In the world of mechanical tools, particularly those designed for elevating heavy loads, a comprehensive understanding of their individual elements is crucial. Each mechanism comprises a variety of intricate components, all working together to ensure efficiency and safety during operation. A clear visual representation of these elements can greatly enhance one’s ability to operate and maintain such devices effectively.

When dealing with complex lifting apparatus, recognizing the specific roles and relationships of each part is fundamental. An organized schematic can serve as an invaluable resource, allowing users to pinpoint areas that require attention, whether for routine maintenance or troubleshooting. Such illustrations simplify the learning process, making it accessible for both novices and seasoned professionals.

Moreover, familiarity with the inner workings of these tools contributes to improved performance and longevity. Users who invest time in understanding how each component interacts are better equipped to handle challenges that may arise during use. This knowledge not only promotes safety but also fosters confidence in operating sophisticated machinery.

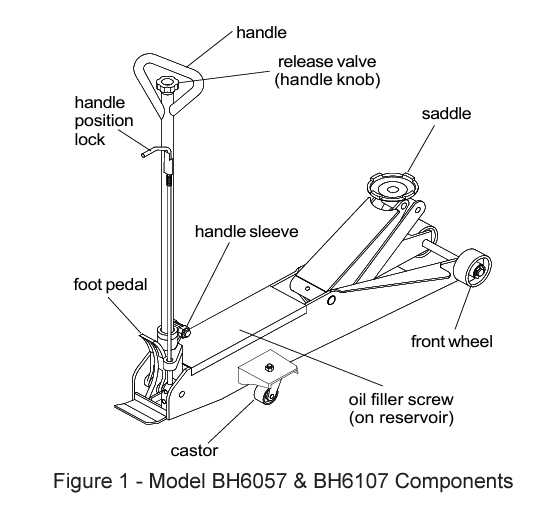

Understanding Blackhawk Jack Components

Exploring the essential elements of lifting mechanisms reveals a complex interplay of various components, each playing a crucial role in ensuring efficient operation and safety. Recognizing these individual pieces not only enhances comprehension but also aids in effective maintenance and troubleshooting.

| Component | Description |

|---|---|

| Frame | The robust structure that supports the entire assembly, providing stability and strength during operation. |

| Piston | A cylindrical part that moves up and down, generating the necessary force to lift heavy objects. |

| Hydraulic Fluid | The essential liquid that transmits power throughout the system, enabling smooth and efficient movement. |

| Release Valve | A critical safety feature that controls the descent of the lifted load, allowing for precise lowering. |

| Handle | The lever used to initiate lifting or lowering, designed for ergonomic operation and ease of use. |

Understanding these components contributes to a greater appreciation of their functionality and the importance of regular checks to ensure safety and performance in lifting applications.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in understanding complex systems. They serve as visual guides that facilitate effective communication, ensuring that users can interpret and apply information correctly. Clarity in these representations enhances user confidence and reduces the likelihood of errors during assembly or maintenance.

Enhancing Understanding

Detailed visuals provide a clearer perspective on components and their interactions. By breaking down intricate designs into understandable segments, they empower individuals to grasp the overall functionality with ease.

Minimizing Errors

When users can refer to exact visual aids, the chances of misinterpretation decrease significantly. This accuracy not only streamlines the process but also safeguards against potential mishaps, leading to safer and more efficient operations.

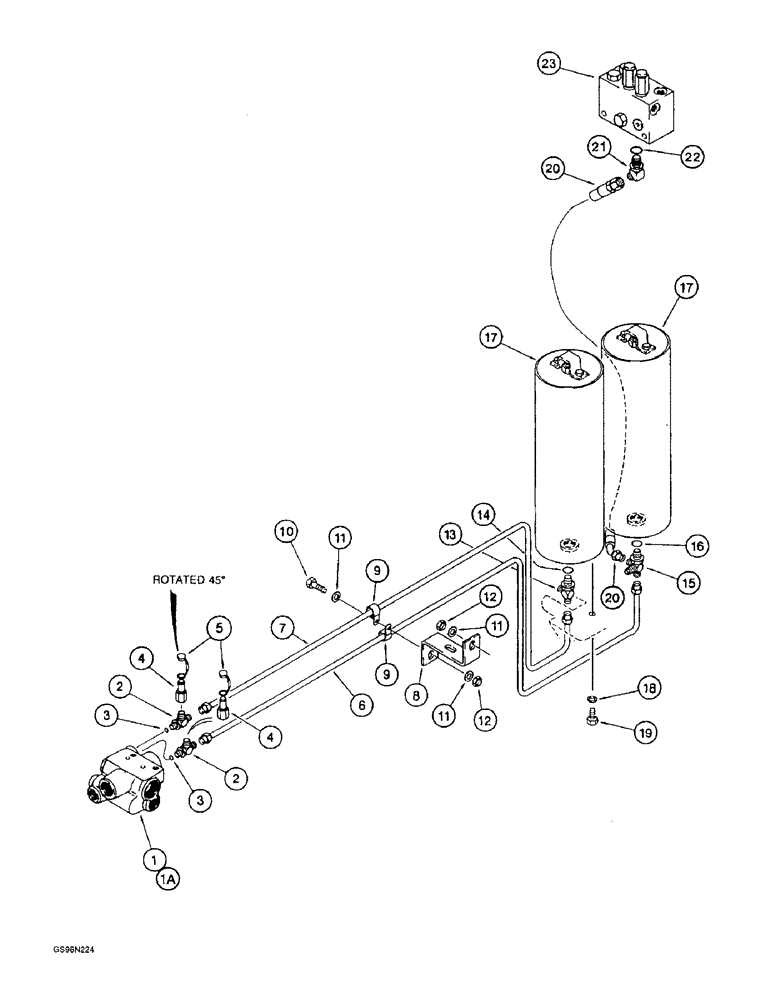

Common Parts of Blackhawk Jacks

This section explores the essential components found in hydraulic lifting devices, focusing on their functionality and importance. Understanding these elements is crucial for both maintenance and effective operation.

Key Components

One of the primary elements is the cylinder, which facilitates the lifting mechanism by converting hydraulic pressure into mechanical force. Another significant part is the piston, which moves within the cylinder to raise or lower the load. Additionally, the base plate provides stability and support during operation, ensuring safety and efficiency.

Supporting Features

Among the supporting features, the release valve plays a vital role by controlling the descent of the load, allowing for precise adjustments. Furthermore, hoses connect the hydraulic fluid reservoir to the cylinder, enabling the transfer of fluid that powers the entire system. Regular inspection of these components ensures optimal performance and longevity of the equipment.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular care and attention. Implementing a structured maintenance routine not only enhances performance but also minimizes the likelihood of unexpected failures. Here are some effective strategies to keep your device in top shape.

Regular Inspections

- Check for wear and tear: Inspect components for any signs of damage or degradation.

- Look for leaks: Ensure that there are no fluid leaks that could compromise functionality.

- Monitor connections: Tighten any loose bolts or fasteners to maintain stability.

Proper Usage

- Follow weight limits: Always adhere to the manufacturer’s specified weight guidelines.

- Avoid overloading: Distribute weight evenly to prevent undue stress on the structure.

- Use as intended: Ensure that the device is utilized only for its designed purpose.

By following these simple yet effective maintenance tips, you can significantly enhance the durability and reliability of your equipment, ensuring it serves you well for years to come.

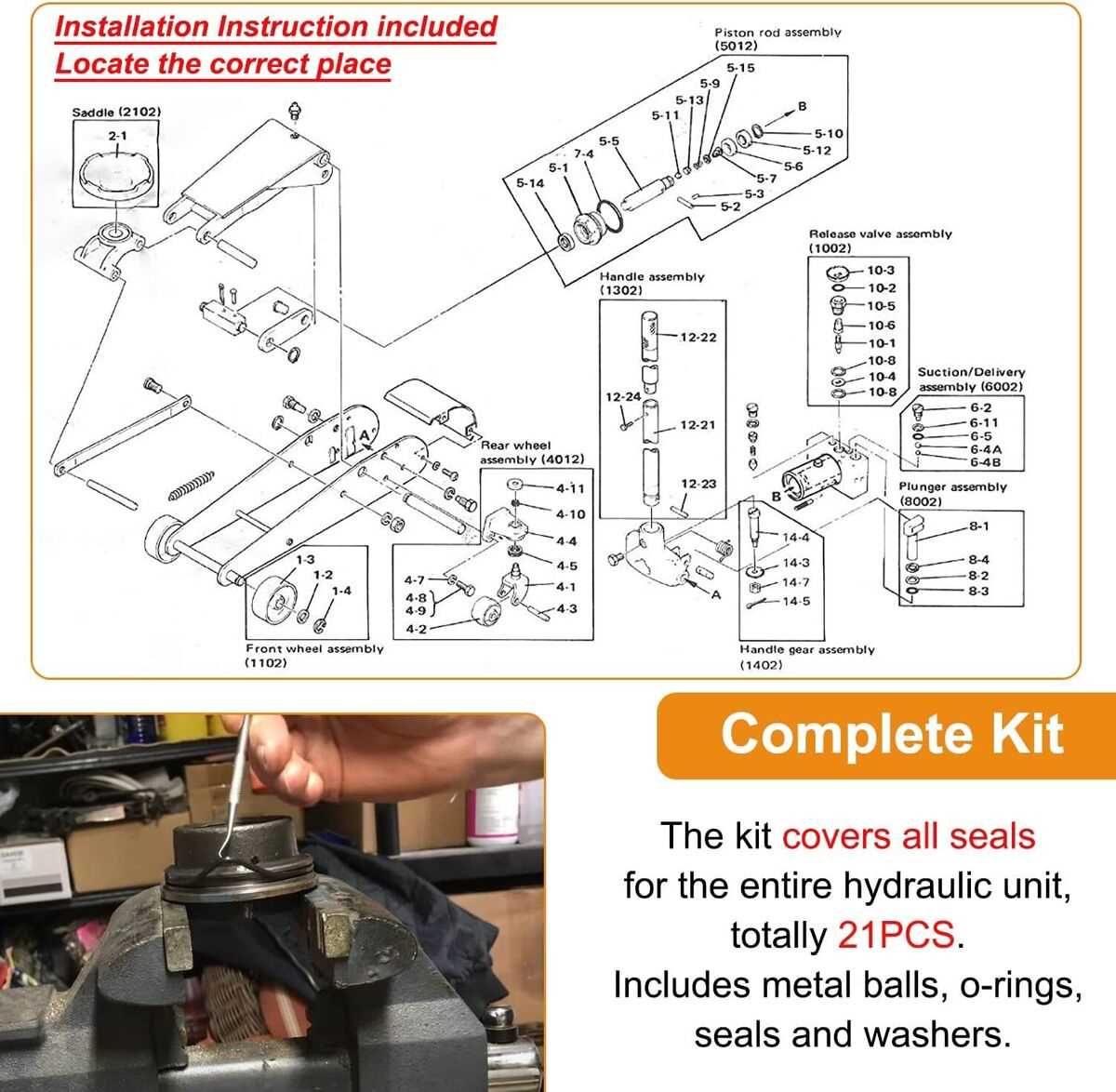

How to Read Parts Diagrams

Understanding visual schematics is essential for anyone looking to maintain or repair equipment. These illustrations serve as a guide, helping users identify components and their relationships. Mastering the art of interpreting these images can streamline the troubleshooting process and enhance repair efficiency.

Key Components of Visual Schematics

- Labels: Each element usually has a corresponding label that indicates its name or part number.

- Connections: Lines or arrows show how parts connect or interact with each other.

- Groupings: Components may be organized into clusters, indicating which parts work together.

Steps to Effectively Interpret Schematics

- Familiarize Yourself: Begin by getting to know the overall layout and design of the schematic.

- Identify Components: Look for labels and familiarize yourself with each part’s function.

- Analyze Connections: Trace the lines to understand how each piece interacts within the assembly.

- Refer to Manuals: Use user manuals or guides for additional context and information about specific components.

By following these guidelines, anyone can become proficient in reading and understanding these crucial illustrations, ultimately leading to more successful maintenance and repairs.

Identifying Replacement Parts Easily

Finding the right components for your equipment can often seem overwhelming. Understanding the key aspects of each element is essential for ensuring seamless replacements. Here are some strategies to streamline the identification process.

Utilize Visual References

- Examine detailed illustrations available in manuals.

- Search for online resources with annotated images.

- Keep a reference list of essential components and their features.

Leverage Online Communities

- Join forums dedicated to equipment enthusiasts.

- Ask for advice or share experiences with other users.

- Participate in discussions about common issues and solutions.

By combining visual aids and community insights, locating the necessary elements becomes more manageable, ultimately enhancing your maintenance efforts.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that enhance the longevity and performance of your equipment. These elements are specifically designed to fit seamlessly and operate efficiently, ensuring reliability and safety in various applications.

Quality Assurance

OEM components undergo rigorous testing and adhere to strict quality standards, providing peace of mind that the product will perform as intended. This consistency in quality translates to fewer failures and a more dependable experience overall.

Warranty Protection

Choosing original components often helps maintain warranty coverage on your equipment. Manufacturers typically require the use of their specific parts for any warranty claims, protecting your investment and ensuring that repairs are handled appropriately.

Common Issues and Solutions

When utilizing lifting equipment, users may encounter various challenges that can impede performance and safety. Understanding these issues is crucial for ensuring effective operation and prolonging the lifespan of the apparatus.

Leakage Problems: Fluid leaks can significantly affect functionality. Regularly inspect seals and connections. If you notice any signs of fluid loss, consider replacing damaged components promptly.

Uneven Lifting: If the mechanism lifts unevenly, check for obstructions or ensure the load is balanced. Adjustments to the load distribution often resolve this issue.

Slow Operation: A sluggish response may indicate low hydraulic fluid levels. Refill as necessary and inspect for any blockages in the system.

Strange Noises: Unusual sounds can signal internal issues. If noises persist, consult a professional to diagnose potential mechanical failures.

Frequent Malfunctions: If breakdowns occur often, it may be time for a comprehensive inspection. Regular maintenance and servicing can prevent future complications.

Comparing Different Blackhawk Models

This section explores various designs of hydraulic lifting devices, highlighting their unique features and specifications. By examining the distinctions among these models, users can make informed choices based on their specific needs and applications.

When evaluating the different variants, consider the following key aspects:

- Weight Capacity: Different models support varying loads, essential for ensuring safety and efficiency.

- Height Range: The lifting range can significantly affect usability for different tasks.

- Construction Material: The materials used in fabrication can impact durability and performance.

- Portability: Some versions are designed for easy transport, while others may be stationary.

Each model offers specific advantages:

- Standard Model: Ideal for general use, it combines decent lifting power with a compact design.

- Heavy-Duty Variant: Designed for industrial applications, this version boasts higher capacity and robustness.

- Compact Design: Best suited for tight spaces, allowing for versatile applications without sacrificing performance.

- Electric Model: This option provides automatic operation, reducing manual effort and enhancing convenience.

Understanding these differences can aid users in selecting the appropriate lifting solution tailored to their specific operational requirements.

Safety Guidelines for Jack Usage

Ensuring safety during lifting operations is paramount to prevent accidents and injuries. Adhering to established protocols and best practices is essential for effective and secure use of lifting equipment.

Preparation and Inspection

Before commencing any lifting task, always conduct a thorough examination of the equipment. Look for signs of wear, damage, or malfunction, and ensure that all components are functioning properly. Never use damaged tools, as this can compromise safety.

Proper Technique

When positioning the lifting device, make sure it is stable and on a level surface. Always follow the manufacturer’s instructions regarding weight limits and usage guidelines. Additionally, maintain a clear area around the lift to prevent accidents and ensure that bystanders are at a safe distance.

Where to Find Quality Parts Online

In today’s digital age, sourcing high-quality components has become more accessible than ever. Whether you’re seeking replacements or upgrades, the internet offers a vast array of options. It’s essential to know where to look to ensure reliability and performance.

Online Marketplaces: Platforms like eBay and Amazon provide a wide selection of goods from various sellers. Always check reviews and ratings to gauge quality.

Specialized Retailers: Numerous websites focus exclusively on specific types of equipment, offering expert advice and specialized items. Research these sites for their reputation in the industry.

Manufacturer Websites: Purchasing directly from the source often guarantees authenticity and quality. Manufacturers usually have online catalogs for easy browsing.

Forums and Community Groups: Engaging in online communities can lead to recommendations for trustworthy vendors. Fellow enthusiasts often share their experiences and insights.

Ultimately, taking the time to explore these avenues will help you find the components that meet your needs effectively.