The structure of a heating device is made up of various essential elements that ensure smooth and efficient operation. Understanding how these individual components interact can help in maintaining the unit and diagnosing potential issues.

Each section of the system plays a crucial role in delivering heat throughout the home, from the ignition of the source to the distribution of warmth. Having a clear understanding of these elements enables users to keep their equipment in optimal working condition.

This guide will help identify and explain the function of key elements involved, offering insights into their operation and importance within the overall setup. By knowing these details, maintenance and troubleshooting become more manageable and effective.

Understanding the Heating System

Heating systems play a crucial role in maintaining comfort during colder months. These units operate by converting energy sources into warm air that is distributed throughout a building. Key components work together to ensure efficient performance, reliability, and safety.

Core functionalities include regulating temperature, controlling airflow, and maintaining a balance between energy consumption and heat output. Understanding how these elements interact can help in troubleshooting and optimizing the system’s efficiency.

Various control mechanisms and safety features are integrated to prevent malfunctions, making it essential to familiarize yourself with the basics of operation and maintenance for long-term performance.

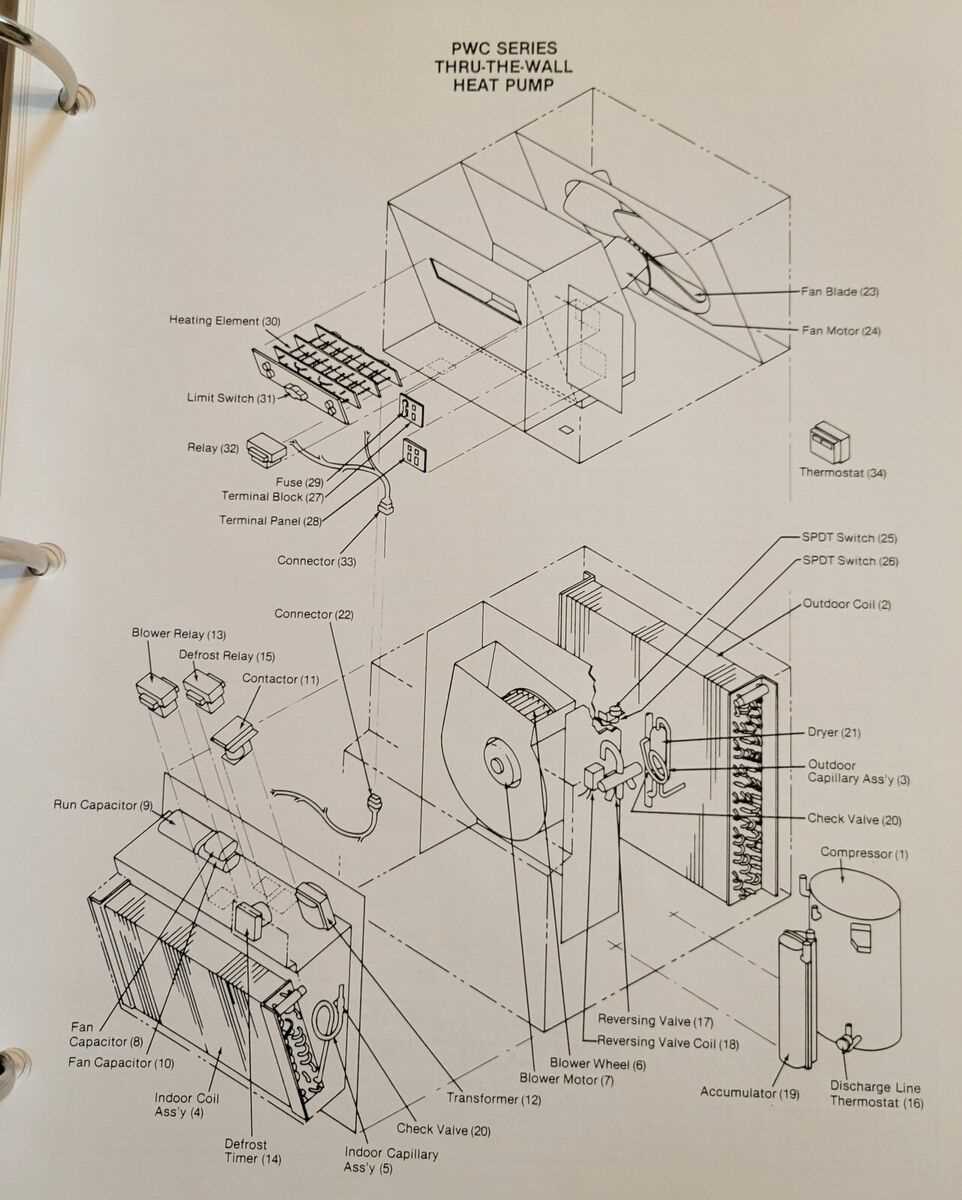

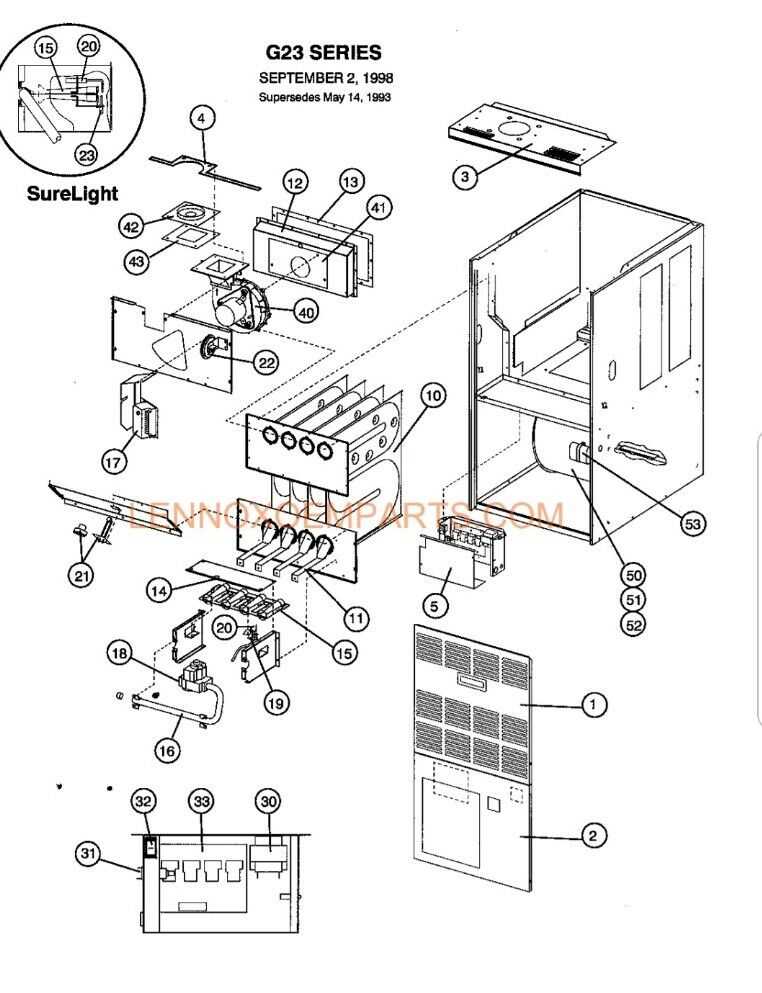

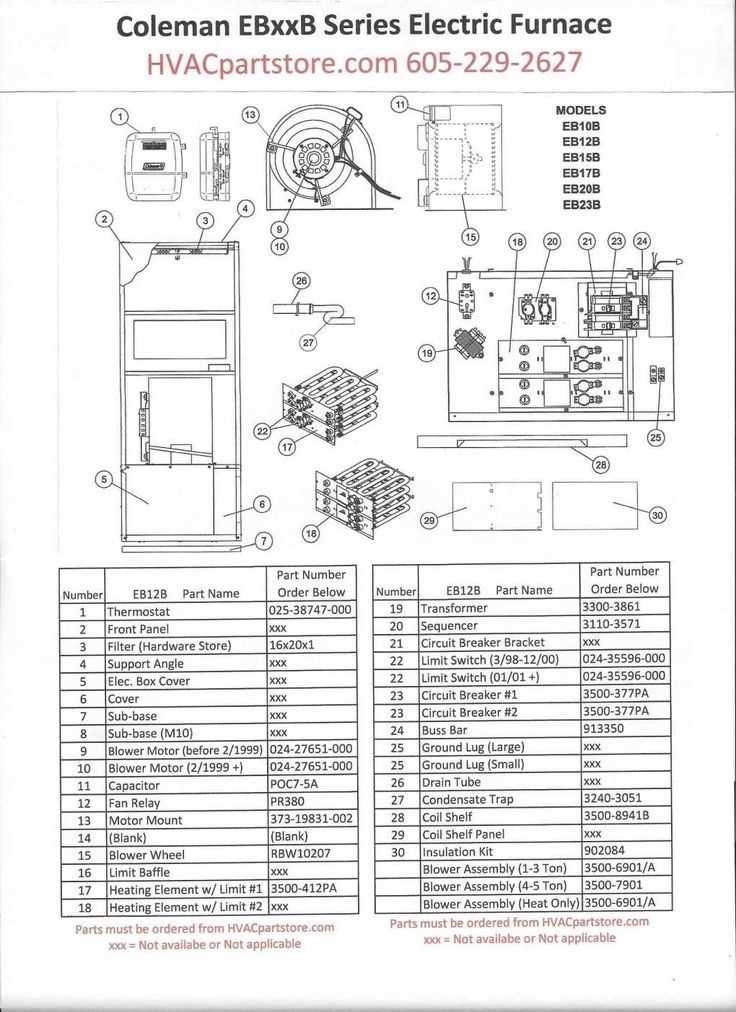

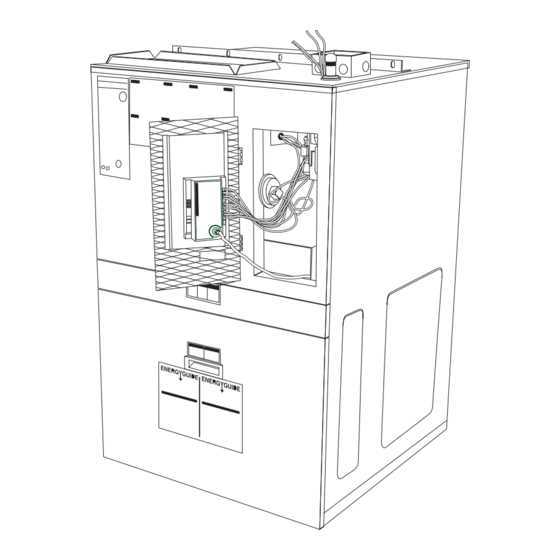

Main Components of Armstrong Furnaces

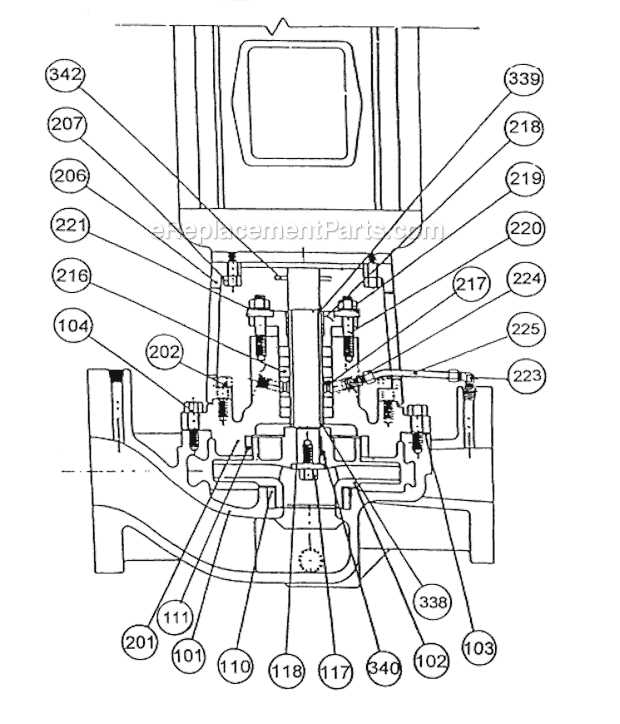

The heating system relies on several key elements working together to ensure efficient and reliable performance. Each section plays a crucial role in maintaining the flow of warm air and keeping the system running smoothly. Understanding these primary sections can help identify potential issues and improve the overall operation.

Heat Exchanger: This unit is responsible for transferring thermal energy from the combustion process to the surrounding air. It ensures that the warm air circulating throughout the building is free from harmful gases.

Blower Motor: The motor drives the fan, which distributes air through the ducts. This component is vital in regulating airflow and ensuring even heat distribution.

Burner Assembly: This part ignites the fuel and produces heat. It is essential for the proper functioning of the entire heating process, providing the necessary warmth.

How to Identify Different Furnace Parts

Understanding the components of heating equipment is essential for ensuring proper maintenance and operation. Recognizing each element can help in troubleshooting and keeping the system in optimal condition. Each part has a unique role in the heating process, and knowing how to spot them is crucial for repairs or upgrades.

Start by observing the system’s outer casing, which protects the internal mechanisms. Behind it, you’ll find a series of connected elements, including the blower motor, responsible for distributing warm air, and the heat exchanger, which transfers thermal energy. Identifying these parts can significantly improve the efficiency of the equipment’s care and upkeep.

Look for the control panel, where settings can be adjusted to regulate the temperature. This section often contains the ignition system as well, which is vital for initiating the heating cycle. Familiarity with these sections allows for better diagnostics when performance issues arise.

Common Issues with Furnace Parts

Heating systems rely on various components to function efficiently, and over time, these elements may experience wear and malfunction. Understanding the typical problems that can occur helps in identifying when maintenance or repairs are necessary. It is essential to be aware of the symptoms and causes behind these issues to ensure optimal performance and prevent costly breakdowns.

One frequent issue involves ignition problems, where the heating unit may fail to start properly, leading to uneven heating. Another common challenge is inadequate airflow, often caused by blockages or malfunctioning fans, which can result in poor temperature regulation. Additionally, sensors and switches can become faulty over time, causing incorrect readings and operational errors.

Regular inspections and timely interventions can significantly reduce the likelihood of these issues, ensuring the heating system operates smoothly throughout its lifespan. Addressing these problems early can prevent more serious

Steps to Replace Damaged Components

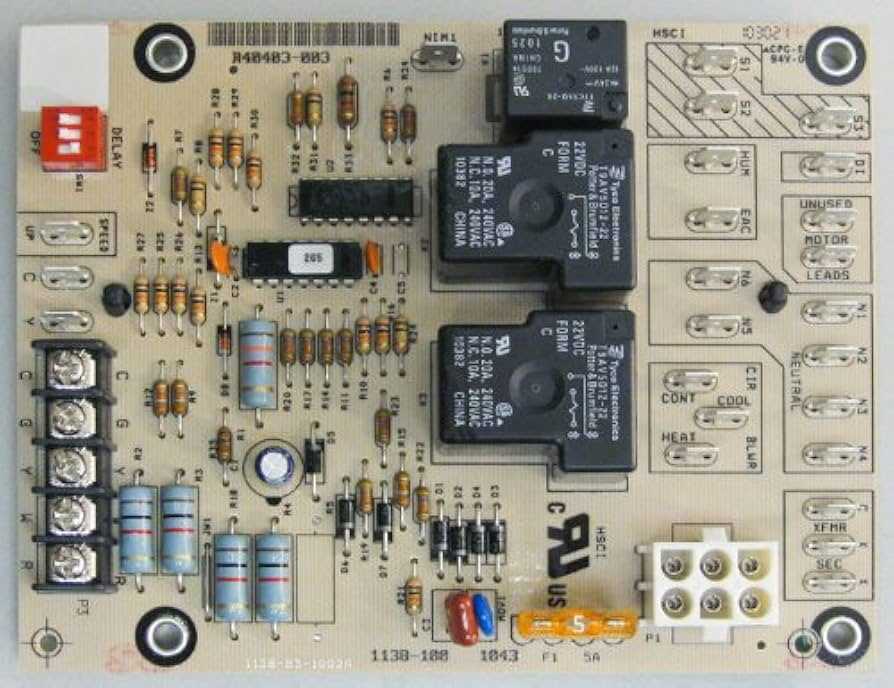

Identifying and replacing malfunctioning elements in heating systems is crucial for ensuring efficient performance. Whether it’s electrical issues, faulty switches, or other internal parts, addressing these promptly can prevent larger issues from developing.

Step 1: Turn off the power supply to the unit to avoid any electrical hazards. Always ensure that the system is completely powered down before starting any repairs.

Step 2: Inspect the unit thoroughly to locate the damaged component. Use a flashlight to carefully examine wires, switches, and other key areas for signs of wear or damage.

Step 3: Once identified, remove the faulty component using the appropriate tools. Make sure to note the wiring and connections for proper reinstallation later

Furnace Maintenance Tips for Longevity

Proper upkeep of heating systems can significantly extend their lifespan and enhance overall efficiency. Regular care not only ensures optimal performance but also minimizes the risk of unexpected failures, ultimately saving time and money. Here are some essential strategies to keep your heating unit in top condition.

Regular Inspections

Routine evaluations help identify potential issues before they escalate into major problems. Consider scheduling professional assessments at least once a year to ensure everything operates smoothly.

Air Filter Maintenance

Clean or replace air filters regularly to maintain proper airflow. Clogged filters can lead to inefficient heating and increased energy consumption.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Professional Inspection | Annually | Identifies issues early |

| Filter Replacement | Every 1-3 months | Ensures efficient airflow |

| Clean Vents and Ducts | Every 2-5 years | Reduces dust buildup |

Energy Efficiency of Modern Furnace Designs

In today’s climate-conscious world, the emphasis on energy conservation has led to innovative advancements in heating systems. These modern designs prioritize efficiency, reducing energy consumption while maintaining optimal comfort levels in residential and commercial spaces.

Key factors contributing to the energy efficiency of contemporary heating solutions include:

- Advanced Insulation: Enhanced materials reduce heat loss, ensuring that the warmth generated is effectively utilized.

- Variable Speed Motors: These components adjust their speed based on demand, minimizing energy usage during less intensive heating periods.

- Smart Thermostats: Integration of technology allows for precise temperature control, adapting to user habits and optimizing performance.

- Modulating Burners: These devices adjust the flame intensity, providing the right amount of heat for the space without wasting resources.

By adopting these features, modern heating systems achieve significantly higher efficiency ratings compared to traditional models, resulting in lower utility bills and reduced environmental impact.

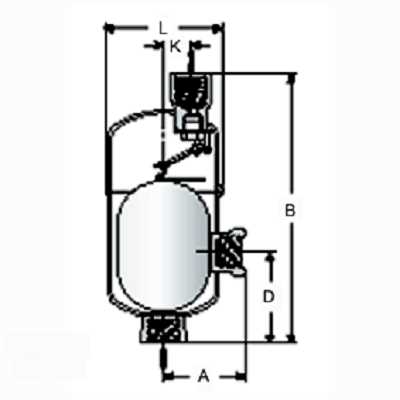

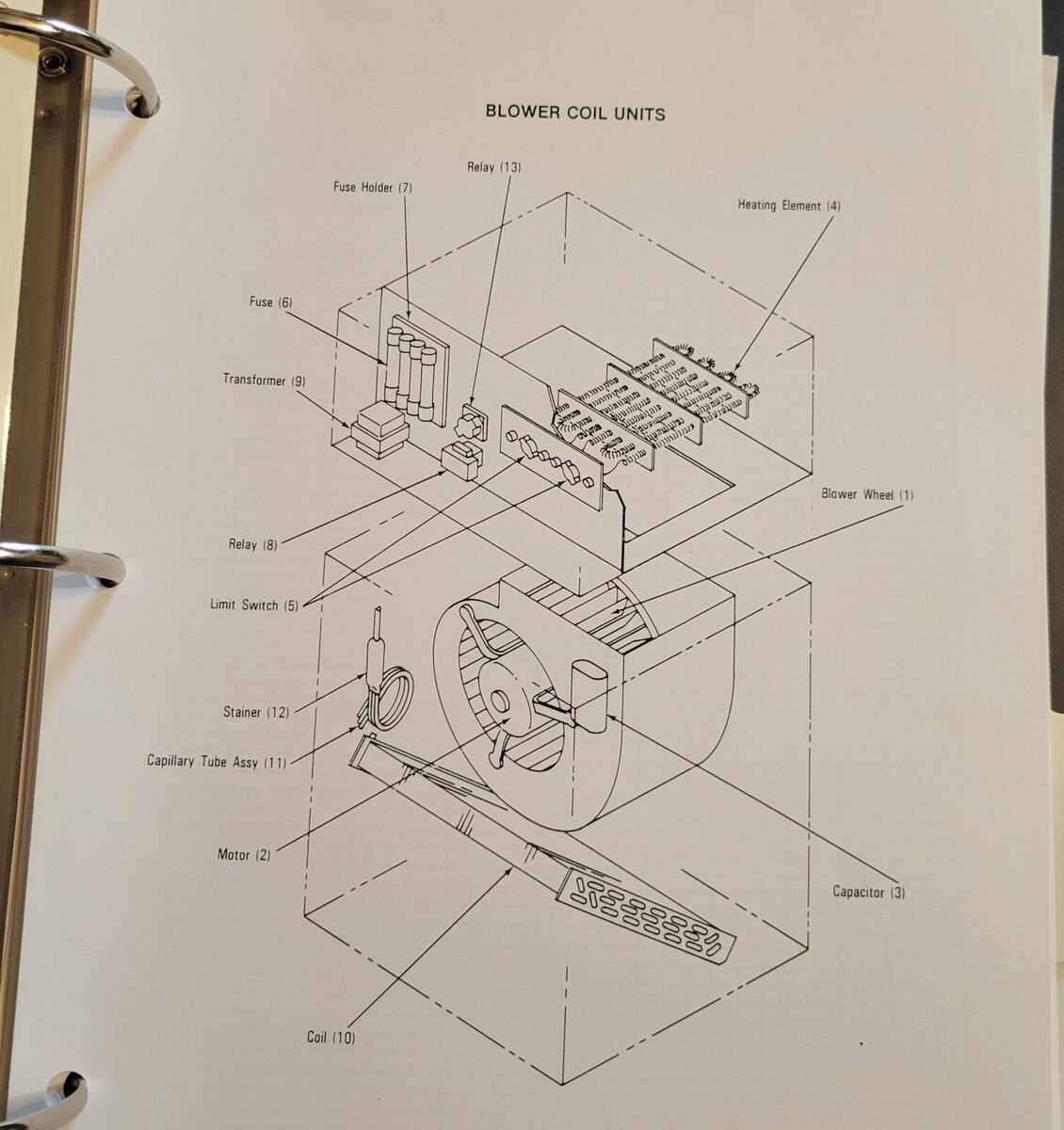

Importance of the Blower in Furnace Operation

The blower plays a crucial role in the efficient functioning of heating systems by facilitating the circulation of air. This component ensures that warm air is distributed evenly throughout the designated space, contributing to a comfortable environment. Without a properly functioning blower, the overall effectiveness of the heating system may be compromised.

Efficient airflow is essential for maintaining optimal performance. The blower not only helps in distributing heated air but also aids in the combustion process by supplying the necessary oxygen. This dual functionality highlights its significance in achieving effective and reliable heating. Regular maintenance of the blower can prevent potential issues and ensure longevity, emphasizing its importance in the overall system operation.

Safety Features of Armstrong Furnaces

The modern heating systems are designed with a variety of protective mechanisms to ensure user safety and optimal performance. These features are crucial in preventing accidents and enhancing the reliability of the equipment.

Automatic Shut-off Mechanism: This essential component immediately halts operation if irregularities are detected, reducing the risk of overheating and potential hazards.

Flame Sensor: A critical feature that monitors the burner’s flame. If the flame is extinguished, the sensor triggers the system to shut down, preventing the release of unburned gas.

Ventilation Systems: Proper airflow is vital for safe operation. Advanced designs incorporate exhaust and intake pathways that facilitate the effective removal of harmful gases, ensuring a safe environment.

Temperature Regulation: Equipped with advanced thermostats, these systems maintain optimal temperatures, minimizing the risk of excessive heat build-up and improving energy efficiency.

Regular Maintenance Alerts: Many modern units include reminders for routine checks, encouraging users to keep the system in top condition and ensuring all safety features function as intended.

Understanding Furnace Airflow and Heat Distribution

Effective management of air circulation and temperature regulation is crucial for achieving optimal comfort in indoor spaces. This section delves into the principles of airflow and heat dissemination, highlighting how these elements work together to maintain a pleasant environment.

Key Components of Airflow

Air circulation is influenced by several factors that ensure efficient movement throughout the living area. Consider the following components:

- Blowers: Devices responsible for moving air within the system.

- Ducts: Channels through which air is transported to various rooms.

- Registers and Grilles: Openings that control air release and intake.

Heat Distribution Techniques

Proper temperature management relies on effective heat distribution methods, which can be classified into various types:

- Convection: Heat transfer through the movement of air.

- Radiation: Transfer of heat through electromagnetic waves, warming surfaces directly.

- Conduction: Heat transfer through solid materials, such as walls and floors.

Understanding these concepts allows for better optimization of the heating system, ensuring comfort while improving energy efficiency.

How to Troubleshoot Furnace Problems

Addressing issues with heating systems can be a straightforward process if approached systematically. Understanding the potential causes of malfunctions is crucial for effective resolution.

Begin by ensuring the system is receiving power. Check the thermostat settings to confirm they are correctly configured. Inspect the circuit breaker or fuse box for any tripped breakers or blown fuses. If the unit is unresponsive, restoring power may solve the issue.

Next, examine the air circulation. Blocked or dirty filters can impede airflow, leading to overheating and performance problems. Regularly replacing or cleaning filters is essential to maintain optimal function.

Additionally, assess any unusual noises or odors. Sounds such as banging or rattling may indicate loose components, while strange smells could suggest electrical issues or burnt materials. In such cases, it’s advisable to consult a professional technician.

Lastly, check for any visible signs of damage or wear on the system. Components that appear cracked or corroded may require replacement. Staying vigilant about maintenance can prolong the life of your heating system.