The 4S model offers a powerful and efficient system designed for high-performance tasks. Understanding how each element works together is crucial for maintaining optimal functionality and ensuring a smooth user experience. This guide provides detailed insights into the structure, helping you gain a deeper understanding of the machine’s core elements.

Each individual component plays a significant role in the overall operation. Whether you’re looking to enhance performance or troubleshoot, a thorough knowledge of these elements will give you the ability to address any potential issues efficiently. Explore the detailed breakdown of each section to fully grasp the inner workings of the system.

Our guide highlights the key elements, providing a clear view of their functionality. By familiarizing yourself with the layout and arrangement, you will be able to maintain and upgrade the model with ease. Dive into the intricacies of the system to unlock its full potential and keep it running at its best.

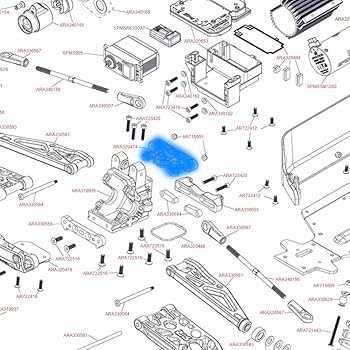

Arrma Outcast 4S Component Breakdown

This section covers the essential elements and structures of a high-performance off-road vehicle. Understanding how each element functions together provides insight into how the model delivers power, control, and durability in various conditions. We will examine the key systems and assemblies that contribute to overall performance.

Main Structural Elements

- Chassis: The foundation of the vehicle, designed to offer strength and flexibility for absorbing impacts during tough terrain rides.

- Suspension System: Ensures smooth handling by absorbing shocks and maintaining stability on uneven surfaces.

- Body Shell: The protective outer layer that not only enhances aerodynamics but also shields the inner workings from external damage.

Core Performance Components

- Motor Assembly: The heart of the vehicle, delivering the required speed and torque for different driving environments.

- Transmission System: Ensures efficient power distribution between the motor and wheels, optimizing performance in various conditions.

- Electronic Speed Control: Regulates the motor’s power output, providing smooth acceleration and braking.

Key Parts Overview and Functions

The main components of this vehicle model are designed to ensure high performance and durability during operation. Each element serves a specific purpose, contributing to the overall efficiency and control. Understanding the role of these crucial elements is essential for maintaining optimal functionality and prolonging the lifespan of the system.

Main Structural Components

The chassis serves as the foundation, providing a sturdy base to support other essential elements. It is engineered to withstand impacts and protect the internal mechanisms. The suspension system absorbs shocks, enhancing stability and smooth movement over rough terrains.

Power and Control Systems

The motor delivers the necessary power, enabling high-speed performance and acceleration. A robust steering mechanism ensures precise control and handling, allowing for quick adjustments during operation. Additionally, the drivetrain efficiently transmits power to the wheels, ensuring consistent traction.

Chassis Design and Structure Details

The overall framework is built to endure challenging conditions while maintaining durability and stability. The structural components are arranged to balance weight and strength, ensuring reliable performance in various environments. Careful attention to the layout enhances the vehicle’s ability to withstand impacts and maintain control during high-speed maneuvers.

Reinforced Components

Key structural elements are reinforced to provide additional strength where it’s most needed. The central frame and surrounding supports have been crafted from high-quality materials, contributing to overall resilience. This robust design reduces the risk of damage from external forces and prolongs the operational life of the vehicle.

Optimized Weight Distribution

Weight distribution plays a crucial role in the handling and stability of the vehicle. The design ensures that critical components are positioned to evenly balance the load, improving maneuverability and reducing stress on individual parts. This layout enhances control and responsiveness, particularly in tight turns and rough terrain.

Suspension System Breakdown

The suspension system plays a critical role in ensuring stability and control during operation. It absorbs shocks and impacts, helping maintain smooth movement across various surfaces. Understanding the key components and how they work together is essential for efficient maintenance and optimization of performance.

Main Components of the Suspension

- Shock Absorbers: These help cushion the vehicle against rough terrain, reducing vibrations and preventing damage to other elements.

- Springs: They provide support and balance, allowing the system to compress and rebound effectively.

- Control Arms: Responsible for linking the wheels to the chassis, enabling smooth movement while minimizing wear.

Adjustment and Maintenance Tips

- Regularly check the shock absorbers for signs of leakage or wear.

- Ensure springs maintain their flexibility and are not deformed.

- Inspect control arms for any signs of bending or looseness, tightening connections if necessary.

By following these steps, the suspension system will continue to function effectively, ensuring optimal handling and reducing the risk of damage to the vehicle during use.

Understanding the Motor and ESC Setup

The combination of the motor and ESC plays a crucial role in ensuring the vehicle’s performance, responsiveness, and overall control. The motor provides the necessary power, while the ESC regulates this energy, allowing precise throttle control and braking. Knowing how these components work together can help improve efficiency and performance.

| Component | Function |

|---|---|

| Motor | Converts electrical energy into mechanical movement, driving the wheels forward or backward. |

| ESC | Manages the power flow from the battery to the motor, controlling speed and providing braking capability. |

| Cooling System | Prevents overheating by dissipating excess heat generated during operation. |

Proper tuning of both components is essential for optimal performance. A well-matched

Steering Mechanism and Linkage Parts

The steering system plays a crucial role in the maneuverability of remote-controlled vehicles, enabling precise control and direction changes. This assembly consists of various components that work together to ensure smooth steering actions. Understanding the individual elements involved in this system is essential for maintaining optimal performance and reliability.

Key Components

The primary elements of the steering mechanism include the servo, linkages, and the steering knuckles. Each part contributes to the overall functionality, allowing for responsive handling and stability during operation.

Functionality and Importance

The steering servo is responsible for translating input signals into movement, while the linkages connect the servo to the steering knuckles, facilitating motion transfer. Proper alignment and condition of these components are vital for effective steering and maneuvering.

| Component | Description |

|---|---|

| Servo | Drives the steering mechanism, providing necessary torque. |

| Linkage | Connects the servo to the steering knuckles, enabling movement. |

| Steering Knuckle | Acts as a pivot point for the wheels, allowing directional changes. |

Wheel Assembly and Tire Specifications

The wheel assembly is a crucial component of any high-performance vehicle, directly influencing handling and stability. Understanding the intricacies of tire specifications can enhance overall performance, ensuring that the vehicle is optimized for various terrains and conditions.

When selecting the right tire and wheel combination, consider factors such as size, tread pattern, and material. These elements play a significant role in traction, durability, and responsiveness. Below is a summary of key specifications relevant to the wheel assembly.

| Specification | Description |

|---|---|

| Diameter | Typically ranges from 4.0 to 6.0 inches, depending on the intended use. |

| Width | Commonly between 2.0 and 3.0 inches for optimal performance. |

| Tread Pattern | Varies from aggressive for off-road use to smooth for on-road applications. |

| Material | Commonly constructed from durable rubber compounds for longevity. |

| Load Rating | Indicates the maximum weight each tire can support, essential for performance. |

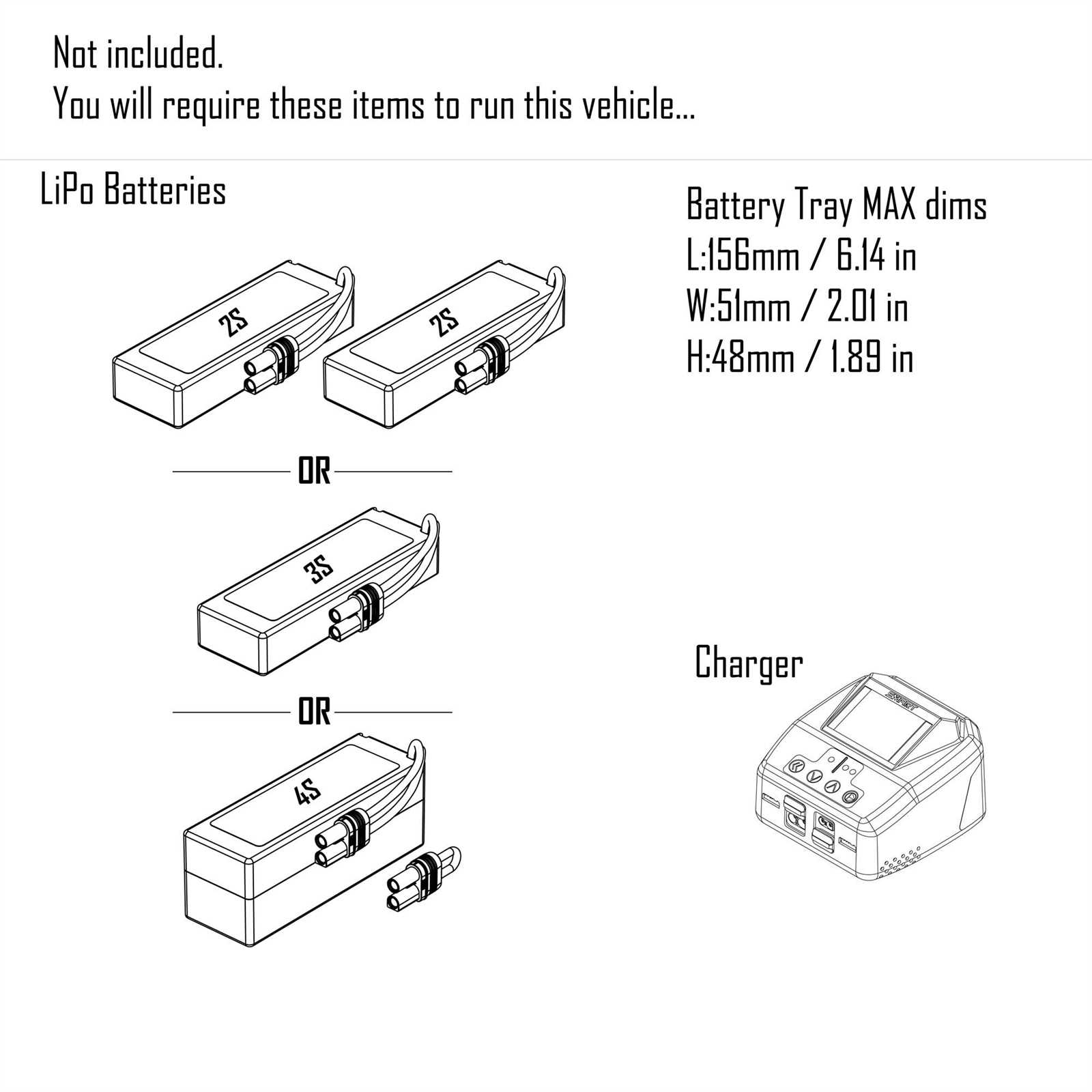

Battery Compartment Layout and Mounts

The configuration of the battery space plays a crucial role in the overall performance and stability of the vehicle. A well-designed layout ensures secure placement of the power source, providing optimal weight distribution and accessibility for maintenance. Understanding the arrangement and fastening methods used for the battery compartment is essential for enthusiasts aiming to enhance their driving experience.

Design Features

Key features of the battery compartment design include:

- Efficient use of space to accommodate various battery sizes.

- Secure mounting points that prevent movement during operation.

- Ventilation openings to manage heat buildup.

Mounting Techniques

Effective mounting techniques contribute significantly to the stability of the power source. These techniques may include:

- Strap systems that hold the battery firmly in place.

- Custom brackets designed for specific battery dimensions.

- Rubber or foam padding to absorb vibrations.

Differential Parts and Functionality

The differential system plays a crucial role in the overall performance of a remote-controlled vehicle, enabling smooth handling and effective power distribution. Understanding its components and how they work together is essential for optimizing vehicle dynamics and ensuring longevity.

This system typically consists of various elements that work in unison to allow for controlled turning and improved traction on diverse surfaces. Each component serves a specific purpose, contributing to the efficient transfer of energy from the motor to the wheels.

| Component | Description |

|---|---|

| Gear Set | Transfers power from the motor and adjusts torque to the wheels. |

| Case | Houses the gears and provides structural integrity. |

| Output Shafts | Connect the differential to the wheels, allowing for rotational movement. |

| Pinion Gear | Engages with the ring gear to facilitate power transfer. |

| Ring Gear | Works with the pinion gear to distribute power to the output shafts. |

Shock Absorbers and Spring System Explained

The suspension system in any vehicle plays a crucial role in ensuring a smooth and controlled ride. Central to this system are the shock absorbers and the springs, which work in harmony to absorb impacts from uneven terrain and maintain stability. Understanding how these components function together can greatly enhance the performance and handling of your vehicle.

Shock absorbers serve to dampen the oscillations caused by springs during compression and rebound. Without these vital components, a vehicle would experience excessive bouncing and an uncomfortable ride. They utilize hydraulic fluid to control the rate of movement, allowing for a balanced response to varying road conditions.

The spring system supports the weight of the vehicle while providing the necessary tension to maintain ride height. Different types of springs, such as coil and leaf varieties, offer varying levels of stiffness and flexibility. A well-tuned spring system works in conjunction with shock absorbers to provide the desired balance between comfort and performance, ensuring optimal handling and responsiveness.

In summary, the synergy between shock absorbers and springs is fundamental to the overall performance of a vehicle’s suspension. Proper maintenance and tuning of these elements can significantly improve ride quality, safety, and the vehicle’s ability to navigate challenging terrains.

Exploded View of Rear Assembly

The rear assembly is a crucial component that contributes to the overall performance and stability of the vehicle. Understanding its intricate structure can aid in maintenance and upgrades, ensuring optimal functionality during use. This section delves into the details of the rear assembly, highlighting its various elements and their interconnections.

Each component plays a significant role in the vehicle’s dynamics, providing support and facilitating movement. An exploded view offers a clear representation of how these parts fit together, making it easier to identify and replace any worn or damaged elements.

| Component | Description | Function |

|---|---|---|

| Rear Chassis | Structural base for rear components | Provides support and rigidity |

| Shock Absorber | Device for absorbing impact | Ensures smooth suspension travel |

| Rear Axle | Horizontal shaft for wheel attachment | Transmits power to the wheels |

| Suspension Arms | Links between chassis and wheels | Facilitates wheel movement |

| Gearbox Housing | Enclosure for gears | Protects and contains gear system |