In the realm of mechanical systems, having a clear understanding of the various elements that constitute a device is essential for effective maintenance and troubleshooting. This section aims to provide insight into the intricate arrangement of components, allowing users to familiarize themselves with the essential building blocks that enable optimal functionality.

Each component plays a vital role in the overall performance of the system, and recognizing their specific functions can greatly enhance operational efficiency. By studying the relationships and placements of these elements, users can develop a more comprehensive grasp of how the system operates as a whole.

Moreover, such knowledge not only aids in routine checks and repairs but also empowers individuals to make informed decisions regarding upgrades or modifications. Understanding the layout of these vital components ensures that users can engage with their equipment confidently and competently.

This section outlines the fundamental components of a specific marine propulsion system. Understanding these elements is crucial for effective maintenance and optimal performance. The following headings provide a comprehensive overview of the various parts and their functions, ensuring users gain valuable insights into the system’s operation.

1. Introduction to the System

Overview of the marine system, emphasizing its significance in boating applications.

2. Major Components

- Engine and transmission assembly

- Control mechanisms

- Cooling systems

3. Functional Overview

Explanation of how each component contributes to overall performance.

4. Maintenance Essentials

- Routine checks and servicing

- Common troubleshooting tips

5. Replacement Parts

Information on sourcing high-quality replacement components for repairs.

6. Assembly Instructions

- Step-by-step guide to reassembly

- Safety precautions during installation

7. Upgrades and Modifications

Suggestions for enhancing performance through specific modifications.

8. Common Issues

- Symptoms of malfunctioning components

- Solutions for frequent problems

9. Expert Tips

Advice from professionals on maintaining efficiency and longevity of the system.

10. Conclusion

Recap of the importance of understanding each part for optimal operation.

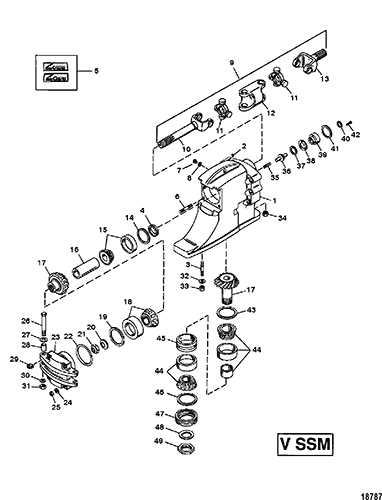

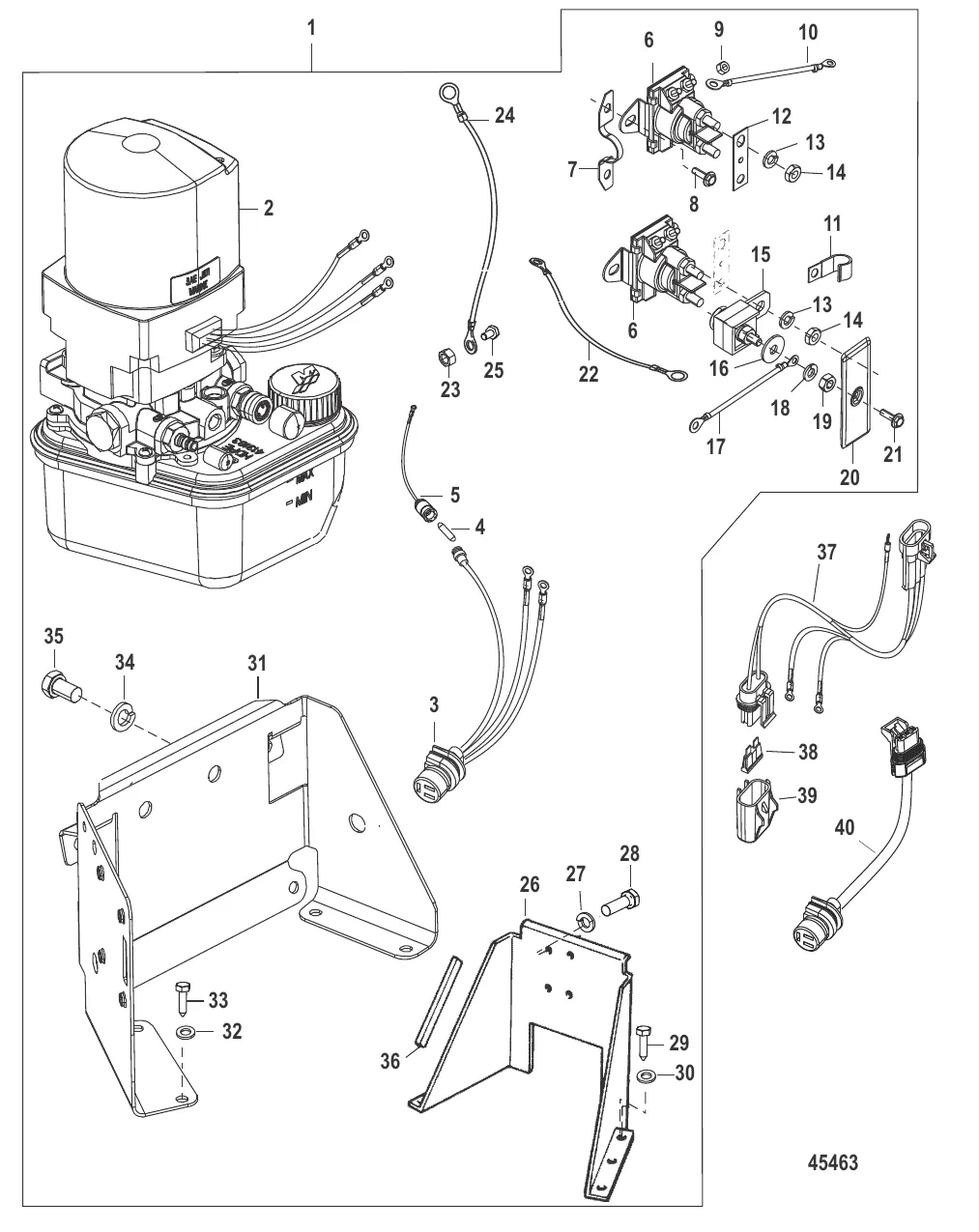

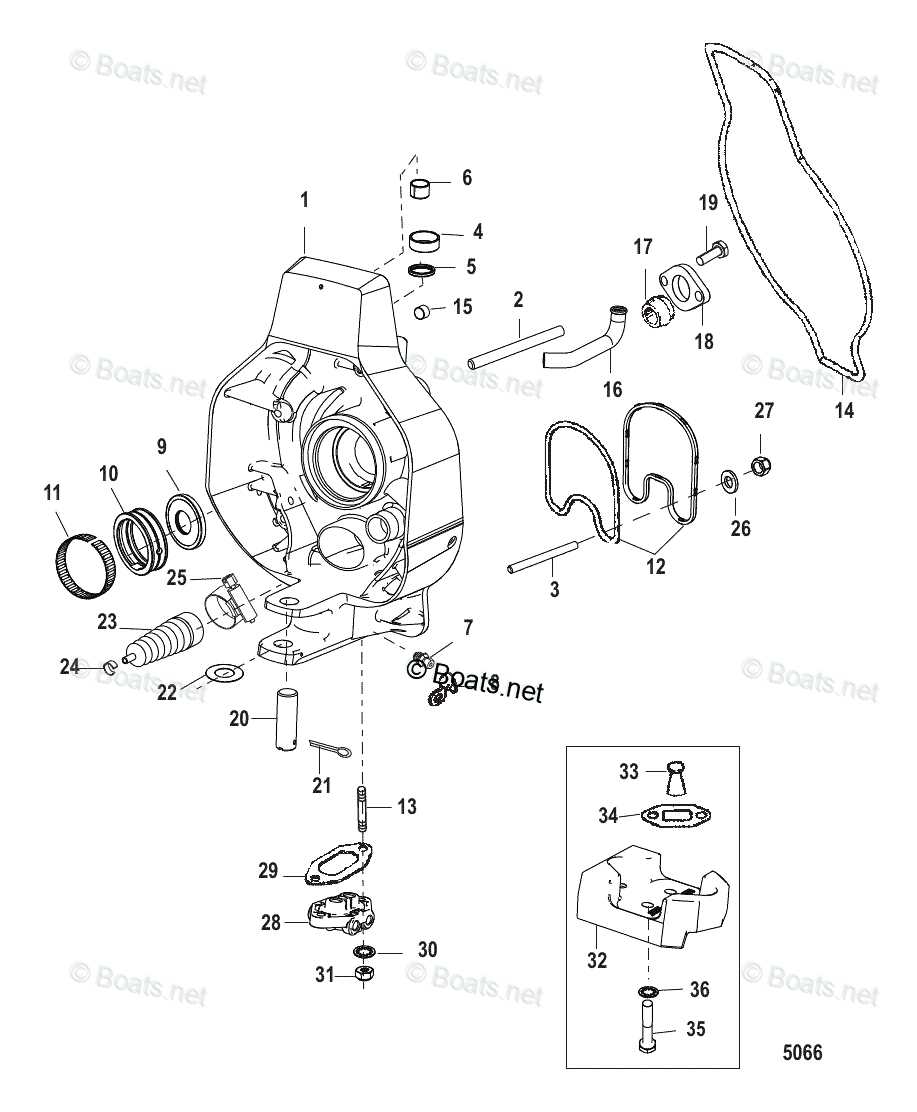

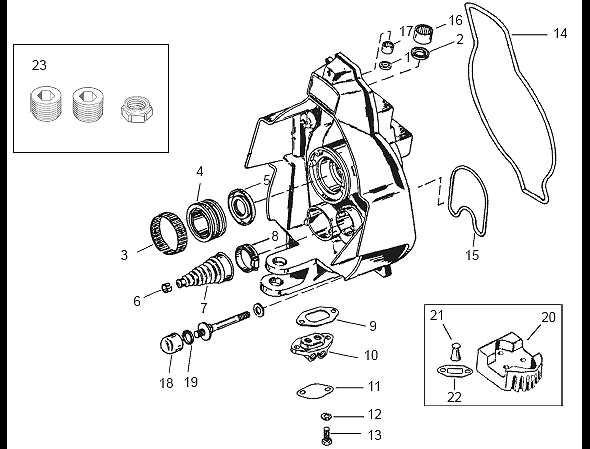

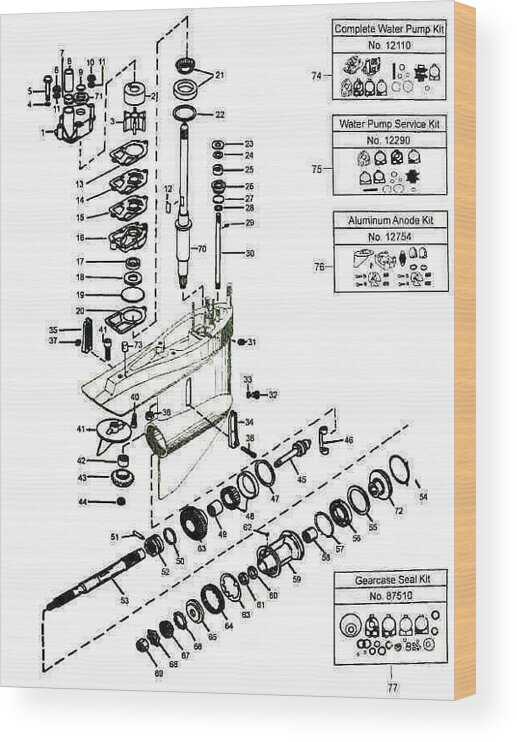

Key Components of Alpha 1

This section focuses on the essential elements that contribute to the functionality and performance of the designated unit. Understanding these components is crucial for effective maintenance and operation, ensuring longevity and optimal performance.

The primary structure serves as the backbone of the assembly, providing support and stability during operation. Its robust design is engineered to withstand various stresses, ensuring reliability in different conditions.

The propulsion mechanism is another vital aspect, responsible for driving the system forward. It operates through a series of interconnected parts that work in harmony to deliver smooth and efficient movement.

The control system plays a pivotal role in managing the operations of the entire setup. This component integrates various sensors and actuators, allowing for precise adjustments and monitoring of performance metrics.

Additional features include safety mechanisms designed to protect the unit from potential hazards. These systems automatically engage during abnormal conditions, safeguarding both the equipment and the operator.

Each of these components is integral to the overall effectiveness of the machine. Regular inspection and maintenance of these elements will enhance performance and extend the service life of the equipment.

Importance of Accurate Diagrams

Detailed illustrations play a crucial role in the understanding and maintenance of complex systems. They provide a visual representation that enhances comprehension, ensuring users can effectively identify and address issues.

Accurate representations offer several key benefits:

- Enhanced Clarity: Clear visuals simplify intricate details, making it easier to grasp essential information.

- Efficient Troubleshooting: Users can quickly locate components and understand their relationships, facilitating faster problem resolution.

- Improved Communication: Well-structured visuals enable effective sharing of information among technicians, engineers, and users.

- Consistency: Standardized illustrations help maintain uniformity across documentation, reducing confusion.

In conclusion, precise visuals are indispensable tools that significantly contribute to the overall efficiency and effectiveness of operations involving intricate machinery.

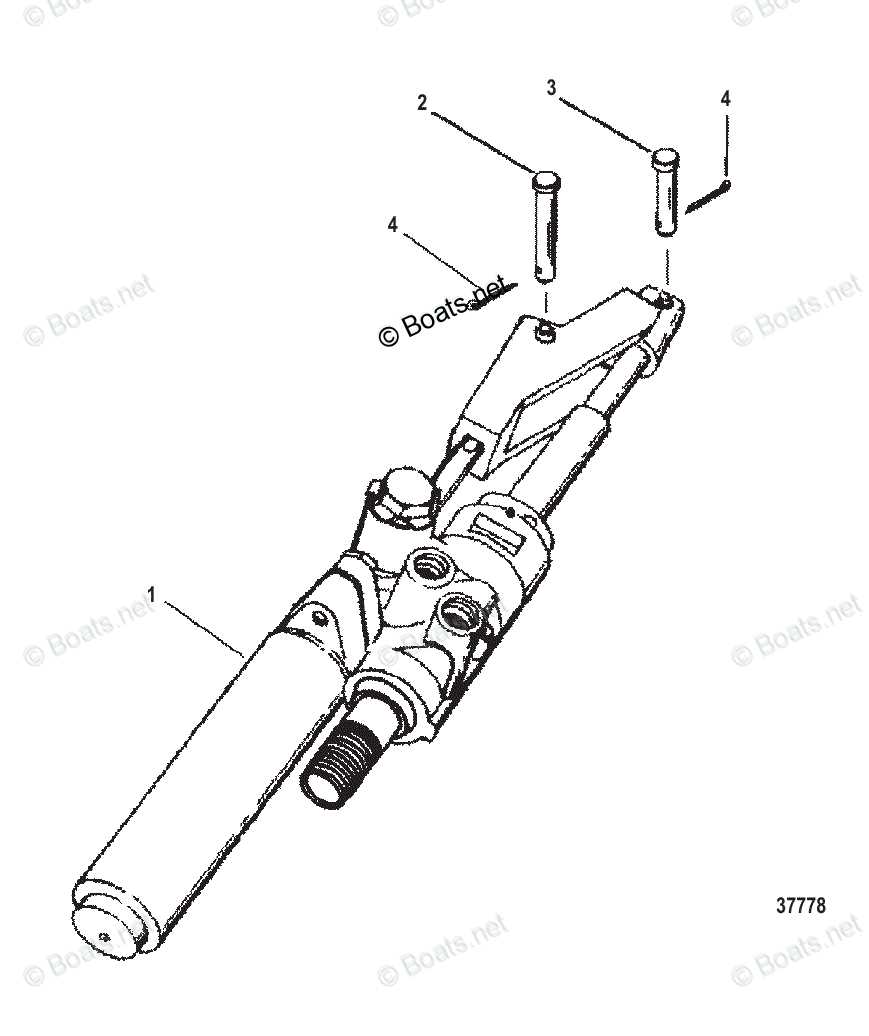

Identifying Parts in the Diagram

Understanding the components represented in the schematic is essential for effective analysis and troubleshooting. This section provides guidance on recognizing various elements depicted in the illustration, facilitating a deeper comprehension of their functions and relationships.

To assist in the identification process, consider the following steps:

- Familiarize Yourself with Symbols: Different symbols represent specific elements. Knowing these symbols will enhance your ability to interpret the layout.

- Follow the Connections: Observe how components are interconnected. This will help you grasp the operational flow and how each element influences others.

- Consult the Legend: Many illustrations include a legend or key that explains each symbol. Referencing this can clarify any uncertainties.

- Utilize Color Coding: Some schematics employ color coding to differentiate between types of components. Pay attention to these colors for quicker identification.

By applying these strategies, you can effectively decode the illustration and gain insights into the overall system’s design and functionality.

Common Issues with Alpha 1 Parts

When dealing with marine propulsion systems, users may encounter various challenges that can affect performance and reliability. Understanding these common issues can aid in preventive measures and maintenance, ultimately extending the lifespan of the equipment.

Wear and Tear

Over time, components may experience significant wear due to exposure to harsh conditions and continuous use. This deterioration can lead to inefficiencies and mechanical failures. Regular inspections can help identify signs of wear early, enabling timely replacements.

Corrosion Problems

Corrosion is a prevalent concern for marine systems, as saltwater can rapidly degrade metals and other materials. Implementing protective coatings and choosing corrosion-resistant materials during replacements can mitigate this issue. Proper maintenance practices, such as rinsing with fresh water after use, can also help prevent damage.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention. Implementing effective maintenance practices not only extends the life of the device but also enhances its efficiency. Below are essential tips to keep in mind for maintaining your machinery.

Regular inspections are crucial. Routinely checking for wear and tear can help identify potential issues before they escalate into significant problems. It is advisable to clean components and lubricate moving parts to prevent friction and damage.

Following the manufacturer’s guidelines is equally important. Adhering to recommended service intervals ensures that each aspect of the machinery receives the necessary care. This practice helps in preserving functionality and avoiding costly repairs.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect components | Monthly | Look for signs of wear and damage. |

| Clean external surfaces | Weekly | Remove dust and debris to improve airflow. |

| Lubricate moving parts | Quarterly | Use appropriate lubricant as specified. |

| Check fluid levels | Monthly | Ensure levels are within the recommended range. |

| Replace worn parts | As needed | Use high-quality replacements for optimal performance. |

How to Read the Diagram Effectively

Understanding a visual representation of components is crucial for efficient assembly and troubleshooting. This section provides insights on how to interpret these illustrations for optimal use. Mastering this skill can significantly enhance your ability to work with the system.

Begin by familiarizing yourself with the layout. Each section typically corresponds to a specific area or function, allowing you to easily locate individual elements. Pay close attention to the labels, as they provide essential information regarding the role and relationship of each component.

Next, utilize a legend or key if available. These tools clarify symbols or markings that may not be immediately obvious. By referring to this guide, you can decipher the meaning of different icons and notations, ensuring accurate comprehension of the entire assembly.

Finally, cross-reference the illustration with any accompanying documentation. Detailed instructions often enhance the understanding of the visual aid, offering context that might be missing from the image alone. This comprehensive approach will lead to a more proficient grasp of the structure and its functionalities.

Replacing Damaged Components

When dealing with a malfunctioning device, addressing damaged elements promptly is crucial to ensure optimal performance. Identifying and substituting faulty components not only restores functionality but also enhances the overall longevity of the equipment. This section outlines essential steps and considerations for effectively replacing compromised parts.

Begin by assessing the damage. Carefully inspect the affected areas to determine which components require replacement. Look for visible signs of wear, cracks, or any other irregularities that may indicate a need for intervention. It is essential to document these findings for reference during the repair process.

Next, gather the necessary tools and replacement items. Depending on the extent of the damage, you may need various tools such as screwdrivers, pliers, or specific implements designed for the task. Ensure that the new components are compatible with your device to avoid further complications.

Once you have everything prepared, proceed to remove the damaged elements. Follow any guidelines provided for disassembly, and take care not to damage surrounding parts. After successfully removing the faulty components, install the replacements carefully, ensuring a secure fit and proper alignment.

Finally, conduct thorough testing after the replacements are made. This step confirms that the new components are functioning correctly and that the overall device performance has been restored. Regular maintenance checks can help prevent future issues and prolong the life of the equipment.

Comparing Alpha 1 with Other Models

This section explores the differences and similarities between the discussed model and various alternatives available on the market. Understanding these distinctions can assist users in making informed decisions based on their specific needs and preferences.

Performance Features

When evaluating different models, performance characteristics play a crucial role. The efficiency and reliability of the discussed unit often set it apart from competitors. While some alternatives may offer higher speeds, the focus here is on consistent output and user-friendly operation.

Durability and Maintenance

Another important aspect is the longevity and upkeep of the systems in question. The model in discussion tends to have superior resilience against wear and tear, which is vital for users looking for long-term investments. Additionally, maintenance requirements vary; while some alternatives necessitate frequent servicing, this model is designed for minimal intervention, ensuring hassle-free use.

Resources for Further Learning

Expanding your knowledge about specific components and their functions can significantly enhance your understanding of complex systems. Various resources are available to help deepen your expertise, including manuals, online tutorials, and community forums. Engaging with these materials can provide valuable insights and practical information.

Numerous instructional websites offer detailed guides and videos that break down the intricacies of different mechanisms. These platforms often feature step-by-step instructions, making it easier to grasp essential concepts. Additionally, user communities can serve as excellent support systems, where enthusiasts share experiences and solutions.

Books and articles written by industry professionals also present in-depth knowledge. Exploring academic publications can provide theoretical frameworks, while practical handbooks focus on real-world applications. Together, these resources can facilitate a comprehensive understanding of intricate devices.

Frequently Asked Questions

This section aims to address common inquiries related to the components and their assembly. Understanding the intricacies of these elements can enhance both the usability and maintenance of the equipment, ensuring optimal performance over time.

| Question | Answer |

|---|---|

| What are the essential components of the system? | The system consists of various integral elements, each serving a specific function to ensure efficient operation. |

| How can I identify the correct replacement pieces? | Refer to the model specifications and component lists provided to ensure compatibility and proper fit. |

| What tools are required for assembly? | A standard toolkit with essential instruments will suffice for most assembly and maintenance tasks. |

| Is there a maintenance schedule to follow? | Regular inspections and periodic upkeep are recommended to prolong the lifespan of the device and its components. |