance consistency.

Lastly, incorporating a performance-oriented transmission can significantly impact the overall driving experience. A transmission that can handle increased torque and provide quicker shifts will complement your upgraded powertrain, resulting in improved acceleration and towing capabilities.

Maintenance Tips for Duramax Engines

Regular upkeep is essential for ensuring optimal performance and longevity of heavy-duty powertrains. By adhering to a structured maintenance schedule, owners can prevent issues and enhance efficiency. Understanding key aspects of care can lead to a smoother driving experience and fewer unexpected repairs.

Regular Fluid Checks

Monitoring and changing fluids is crucial. Engine oil, coolant, and transmission fluid should be checked frequently. Keeping these fluids at proper levels helps maintain temperature control and lubrication, preventing wear and tear.

Filter Replacements

Air and fuel filters play vital roles in engine health. Regularly replacing these components ensures that the engine receives clean air and fuel, which is essential for efficient combustion and performance. A clean system reduces the risk of clogs and enhances overall efficiency.

Where to Find Reliable Diagrams

Finding trustworthy illustrations for mechanical components is essential for effective maintenance and repairs. Reliable resources not only enhance understanding but also ensure that tasks are performed accurately. Here are some valuable avenues to explore when seeking these visuals.

Online Resources

The internet offers a vast array of platforms dedicated to automotive information. Websites that specialize in vehicle repairs often provide detailed visuals that are easy to navigate. Look for platforms that have user reviews and ratings to gauge reliability.

Manuals and Publications

Printed manuals, such as service books or factory guides, are time-tested resources. They typically include comprehensive diagrams that can be invaluable for both novices and experienced technicians. Ensure the manuals are specific to the model in question for the best results.

| Resource Type | Examples | Notes |

|---|---|---|

| Online Platforms | RepairPal, AutoZone | Check user feedback for credibility. |

| Printed Manuals | Haynes, Chilton | Focus on model-specific editions. |

| Forums and Communities | Reddit, specialized car forums | Great for peer-shared resources. |

Aftermarket vs. OEM Duramax Parts

The choice between replacement components from original manufacturers and those from third-party suppliers often leads to a heated debate among enthusiasts. Each option presents unique advantages and considerations that can impact performance, reliability, and overall satisfaction. Understanding these differences is essential for making an informed decision.

Quality and Performance

Original components are typically engineered to meet specific standards set by manufacturers, ensuring optimal functionality and longevity. In contrast, third-party offerings can vary widely in quality, with some brands providing superior alternatives that may even enhance performance.

Cost Considerations

When evaluating expenses, original parts generally come with a higher price tag due to brand reputation and warranty coverage. Conversely, aftermarket options can be more budget-friendly, but careful research is necessary to avoid subpar products that could lead to additional costs in the long run.

| Aspect | OEM | Aftermarket |

|---|---|---|

| Quality | High, consistent | Varies by brand |

| Cost | Generally higher | More affordable |

| Warranty | Often included | Varies by manufacturer |

| Availability | Limited to specific vendors | Widely accessible |

Tools Needed for Duramax Repairs

When working on high-performance diesel engines, having the right equipment is essential for ensuring smooth and effective maintenance. Proper tools not only facilitate repairs but also help prevent damage to components. Below is a list of essential implements that can make the repair process more efficient.

- Socket Set: A comprehensive socket set is vital for removing and securing various fasteners.

- Wrench Set: An assortment of wrenches, including both metric and standard sizes, is crucial for accessing tight spaces.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, which is critical for engine integrity.

- Oil Filter Wrench: Specifically designed to remove and install oil filters without damage.

- Compression Tester: Helps in diagnosing engine performance by measuring cylinder pressure.

- Diagnostic Scanner: Essential for reading fault codes and monitoring engine parameters during repairs.

In addition to these primary tools, there are several other implements that can enhance your repair capabilities:

- Pliers and Cutters: Useful for handling wires and small components.

- Multimeter: A must-have for electrical diagnostics and troubleshooting.

- Fluid Extractor: Helps in draining fluids efficiently during maintenance.

- Shop Manual: Provides detailed procedures and specifications for repairs.

Equipping your workspace with these tools will significantly improve your ability to perform repairs effectively and maintain the performance of the engine.

Understanding Duramax Engine Specifications

This section explores the key characteristics and features of a popular diesel engine, focusing on its design, performance, and overall functionality. By examining these specifications, enthusiasts and technicians can gain a deeper appreciation for its capabilities and applications in various vehicles.

| Specification | Details |

|---|---|

| Engine Type | V8 Diesel |

| Displacement | 6.6 Liters |

| Power Output | Estimated 400 HP |

| Torque | Estimated 765 lb-ft |

| Fuel System | Common Rail Direct Injection |

| Turbocharger | Variable Geometry Turbo |

Understanding these essential specifications allows for better maintenance and performance tuning, ultimately enhancing the driving experience.

Frequently Asked Questions on Duramax Parts

This section aims to address common inquiries related to components for a specific heavy-duty engine, providing insights to both enthusiasts and professionals. Understanding these elements is crucial for maintenance and upgrades, ensuring optimal performance and longevity.

| Question | Answer |

|---|---|

| What are the most essential components for maintenance? | Regular checks on filters, injectors, and oil pumps are vital for longevity. |

| How often should I replace the filters? | It’s recommended to change them every 15,000 to 30,000 miles, depending on usage. |

| Can I upgrade components for better performance? | Yes, performance upgrades can enhance efficiency, but ensure compatibility. |

| Where can I find quality replacements? | Authorized dealers and trusted online retailers offer reliable options. |

| Is it necessary to use OEM components? | While OEM parts ensure perfect fitment, quality aftermarket options are available. |