When exploring the inner workings of grooming equipment, it’s essential to grasp how each element functions together to ensure smooth performance. The internal setup of such devices consists of numerous components that, when combined correctly, allow for efficient operation. Understanding how these parts connect can help you maintain and repair your device with greater confidence.

Whether you’re fine-tuning or replacing specific pieces, knowing the configuration is key. Each component plays a crucial role, from the smallest mechanical piece to the larger driving mechanisms. This guide will provide insights into the intricate layout of grooming devices, ensuring you can handle adjustments or fixes with ease.

Delving into the structure of these machines can seem complex at first, but with a clear view of how everything fits together, tasks such as cleaning or part replacement become more manageable. Proper care and understanding of the device

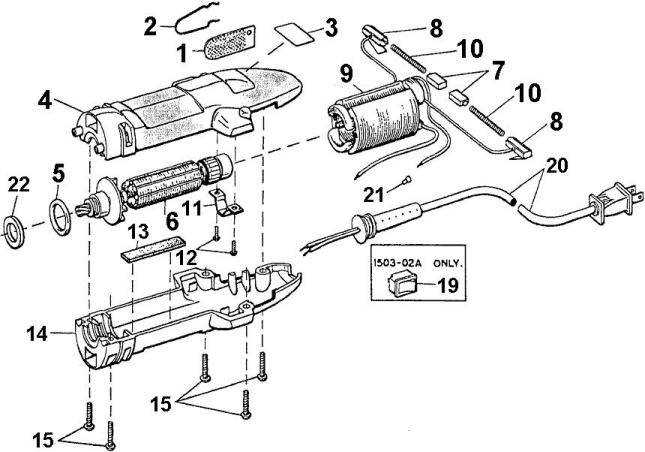

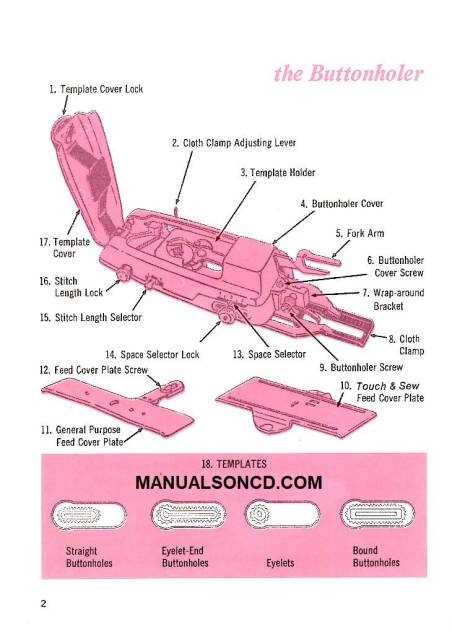

Overview of Clipper Components

Understanding the various elements that make up a grooming tool is essential for anyone interested in its functionality and maintenance. Each component plays a crucial role in ensuring optimal performance, contributing to the overall efficiency and effectiveness of the device. This section delves into the essential features that define such instruments, offering insights into their structure and operation.

Key Functional Elements

The primary functional elements are designed to work in harmony, allowing the device to operate smoothly. These parts include the motor, which drives the cutting mechanism, and the blades, which are responsible for achieving a clean and precise trim. The housing also plays a significant role in protecting the internal components and providing a comfortable grip for the user.

Maintenance and Care

Regular maintenance is vital for prolonging the life of the grooming tool. This includes cleaning and lubricating the cutting mechanism to prevent wear and tear. Additionally, inspecting the casing and components for damage can help ensure consistent performance over time. Understanding how each part contributes to the tool’s functionality enables users to maintain it effectively and avoid common pitfalls.

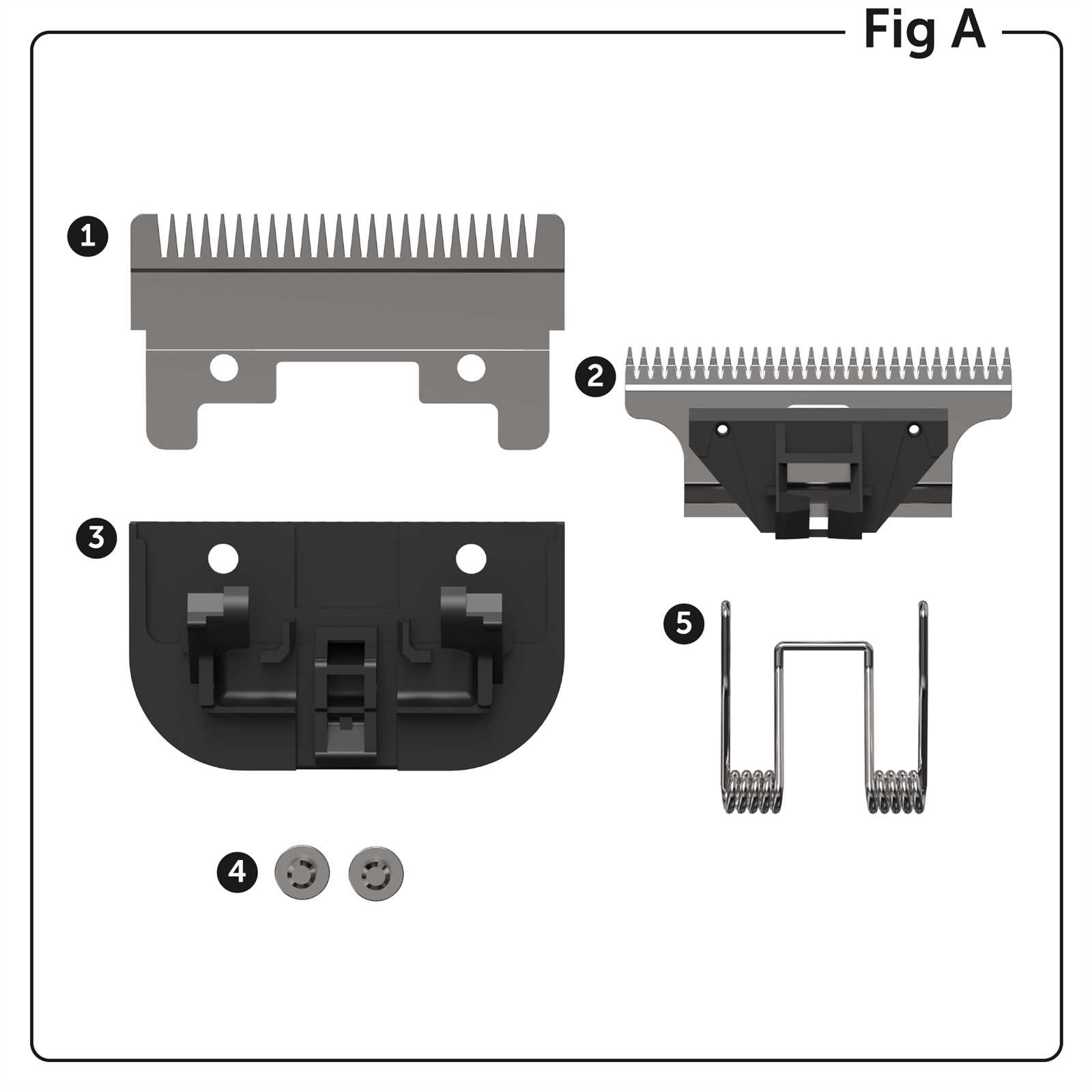

Understanding the Blade Assembly

The blade configuration is crucial for the effective operation of trimming devices. It consists of various components that work together to achieve precise cutting results. Understanding how these elements interact can greatly enhance performance and maintenance, ensuring that the device operates smoothly and efficiently.

The cutting edges are typically constructed from durable materials, designed to withstand frequent use while maintaining sharpness. Proper alignment and tension of these components are vital for optimal cutting performance. Regular inspection and care can prevent common issues such as uneven cutting or pulling of hair.

Additionally, different styles and sizes of these configurations cater to various trimming needs, providing versatility for users. Whether for professional grooming or personal use, knowledge of the blade setup can significantly improve the overall experience and outcomes.

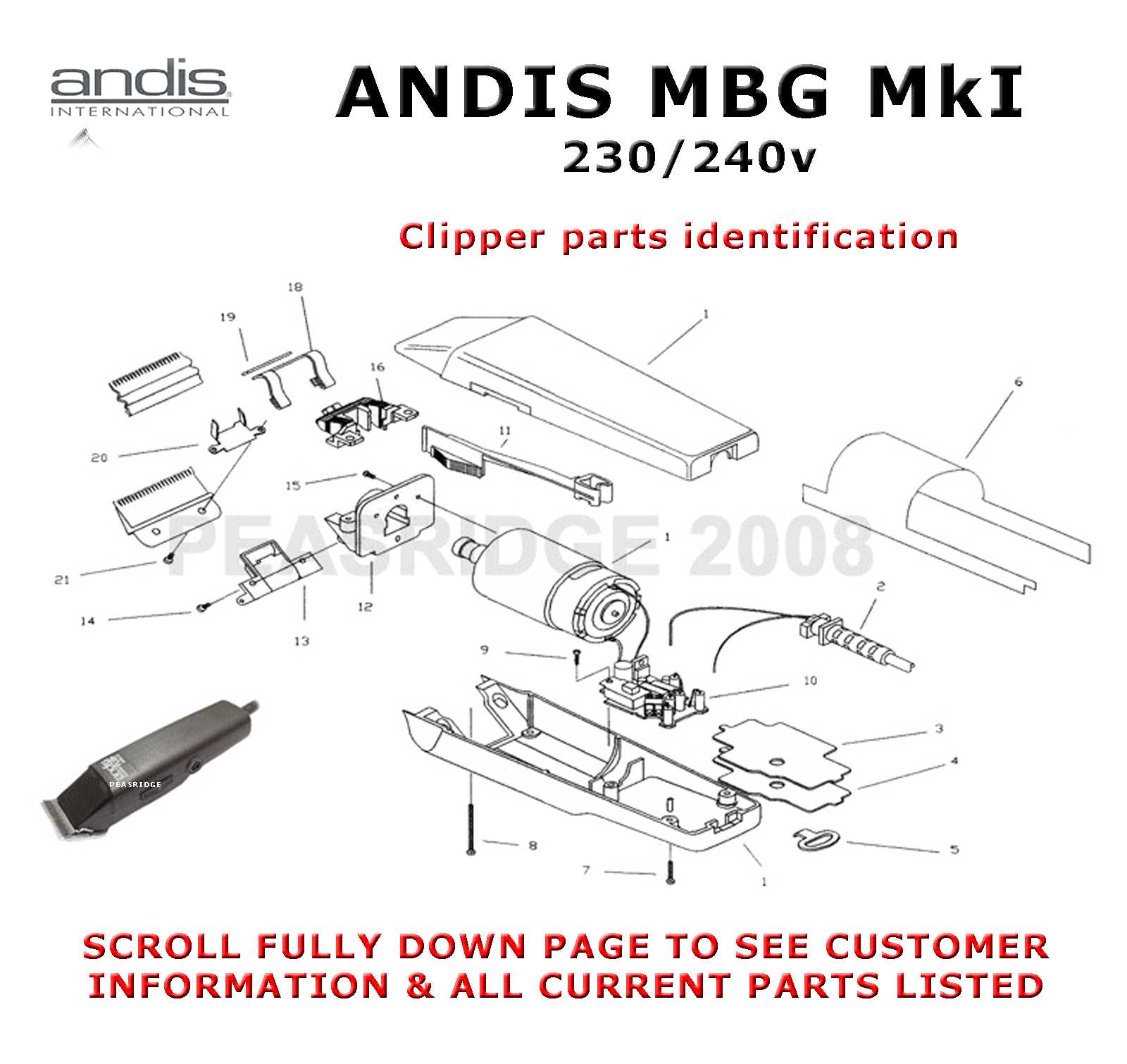

Motor Structure and Function

The motor serves as the essential component that powers various devices, converting electrical energy into mechanical energy. This transformation is crucial for enabling the operation of tools designed for cutting and grooming. Understanding the motor’s design and its operational principles is fundamental for effective maintenance and troubleshooting.

At the core of the motor’s functionality lies the rotor, which rotates within a magnetic field, creating motion. The interaction between the rotor and the stator generates the necessary torque to drive the blades or other mechanisms efficiently. The efficiency of this process depends on several key elements, including the windings, bearings, and housing.

| Component | Function |

|---|---|

| Rotor | Converts electrical energy into rotational motion. |

| Stator | Creates a magnetic field that interacts with the rotor. |

| Windings | Conduct electricity to generate a magnetic field. |

| Bearings | Support the rotor’s rotation and reduce friction. |

| Housing | Protects internal components and facilitates heat dissipation. |

By comprehending the structure and roles of these components, users can appreciate how the motor operates and the significance of regular maintenance to ensure optimal performance. This knowledge also aids in identifying potential issues that may arise during operation.

Drive Mechanism Breakdown

In this section, we delve into the intricate components that power the movement of the device. It’s essential to understand the inner workings responsible for the operational dynamics, highlighting the key elements orchestrating motion. By exploring the mechanisms driving functionality, we uncover how each component collaborates to ensure smooth operation. These internal structures play a pivotal role in the overall performance, demonstrating the synergy of parts in motion control.

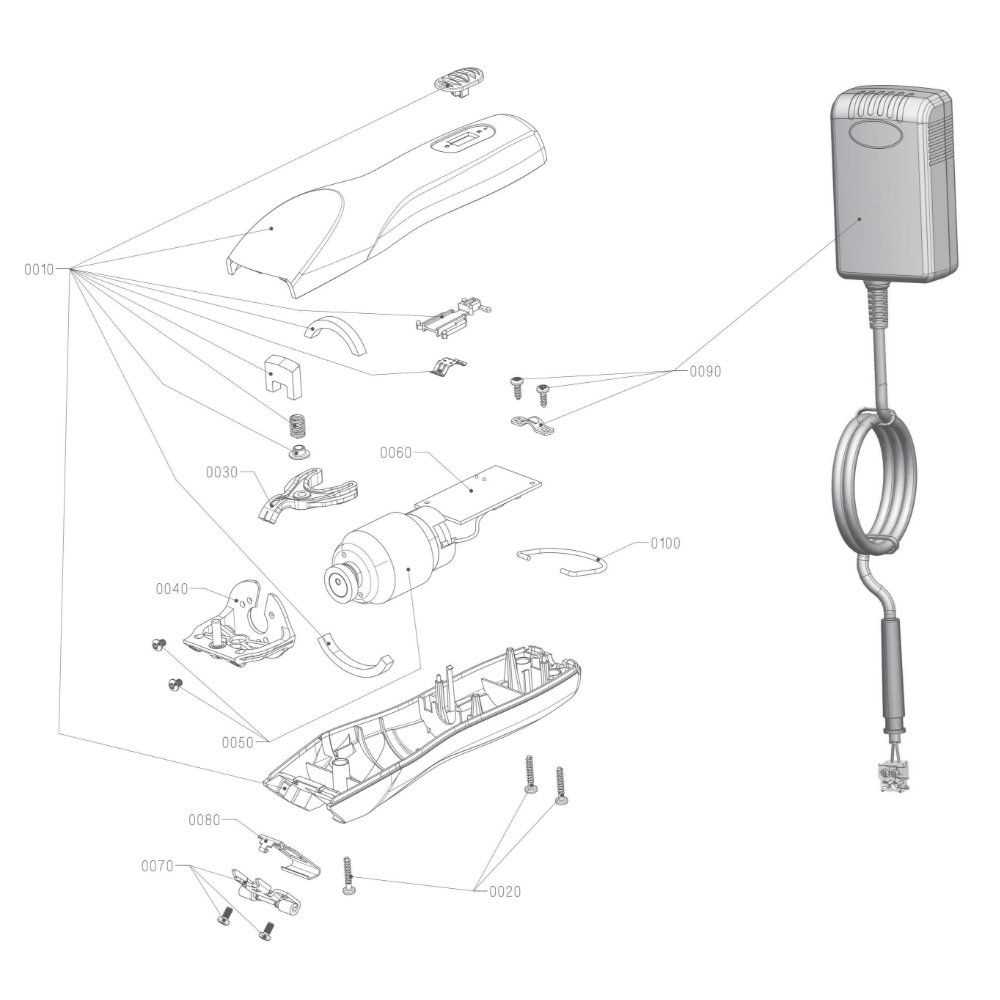

Clipper Housing and Casing Details

The exterior structure of grooming devices plays a crucial role in their functionality and user experience. Understanding the design and materials used in this protective shell can enhance the longevity and performance of the appliance. A well-constructed casing not only safeguards internal components but also contributes to the overall ergonomic feel, ensuring comfort during use.

Material Composition: The housing is typically made from durable plastics or metals, providing a balance between lightweight design and robustness. High-quality materials help prevent wear and tear from daily use, while also resisting heat and moisture, which are common in grooming tasks.

Design Features: Many models incorporate various design elements such as textured grips and contoured shapes, which improve handling and control. Additionally, venting systems may be integrated into the casing to facilitate heat dissipation, ensuring that the internal machinery operates efficiently without overheating.

Accessibility: Thoughtful casing design also allows for easy access to internal components during maintenance. This feature simplifies cleaning and repairs, making it easier for users to maintain their equipment and extend its service life.

In summary, the external structure of grooming tools is vital for their efficiency and durability. A well-designed housing not only protects the inner workings but also enhances user comfort and ease of maintenance, leading to a better grooming experience overall.

Electrical Wiring and Connections

Understanding the fundamentals of electrical connections is crucial for ensuring optimal performance and safety in various devices. Proper wiring techniques enhance functionality and contribute to the longevity of the equipment. This section delves into the essential aspects of electrical connections, emphasizing the importance of careful planning and execution in the assembly process.

Importance of Correct Wiring

Correct wiring plays a vital role in the effective operation of electrical appliances. It prevents issues such as short circuits and overheating, which can lead to equipment failure or hazards. Using appropriate materials and following standard practices ensures reliable connectivity, thereby maintaining consistent performance.

Connection Techniques

Various techniques are employed to achieve secure and efficient connections. Twisting wires together, utilizing connectors, and soldering are common methods that ensure solid contact points. Each technique has its advantages and is chosen based on the specific requirements of the device, including voltage levels and operational demands.

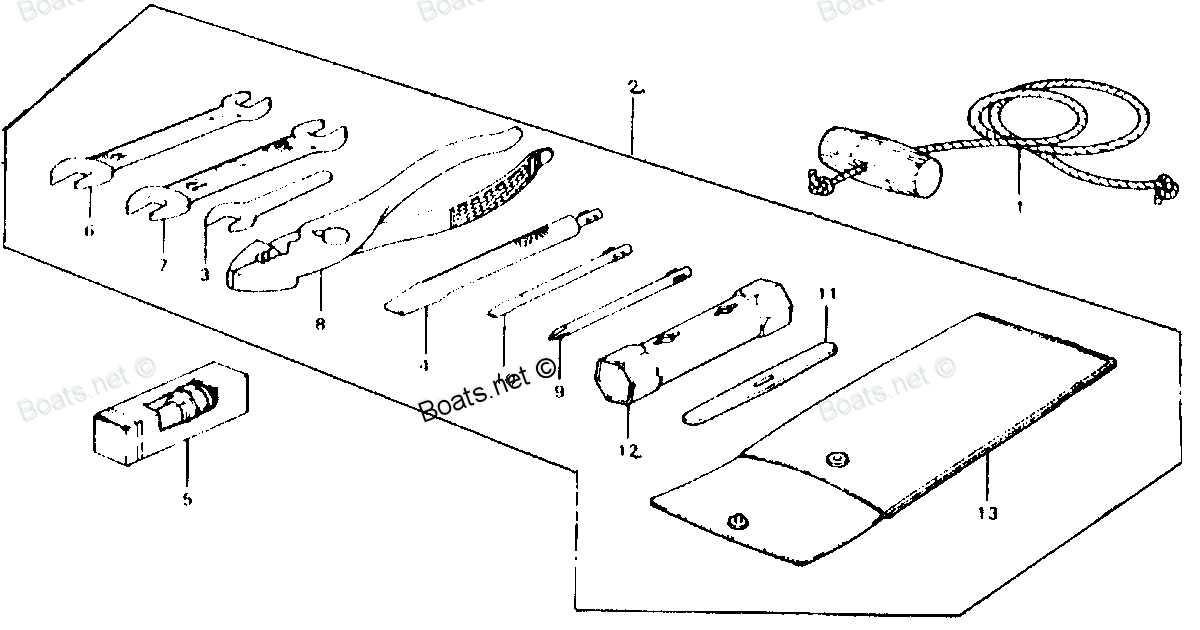

Cleaning and Maintenance Tips

Proper upkeep of grooming tools is essential for optimal performance and longevity. Regular cleaning helps prevent buildup of hair and debris, ensuring that your equipment operates smoothly and effectively. Adopting a maintenance routine can significantly enhance the lifespan of your devices, making them a worthwhile investment.

Routine Cleaning Procedures

Establishing a regular cleaning schedule is crucial. After each use, follow these steps to maintain your equipment:

| Step | Action |

|---|---|

| 1 | Remove any hair clippings from the exterior using a soft brush. |

| 2 | Detach the cutting blade and clean it with a cleaning solution. |

| 3 | Lubricate the blades with oil designed for grooming instruments. |

| 4 | Reattach the blade securely before storing the device. |

Storage Recommendations

Proper storage is equally important in maintaining the condition of your grooming tools. Always keep them in a cool, dry place, away from direct sunlight. Utilize a protective case or pouch to shield them from dust and accidental damage. Following these guidelines will help you ensure that your tools remain in peak condition for years to come.

Replacement Parts and Compatibility

When it comes to maintaining grooming tools, understanding the options for substitution and their compatibility is essential. The availability of compatible components ensures that your device remains functional and efficient, catering to the diverse needs of users. Selecting the right elements not only prolongs the lifespan of the equipment but also enhances its performance.

Finding Compatible Components

Identifying the appropriate elements for your grooming device involves considering specifications and design. It’s important to check the manufacturer’s guidelines to ensure that the replacements align with the original model. This practice helps in avoiding mismatches that could hinder performance.

Benefits of Using Quality Replacements

Utilizing high-quality substitutes can significantly improve the efficiency of your grooming equipment. Quality alternatives often offer better durability and can lead to a more satisfying grooming experience. Additionally, choosing reputable brands ensures that you invest in reliable solutions that meet safety standards.

Troubleshooting Common Clipper Issues

Regular maintenance and proper handling are essential for ensuring the longevity and effectiveness of grooming tools. However, users may encounter various challenges during operation. Identifying the root causes of these problems is crucial for restoring functionality and enhancing performance.

Motor Performance Problems

Inconsistent power or complete motor failure can stem from several factors. Firstly, check the power source to ensure it is functioning correctly. Additionally, inspect the internal wiring and connections for any signs of wear or damage. If the motor overheats, allow it to cool down before using it again, as overheating may indicate excessive load or inadequate lubrication.

Cutting Quality Issues

When the cutting performance becomes subpar, the issue often lies with the cutting mechanism. Dull blades can result in uneven trimming, so regular sharpening or replacement is necessary. Ensure that the blades are properly aligned and securely fastened to prevent any movement during use. Lastly, clean the blades frequently to remove hair and debris, which can hinder performance.

Lubrication Points and Techniques

Proper maintenance of grooming devices is crucial for their longevity and performance. Regular lubrication helps to minimize friction between moving components, ensuring smooth operation and extending the lifespan of the device. Understanding where to apply lubricant and the methods for effective application can make a significant difference in the upkeep of these tools.

Key Areas for Lubrication

Focus on specific areas such as the motor housing, blades, and pivot points. These locations are prone to wear and tear, and a small amount of lubricant can enhance their efficiency. Pay attention to any designated oiling ports, as they often indicate where lubrication is most needed.

Techniques for Application

When applying lubricant, use a few drops of high-quality oil to each key area. It’s essential to avoid over-lubricating, as excess oil can attract dirt and debris, potentially causing more harm than good. A soft cloth can be used to wipe off any excess and ensure that the lubricant penetrates the necessary components effectively.

Frequency of Maintenance

Regularly lubricating your grooming tools after every few uses will help maintain optimal performance. However, the frequency may vary depending on usage intensity. Always refer to the manufacturer’s guidelines for specific recommendations.

Assembly Guide for Beginners

This section aims to provide a comprehensive overview for novices interested in the process of putting together essential components of grooming equipment. Understanding the arrangement of various elements is crucial for ensuring optimal performance and longevity of the device. Whether you are a first-time user or simply looking to enhance your skills, this guide will facilitate your learning experience.

Before starting, it’s essential to familiarize yourself with the various components that make up the tool. Each piece plays a vital role in the overall functionality, and knowing their specific functions will help in the smooth integration of each element.

| Component | Description | Purpose |

|---|---|---|

| Blade | The cutting edge that trims hair. | Essential for achieving desired lengths and styles. |

| Guard | A plastic attachment that controls hair length. | Protects the skin and offers styling versatility. |

| Motor | The mechanism that powers the blades. | Provides the necessary force for effective cutting. |

| Housing | The outer casing that protects internal components. | Ensures durability and safety during use. |

| Power Cord | The electrical cable supplying energy to the device. | Facilitates operation by connecting to a power source. |

By understanding these components and their roles, you will be better equipped to assemble your grooming tool effectively, leading to improved performance and satisfaction.