In the world of machinery and technology, having a clear visual representation of individual elements is crucial for effective maintenance and assembly. Such illustrations provide a roadmap, guiding users through the intricate relationships between various components. This visual aid ensures that both professionals and enthusiasts can grasp the complex interactions that define the functionality of a system.

By exploring these representations, one can gain insight into how different pieces fit together and contribute to overall performance. This understanding not only facilitates repairs and replacements but also enhances the efficiency of the entire operation. Recognizing the significance of each part enables users to troubleshoot issues more effectively, ensuring longevity and reliability.

Moreover, these visual tools can serve as an educational resource, helping newcomers to familiarize themselves with specific systems. They demystify the complexities of machinery, making it easier to navigate the intricacies of assembly and disassembly. As a result, having access to detailed visuals becomes indispensable for anyone working with or studying such technologies.

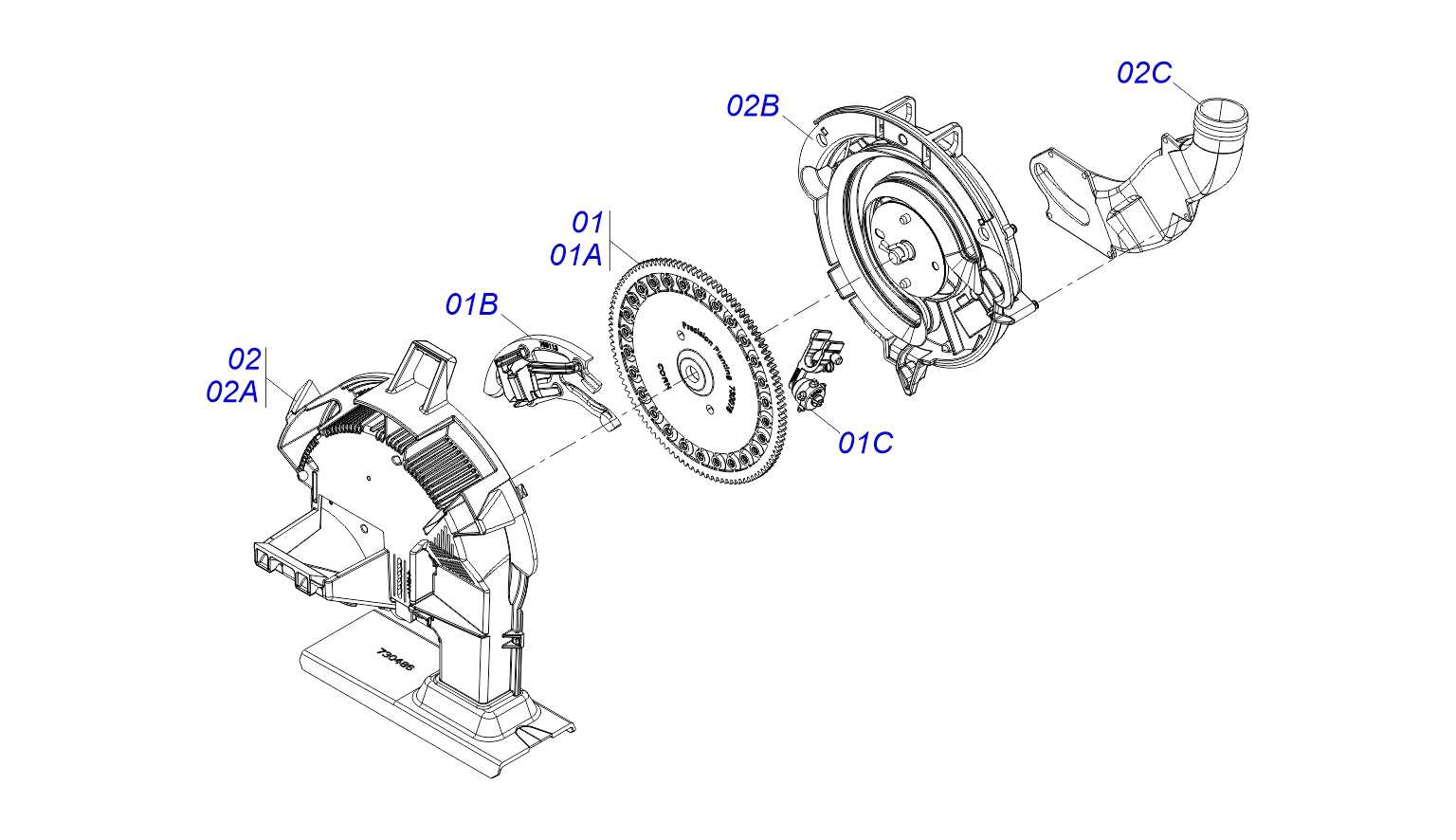

Understanding Bg56c Parts Diagram

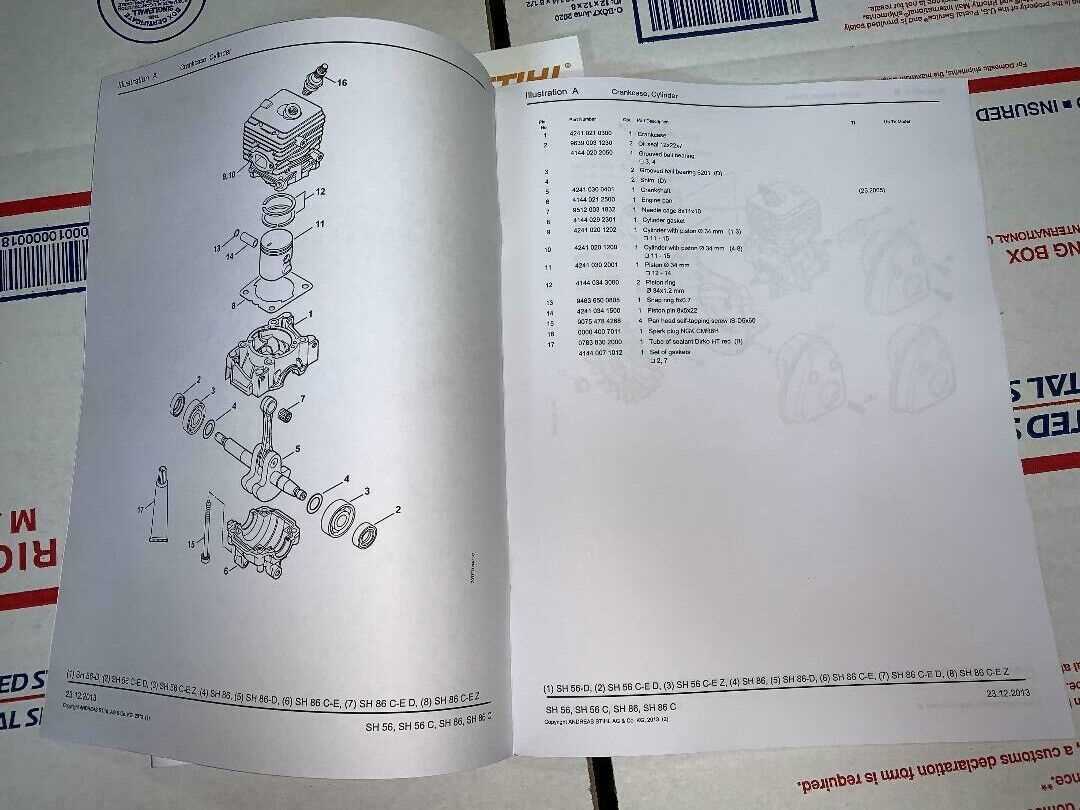

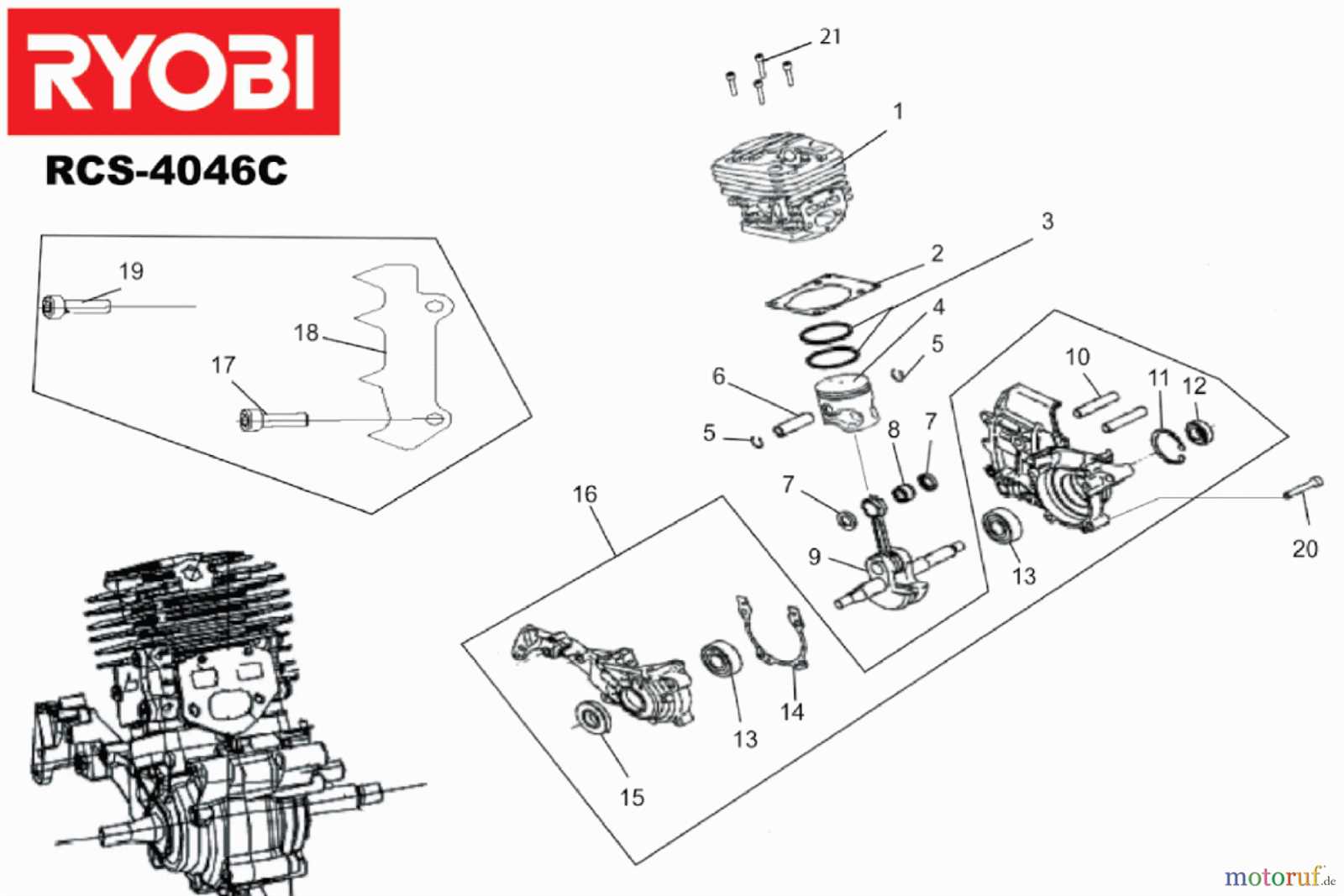

This section provides a comprehensive overview of the visual representation that illustrates the various components of a particular device. Such an illustration is essential for users to grasp the relationships and functions of each element within the system, aiding in troubleshooting and maintenance.

To effectively utilize the visual representation, one should familiarize themselves with the labeling system used to identify each segment. Knowing how to interpret these labels is crucial for proper assembly and repair tasks.

| Component Name | Description | Function |

|---|---|---|

| Motor | The driving force of the device. | Provides the necessary power for operation. |

| Housing | The outer shell protecting internal components. | Offers structural support and safety. |

| Blade | The cutting element used in operation. | Performs the primary function of cutting. |

| Switch | The control mechanism for turning the device on/off. | Enables user control over the operation. |

By understanding the roles and interconnections of each component, users can enhance their operational efficiency and extend the lifespan of the equipment. Familiarity with this visual representation not only facilitates effective usage but also empowers users to undertake minor repairs confidently.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex systems. They provide clarity, helping users to identify each element and its function within the whole structure. This enhanced comprehension facilitates maintenance, troubleshooting, and efficient assembly.

Utilizing these visual aids can significantly reduce errors and save time during repairs. They serve as a reference point, ensuring that every piece is accounted for and correctly placed. By breaking down intricate machinery into manageable visuals, users can navigate their tasks with greater confidence.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual guides simplify complex information. |

| Efficiency | Reduces time spent on repairs and assembly. |

| Error Reduction | Minimizes mistakes in identifying and placing components. |

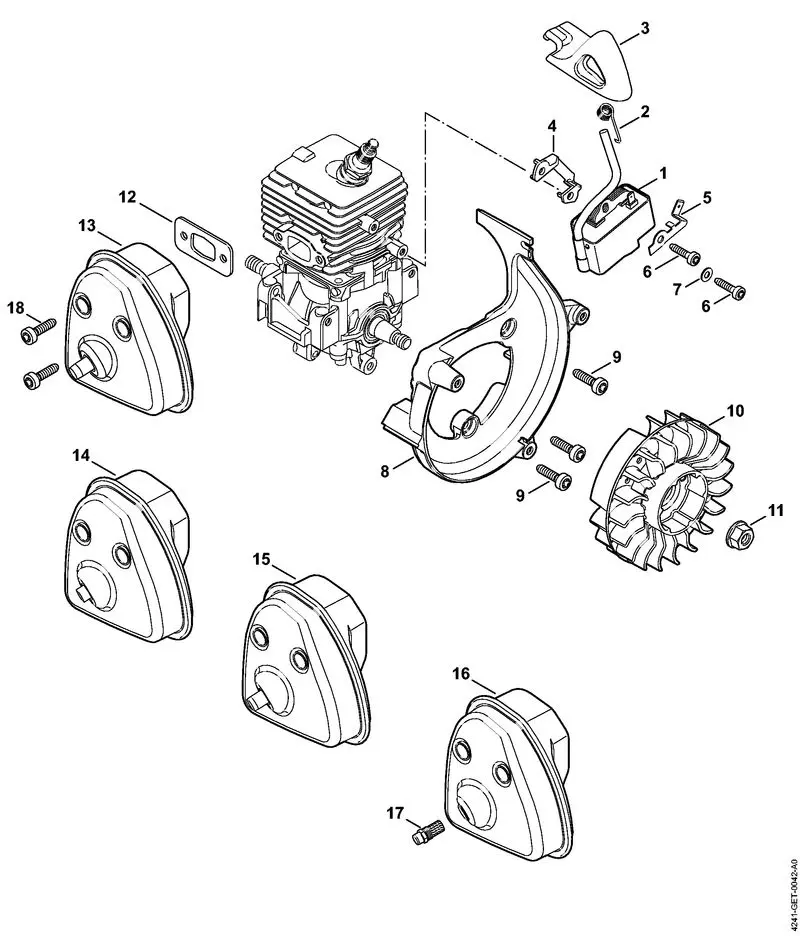

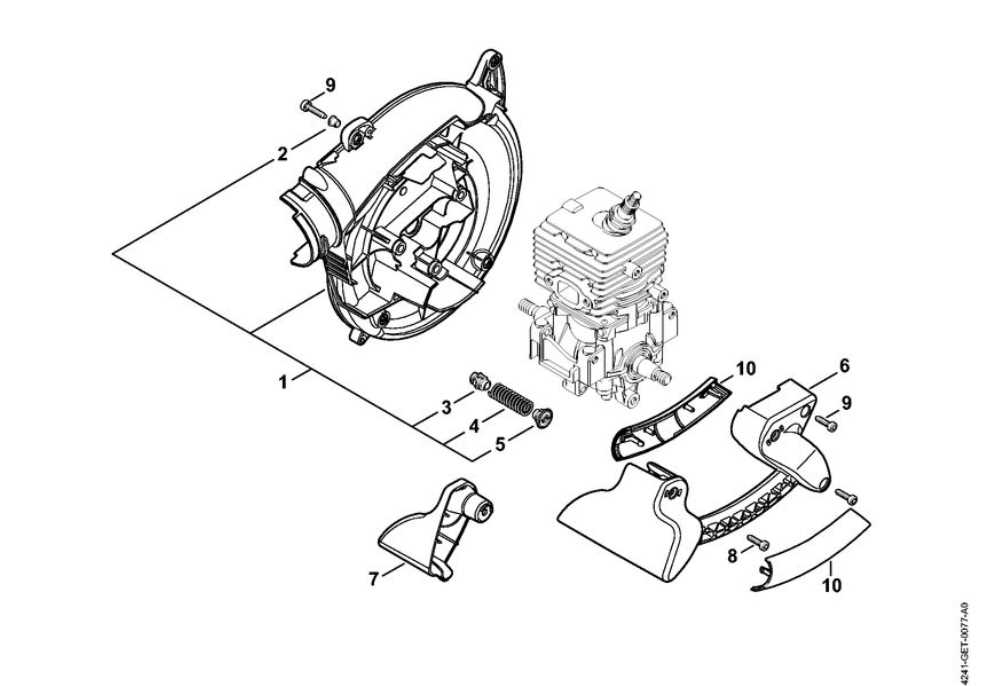

Key Components of Bg56c Model

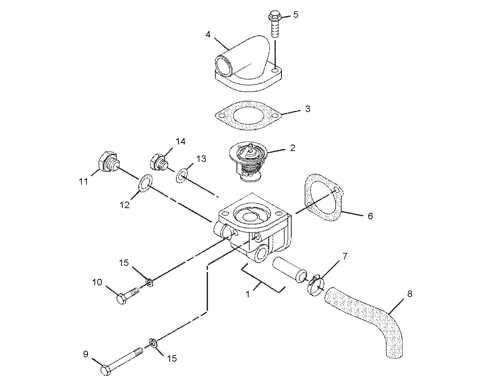

This section focuses on the essential elements that contribute to the functionality and efficiency of the model. Understanding these fundamental parts is crucial for effective maintenance and performance enhancement.

| Component | Description |

|---|---|

| Engine | The powerhouse driving the entire mechanism, ensuring optimal performance. |

| Chassis | The structural framework that supports various components, providing stability. |

| Control System | A sophisticated interface allowing user interaction and system regulation. |

| Transmission | Facilitates power transfer, enabling smooth operation across different speeds. |

| Fuel System | Ensures a reliable supply of energy, crucial for uninterrupted functioning. |

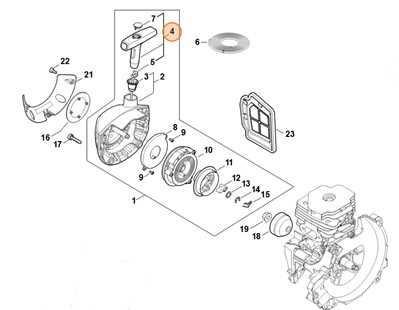

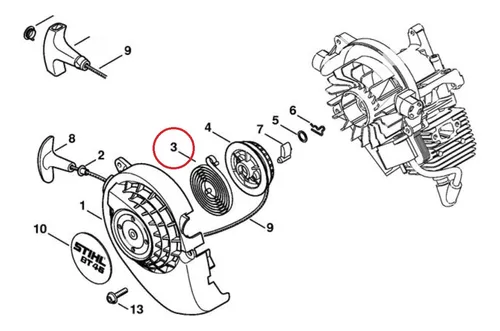

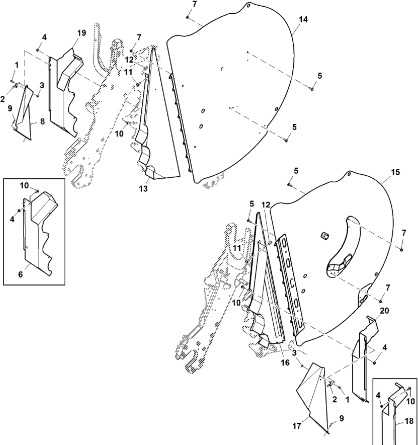

How to Read Parts Diagrams

Understanding visual schematics is essential for anyone involved in assembly, maintenance, or repair tasks. These illustrations serve as guides, presenting a detailed layout of components and their interconnections. By familiarizing yourself with the symbols and notations used, you can effectively navigate the complexities of any mechanical system.

| Element | Description |

|---|---|

| Legend | Contains symbols and their meanings, essential for interpreting the visuals. |

| Reference Numbers | Indicate specific items in the accompanying list, linking visuals to descriptions. |

| Connections | Show how various parts fit together, highlighting assembly or installation sequences. |

| Orientation | Indicates the viewpoint from which the illustration is made, crucial for proper assembly. |

By mastering these elements, you can delve deeper into the workings of any system, leading to more efficient troubleshooting and repair processes.

Common Issues in Bg56c Parts

When dealing with mechanical components, certain challenges frequently arise that can hinder optimal performance. Understanding these issues can help in maintaining functionality and prolonging the lifespan of the equipment.

Frequent Malfunctions

Components can experience wear and tear over time, leading to breakdowns. Regular inspections can help identify these problems early.

Material Degradation

The quality of materials used can significantly affect durability. Poor-quality parts are more susceptible to failure and can lead to costly repairs.

| Issue | Description | Solution |

|---|---|---|

| Wear | Components lose effectiveness due to repeated use. | Regular maintenance and timely replacements. |

| Corrosion | Oxidation of metal parts can lead to failure. | Use protective coatings and store in dry conditions. |

| Misalignment | Improper alignment can cause excessive friction. | Adjust and realign during servicing. |

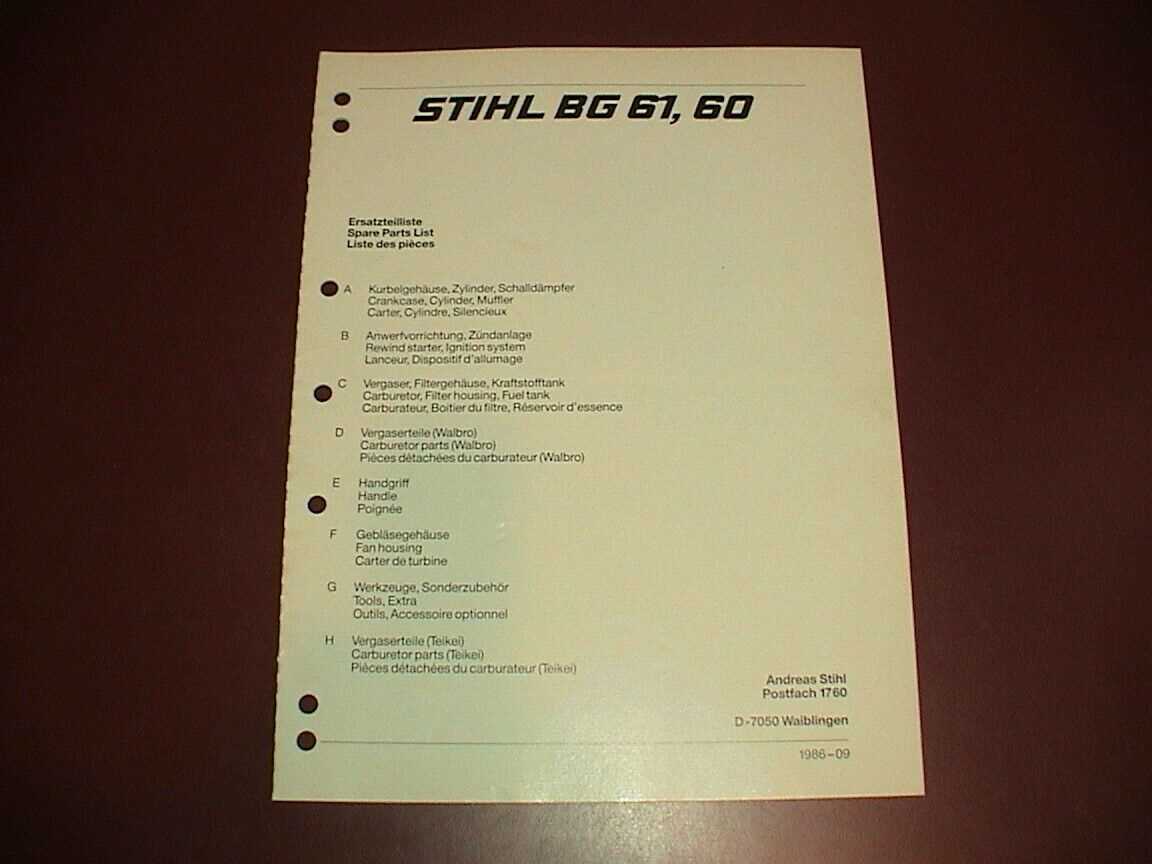

Where to Find Accurate Diagrams

Locating precise illustrations is essential for effective maintenance and repair tasks. Numerous resources can aid in acquiring reliable visuals that enhance understanding and facilitate proper assembly.

- Manufacturer Websites: Start with the official sites of the equipment’s producer. They often provide comprehensive resources.

- Technical Manuals: Access user guides or technical documents that accompany the equipment; these typically contain valuable visuals.

- Online Forums: Engage with community discussions where enthusiasts and professionals share resources and tips.

- Specialized Retailers: Explore retailers that specialize in related tools or machinery; they often have diagrams available for reference.

- Library Resources: Consider visiting local libraries or digital archives that may house reference books or technical publications.

Benefits of Using Parts Diagrams

Utilizing visual representations of components greatly enhances understanding and efficiency in various tasks. These illustrations serve as invaluable tools for both beginners and experts, facilitating clearer communication and quicker problem-solving.

Enhanced Clarity

- Visual aids simplify complex systems.

- They help identify components quickly.

- Eliminate confusion by providing a clear reference.

Improved Maintenance

- Streamline repair processes by showing necessary elements.

- Facilitate accurate ordering of replacements.

- Ensure correct assembly by following visual guides.

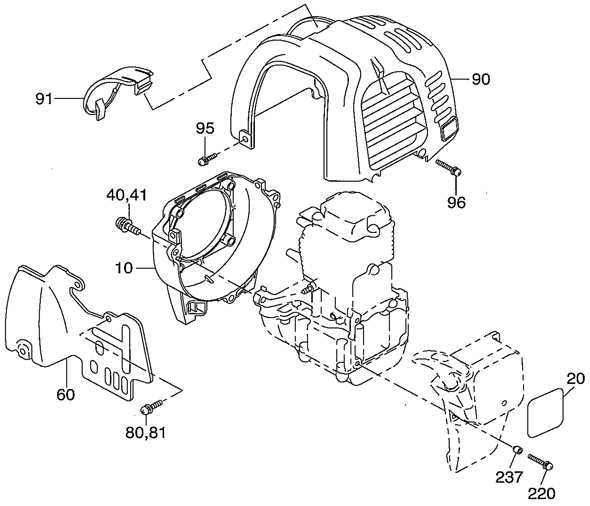

Maintenance Tips for Bg56c Equipment

Proper upkeep of machinery is crucial for ensuring optimal performance and longevity. Regular maintenance not only helps prevent unexpected breakdowns but also enhances efficiency. Below are essential practices to keep your equipment running smoothly.

Routine Inspection

Conducting regular inspections is vital for identifying potential issues early. Here are key areas to focus on:

- Check for wear and tear on critical components.

- Inspect fluid levels and replenish as necessary.

- Look for signs of leaks or corrosion.

- Examine filters and replace them according to the schedule.

Cleaning Procedures

Maintaining cleanliness can significantly impact performance. Follow these steps:

- Remove debris from the equipment after each use.

- Use appropriate cleaning agents for various surfaces.

- Ensure air intakes are free from obstructions.

- Regularly clean or replace spark plugs and ignition components.

Comparing Bg56c with Other Models

When evaluating various models within the same category, it’s essential to analyze their features, efficiency, and overall performance. This comparison not only highlights strengths and weaknesses but also guides potential users in making informed choices.

Key Features

- Engine Power: Examining the horsepower and torque specifications.

- Weight and Portability: How easily each model can be transported and handled.

- Fuel Efficiency: Comparing consumption rates and operational costs.

Performance Analysis

- Durability: Assessing materials used and longevity in various conditions.

- Ease of Maintenance: Evaluating how simple it is to service and replace components.

- User Reviews: Gathering feedback from real-world users to gauge satisfaction.

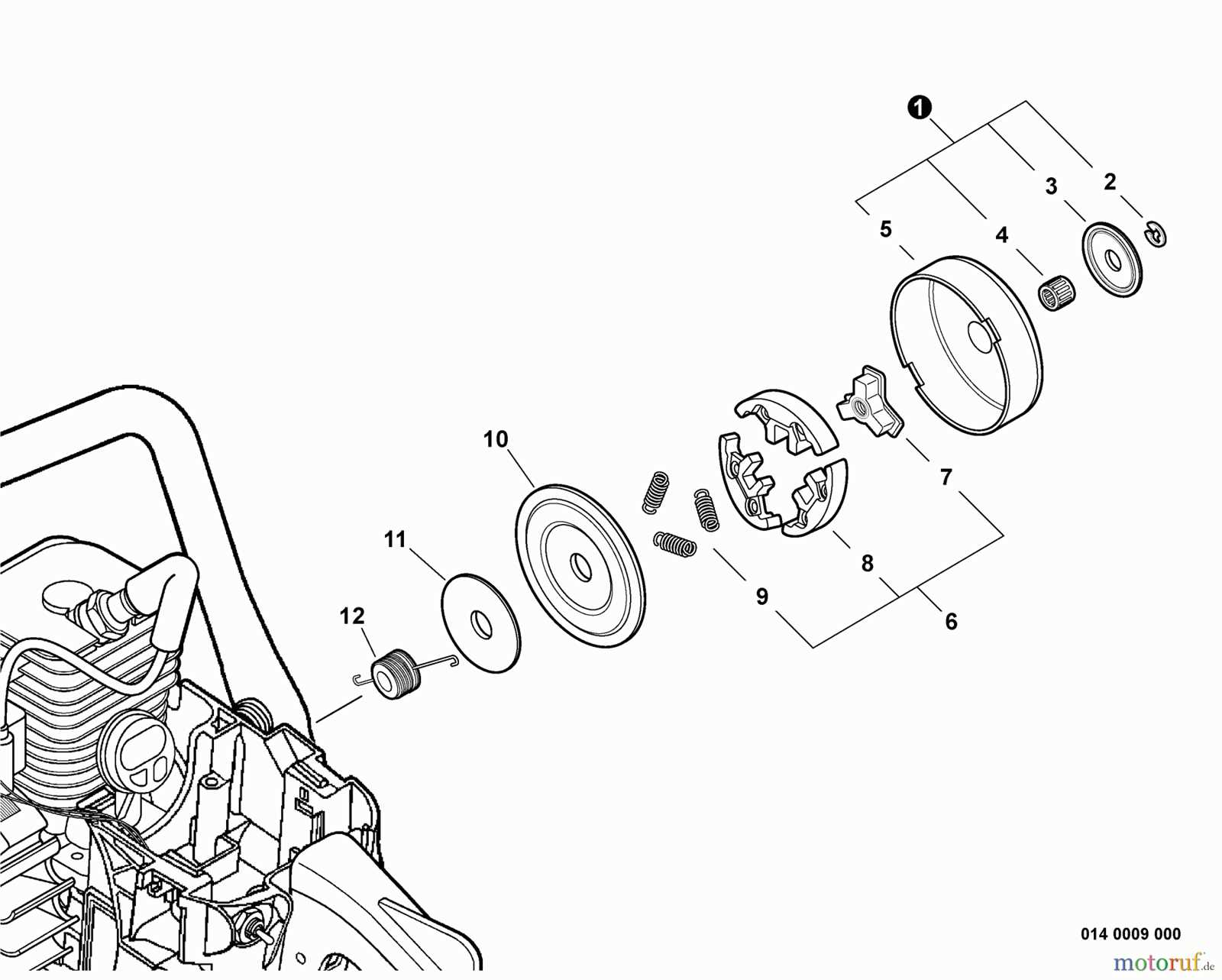

Replacing Parts: A Step-by-Step Guide

When it comes to maintaining and improving machinery, understanding the replacement process is crucial. This guide aims to provide a comprehensive approach to swapping out components, ensuring efficiency and functionality. By following these steps, you can enhance the lifespan and performance of your equipment.

Preparation and Tools

Before starting the replacement process, gather all necessary tools and materials. Ensure you have a clean workspace and proper safety gear. Familiarize yourself with the components involved and consult any available documentation for reference. This preparation will streamline the process and minimize potential errors.

Step-by-Step Replacement Process

Begin by disconnecting the equipment from its power source to ensure safety. Carefully remove the old component, taking note of its orientation and connections. This will help you install the new piece correctly. Place the new component in position, ensuring all connections are secure. Finally, restore the power and test the equipment to confirm everything functions as intended. Remember, taking your time and following these steps will lead to a successful replacement.

Tools Needed for Repairs

When tackling mechanical issues, having the right tools is crucial for efficient and effective repairs. The appropriate instruments not only streamline the process but also enhance safety and precision. Understanding which equipment to gather can make all the difference in successfully restoring functionality.

Essential Instruments

Start with a basic toolkit that includes screwdrivers, wrenches, and pliers. These tools serve as the foundation for most repair tasks. A sturdy multimeter is also vital for diagnosing electrical problems, while jack stands provide stability when working underneath equipment.

Advanced Equipment

For more intricate repairs, consider acquiring specialized tools like a torque wrench for precise tightening and a parts cleaner to maintain cleanliness. Investing in quality gear ensures durability and reliability during your projects.

FAQs about Bg56c Components

This section addresses common inquiries related to various elements found in specific equipment. Understanding these components can enhance your experience and ensure proper usage.

- What types of elements are typically included?

Commonly, you will find mechanical parts, electrical components, and structural elements.

- How do I identify a faulty element?

Look for signs of wear, unusual noises, or performance issues.

- Where can I find replacement items?

Authorized dealers and online retailers often stock compatible components.

- Are there any specific maintenance tips?

Regular cleaning and inspections can prolong the lifespan of these items.

- Can I upgrade components for better performance?

Yes, certain upgrades can enhance efficiency and functionality.

Getting Help from Professionals

When faced with intricate machinery issues, seeking assistance from experts can be invaluable. Professionals possess the knowledge and experience necessary to diagnose problems accurately and provide effective solutions. Their insights often save time and prevent further complications.

Engaging specialists not only ensures that tasks are completed efficiently but also offers peace of mind. These individuals understand the nuances of various systems and can deliver tailored advice. Moreover, their access to advanced tools and resources enhances the quality of service.

In situations where self-service proves challenging, consulting with knowledgeable individuals can be the ultimate approach. Their expertise helps in navigating complex repairs or maintenance, leading to optimal performance and longevity of the equipment.