Understanding the inner workings of a machine can be essential for its maintenance and repair. This section provides a detailed look at how different elements come together to ensure smooth operation. Each part plays a critical role, contributing to the overall efficiency and reliability of the system.

In this guide, we will explore how various components interact, highlighting their individual functions and importance. By familiarizing yourself with the layout, you can gain deeper insight into the operational mechanisms and better handle any troubleshooting or replacement tasks.

Key elements of the system are interconnected, and recognizing their placement helps in diagnosing potential issues. Whether you’re performing regular maintenance or seeking to restore functionality, a clear understanding of how the unit is assembled is crucial. With this knowledge, you can ensure that each component is performing optimally.

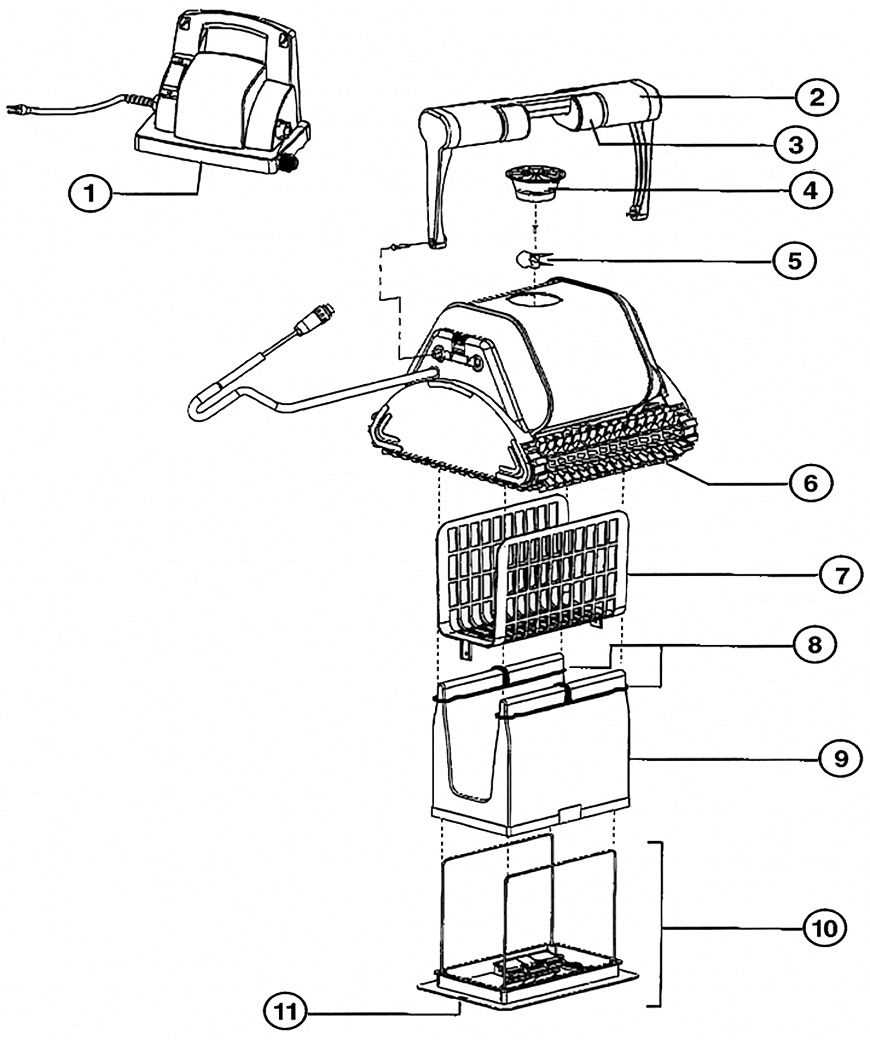

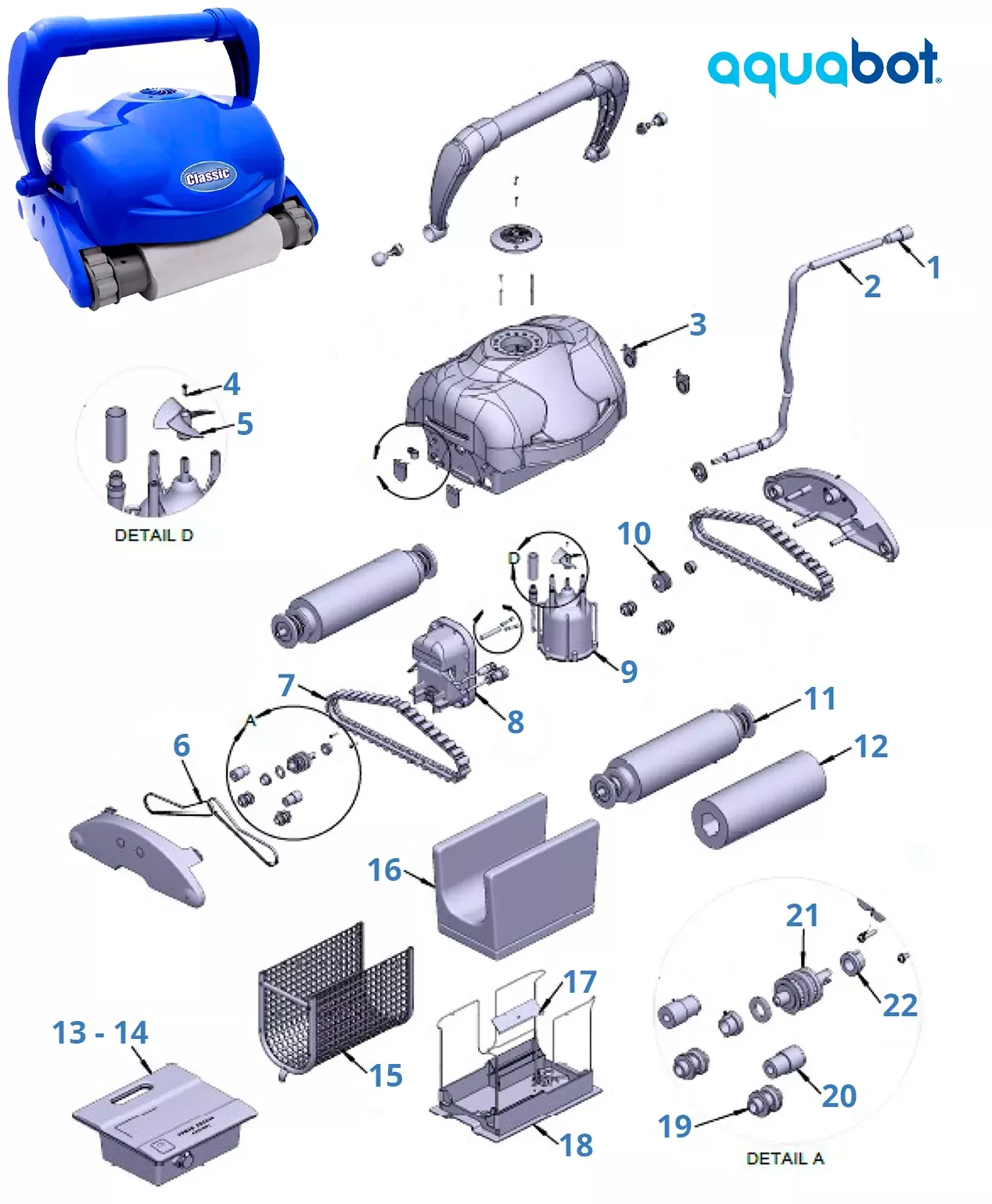

Understanding the Aquabot Component Layout

In this section, we will explore the structure and organization of a popular pool cleaning device. By familiarizing yourself with the arrangement of key elements, you’ll gain a clearer understanding of how each section works together to ensure efficient operation.

Main Structural Elements

- The exterior casing, which houses and protects internal mechanisms, is designed for durability and water resistance.

- The motor assembly serves as the powerhouse, enabling movement and driving various functions.

- A filtration system captures debris, keeping the device operating at peak efficiency.

Internal Mechanism Overview

- Power module: This section manages the energy distribution to other components.

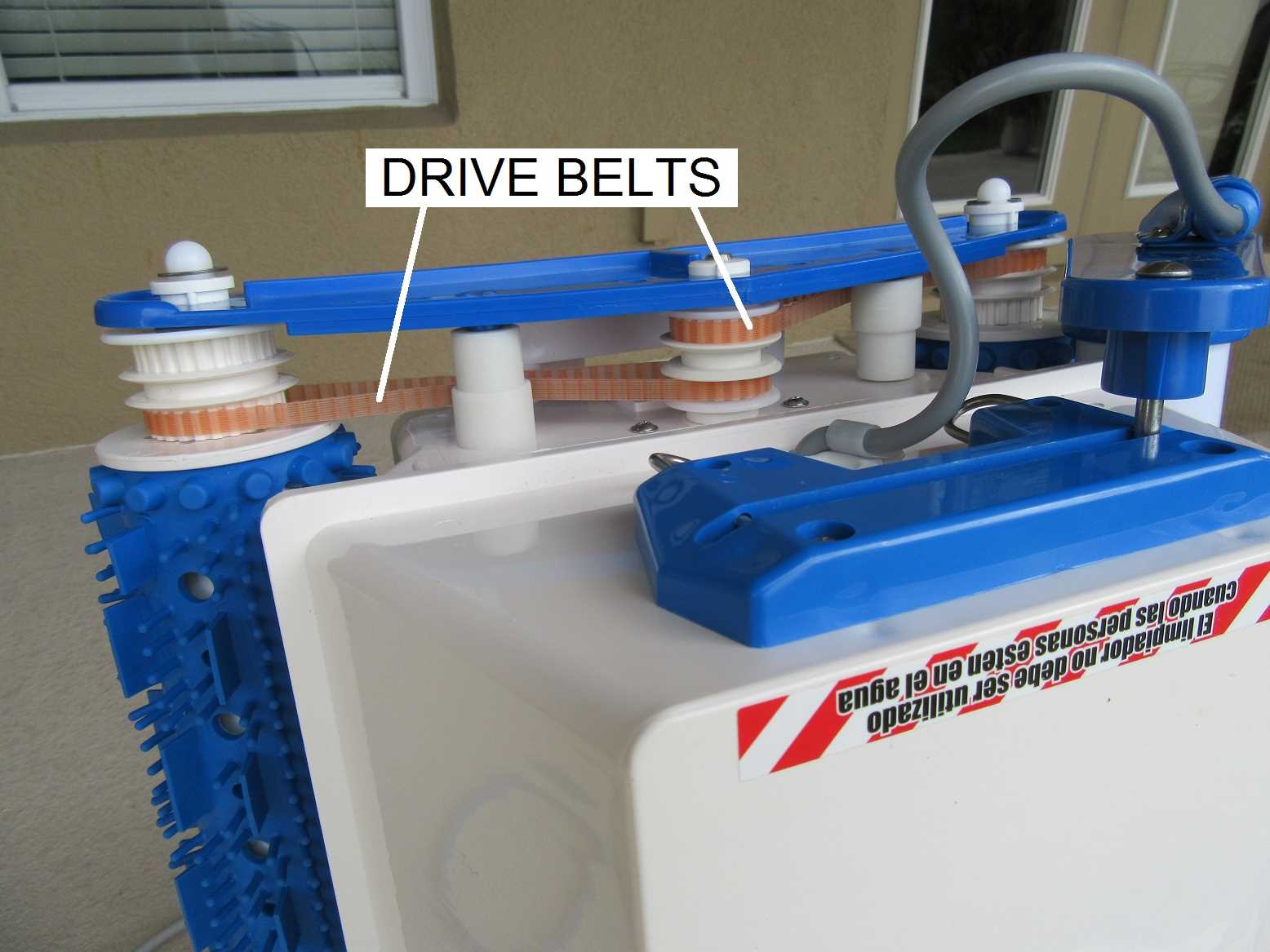

- Movement unit: A series of belts and wheels that facilitate smooth navigation across surfaces.

- Debris collection: A chamber where dirt and particles are stored until maintenance is performed.

By understanding how these elements interact, you can better troubleshoot and maintain the device fo

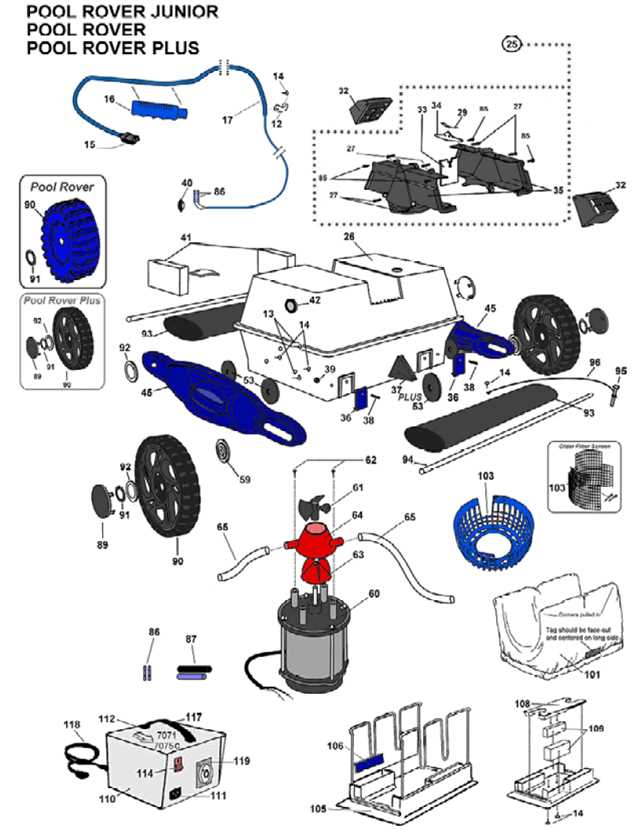

Key Elements of an Aquabot System

The system consists of several essential components that work together to ensure smooth operation and optimal performance. Each of these elements plays a crucial role in maintaining efficiency and reliability, contributing to the overall functionality of the mechanism.

Propulsion Unit: This element is responsible for the movement and navigation within the system. It ensures consistent motion, allowing the device to cover the intended area efficiently.

Filtration Mechanism: A key part of the system, this mechanism captures unwanted particles and debris, ensuring the cleanliness of the environment where the device operates. It helps maintain performance by reducing the load on other components.

Control Module: This part oversees the entire operation. It processes commands and adjusts the behavior of the system based on the settings or external conditions, ensuring everything runs smoothly.

Energy Source: The power source ensures continuous operation. It is designed to supply the necessary energy to keep all components functional throughout their operational cycle.

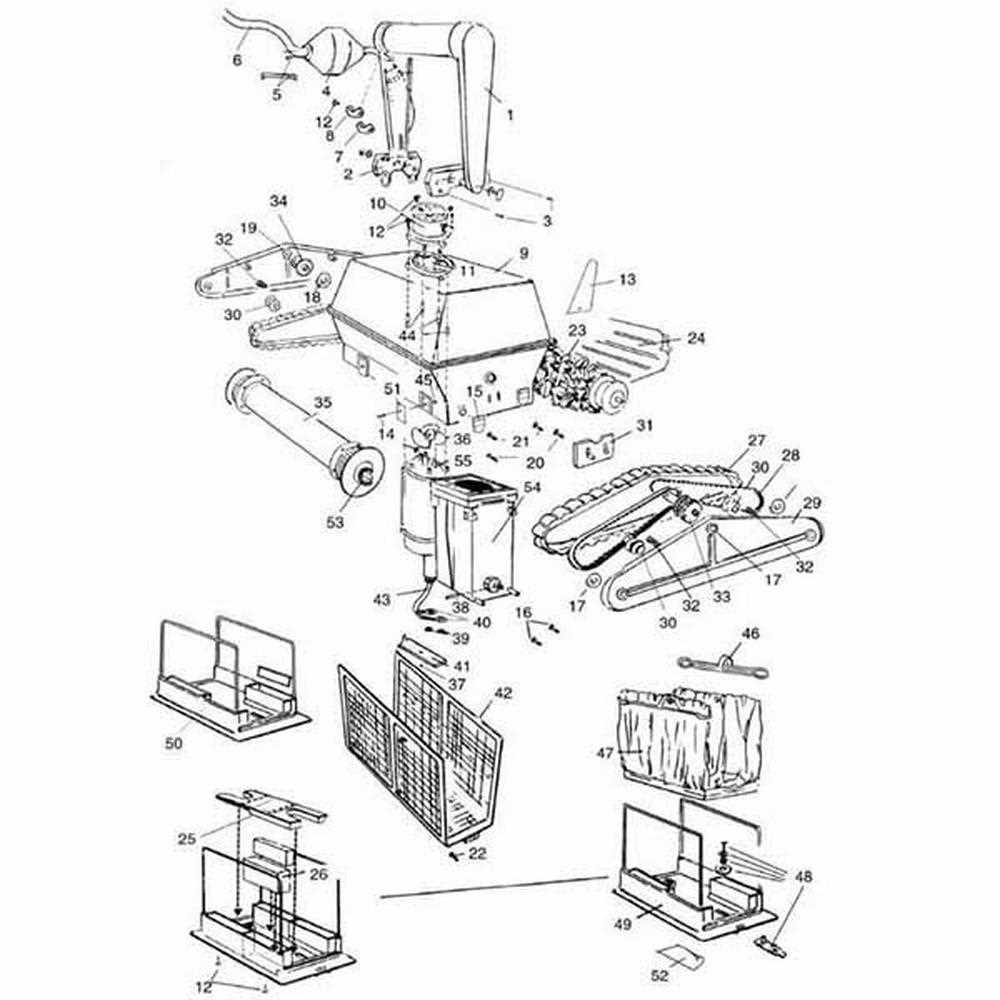

Exploring the Motor and Gear Setup

Understanding how the motor and gears function together is crucial for efficient movement and operation. These components are responsible for converting electrical energy into mechanical motion, ensuring that every motion is precisely controlled. The interaction between these elements plays a significant role in smooth performance, especially when navigating various environments.

The Role of the Motor

The motor is the heart of the system, providing the necessary power to drive the entire mechanism. It works by transforming electrical currents into rotational force, which is then transferred to other components. This rotation is essential for driving wheels or propellers, depending on the system’s design.

Gears and Their Function

Gears act as intermediaries between the motor and moving parts, adjusting the speed and torque. By meshing together, they either increase torque at the cost of speed or vice versa. This allows for precise control of the system’s overall movement, ensuring stability and efficiency.

| Component | Function | ||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Component | Function | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Filter Chamber | Houses the main filtration elements and facilitates the water flow through the system. | ||||||||||||||||||||||||||||||

| Collection Basket | Traps larger debris, such as leaves and dirt, preventing

Guide to Aquabot Electrical ConnectionsUnderstanding the structure of electrical links within a robotic cleaning system is crucial for both maintenance and troubleshooting. Each component relies on a specific configuration to ensure smooth operation, making it essential to comprehend how power is routed through the unit. By familiarizing yourself with the core pathways and connectors, you can efficiently address any connectivity issues or optimize performance. Wiring Layout: The system relies on a network of cables that transfer energy between different sections. These lines typically connect key modules, ensuring consistent energy flow and communication between critical components. Proper alignment of these pathways is essential for smooth functioning. Key Connectors: Various plug-ins are used to join different circuits, each playing a role in maintaining the overall system’s efficiency. These connection points are designed to ensure secure and reliable links between individual modules, facilitating proper signal transmission. Accurate understanding of these electrical pathways will enable users to pinpoint issues more efficiently and maintain the system in optimal working condition. Always ensure that all connections are secure and free from damage to avoid unnecessary interruptions. How the Drive System WorksThe drive mechanism is a crucial component that enables efficient movement and navigation. It functions by converting energy into motion, allowing the device to traverse various surfaces effectively. This system is designed to provide stability and control, ensuring optimal performance during operation. Components of the Drive MechanismThe drive mechanism comprises several key elements that work together to facilitate movement. Each component plays a specific role in the overall functionality, contributing to the seamless operation of the system.

Operational Dynamics

The interplay between these components creates a responsive and agile drive system. By adjusting the motor’s output through the control system, the device can navigate various terrains efficiently. The gearbox ensures that power is optimally utilized, enhancing both speed and maneuverability. Inspecting the Pump and Flow MechanismExamining the pump and flow system is crucial for ensuring optimal functionality and performance. This process involves assessing various components responsible for water movement and circulation. Regular inspection can help identify potential issues that may impede efficiency and affect the overall operation. Key Components to Check

Steps for Effective Inspection

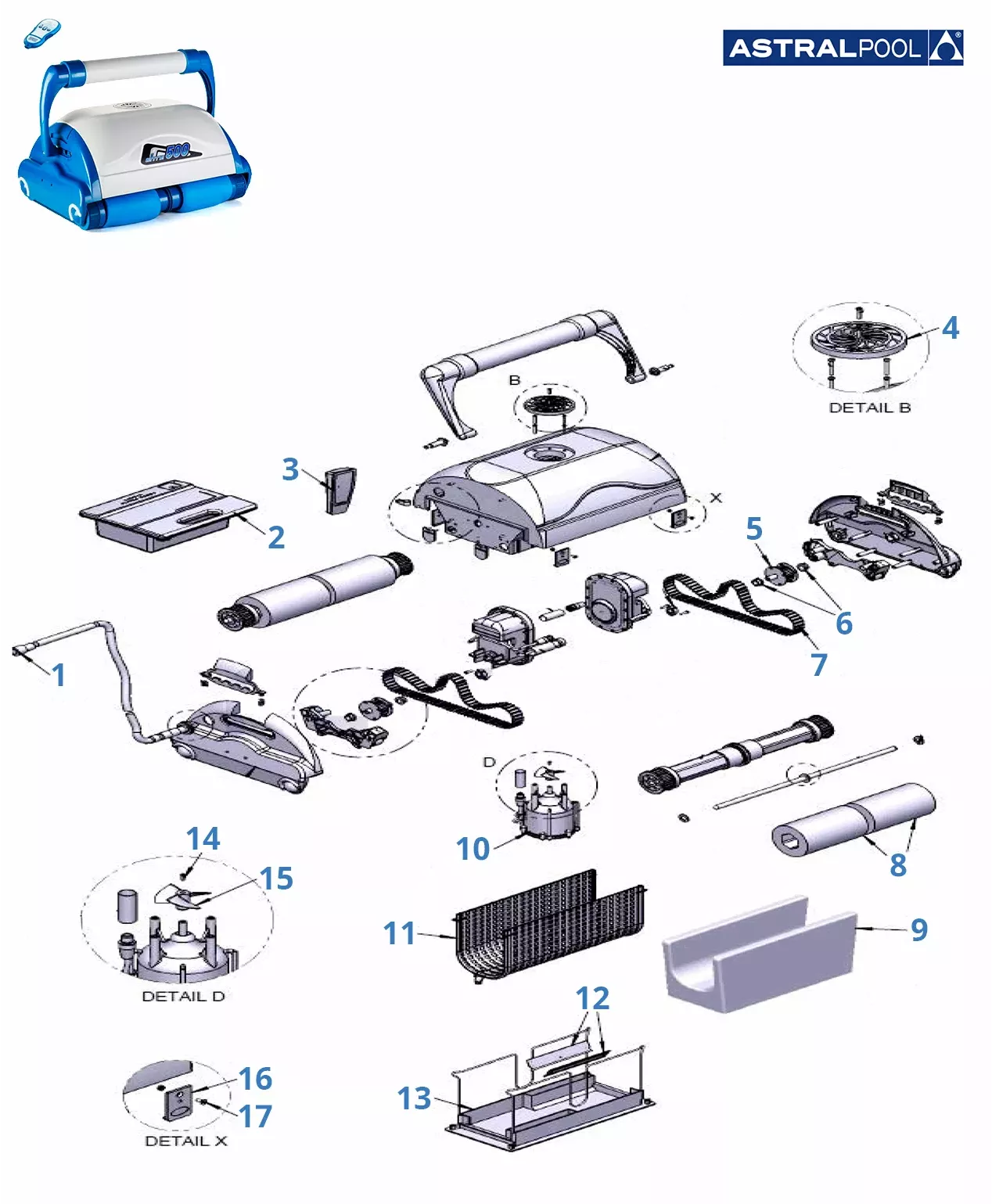

By regularly inspecting these components, users can enhance the longevity and effectiveness of the flow system, ensuring that it operates smoothly and efficiently. Understanding the Role of Sensors

Sensors play a crucial role in modern automated systems, enabling them to perceive and react to their environment. These devices collect data and provide feedback, which is essential for maintaining optimal performance and ensuring safety. By gathering information about various parameters, sensors help in making informed decisions that enhance the overall efficiency of the system. In the context of automation, sensors can monitor elements such as temperature, pressure, and motion. This real-time data is vital for adjusting operational processes and achieving desired outcomes. Furthermore, the integration of sensors allows for improved diagnostics, facilitating timely maintenance and reducing downtime. Ultimately, the effective functioning of automated equipment heavily relies on the accuracy and reliability of its sensors. Understanding their role is fundamental to maximizing performance and ensuring longevity in any automated setup. Exploring the Brushing MechanismThe brushing mechanism plays a vital role in the efficient cleaning process of robotic cleaners. This system is designed to effectively dislodge debris and contaminants from various surfaces, ensuring optimal cleanliness. Understanding its components and operation can provide insights into how these devices maintain pristine environments with minimal effort. Key ComponentsAt the heart of the brushing mechanism are several essential elements that work together seamlessly. Each component contributes to the overall functionality and effectiveness of the cleaning process. Below is a table summarizing the main elements involved:

Operational Insights

The brushing system operates through a combination of rotational and lateral movements. The brushes rotate at specific speeds to maximize dirt capture while maintaining surface integrity. Additionally, the coordination of the motor and drive mechanism ensures that the device can navigate different terrains effectively. This intricate design allows for thorough cleaning, making it an indispensable feature in modern cleaning technologies. Understanding the Control Unit FeaturesThe control unit serves as the brain of the system, orchestrating various functions to ensure optimal performance. Its design encompasses an array of features that enhance usability, efficiency, and monitoring capabilities. By grasping these elements, users can better appreciate how to interact with the device and maximize its functionality. Key Functions of the Control UnitThis central component is equipped with numerous functions that streamline operations. From programming cycles to monitoring performance, each feature contributes to a seamless user experience. Below are some essential capabilities:

Importance of User InterfaceThe user interface of the control unit plays a crucial role in the overall experience. A well-designed interface facilitates easy navigation and control, allowing users to make adjustments without confusion. Features such as clear displays and intuitive buttons ensure that even those with minimal technical expertise can operate the system effectively. Troubleshooting Common Aquabot Parts IssuesWhen dealing with robotic cleaning devices, users often encounter various challenges that can affect performance. Identifying and resolving these issues can significantly enhance functionality and extend the lifespan of the equipment. This section outlines some common problems and offers practical solutions to help users maintain optimal operation. 1. Insufficient Cleaning Performance If the device is not cleaning effectively, it may be due to clogged filters or brushes. Inspect the filtration system and ensure it is free from debris. Regular cleaning of these components is crucial for maintaining efficiency. 2. Unusual Noises During Operation Noises that are louder than normal can indicate mechanical issues. Check for any foreign objects that may have lodged in the rotating parts. Lubricating moving components can also help reduce noise. 3. Erratic Movement If the unit is not navigating correctly, it could be a result of damaged sensors or wheels. Examine the sensor pathways for obstructions and ensure that the wheels are intact and free from debris. Proper alignment and functionality are essential for smooth movement. 4. Power Issues Problems related to power can often be traced back to the charging station or battery. Verify that the charging contacts are clean and ensure the device is docking properly. If issues persist, testing the battery for wear may be necessary. By following these troubleshooting steps, users can address common challenges associated with robotic cleaning devices, ensuring they operate effectively and efficiently. Maintenance Tips for Aquabot Components

Regular upkeep of your cleaning device’s elements is essential to ensure its efficiency and longevity. Proper maintenance not only enhances performance but also reduces the risk of malfunctions and costly repairs. By following a few straightforward guidelines, you can extend the lifespan of various components and enjoy a cleaner environment. Routine Inspections

Conducting regular inspections is crucial to identify any signs of wear or damage. Check for loose connections, cracks, or debris accumulation in critical areas. Addressing minor issues promptly can prevent them from escalating into more significant problems. Cleaning and LubricationKeep all moving parts clean and well-lubricated to ensure smooth operation. Use a soft brush or cloth to remove dirt and grime, and apply appropriate lubricant to reduce friction. This practice will enhance the efficiency of your device and minimize the risk of mechanical failures. |