In the realm of machinery and engineering, the arrangement and functionality of various elements play a crucial role in ensuring optimal performance. A comprehensive overview of these configurations provides insights into the intricate relationships between individual components and their collective impact on system efficiency. This exploration reveals the underlying principles that govern mechanical interactions, shedding light on both common practices and advanced methodologies.

The visual representation of these configurations serves not only as a tool for analysis but also as a guide for maintenance and troubleshooting. By dissecting the structure of these assemblies, one can gain a clearer understanding of how forces are transmitted and how to achieve desired outcomes in design and operation. This knowledge is invaluable for engineers, technicians, and anyone involved in the management of mechanical systems.

Moreover, grasping the nuances of these layouts enhances the ability to innovate and improve existing designs. Whether for academic study or practical application, the clarity provided by such visual tools fosters a deeper appreciation of the complexities within mechanical engineering. Ultimately, this understanding contributes to the advancement of technology and the creation of more efficient systems.

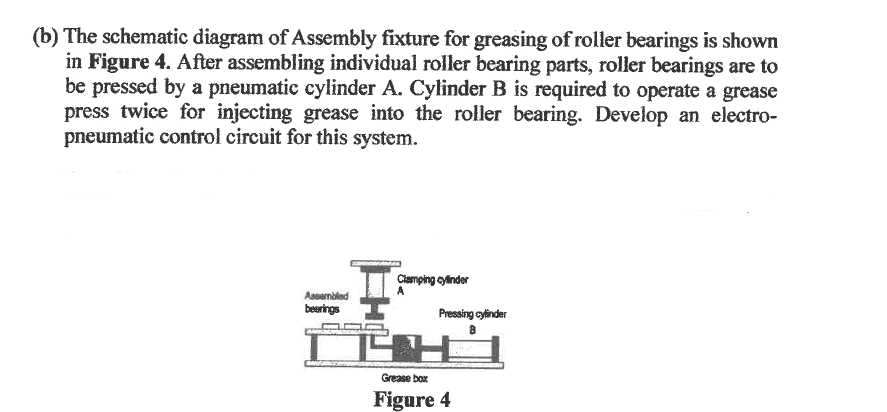

Understanding Bearing Parts Diagrams

Grasping the layout of mechanical components is crucial for effective assembly and maintenance. These visual representations serve as blueprints, illustrating how various elements interact within a system. Familiarity with these schematics enhances troubleshooting abilities and ensures proper installation of crucial elements.

Key Components in the Layout

The visual representation typically includes numerous essential elements, each serving a specific function. Among these, you’ll find rings, balls, and cages, each contributing to the overall efficiency and functionality. Recognizing these components and their arrangements helps in understanding the mechanics at play, facilitating better performance.

Interpreting the Visual Representation

Deciphering these visuals requires an understanding of symbols and notations used to depict different elements. Each symbol often corresponds to a particular function or type, allowing users to identify critical aspects quickly. Mastery of these representations not only aids in repair tasks but also enhances comprehension of overall mechanical systems.

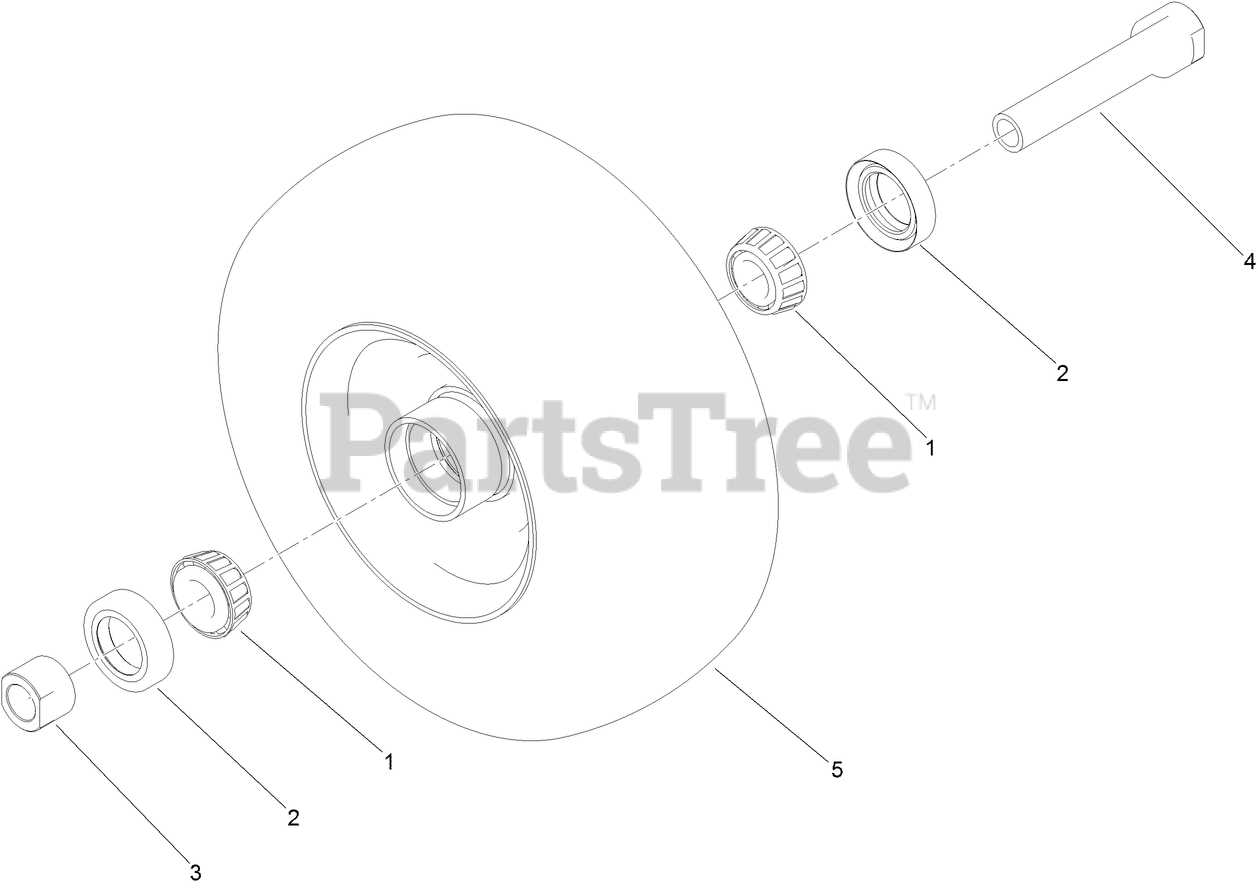

Components of a Bearing Assembly

The functionality of a rotational mechanism relies on several key elements working in harmony. These essential components contribute to the smooth operation and longevity of the system, ensuring efficiency under various conditions. Understanding each element is crucial for proper maintenance and optimization.

The inner race serves as a stable surface for the rolling elements, allowing them to maintain a precise path during rotation. The outer race complements this by providing an external structure that houses the rolling elements and absorbs external forces. The rolling elements themselves are designed to reduce friction, facilitating smooth movement between the races.

A cage or separator is often included to maintain spacing between the rolling elements, preventing wear and tear through contact. Lubrication is another critical factor, as it minimizes friction and dissipates heat generated during operation, prolonging the assembly’s lifespan.

Types of Bearings Explained

Understanding the various forms of rotational support systems is essential for grasping their applications and functions in different machinery. These mechanisms facilitate movement while minimizing friction, ultimately enhancing efficiency and durability.

Rolling Elements

One common category features rolling elements, which include spheres and cylinders that enable smooth movement. These systems are known for their ability to support heavy loads while providing low resistance. Ball and cylindrical types are frequently used in various industrial applications due to their reliability.

Sliding Mechanisms

Another type consists of sliding mechanisms, which utilize a different approach to reduce friction. These systems often employ a lubricant to ensure smooth operation. Plain and journal types are essential in scenarios where alignment and load distribution are critical, offering unique advantages in specific contexts.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in various technical fields, serving as a foundation for understanding complex systems. They provide clarity and detail, ensuring that users can effectively interpret and implement the information presented. The effectiveness of these visual representations can significantly influence the efficiency of processes and the accuracy of results.

Clear communication is essential when conveying technical concepts. Accurate visuals eliminate ambiguity, allowing engineers, technicians, and operators to grasp intricate details without misinterpretation. This clarity not only enhances individual comprehension but also fosters collaboration among team members, as everyone can refer to the same well-defined visual reference.

Furthermore, the role of precise visuals extends beyond initial comprehension. They serve as valuable tools for training and education, helping newcomers familiarize themselves with complex systems quickly. When new team members can rely on accurate illustrations, the onboarding process becomes more efficient, reducing the learning curve and enabling them to contribute effectively in a shorter timeframe.

In addition, detailed representations are vital during troubleshooting and maintenance. When issues arise, having an accurate visual reference allows for quicker identification of potential problems, facilitating timely repairs and minimizing downtime. This can lead to significant cost savings and improved operational efficiency.

Ultimately, the significance of well-crafted illustrations cannot be overstated. They are instrumental in ensuring safety, enhancing productivity, and fostering innovation within any technical discipline.

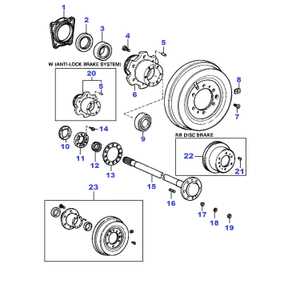

Common Applications of Bearings

These essential components play a crucial role in various industries by facilitating smooth motion and reducing friction. Their versatility allows them to be utilized in numerous applications across different sectors, ensuring efficiency and reliability in machinery and equipment.

Some of the most prevalent uses include:

- Automotive Industry:

- Engines

- Wheel hubs

- Transmissions

- Aerospace:

- Aircraft engines

- Landing gear

- Control surfaces

- Manufacturing:

- Conveyor systems

- Machine tools

- Robotic arms

- Home Appliances:

- Washing machines

- Fans

- Refrigerators

- Medical Equipment:

- Surgical instruments

- Diagnostic machines

- Patient mobility aids

By providing support and enabling rotation, these elements contribute significantly to the performance and longevity of a wide range of devices.

How to Read Bearing Diagrams

Understanding technical illustrations related to mechanical components is crucial for anyone working in engineering or maintenance. These visuals provide essential information about assembly, orientation, and functionality. Here’s a guide to effectively interpreting these representations.

When approaching these visuals, consider the following elements:

- Symbols: Familiarize yourself with common symbols used to represent various components. Each symbol conveys specific information about the element’s role.

- Dimensions: Pay attention to numerical values, as they indicate sizes and measurements critical for accurate fitting and assembly.

- Labels: Descriptive labels often accompany visuals, providing clarity on what each component represents and its function within the system.

Here are steps to enhance your comprehension:

- Identify the Overview: Start by looking for an overall view or key that summarizes the different components included in the visual.

- Study Individual Elements: Break down the illustration by focusing on one element at a time. Understand its shape, size, and how it interacts with neighboring elements.

- Refer to Additional Documentation: Cross-reference with manuals or guides that provide deeper insights into the components and their relationships.

- Practice: Regularly engage with different illustrations to become more adept at quickly understanding new representations.

By following these guidelines, you will enhance your ability to read and interpret technical illustrations, ultimately improving your understanding of mechanical systems.

Maintenance Tips for Bearings

Regular upkeep is essential for ensuring the longevity and optimal performance of rotating components in various machinery. Proper attention to these elements can prevent premature wear, reduce downtime, and enhance efficiency.

Here are some effective strategies to maintain these crucial components:

- Regular Inspection: Periodically check for signs of wear or damage. Look for unusual noises or vibrations that may indicate underlying issues.

- Proper Lubrication: Ensure that lubrication is applied according to the manufacturer’s recommendations. Use the correct type and amount to minimize friction and heat.

- Contamination Prevention: Keep the area clean and free of dust and debris. Use seals and shields to protect against contaminants that could compromise functionality.

- Alignment Checks: Ensure that components are correctly aligned. Misalignment can lead to uneven wear and potential failure.

- Temperature Monitoring: Regularly monitor operating temperatures. Excess heat can signal issues that need immediate attention.

By following these maintenance tips, you can significantly extend the lifespan and reliability of your rotating components, ensuring smooth operation and reducing the risk of unexpected failures.

Impact of Wear on Performance

Wear is an inevitable process that can significantly affect the functionality of mechanical systems. Understanding its implications is crucial for maintaining efficiency and reliability.

The consequences of wear can manifest in various ways:

- Decreased operational efficiency

- Increased energy consumption

- Higher maintenance costs

- Shortened lifespan of components

To mitigate these effects, consider the following strategies:

- Regular inspections and monitoring

- Implementing lubrication systems

- Choosing materials resistant to wear

- Adjusting operational parameters to reduce stress

Addressing wear proactively can lead to enhanced performance and durability in machinery.

Choosing the Right Bearings

Selecting the appropriate components for rotational support is crucial for ensuring optimal performance and longevity in machinery. The right choice can significantly influence efficiency, reduce wear, and enhance overall functionality.

Considerations when making this choice include load capacity, speed ratings, and environmental conditions. Identifying the specific requirements of your application will guide you in selecting the most suitable options available.

It is essential to evaluate materials and design types, as they can affect durability and maintenance needs. Conducting thorough research and consulting with experts can lead to an ultimate selection that meets your operational demands.

Tools for Diagram Creation

Creating visual representations of complex systems requires specialized instruments that facilitate clarity and precision. These resources enable users to transform ideas into structured formats, enhancing understanding and communication among stakeholders.

Software Solutions

Numerous software applications are available, each offering unique features. Programs like Lucidchart and Visio provide intuitive interfaces that allow for easy customization and collaboration. Users can delve into various templates to streamline their workflow and achieve the ultimate result.

Online Platforms

Web-based tools have gained popularity for their accessibility and ease of use. Platforms such as Canva and Google Drawings allow for quick creations without the need for installation. These services often include shared editing capabilities, making it simple to engage multiple contributors in the design process.

Future Trends in Bearing Technology

As industries continue to evolve, innovations in rotational support components are poised to redefine performance and efficiency. The future of this technology hinges on several key advancements that promise to enhance durability, reduce friction, and improve energy consumption.

- Smart Materials: Development of self-lubricating and adaptive materials will lead to improved longevity and maintenance-free solutions.

- IoT Integration: Connectivity features will allow for real-time monitoring, enabling predictive maintenance and reducing downtime.

- Miniaturization: Shrinking component sizes will enhance design flexibility and application in compact devices.

- Sustainability: A shift towards eco-friendly manufacturing processes and recyclable materials will be crucial for reducing environmental impact.

These trends signify a transformative phase in the field, where innovation will drive greater efficiency and adaptability across various applications.