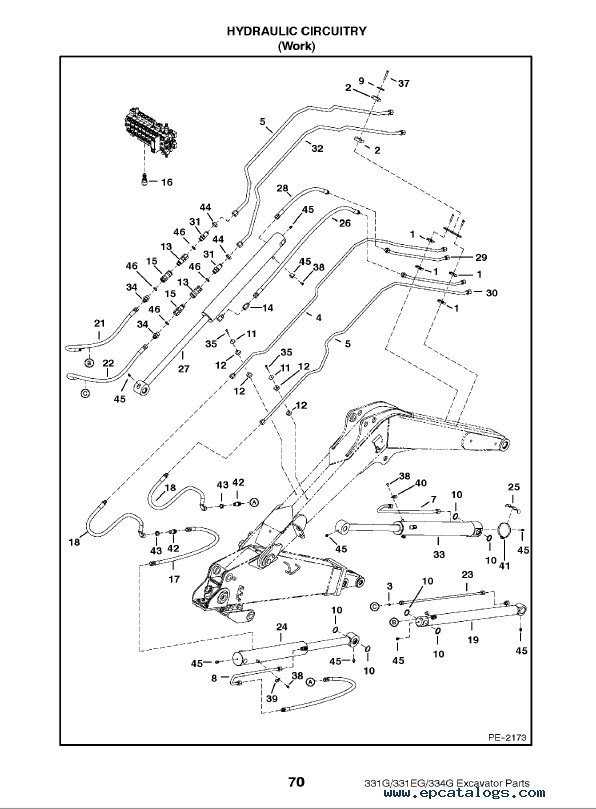

Efficient operation of various machinery relies on the precise coordination of numerous internal elements. When considering maintenance or troubleshooting, it is essential to have a clear understanding of how each section connects and interacts within the overall system. This knowledge not only ensures smooth functionality but also extends the lifespan of the equipment.

Examining the internal framework provides valuable insights into how each element works together. By studying the layout and structure, you can identify key sections that may require attention or replacement. Understanding these connections enables more efficient repair and upkeep, minimizing downtime and enhancing performance.

In addition, analyzing detailed configurations helps users and technicians foresee potential wear or malfunction areas. This proactive approach improves the long-term reliability of the equipment, ensuring that each individual part continues to work in harmony with the entire system.

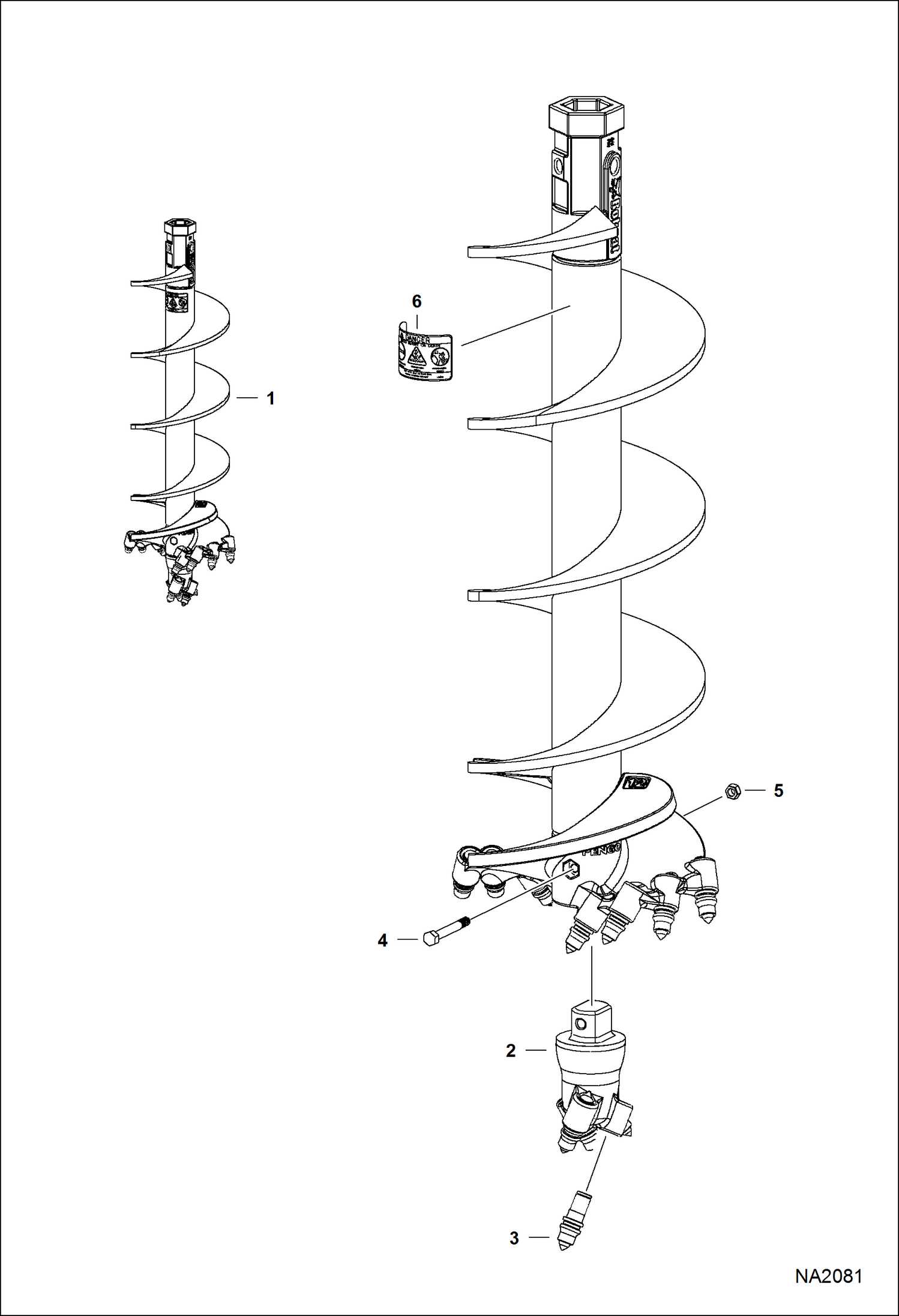

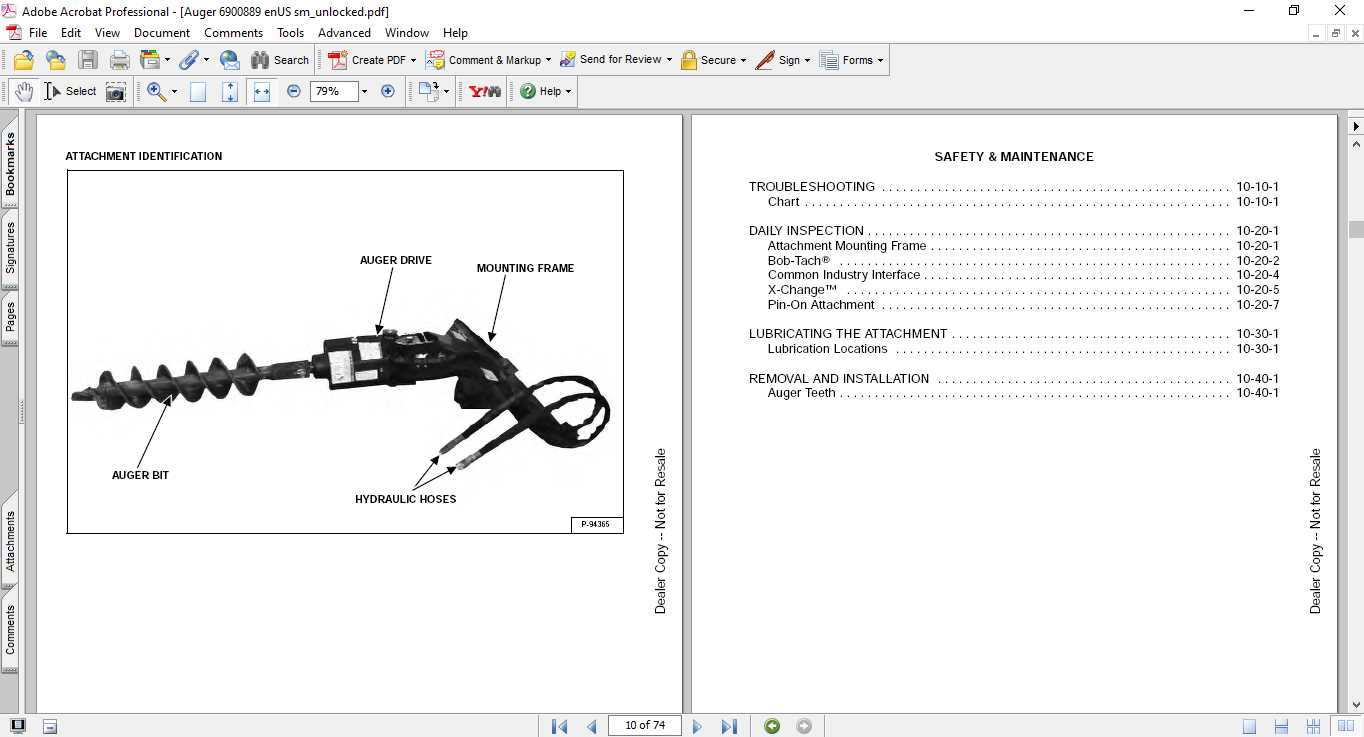

Understanding the Bobcat 30C Auger Components

Grasping the individual elements that make up this machinery is crucial for its efficient operation and maintenance. Each component plays a specific role in ensuring the device functions smoothly, providing both power and precision during its use. Familiarizing yourself with these elements will help extend the lifespan of the equipment and minimize downtime caused by wear and tear.

The main sections of the tool involve several interrelated mechanical parts that work together to deliver optimal performance. Below is a breakdown of these key components:

- Drive system: This element powers the tool, converting energy into motion. It serves as the heart of the device, enabling other parts to perform their tasks.

- Cutting edge: Responsible for direct interaction with the ground or material, this sharp component ensures precise and effective operation in various conditions.

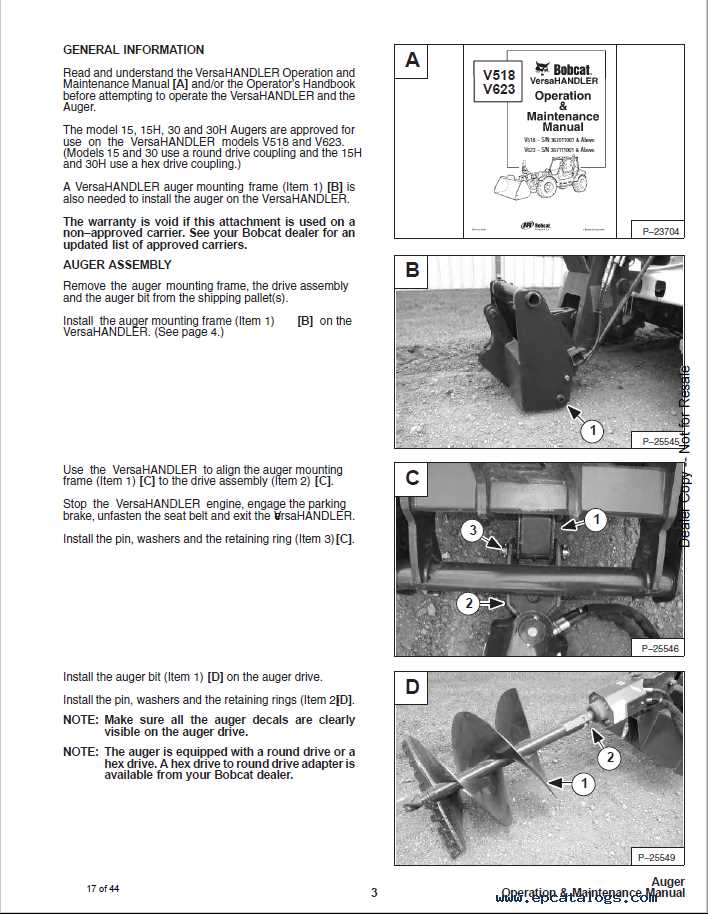

- Mounting frame: This section connects the equipment to other machinery, ensuring stability and alignment during use.

- Hydraulic connections: These channels allow fluid to flow, powering the system and ensuring smooth functionality across all mechanical parts.

Regular inspections of these critical areas will help detect any potential issues early, ensuring your equipment remains in top condition.

Main Functions of the Bobcat Auger System

The core system is designed to efficiently perform digging and drilling tasks, especially in challenging terrains. It allows for easy and precise ground penetration, making it suitable for a variety of construction and landscaping applications.

Efficient Ground Penetration

The primary purpose of this system is to ensure smooth and effective operation in both hard and soft soils. The machine adapts to different ground conditions, offering consistent performance regardless of the surface type.

- Optimized for drilling through compact materials

- Reduces effort and time required for excavation

- Provides control and precision in all weather conditions

Versatility in Applications

Its multifunctional design makes it an ideal choice for a wide range of tasks beyond digging. With the right adjustments, it can handle everything from post-hole installation to large-scale earthmoving projects.

- Suitable for fence installation and foundation work

- Handles complex landscaping jobs with ease

- Compatible with various attachments for extended usability

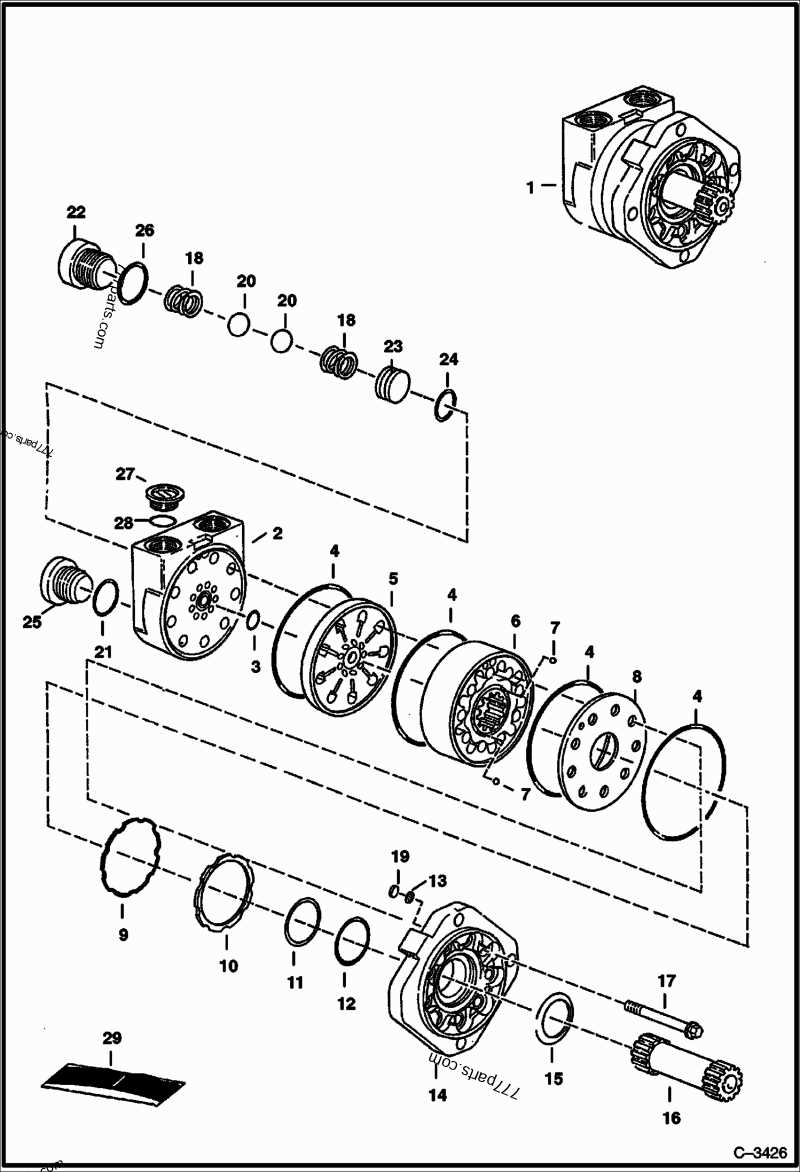

Key Elements of the Drive Assembly

The drive assembly is a crucial component responsible for the efficient operation of mechanical systems that rely on rotational motion. Its well-coordinated elements ensure the smooth transfer of power, enabling consistent and reliable performance across various applications. Understanding these key elements is essential for maintaining functionality and preventing potential issues.

Main Components

The drive assembly consists of several integral parts that work together to transmit force. These include the central drive mechanism, a gear system that adjusts torque, and a housing unit that protects the internal structure. Each element plays a vital role in maintaining proper alignment and functionality during operation.

Functionality and Maintenance

Ensuring that the drive assembly functions optimally requires regular inspection and maintenance. Key focus areas include checking the alignment of gears, lubricating moving parts, and ensuring that protective covers are intact. Proper upkeep will extend the lifespan of the assembly and prevent costly repairs.

Hydraulic Motor Parts and Their Roles

Hydraulic motors are key components in a variety of mechanical systems, driving motion through fluid power. The internal structure of these motors consists of several essential elements, each contributing to the motor’s functionality. Understanding the different components and their specific purposes helps to maintain efficient performance and reliability.

Main Components of Hydraulic Motors

The core of any hydraulic motor consists of multiple rotational elements that convert fluid pressure into mechanical motion. These include the rotor, which rotates under pressure, and the stator, which holds stationary components. Together, these parts work to generate torque and transfer power effectively.

Supporting Elements

In addition to the main moving parts, hydraulic motors rely on supporting components such as seals and bearings to ensure smooth operation and prevent leaks. These elements not only extend the life of the motor but also ensure optimal performance under high-pressure conditions.

Auger Bit Features and Specifications

The characteristics and technical details of drilling tools are essential for understanding their performance and versatility. These tools are designed to efficiently handle different types of soil, providing reliable and consistent results during operations.

Key Features

Drilling tools are built with various features aimed at improving efficiency and durability. Some include reinforced cutting edges, which increase their longevity in tougher materials. Additionally, their design allows for optimal penetration, ensuring smoother operation. Compatibility with different attachments also adds to their flexibility in diverse environments.

Technical Specifications

| Specification | Detail |

|---|---|

| Cutting Diameter | 6 to 24 inches |

| Length | 48 to 72 inches |

| Material | High-strength steel |

| Weight | 50 to 200 lbs |

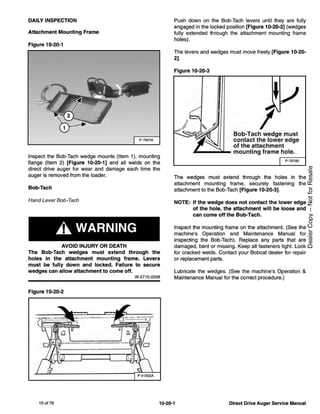

Maintenance Tips for Optimal Auger Performance

Regular upkeep is essential to ensure the efficiency and longevity of your drilling equipment. Proper maintenance not only enhances performance but also prevents unexpected breakdowns, allowing for smooth operation during tasks. Adopting a consistent maintenance routine can significantly extend the life of your machinery while maximizing its productivity.

Routine Inspections

Frequent inspections are crucial for identifying potential issues before they escalate. Check for signs of wear and tear, such as cracks or abnormal movements. Ensure that all components are securely fastened and that there are no leaks in the hydraulic system. Addressing minor problems promptly can prevent costly repairs later.

Lubrication and Cleaning

Keeping the machinery clean and well-lubricated is vital for optimal performance. Regularly apply appropriate lubricants to moving parts to reduce friction and wear. Additionally, clean any debris or build-up that may affect functionality. A clean working environment enhances the overall efficiency of your equipment and helps maintain its operational integrity.

Common Replacement Parts for Bobcat 30C

When operating heavy machinery, it’s crucial to be aware of the components that may require regular maintenance or replacement. Ensuring optimal performance and longevity of the equipment often involves replacing specific elements that experience wear and tear over time. Below are some frequently replaced components that are essential for maintaining efficient operation.

Key Components to Monitor

- Drive Belts

- Hydraulic Hoses

- Filters

- Seals and Gaskets

- Electrical Connectors

Maintenance Tips

- Regularly inspect drive belts for signs of wear.

- Check hydraulic hoses for leaks and replace as necessary.

- Change filters according to the manufacturer’s recommendations.

- Ensure seals and gaskets are intact to prevent fluid loss.

- Inspect electrical connectors for corrosion and secure connections.

Identifying Wear and Tear on Components

Recognizing the signs of deterioration in machinery components is crucial for maintaining optimal performance and prolonging equipment life. Regular inspection can help identify issues before they escalate, allowing for timely interventions. This section focuses on the common indicators of wear, which can vary depending on the specific part and its usage.

Common Signs of Wear

Components may exhibit several visible signs of wear, including cracking, deformation, or unusual surface roughness. Pay attention to any changes in appearance or functionality, as these can signal potential failures. Regular monitoring of these signs can aid in establishing a maintenance schedule that suits the equipment’s operational demands.

Importance of Routine Checks

Implementing routine checks can significantly reduce the risk of unexpected breakdowns. Establishing a systematic approach to inspecting components will not only enhance performance but also promote safety during operation. By prioritizing these assessments, operators can ensure that machinery remains in peak condition, thereby optimizing productivity.

Proper Lubrication for Auger Longevity

Ensuring the optimal performance and extended lifespan of drilling equipment requires careful attention to lubrication practices. Proper maintenance of these tools is essential, as it significantly affects their efficiency and durability. A well-lubricated mechanism reduces friction, prevents wear, and minimizes the risk of overheating during operation.

Types of Lubricants

Choosing the right lubricant is crucial for effective maintenance. Various types of greases and oils are available, each designed for specific environmental conditions and operational demands. For instance, heavy-duty grease is ideal for high-load applications, while lighter oils may be suitable for high-speed operations. Always refer to the manufacturer’s recommendations to select the appropriate product.

Application Techniques

Applying lubricant correctly can enhance the performance of the machinery. Ensure that all moving parts receive adequate coverage without over-lubricating, as excess grease can attract dirt and debris, leading to potential damage. Regular inspection and reapplication based on usage frequency are key to maintaining optimal functionality.

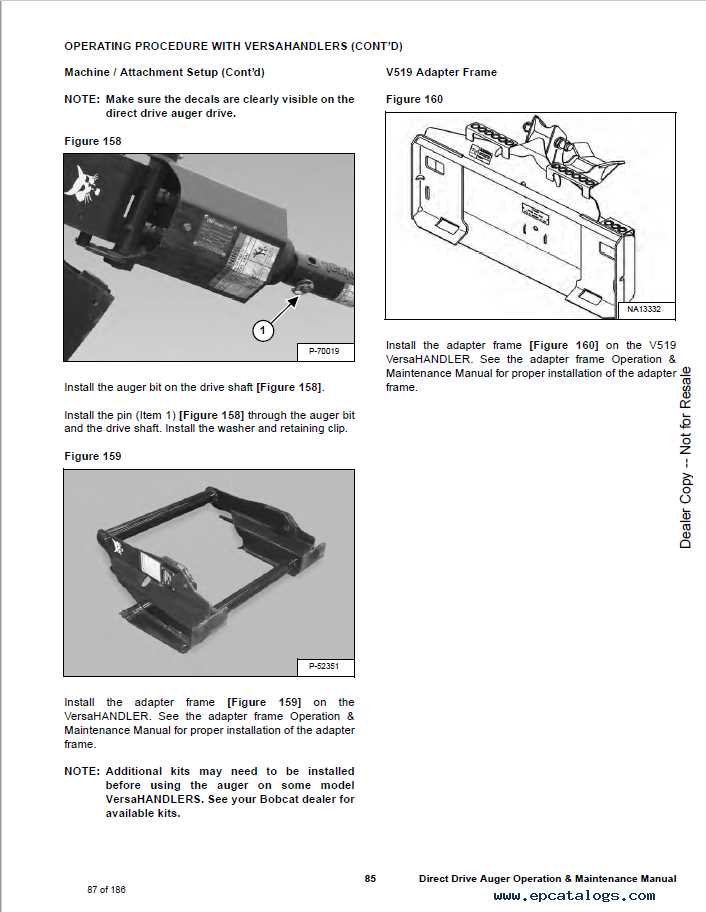

Installation Guide for Bobcat Auger Parts

This section provides essential guidance on the assembly and setup of equipment components, ensuring efficient operation and longevity. Proper installation is crucial for maximizing performance and minimizing potential issues during use. Following the instructions meticulously will lead to a smooth and successful setup process.

Preparation Steps

Before commencing the installation, it is important to gather all necessary tools and components. Ensure that you have a clean workspace and review the manufacturer’s specifications for each item to familiarize yourself with their functions.

Assembly Instructions

The following table outlines the step-by-step procedure for assembling the components:

| Step | Description |

|---|---|

| 1 | Secure the main body in a stable position to prevent movement during installation. |

| 2 | Align the connecting elements, ensuring they match correctly with the designated slots. |

| 3 | Tighten all screws and bolts firmly, following the recommended torque specifications. |

| 4 | Double-check all connections for stability and make any necessary adjustments. |

| 5 | Conduct a final inspection to confirm everything is properly installed before operational use. |

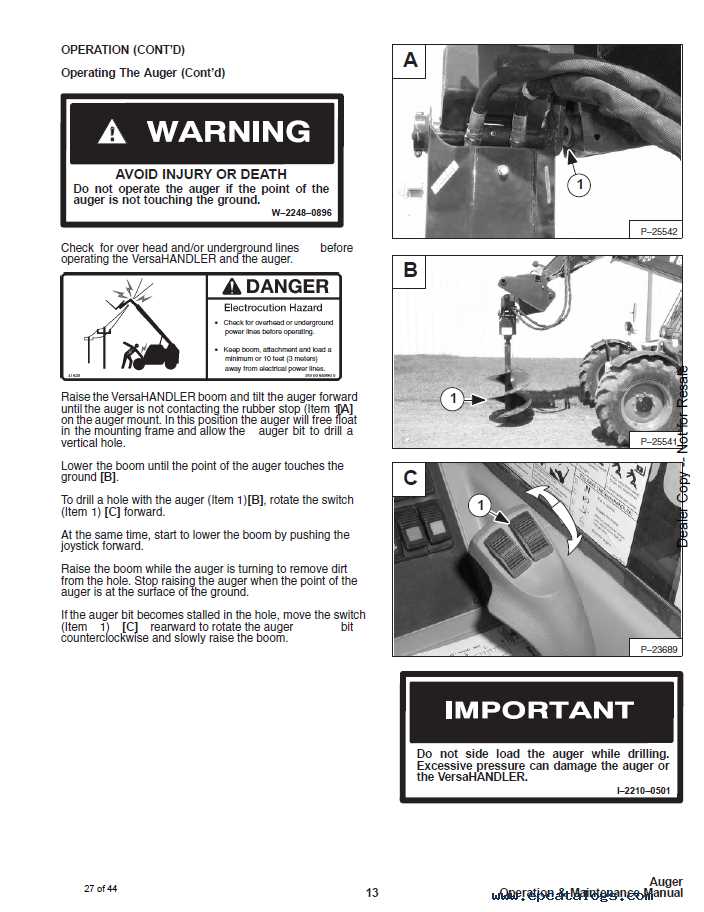

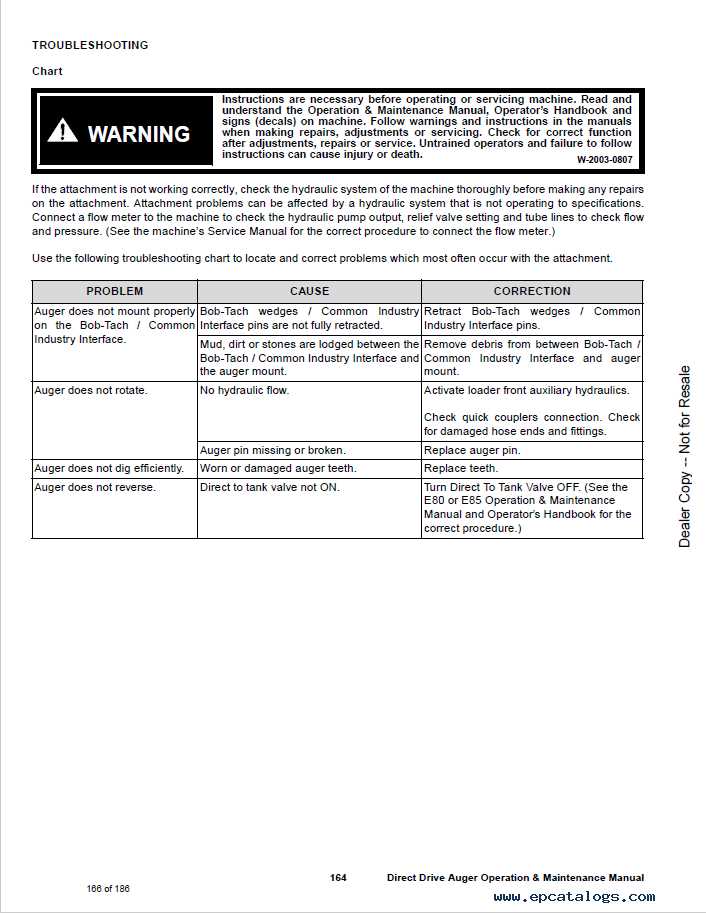

Troubleshooting Common Auger Issues

When operating drilling equipment, encountering difficulties can be frustrating. Identifying and resolving these common challenges is essential to maintaining efficiency and productivity. This section provides insights into frequent problems and their potential solutions, ensuring that your equipment operates smoothly.

1. Equipment Not Starting: If the machinery fails to initiate, check the power supply and connections. Ensure that the ignition system is functioning correctly. Additionally, inspect fuses and circuit breakers for any interruptions.

2. Inconsistent Performance: Fluctuations in drilling speed or power may indicate issues with the motor or the hydraulic system. Regular maintenance, including checking fluid levels and filters, can prevent these inconsistencies. Replace any worn components promptly.

3. Overheating: If the unit becomes excessively hot during operation, it could be a sign of inadequate lubrication or airflow. Ensure that all cooling systems are unobstructed and that lubricants are at optimal levels to reduce friction and heat.

4. Vibrations or Unusual Noises: Excessive vibrations or strange sounds can suggest misalignment or worn parts. Conduct a thorough inspection to identify loose bolts or damaged elements, and tighten or replace them as necessary to restore smooth operation.

By following these troubleshooting tips, operators can effectively address and resolve typical issues, ensuring the longevity and reliability of their drilling equipment.