In the realm of elevated utility vehicles, comprehending the arrangement and functionality of various elements is essential for effective operation and maintenance. This section delves into the intricate schematics that outline the essential components of these specialized vehicles, providing insights that facilitate troubleshooting and repairs.

Each vehicle serves a unique purpose, and its assembly reflects the specific demands placed upon it. By examining these layouts, operators can gain a deeper understanding of how each element interacts within the larger system. This knowledge is crucial for ensuring optimal performance and safety during use.

Moreover, familiarizing oneself with the various components not only aids in the identification of parts but also enhances overall efficiency. The detailed illustrations presented herein will serve as a valuable resource for technicians and operators alike, bridging the gap between theory and practical application.

Overview of Altec Bucket Trucks

The vehicles designed for aerial work play a crucial role in various industries, providing safe access to elevated areas. These machines are equipped with innovative features that enhance productivity and ensure the well-being of operators while performing tasks at significant heights. Understanding the components and functionality of these specialized machines is essential for efficient maintenance and operation.

Key Features and Benefits

These aerial work platforms are built with durability and versatility in mind. Their ability to reach high elevations allows technicians and workers to perform a wide range of activities, from utility maintenance to construction projects. The incorporation of advanced safety mechanisms, such as stabilizers and harness systems, significantly reduces the risk of accidents, making them indispensable in the field.

Maintenance and Reliability

Regular upkeep is vital to ensure these elevated work vehicles remain operational and safe. Familiarity with their structure and the various systems involved allows operators to perform routine inspections and identify potential issues before they escalate. This proactive approach not only extends the lifespan of the equipment but also enhances overall performance.

Essential Components of Bucket Trucks

The functionality of aerial work platforms relies heavily on a variety of critical elements that work in harmony to ensure efficiency and safety. Understanding these components is essential for anyone involved in the operation, maintenance, or design of these vehicles. Each part plays a significant role in supporting various tasks, providing stability, and enhancing the overall performance of the machine.

| Component | Description |

|---|---|

| Platform | The elevated work area that allows personnel to access high locations safely. |

| Boom | A telescoping arm that extends the platform to desired heights. |

| Chassis | The structural framework that supports the entire assembly and provides mobility. |

| Stabilizers | Support structures that increase stability when the platform is elevated. |

| Control System | The mechanism used to operate the platform and boom movements. |

| Hydraulic System | A system that powers the boom and platform movements through fluid pressure. |

Understanding these key components is crucial for maintaining the operational integrity of aerial work solutions and ensuring a safe working environment for all personnel involved.

Understanding the Hydraulic System

The hydraulic system is a crucial component in various machinery, facilitating efficient movement and operation through the transfer of fluid power. This system relies on the principles of fluid mechanics to perform essential functions, enabling the lifting and maneuvering of heavy loads with precision.

At its core, the hydraulic assembly comprises several key elements, including pumps, cylinders, and valves. Pumps are responsible for generating fluid pressure, which is then transmitted through hoses to hydraulic cylinders. These cylinders convert hydraulic energy into mechanical motion, allowing for the lifting or lowering of loads. The valves play a pivotal role in controlling the flow and direction of the fluid, ensuring that the system operates smoothly and safely.

Maintaining the integrity of the hydraulic system is vital for optimal performance. Regular inspections and timely maintenance can prevent leaks, which can lead to decreased efficiency or even system failure. Understanding the components and functionality of this system empowers operators to address issues promptly and ensure continued reliability in various applications.

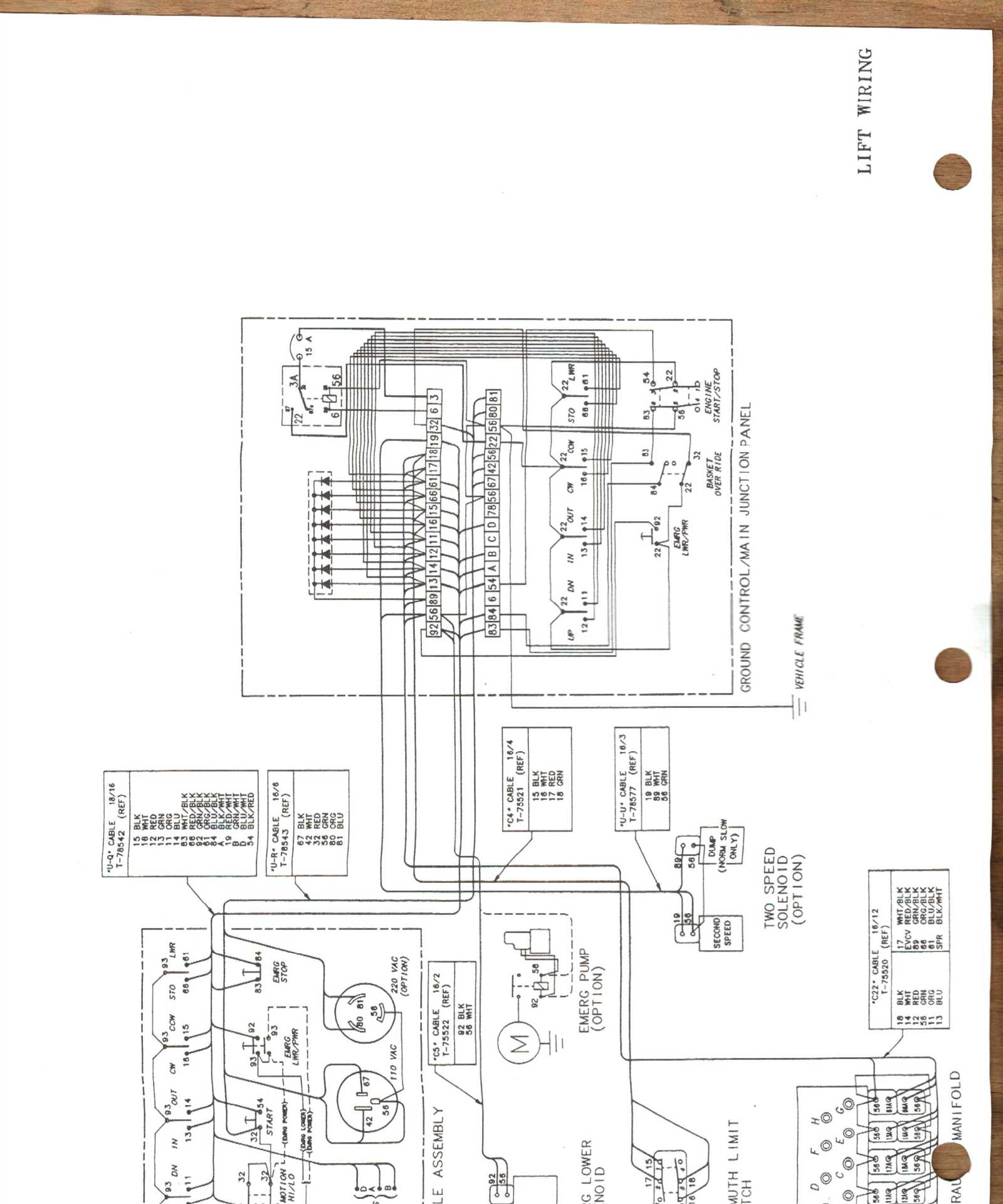

Key Electrical Parts Explained

Understanding the essential components that facilitate the functionality of aerial work platforms is crucial for ensuring their reliable operation. These electrical elements play a significant role in controlling various systems, providing power, and enabling safe maneuverability. This section will delve into the key electrical components commonly found in these vehicles, highlighting their importance and functions.

Control Systems

The control systems act as the brain of the operation, allowing the operator to manage the various functionalities of the equipment. This includes everything from boom movement to stabilizer deployment. These systems are designed to be user-friendly, often featuring intuitive interfaces that streamline operation while prioritizing safety.

Power Distribution Units

Power distribution units are vital for managing the electrical supply throughout the platform. They ensure that all components receive the necessary voltage and current to function properly. By distributing power efficiently, these units contribute to the overall performance and longevity of the equipment, minimizing the risk of electrical failures and enhancing operational reliability.

Maintaining Your Altec Equipment

Regular upkeep of your machinery is essential for ensuring optimal performance and longevity. Proper care not only prevents unexpected breakdowns but also enhances safety during operation. By following a few fundamental practices, you can keep your equipment in top condition and maximize its efficiency.

Key Maintenance Practices

- Conduct routine inspections to identify wear and tear.

- Clean components regularly to remove debris and dirt.

- Lubricate moving parts to reduce friction and prevent corrosion.

- Replace worn or damaged components promptly to avoid further issues.

- Monitor fluid levels and replace filters as necessary.

Documentation and Record Keeping

Maintaining accurate records of service and repairs is crucial for tracking the history of your equipment. This documentation can aid in scheduling future maintenance and help you identify recurring issues. Additionally, keeping a log of all inspections and repairs provides valuable information for potential resale or warranty claims.

Identifying Safety Features and Devices

Ensuring the well-being of operators and personnel in aerial work environments is paramount. Various mechanisms and equipment are designed to enhance security and mitigate potential hazards during operations at height. Recognizing these essential components can significantly contribute to a safer working atmosphere.

First and foremost, it is crucial to familiarize oneself with fall protection systems, which are implemented to prevent accidental falls from elevated positions. These systems may include harnesses, lanyards, and anchorage points, all serving to secure individuals while working at heights.

Additionally, emergency shut-off switches play a vital role in safeguarding personnel. Strategically placed, these devices allow for immediate cessation of operations in case of an unforeseen event, reducing the risk of injury or equipment damage.

Furthermore, stability indicators are essential tools that inform operators about the equipment’s condition. These indicators alert users when the unit is at risk of tipping or losing balance, ensuring proactive measures can be taken.

By understanding these safety features and devices, operators can enhance their awareness and preparedness, ultimately leading to improved safety standards in their work environment.

Common Repairs and Troubleshooting Tips

Understanding the typical maintenance and repair procedures can enhance the longevity and performance of elevated work platforms. This section offers insights into common issues and effective solutions that operators may encounter, ensuring a safer and more efficient operation.

Frequent Issues and Their Solutions

- Hydraulic System Malfunctions:

- Check for leaks in hoses and fittings.

- Ensure that fluid levels are adequate and free from contaminants.

- Inspect the hydraulic pump for proper functioning.

- Electrical Failures:

- Examine wiring for frays or breaks.

- Test battery connections and charge levels.

- Verify the operation of circuit breakers and fuses.

Preventive Measures

- Conduct regular inspections of mechanical components.

- Keep the equipment clean to prevent corrosion.

- Follow the manufacturer’s recommended maintenance schedule.

Upgrades and Customization Options

Enhancing and personalizing utility vehicles can significantly improve their performance and functionality. There are numerous avenues for upgrading various components to cater to specific operational needs, ensuring that the equipment not only meets but exceeds expectations.

One popular area for enhancement involves the power system. Upgrading the electrical components can lead to increased efficiency and reliability. For instance, incorporating advanced battery systems can provide extended operational time, reducing downtime and increasing productivity.

Another significant aspect is the control systems. Customizing the interface and controls can streamline operations, allowing for smoother and more intuitive handling. Options such as touchscreen displays or ergonomic control layouts can enhance user experience and safety.

Additionally, integrating new technologies such as telematics can provide real-time data monitoring, allowing operators to track performance metrics and schedule maintenance proactively. This not only helps in maintaining optimal functionality but also extends the lifespan of the equipment.

Finally, structural modifications can be made to improve accessibility and versatility. Options like additional storage compartments or adjustable mounting systems can optimize space and enhance the vehicle’s overall utility.

Parts Availability and Sourcing

Accessing essential components for specialized vehicles can significantly influence operational efficiency. Understanding where to find high-quality replacements and accessories is crucial for maintaining equipment functionality and reliability.

Where to Find Components

- Authorized Dealers: These vendors provide genuine items and ensure compatibility with specific machinery.

- Online Retailers: E-commerce platforms often offer a wide range of alternatives, including aftermarket solutions.

- Local Suppliers: Regional distributors can provide timely access to necessary materials, reducing downtime.

- Manufacturer Websites: Direct sources often list available inventory and may offer warranty options.

Considerations for Sourcing

- Quality Assurance: Prioritize suppliers who guarantee the durability and performance of their items.

- Price Comparisons: Evaluating costs across different sources can lead to significant savings.

- Availability: Ensure that the desired components are readily in stock to avoid project delays.

- Customer Support: A reliable supplier should offer assistance with inquiries or issues regarding their products.

Regulatory Compliance and Standards

Ensuring adherence to relevant regulations and established guidelines is vital for the safety and efficiency of equipment used in various industries. Compliance not only guarantees operational integrity but also safeguards the well-being of personnel and the public. Understanding the necessary standards can enhance the reliability of machinery while fostering trust among users and stakeholders.

Importance of Compliance

Adhering to regulatory standards is essential for minimizing risks and maintaining safe working conditions. Compliance helps in identifying potential hazards, implementing safety measures, and ensuring that all components function as intended. Regular inspections and adherence to these standards play a crucial role in prolonging the lifespan of equipment and avoiding costly repairs.

Key Standards to Consider

Various organizations set forth guidelines that outline best practices for equipment safety and performance. Below is a table summarizing some of the key standards that should be considered:

| Standard | Description | Authority |

|---|---|---|

| ANSI A92 | Outlines safety requirements for aerial devices. | American National Standards Institute |

| OSHA Regulations | Defines safety standards for the workplace. | Occupational Safety and Health Administration |

| ISO 9001 | Focuses on quality management systems. | International Organization for Standardization |