Understanding how various elements of a device come together ensures easier maintenance and troubleshooting. By familiarizing yourself with the layout of the different components, it becomes simpler to identify which part may require attention or replacement.

Efficient upkeep starts with recognizing the individual elements of your machine. With regular use, certain components may experience wear, making it crucial to know where everything is located. This awareness allows for timely interventions, ensuring the longevity and performance of the equipment.

Each piece plays a vital role in the overall functionality. By becoming more knowledgeable about the inner workings, you’ll not only

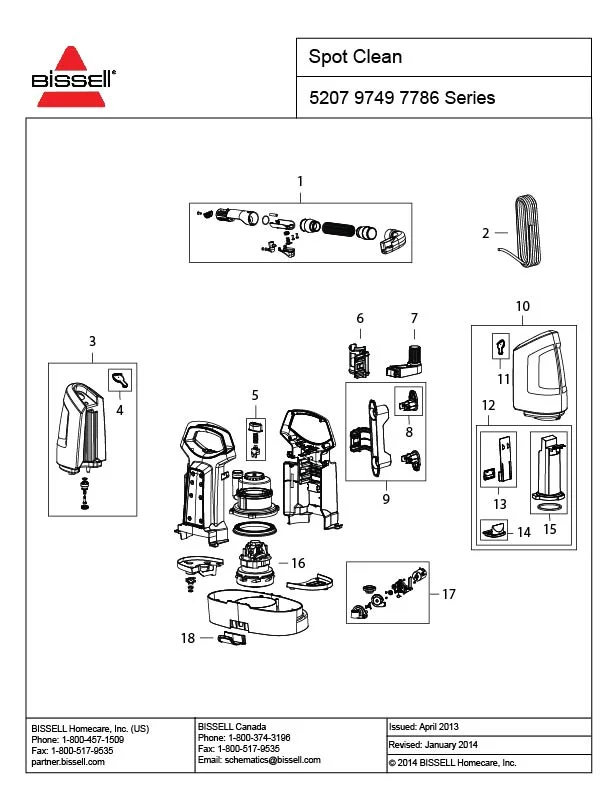

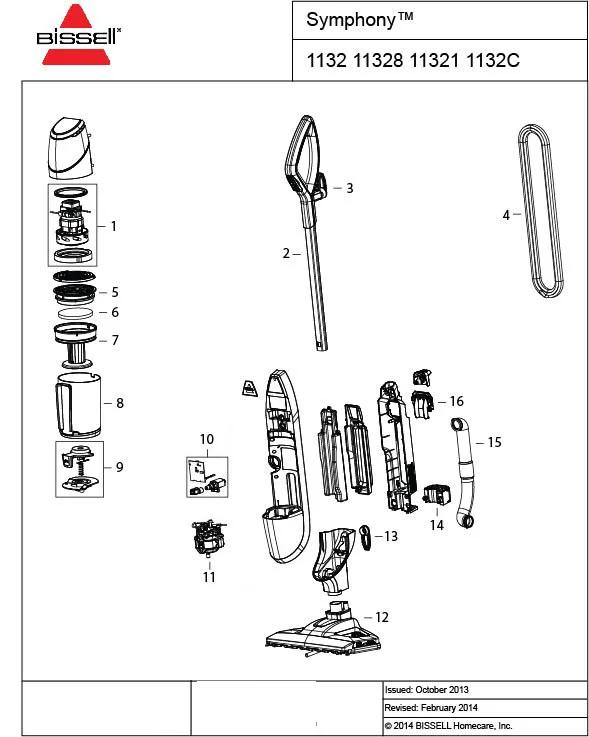

Bissell Spotbot Parts Overview

This section provides a detailed look at the components and features of the cleaning device. Each element plays a crucial role in ensuring the machine functions efficiently. By understanding the different elements, users can easily identify the areas that may need attention or replacement over time.

- Cleaning mechanism: The central system responsible for tackling dirt and stains on various surfaces.

- Liquid reservoir: A container designed to hold cleaning solutions or water for effective cleaning.

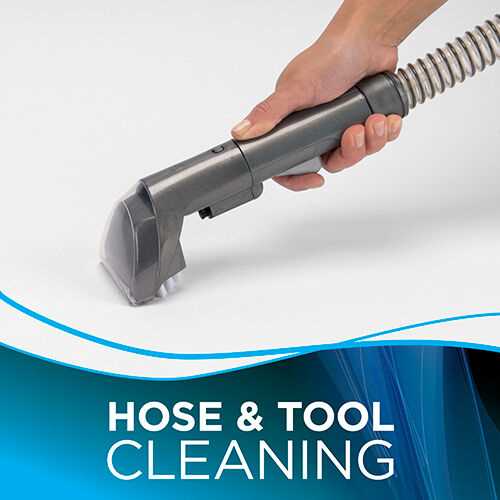

- Hose and attachment system: Flexible tubing and nozzles that allow for targeted cleaning in hard-to-reach spots.

- Control panel: The interface for adjusting settings and modes for different cleaning needs.

- Brush system: A set of rotating brushes that work to scrub and lift dirt from surfaces.

- Collection tank: A receptacle that stores dirty water and debris after cleaning is completed.

By familiarizing oneself with these key elements, it becomes easier to maintain the device and keep it running smoothly for an extended period.

Understanding Key Components Functionality

Each device is composed of various essential elements that work together to ensure proper operation. Recognizing how these components interact with one another is crucial for efficient maintenance and troubleshooting. Every part has a specific role, contributing to the overall performance and longevity of the machine.

Motor and Pump: The motor generates power that drives the entire mechanism, while the pump is responsible for controlling the flow of liquids. Together, they provide the necessary force for various functions, ensuring smooth operation.

Cleaning Solution Dispenser: This element releases cleaning liquid at the appropriate time and in the right amount, aiding in removing dirt and stains. Its precision contributes to the effectiveness of the cleaning process.

Brush System: The rotating brushes scrub surfaces, helping to lift and remove debris. These brushes are crucial for thorough cleaning, as they agitate the dirt and make it easier to extract.

Understanding how each component functions not only improves performance but also helps in identifying potential issues before they become serious problems.

How to Identify Replacement Parts

Recognizing the correct components for repair can significantly extend the lifespan of any device. By learning how to distinguish between different elements, you ensure proper maintenance and avoid further issues. Understanding the key differences and where to find the right solutions is essential.

Steps to Follow

- Examine the manual for specifications of each item that needs replacing.

- Look for identifying marks or labels on the existing components.

- Compare the size, shape, and connection points to ensure compatibility.

Using Online Resources

- Search for the device model number on reliable sources.

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the continued performance and durability of your device. By following a few key practices, you can greatly extend its lifespan and avoid potential issues in the future.

- Regularly clean all accessible components to prevent buildup of dirt and debris.

- Inspect hoses and connections for wear or blockages that might hinder performance.

- Replace filters periodically to maintain optimal efficiency and airflow.

- Ensure

Essential Cleaning Solutions Compatibility

The efficiency of cleaning devices depends heavily on the compatibility of various solutions used for different tasks. Understanding the appropriate solution for specific situations ensures optimal performance and long-lasting use. Selecting the right product is crucial for maintaining both the equipment and the surfaces being treated.

Types of Cleaning Solutions

- General-purpose cleaners for everyday use

- Specialized formulas for pet-related messes

- Deep cleaning agents for heavy stains and dirt

Compatibility Factors to Consider

- Surface type: Ensure the solution is safe for carpets, tiles

Troubleshooting Common Mechanism Issues

When encountering difficulties with your cleaning device, it’s essential to identify and resolve common mechanical problems effectively. Understanding these issues can help ensure optimal performance and prolong the lifespan of the appliance.

1. Lack of Suction: If the unit is not picking up debris as expected, check for clogs in the hose or filters. Make sure all connections are secure and that the collection tank is not full.

2. Unusual Noises: Strange sounds during operation may indicate loose parts or wear. Inspect the moving components and ensure everything is properly assembled.

3. Leakage: If you notice fluid escaping from the device, it could be due to damaged seals or improper assembly. Examine the seals and tighten any loose connections to prevent spills.

4. Power Issues: If the machine fails to start, check the power source and ensure the cord is undamaged. Resetting the device may also resolve temporary electrical issues.

By addressing these common problems promptly, you can maintain the functionality and efficiency of your cleaning equipment.

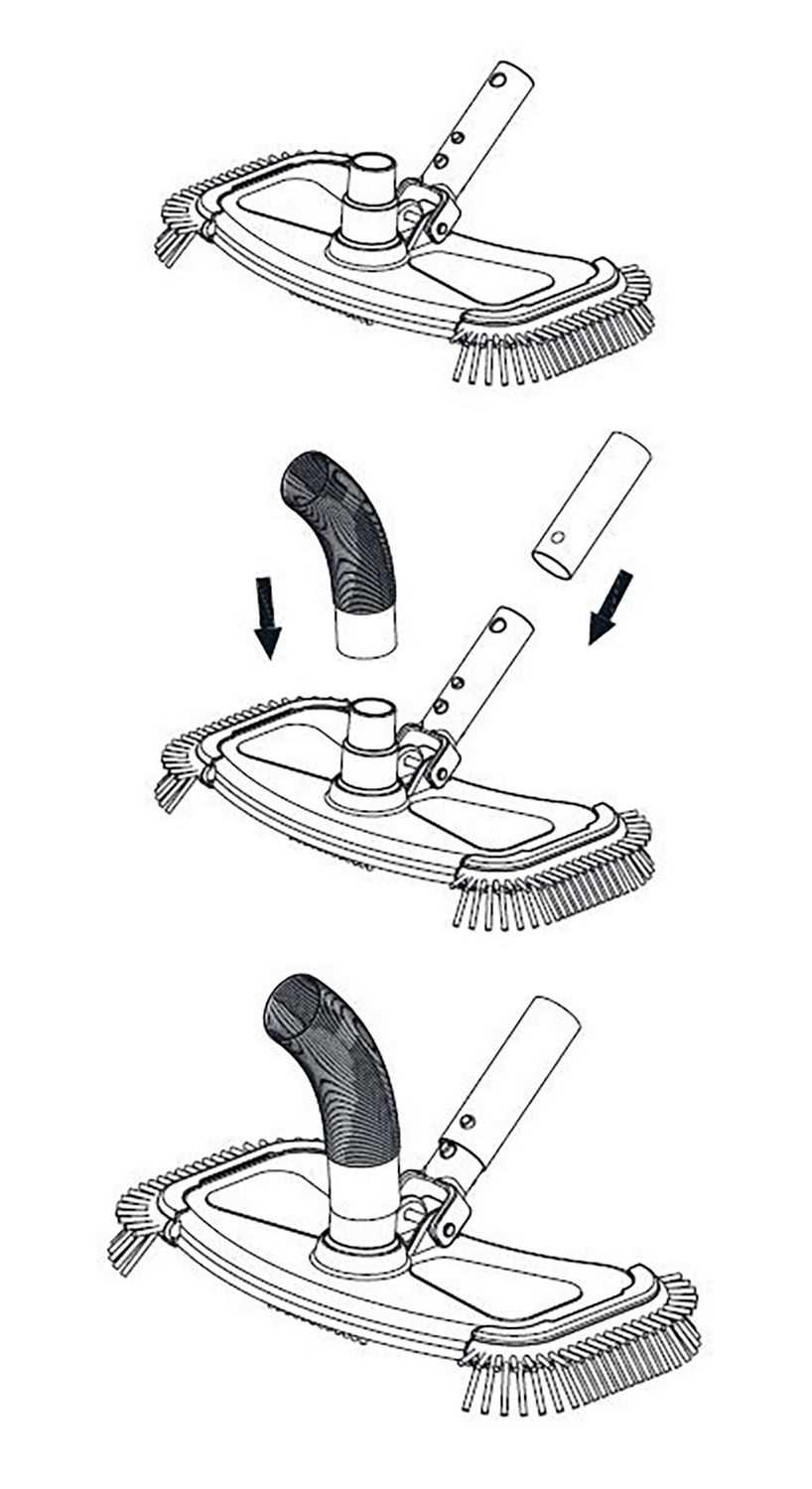

Proper Assembly of the Device

Assembling the unit correctly is crucial for its optimal performance. Understanding the various components and how they fit together will ensure effective operation and longevity. This section provides insights into the assembly process, guiding users through each step to achieve a seamless setup.

Essential Steps for Assembly

Follow these key steps to assemble your device efficiently:

- Begin by organizing all components on a clean surface.

- Identify the main body and ensure all attachments are accessible.

- Align each component according to the provided instructions.

- Securely fasten all parts, ensuring there are no loose connections.

- Perform a final inspection to confirm that everything is in place.

Component Overview

The following table summarizes the essential parts involved in the assembly:

Component Description Main Body The core structure housing the motor and controls. Cleaning Tank Container for holding cleaning solution and dirty water. Hose Attachment Flexible tube used for targeted cleaning in hard-to-reach areas. Brush Head Component designed to agitate dirt and stains for effective cleaning. Optimal Usage for Deep Cleaning

Effective cleaning of surfaces often requires the right techniques and tools to achieve the best results. Understanding the methods and strategies for utilizing specialized cleaning equipment can greatly enhance the overall efficiency of the process. This section aims to provide insights into the optimal practices for deep cleaning, ensuring thorough removal of stains and dirt from various surfaces.

Preparation is Key: Before starting the cleaning process, it is essential to prepare the area adequately. Remove any loose debris or items from the surface, allowing for easier access and a more efficient cleaning experience.

Choose the Right Solution: Selecting the appropriate cleaning solution is crucial for effective results. Look for formulations that are designed specifically for deep cleaning, as these products are often more effective in breaking down tough stains and grime.

Technique Matters: Employing the right technique can make a significant difference. Use a methodical approach, focusing on one section at a time to ensure that every area receives adequate attention. This helps in achieving a more uniform clean and prevents re-soiling of already cleaned areas.

Follow-Up Maintenance: After completing the deep cleaning process, it is important to follow up with routine maintenance. Regular upkeep helps in preserving the cleanliness achieved and minimizes the need for extensive cleaning sessions in the future.

By adhering to these guidelines, individuals can maximize the effectiveness of their cleaning efforts, ensuring a pristine and well-maintained environment.

Disassembling Techniques for Repairs

Understanding the methods for dismantling a device is essential for effective maintenance and troubleshooting. By following systematic procedures, users can identify issues and perform necessary repairs efficiently.

Before starting the disassembly process, it is crucial to gather the right tools. Here are some commonly used tools for this purpose:

- Screwdrivers (flathead and Phillips)

- Wrenches of various sizes

- Pliers

- Plastic prying tools

- Organizational containers for small parts

To ensure a smooth disassembly, consider the following techniques:

- Preparation: Clear the workspace and gather all necessary tools before beginning.

- Document the process: Take photos or notes at each step to assist in reassembly.

- Work systematically: Remove components in a logical order, starting from the outer parts and moving inward.

- Label parts: Use labels or containers to keep track of screws and small components during the process.

- Handle with care: Avoid using excessive force when removing parts to prevent damage.

By implementing these strategies, individuals can effectively address issues and extend the lifespan of their devices.

Materials Used in Parts Manufacturing

The selection of materials is crucial in the creation of components, influencing not only durability but also performance and efficiency. Various substances are utilized to achieve the desired properties, catering to different functional requirements.

Plastics are commonly favored for their lightweight and versatile nature, offering resistance to moisture and chemicals. These materials can be molded into intricate shapes, making them ideal for complex designs.

Metals, such as steel and aluminum, are often chosen for their strength and resilience. They provide structural integrity, essential for components subjected to stress or strain. Additionally, metals can withstand high temperatures, making them suitable for various applications.

Another category includes composites, which combine multiple materials to leverage their respective advantages. This innovation results in components that are both lightweight and robust, ideal for modern manufacturing needs.

Understanding the properties and benefits of these materials aids manufacturers in selecting the appropriate substances to enhance functionality and longevity in production.

Where to Purchase Spare Parts

Finding the right components for your cleaning device is essential for maintaining its performance. There are several avenues to explore when seeking replacements, ensuring that you can easily acquire what you need without hassle.

Online Retailers

The internet offers a vast selection of options for purchasing necessary components. Here are some popular online platforms:

- Amazon – A wide range of options and user reviews to assist in your selection.

- eBay – Both new and used items can be found at competitive prices.

- Specialized websites – Certain retailers focus specifically on cleaning equipment, offering tailored solutions.

Local Stores

If you prefer a hands-on approach, consider visiting nearby shops. Look for:

- Home improvement stores – Often carry a selection of maintenance supplies.

- Electronics retailers – May stock specific components for various models.

- Appliance repair shops – These can be invaluable for hard-to-find items.

Regardless of the method chosen, ensure to verify compatibility with your model to achieve optimal functionality.

Upgrading Your Bissell Spotbot

Enhancing the functionality of your cleaning device can significantly improve its efficiency and effectiveness. Upgrades may include replacing worn-out components, adding new features, or utilizing advanced accessories to optimize performance. These modifications not only extend the lifespan of your equipment but also ensure that it operates at its best, meeting your cleaning needs more effectively.

Key Components for Improvement

- Replacement Brushes: Consider high-quality brushes that are designed to tackle tough stains more effectively.

- Advanced Cleaning Solutions: Using specialized cleaning formulas can enhance stain removal capabilities.

- Additional Accessories: Accessories such as extension hoses or upholstery tools can broaden the range of tasks your device can handle.

Steps to Upgrade

- Assess Current Condition: Examine the existing components for wear and tear.

- Research Options: Look for compatible upgrades that enhance functionality.

- Purchase Upgrades: Acquire necessary parts or accessories from reputable suppliers.

- Install New Components: Follow guidelines for installing any new features or parts securely.

- Test Functionality: After installation, conduct a thorough test to ensure everything operates smoothly.