In the realm of woodworking and metalworking, mastery over the various elements of cutting tools is essential for efficiency and precision. Each machine comprises distinct sections that work in unison to deliver optimal performance, ensuring smooth operation and accurate results.

Familiarity with these individual components can greatly enhance one’s skill in maintenance and operation. By exploring the intricate relationships between the different segments, one can delve into the functionality that drives successful projects.

Ultimately, a comprehensive understanding of the mechanical structure not only empowers users but also aids in troubleshooting common issues, paving the way for improved craftsmanship and innovation.

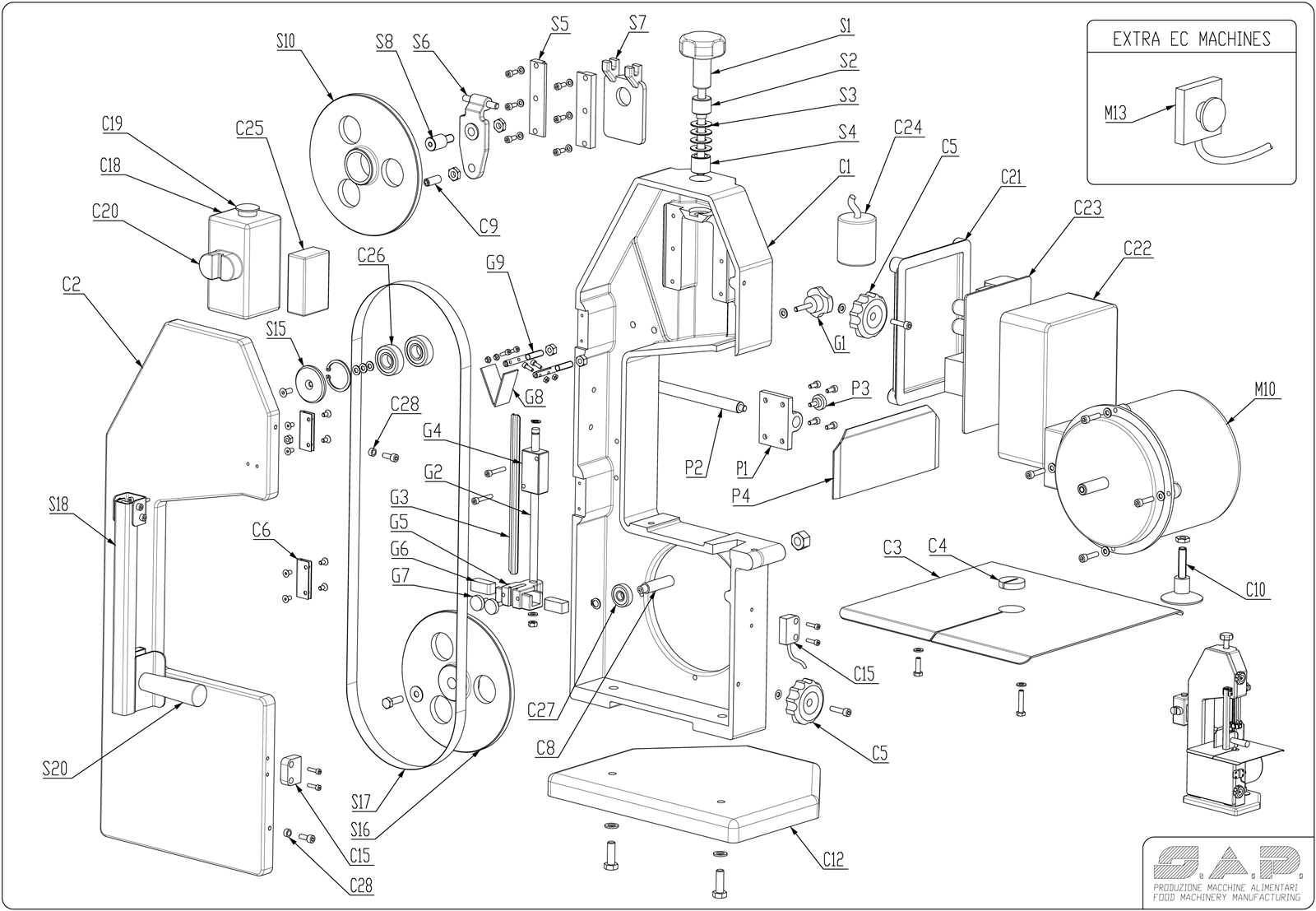

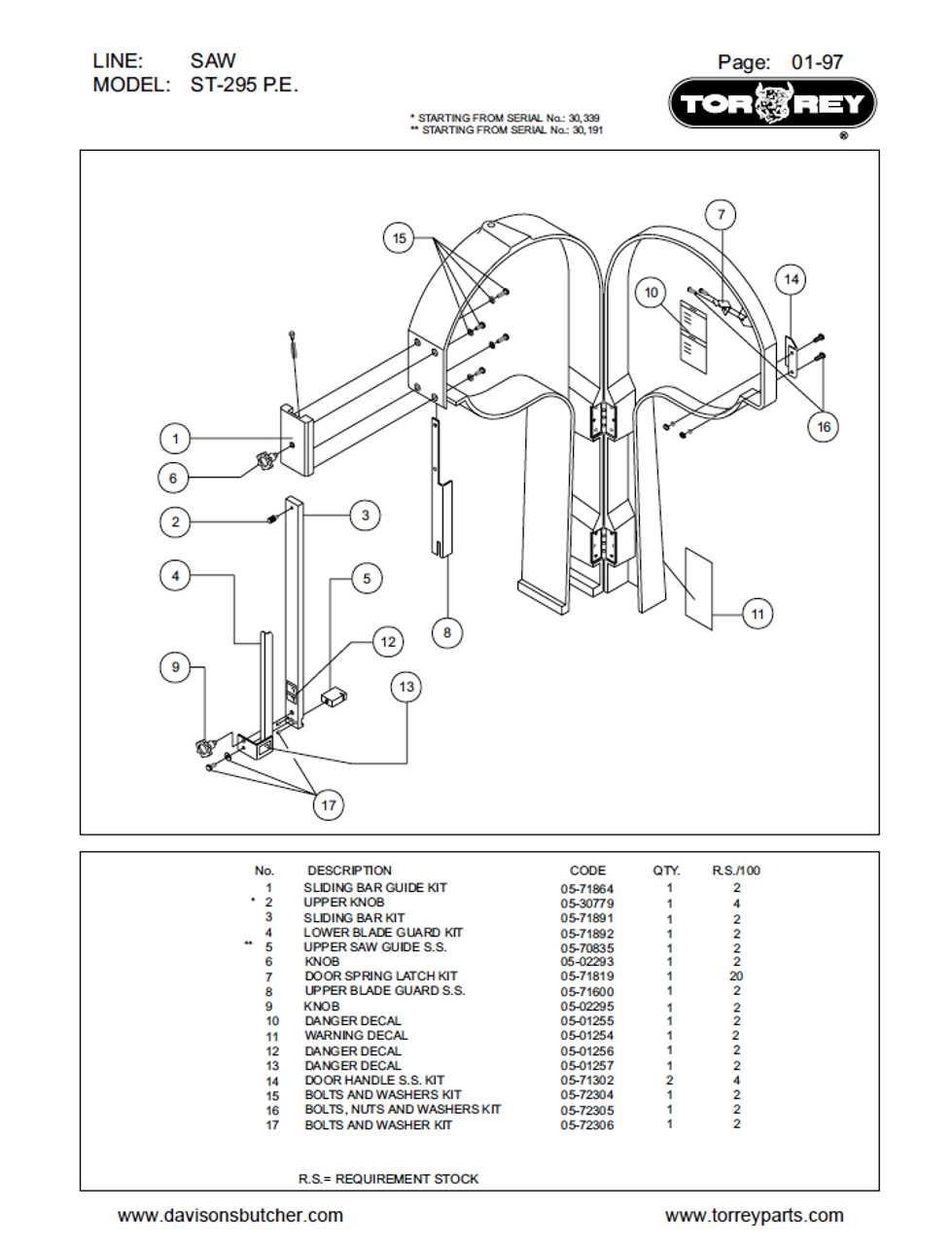

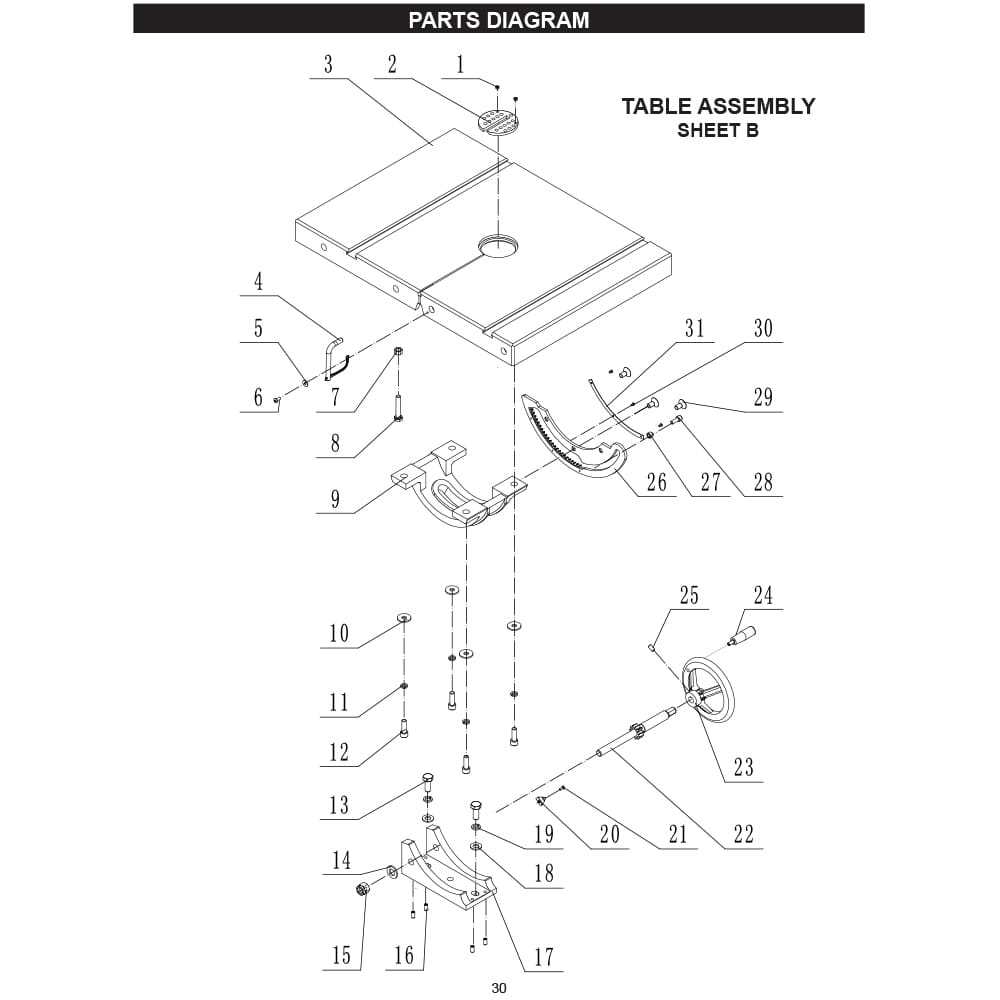

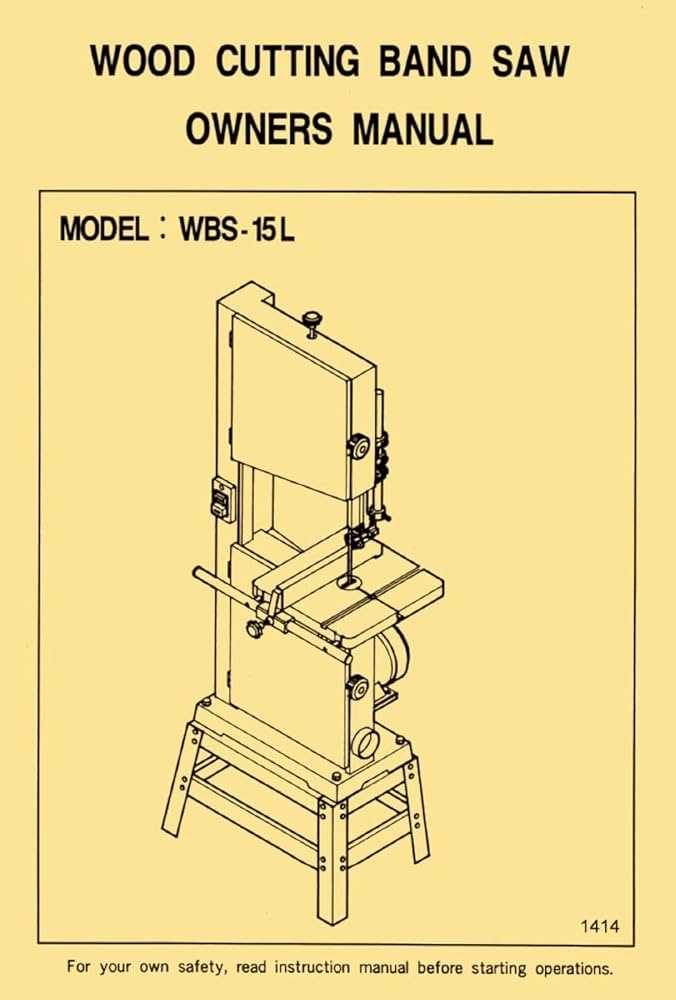

Bandsaw Parts Overview

This section provides an insightful look into the essential components of a cutting tool designed for precise and versatile cutting. Understanding these elements is crucial for maintenance, operation, and enhancing performance in various woodworking and metalworking tasks.

Main Components

The primary elements of this equipment are vital for its efficient functionality. Each component plays a specific role, contributing to the overall effectiveness of the tool.

| Component | Function |

|---|---|

| Frame | Supports the structure and stability during operation. |

| Blade | Facilitates cutting through various materials with precision. |

| Table | Provides a stable surface for material placement. |

| Motor | Powers the blade, enabling cutting action. |

Add-On Features

In addition to the core elements, there are optional enhancements that can further improve the cutting experience. These features can provide added convenience and functionality, making the tool even more adaptable to specific tasks.

Understanding Bandsaw Functionality

Exploring the mechanics of a cutting tool reveals a fascinating interplay of components that work together to achieve precision and efficiency in slicing materials. This intricate system allows for a smooth operation, catering to various cutting tasks, from fine detail work to heavy-duty projects.

Key Mechanisms at Play

At the heart of this tool is a looped blade that runs continuously, supported by wheels that drive its movement. The tension applied to the blade is crucial, as it ensures stability and accuracy during operation. Guide blocks play an essential role in maintaining the blade’s alignment, reducing friction and preventing deviation from the intended path.

Importance of Adjustability

Another critical aspect is the ability to adjust various settings, allowing users to modify the tool’s capabilities according to the material being cut. Blade speed and cutting height are vital factors that influence the quality of the cut, making customization a key feature for effective use. Understanding these elements enhances operational efficiency and results in superior craftsmanship.

Key Components of a Bandsaw

Understanding the essential elements of this cutting tool is crucial for effective operation and maintenance. Each component plays a vital role in ensuring precision and efficiency in various applications.

Main Elements

- Blade: The cutting tool that performs the actual work.

- Table: The surface where materials are placed for cutting.

- Frame: The structure that supports all other components.

- Guide Wheels: These ensure the blade runs smoothly and accurately.

- Motor: The power source that drives the blade.

Supportive Features

- Tension Mechanism: Adjusts the tightness of the blade for optimal performance.

- Fence: A guide for making straight cuts.

- Adjustment Knobs: Allow for customization of settings based on material type.

- Dust Collection: Helps maintain a clean workspace and improves visibility.

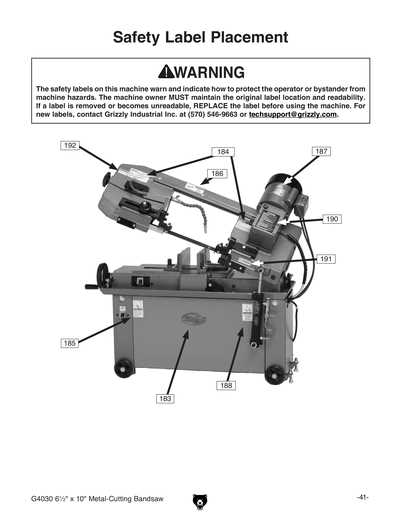

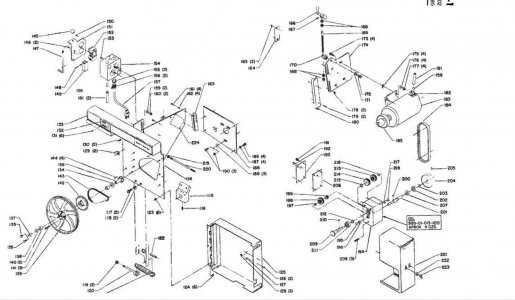

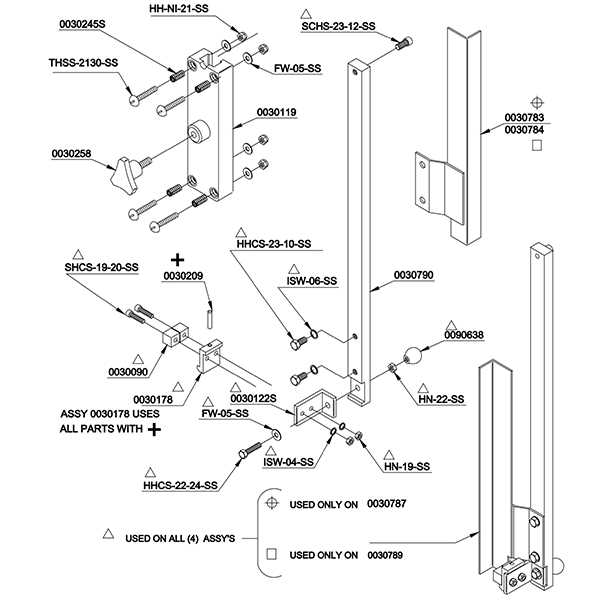

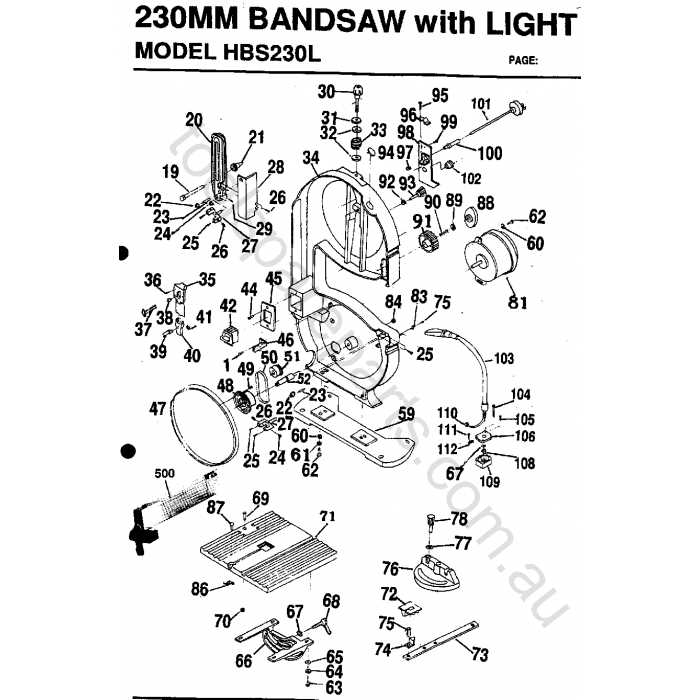

How to Read a Parts Diagram

Understanding a visual representation of equipment components is crucial for effective maintenance and repairs. By familiarizing yourself with the symbols and layout, you can easily identify each element and its function within the machine.

Key Elements to Focus On

When analyzing the illustration, pay attention to the labeling, which typically includes both names and numbers. This information will guide you in locating the correct elements during assembly or disassembly.

| Label | Description |

|---|---|

| 1 | Main frame |

| 2 | Cutting mechanism |

| 3 | Drive motor |

Interpreting Symbols and Lines

Lines connecting various symbols indicate relationships and connections between elements. Solid lines typically denote physical connections, while dashed lines may represent adjustable or movable parts.

Common Bandsaw Accessories Explained

Understanding the various tools and enhancements available can significantly improve your cutting experience and efficiency. These additional components are designed to optimize functionality, increase safety, and expand the range of projects you can tackle. Familiarizing yourself with these accessories is essential for anyone looking to elevate their woodworking skills.

Blade Guides: These are crucial for maintaining blade alignment and stability during operation. Properly adjusted guides help reduce blade deflection, leading to cleaner cuts and extending the lifespan of the blade.

Rip Fence: This tool provides a straight edge for making accurate, consistent cuts. A well-calibrated rip fence allows for easy measurement adjustments, making it invaluable for repetitive cutting tasks.

Table Extensions: For larger workpieces, extensions offer additional support and stability. This accessory helps prevent material from tipping or falling during cutting, ensuring safer operations.

Blades: Choosing the right cutting tool is vital. Various types are available, designed for different materials and cutting techniques. Understanding the specifics of each type will allow for more precise and effective results.

Dust Collection Systems: Maintaining a clean workspace is essential for safety and efficiency. A good dust collection system minimizes debris buildup, improving visibility and reducing the risk of accidents while working.

Incorporating these accessories into your setup not only enhances performance but also transforms the overall woodworking experience, allowing for greater creativity and productivity.

Maintenance Tips for Bandsaw Parts

Regular upkeep is essential for ensuring optimal performance and longevity of your cutting tool. Proper care not only enhances efficiency but also minimizes the risk of unexpected breakdowns. By focusing on key components, users can maintain smooth operation and achieve precise results.

Cleaning and Lubrication

Keep all moving elements free of debris and build-up. Dust and residue can lead to unnecessary wear. Regular cleaning with appropriate solutions helps preserve functionality. Additionally, applying the right lubricant to pivot points reduces friction and promotes a longer lifespan.

Alignment and Tension

Ensure that all components are properly aligned and adjusted. Incorrect alignment can cause uneven cuts and increased strain on the motor. Regularly check and adjust tension to prevent slipping, which can compromise cutting accuracy and damage the tool over time.

Identifying Worn-Out Components

Understanding the signs of deterioration in machinery is crucial for maintaining optimal performance. Over time, various elements may experience wear and tear, leading to inefficiencies and potential failures. Recognizing these signs early can save time and resources.

Visual Inspection: Regularly examine the machinery for visible damage, such as cracks or excessive rust. Pay attention to areas where friction occurs, as these are often the first to show signs of fatigue.

Performance Issues: Noticeable changes in performance, such as unusual noises or reduced efficiency, can indicate that certain components are losing their effectiveness. Listen for sounds that deviate from the norm, as they may signal a problem.

Measurement Checks: Utilize calipers and gauges to measure critical dimensions. If components deviate from specified tolerances, it may be time for replacement. Consistent monitoring can help in making informed decisions.

Maintenance Records: Keeping detailed logs of inspections and repairs allows for tracking patterns of wear. Historical data can provide insights into which parts are prone to degradation, enabling proactive management.

Importance of Blade Guides

Effective cutting performance hinges on the stability and accuracy provided by specific components that support the cutting element. These crucial elements ensure precise tracking and minimize vibrations, ultimately enhancing the quality of the cut.

- Improved Accuracy: Proper alignment leads to straighter cuts.

- Reduced Wear: Guides protect the cutting tool from unnecessary damage.

- Enhanced Safety: Stability prevents unexpected movement during operation.

Understanding the role of these components can significantly impact both the efficiency of your work and the lifespan of your equipment. Regular maintenance and adjustments are essential for optimal functionality.

Adjusting Tension for Optimal Cutting

Proper tensioning of the blade is crucial for achieving precise and efficient cuts. When the force applied to the blade is correctly calibrated, it enhances stability, minimizes vibrations, and prolongs the lifespan of the cutting tool. Understanding how to adjust this tension effectively can significantly impact the quality of your workpiece and the overall performance of your equipment.

To ensure optimal tension, follow these steps:

| Step | Description |

|---|---|

| 1 | Loosen the existing tension before making adjustments to prevent damage. |

| 2 | Check the manufacturer’s recommendations for ideal tension settings specific to your blade type. |

| 3 | Gradually tighten the blade, ensuring it is snug but not overly tight. |

| 4 | Test the blade by making a few cuts on scrap material, monitoring for any deviations or issues. |

| 5 | Readjust if necessary, based on performance feedback from your test cuts. |

Maintaining the right level of tension is an ongoing process. Regular inspections and adjustments will help in achieving consistent cutting results and improve the overall efficiency of your operations.

Role of the Motor in Operation

The motor serves as the heartbeat of the machine, providing the necessary power to facilitate smooth and efficient cutting processes. Its functionality directly impacts the overall performance, influencing speed, precision, and the ability to handle various materials.

By converting electrical energy into mechanical motion, the motor ensures that the blade operates consistently, allowing for intricate designs and clean finishes. The choice of motor plays a crucial role in determining the machine’s capacity and suitability for specific tasks.

Maintenance of the motor is essential for optimal performance, as wear and tear can lead to decreased efficiency and potential operational issues. Regular checks and timely interventions can prolong its lifespan and enhance productivity.

Safety Features of a Bandsaw

Ensuring a secure working environment is paramount when using cutting machinery. Various mechanisms and technologies are implemented to minimize risks and enhance user protection. Understanding these safety features can greatly reduce the likelihood of accidents and injuries during operation.

| Safety Feature | Description |

|---|---|

| Blade Guard | A protective cover that shields the user from the exposed blade, reducing the chance of accidental contact. |

| Emergency Stop | A readily accessible button that halts operation immediately in case of an emergency, ensuring quick response to unforeseen situations. |

| Anti-Kickback Device | A mechanism that prevents the material from being forcibly ejected back towards the operator, enhancing control during cutting. |

| Blade Tension Indicator | A feature that indicates the proper tension of the cutting blade, helping to prevent breakage and ensuring optimal performance. |

| Foot Pedal Switch | An option for hands-free operation, allowing the user to control the machine’s power without removing their hands from the material. |

By recognizing and utilizing these protective elements, users can create a safer workspace and maintain greater focus on their cutting tasks, leading to more efficient and secure operations.

Replacing Bandsaw Parts: A Guide

Maintaining your cutting tool’s efficiency is crucial for optimal performance. This guide provides essential insights into the process of swapping out components to ensure longevity and functionality. Understanding when and how to replace these crucial elements can save time and enhance the overall cutting experience.

Identifying the Right Components

Before embarking on the replacement journey, it’s vital to pinpoint which components require attention. Regular inspections can help detect wear and tear, allowing for timely interventions that prevent further damage.

Gathering Necessary Tools

Having the right tools on hand streamlines the replacement process. Essential items include wrenches, screwdrivers, and safety equipment to protect against potential hazards during the procedure.

Step-by-Step Replacement Process

Start by disconnecting the power source to ensure safety. Follow the manufacturer’s instructions closely, as they provide the ultimate guidance for disassembly and reassembly. Carefully remove the worn-out component and install the new one, ensuring a secure fit.

Testing Functionality

After replacement, it’s crucial to test the machine’s functionality. Run it at a low speed initially to check for any irregularities. Proper testing ensures that the new component integrates smoothly with the rest of the system.

Understanding the Table and Fence System

The table and fence system is a crucial component for achieving precision in cutting operations. It provides a stable surface for workpieces and a guide to ensure accurate cuts. Mastering this system allows users to enhance their overall efficiency and effectiveness when performing various tasks.

The table serves as the foundational surface where materials are placed for processing. It is essential for stability and support, enabling users to work with larger or heavier items securely. Many models feature adjustable height settings, allowing customization for different projects and user preferences.

The fence acts as a guide, ensuring that cuts are straight and consistent. It can be positioned at varying angles and distances from the blade, making it versatile for both straight cuts and angled operations. Proper alignment of the fence is critical for maintaining accuracy, as even minor misalignments can lead to significant errors in the final product.

Understanding how to effectively utilize the table and fence system can greatly impact the quality of the work produced. Regular maintenance and adjustments are necessary to keep these components in optimal condition, promoting safety and performance during use.