When it comes to maintaining and repairing modern construction equipment, having a clear understanding of how each element is interconnected is essential. The ability to visualize the various elements involved in a machine’s design allows for easier identification of what might need attention during service or replacement.

In this section, we’ll explore the detailed layout of a compact piece of machinery. By breaking down each component, you’ll gain a clearer picture of how they work together, ensuring efficient performance and minimizing downtime. Whether you are troubleshooting or performing regular maintenance, understanding these key aspects will streamline the entire process.

From the engine block to the hydraulic system, every element has its role to play. By familiarizing yourself with the internal setup, you can avoid costly mistakes and keep the equipment in peak condition for years to come. Let’s take a closer look at the structure to deepen your knowledge and simplify any future

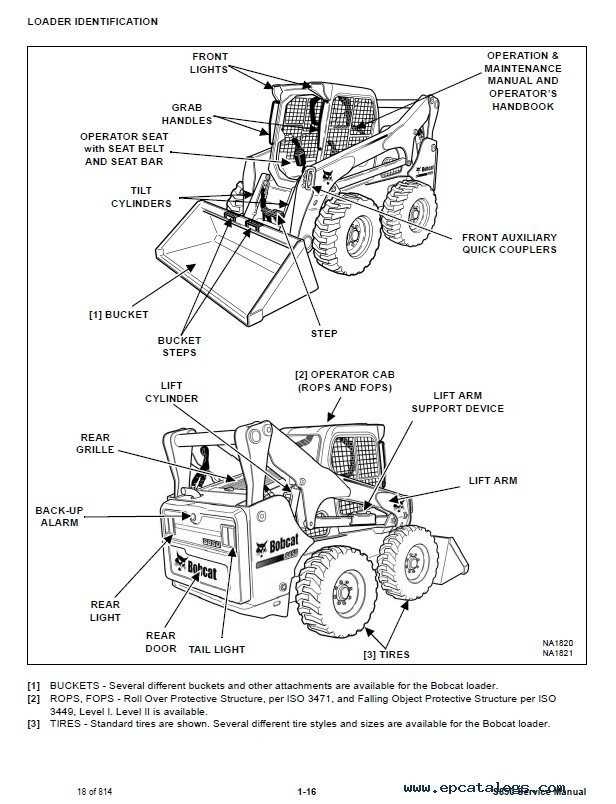

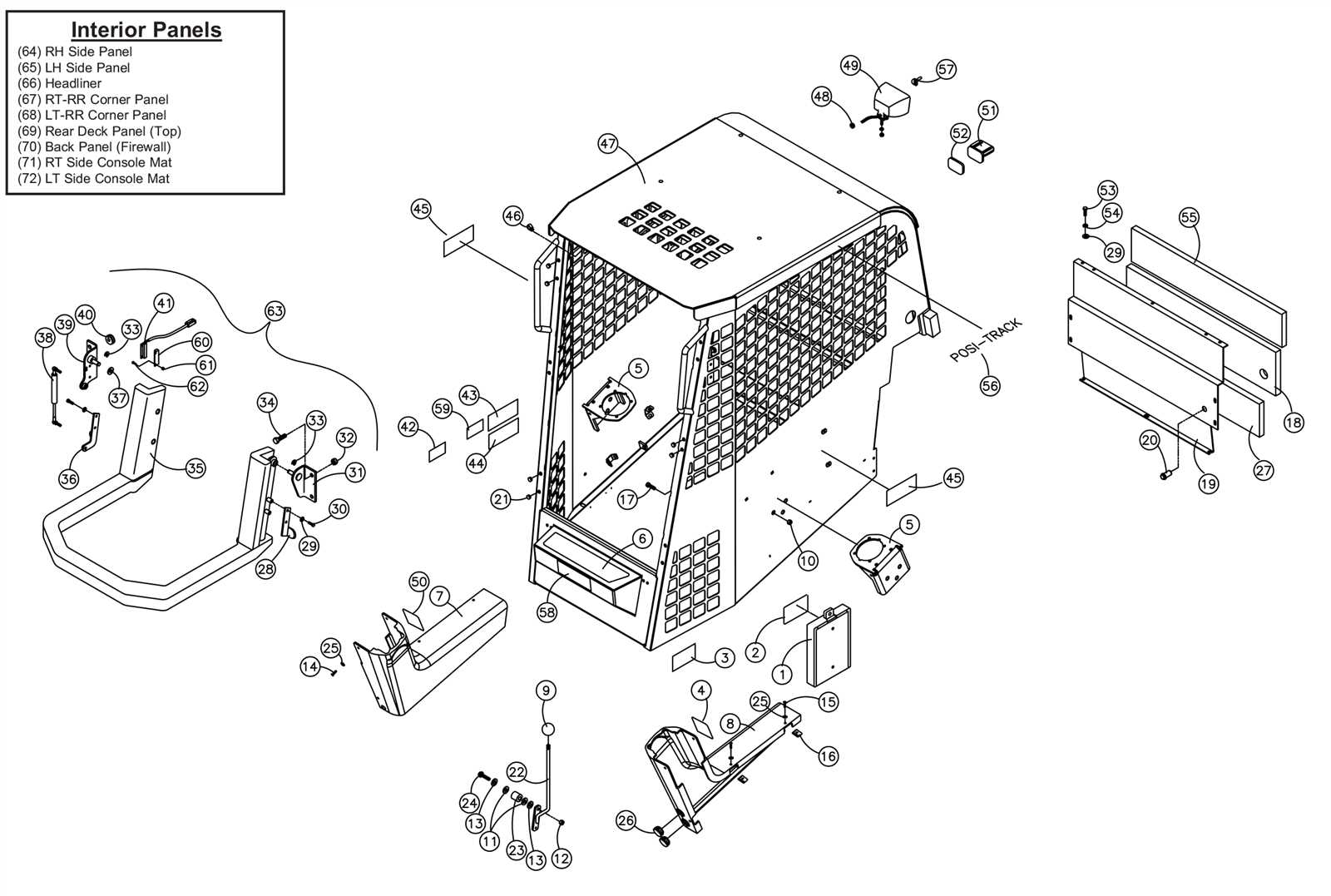

Understanding the Bobcat T450 Components

In this section, we will explore the various elements that make up this versatile machine, providing insight into how these individual pieces contribute to its overall functionality. Each component is carefully designed to ensure optimal performance, whether it’s used in demanding tasks or routine operations.

Key Systems Overview

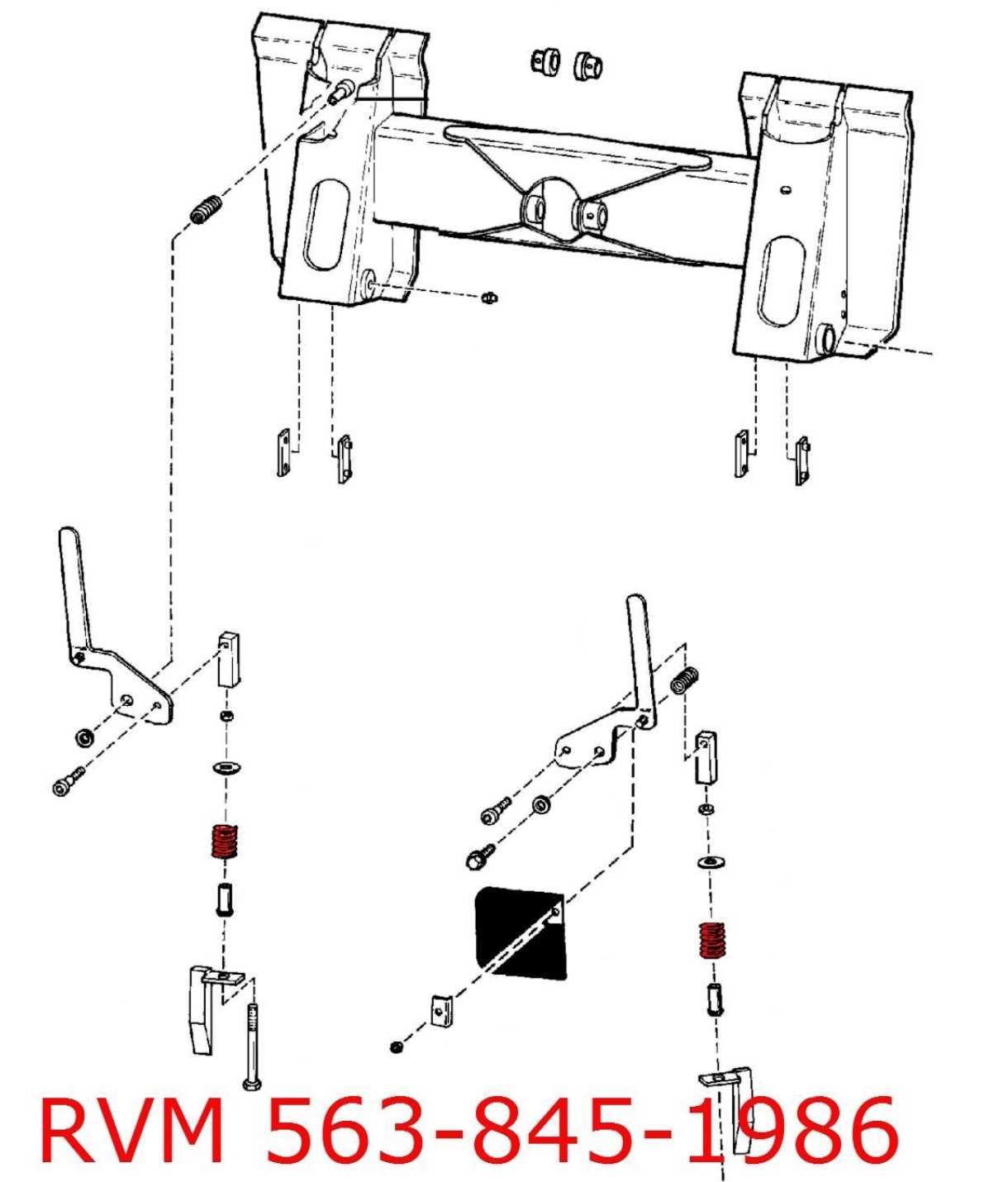

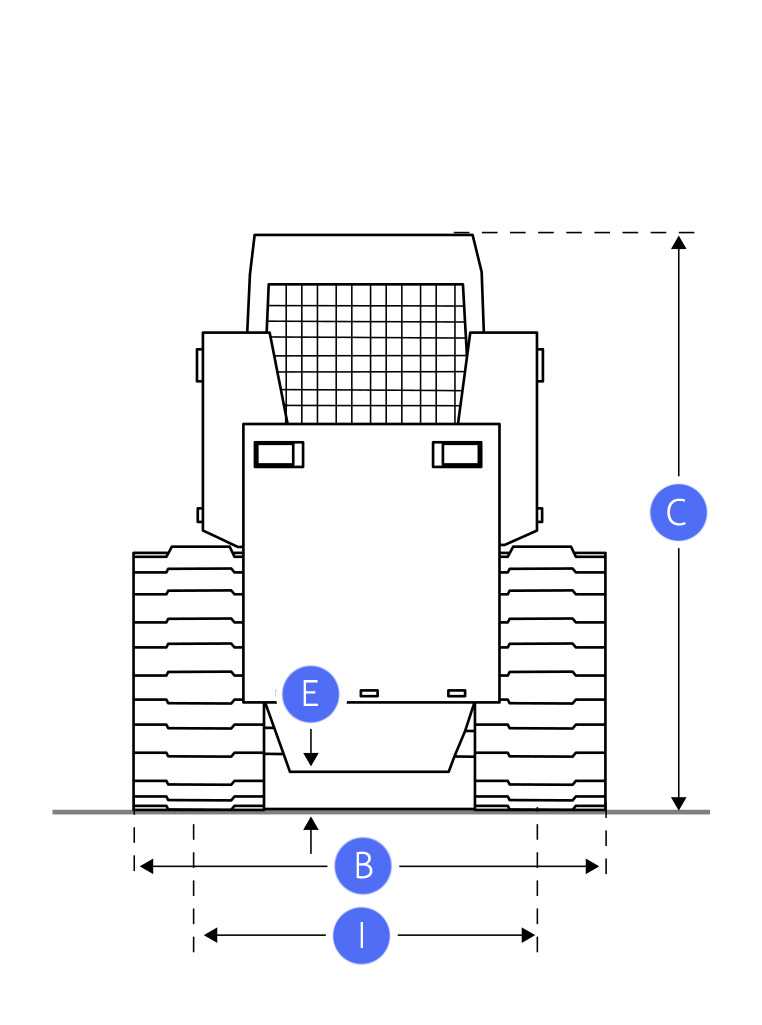

The machine’s key systems include its propulsion unit, control mechanisms, and work attachments. These systems work in harmony to provide efficiency, power, and precision. The propulsion unit drives the machine forward, while the control mechanisms allow for smooth operation. Work attachments can be swapped easily to suit a variety of tasks.

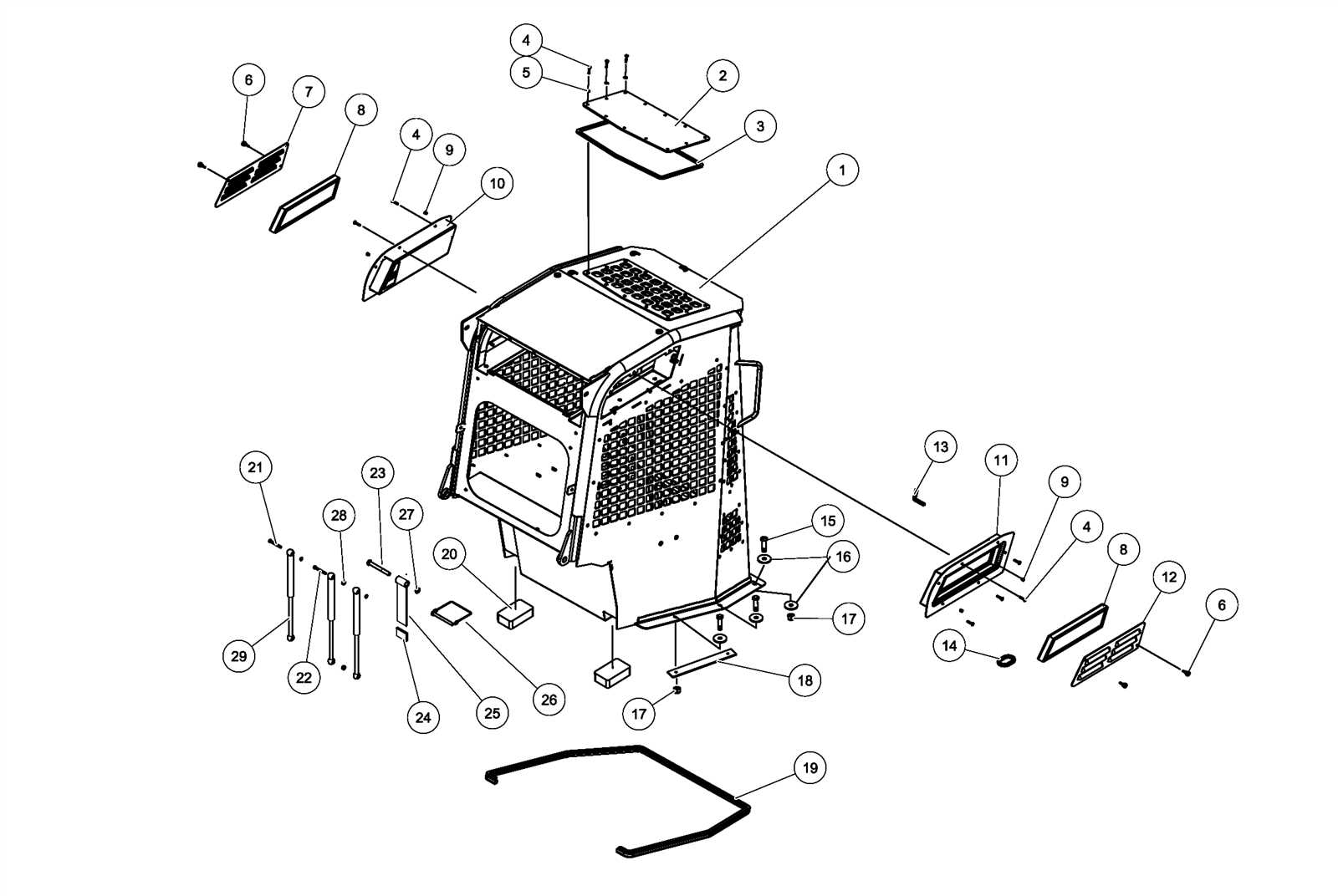

Component Breakdown

Below is a breakdown of the main components, showcasing how each contributes to the machine’s performance and ease of use:

| Component | Function | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

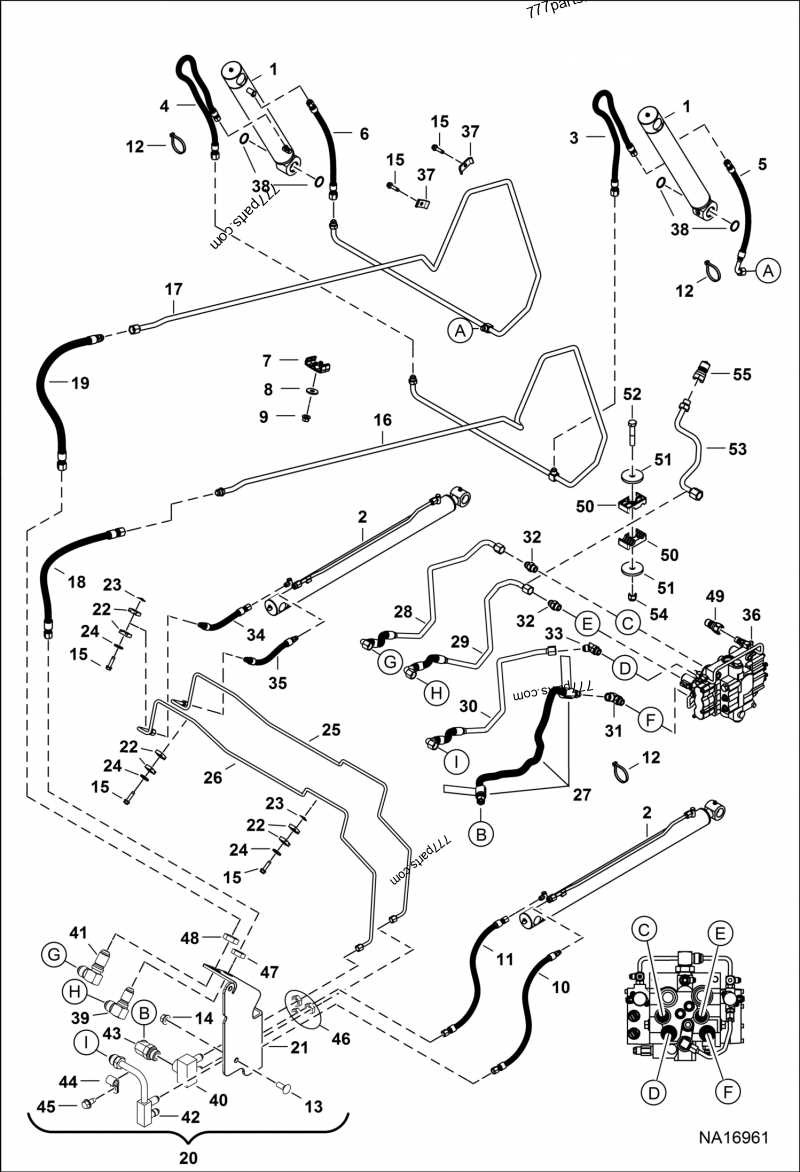

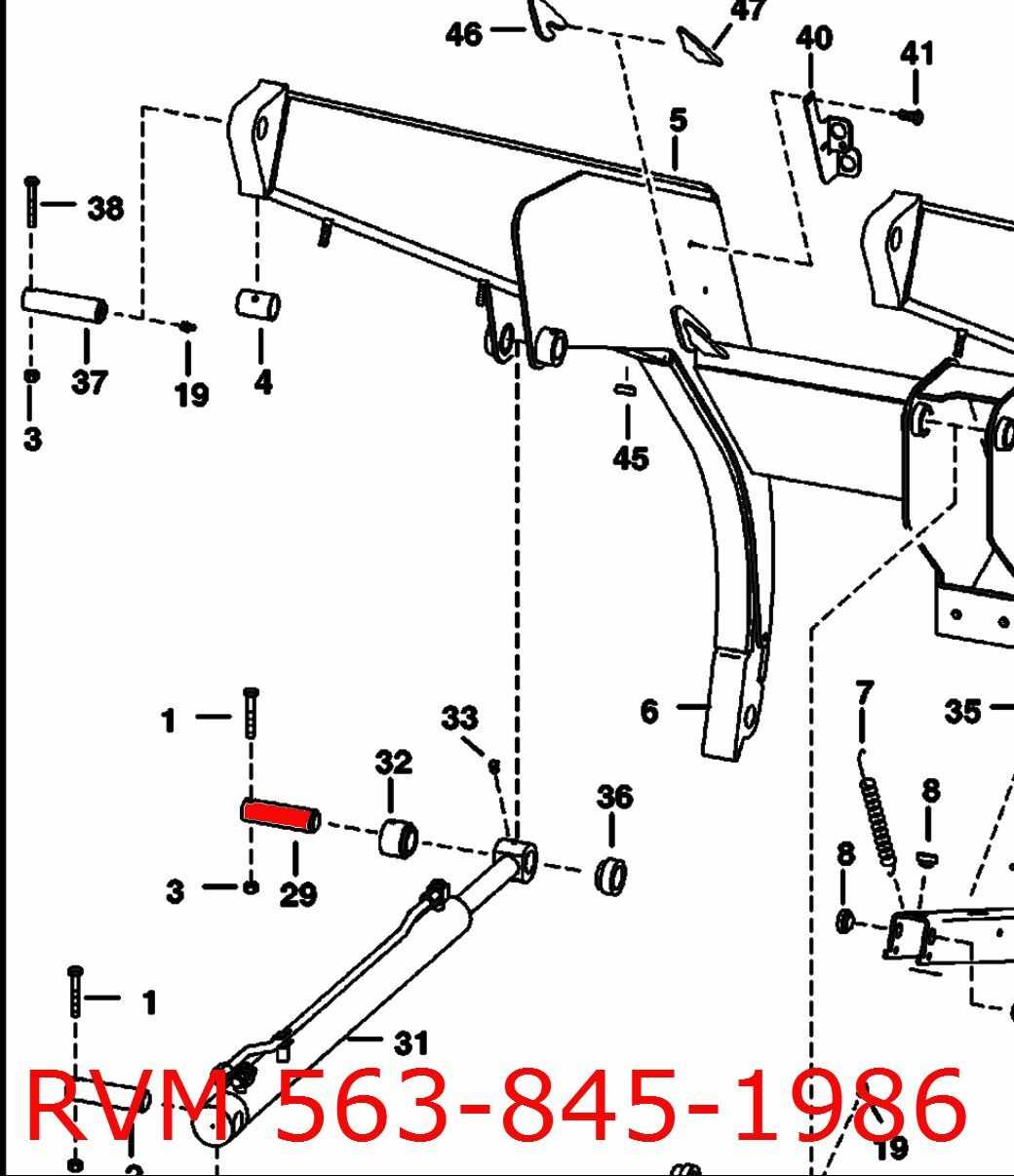

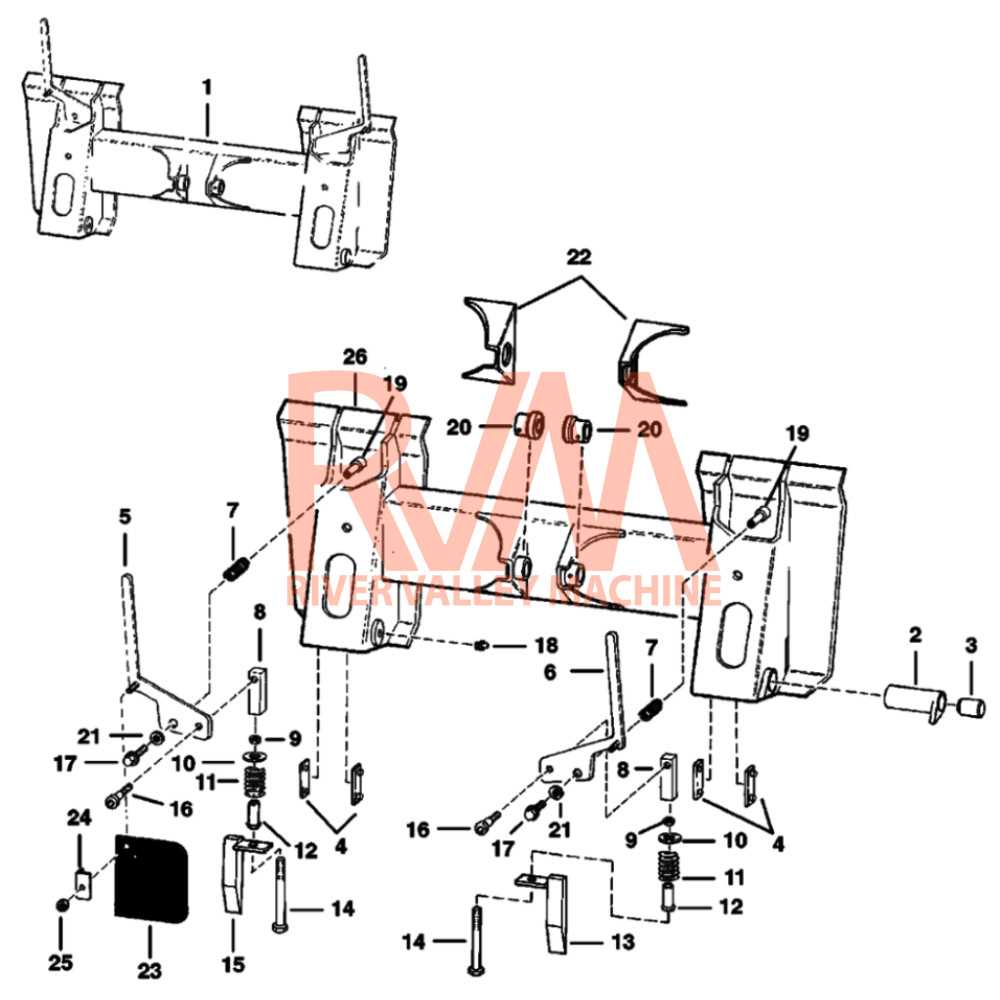

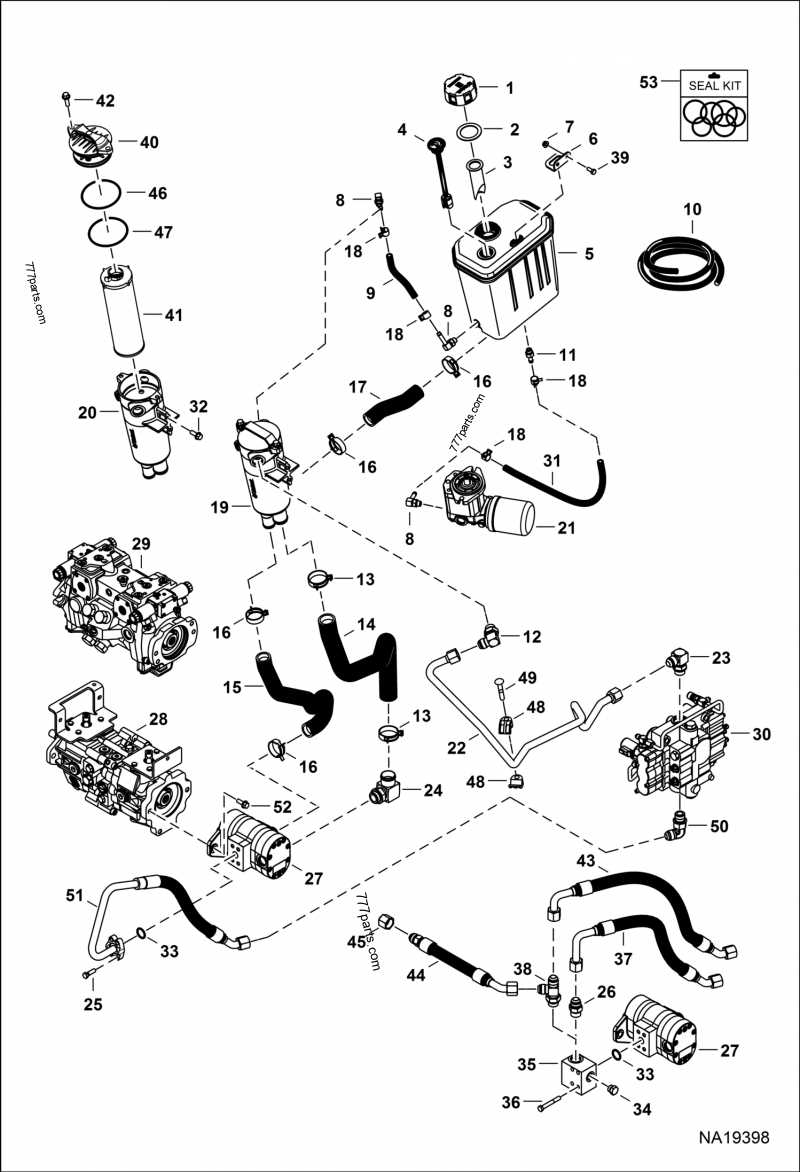

| Detailed Layout of Hydraulic System

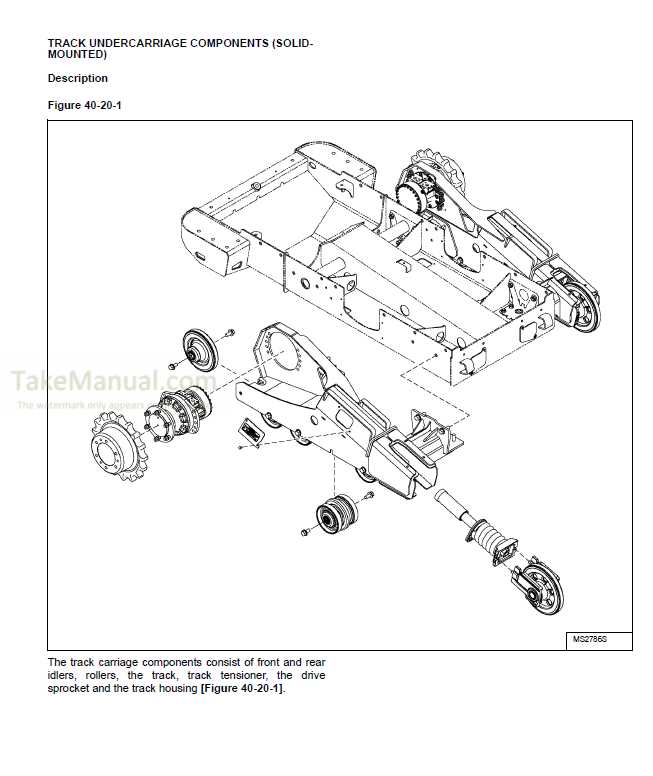

The hydraulic system is a critical component in the efficient operation of machinery. It is designed to facilitate the movement of various mechanical parts by transmitting force through pressurized fluid. Understanding its layout provides insight into the flow of energy and how it powers essential functions. This section will outline the primary connections and flow paths within this system, explaining how each element works together to ensure smooth performance. Main Hydraulic ComponentsThe hydraulic system is composed of key elements such as the pump, valves, and cylinders. The pump is responsible for generating the required fluid pressure, which is then directed through a series of valves that control the flow and direction of the hydraulic fluid. Cylinders convert this pressurized fluid into mechanical force, Track Assembly Overview for Bobcat T450The track system plays a crucial role in the movement and stability of the machine. This section will cover the essential components involved in the assembly and how they contribute to the overall performance of the vehicle on various terrains. The track structure is designed for durability, allowing the machine to handle heavy loads while maintaining optimal traction. The key components include the rubber tracks, rollers, idlers, and drive sprockets, each working together to provide smooth movement and stability. Tracks provide grip and distribute weight evenly, preventing excessive wear and ensuring a firm hold on the ground. The rollers support the tracks, allowing them to rotate freely and absorb impact from uneven surfaces. Idlers help maintain tension in the track system, while the drive sprockets ensure effective power transmission from the engine to the track, propelling the vehicle forward. This interconnected assembly is vital for maximizing operational efficiency Exploring the Engine Compartment Design

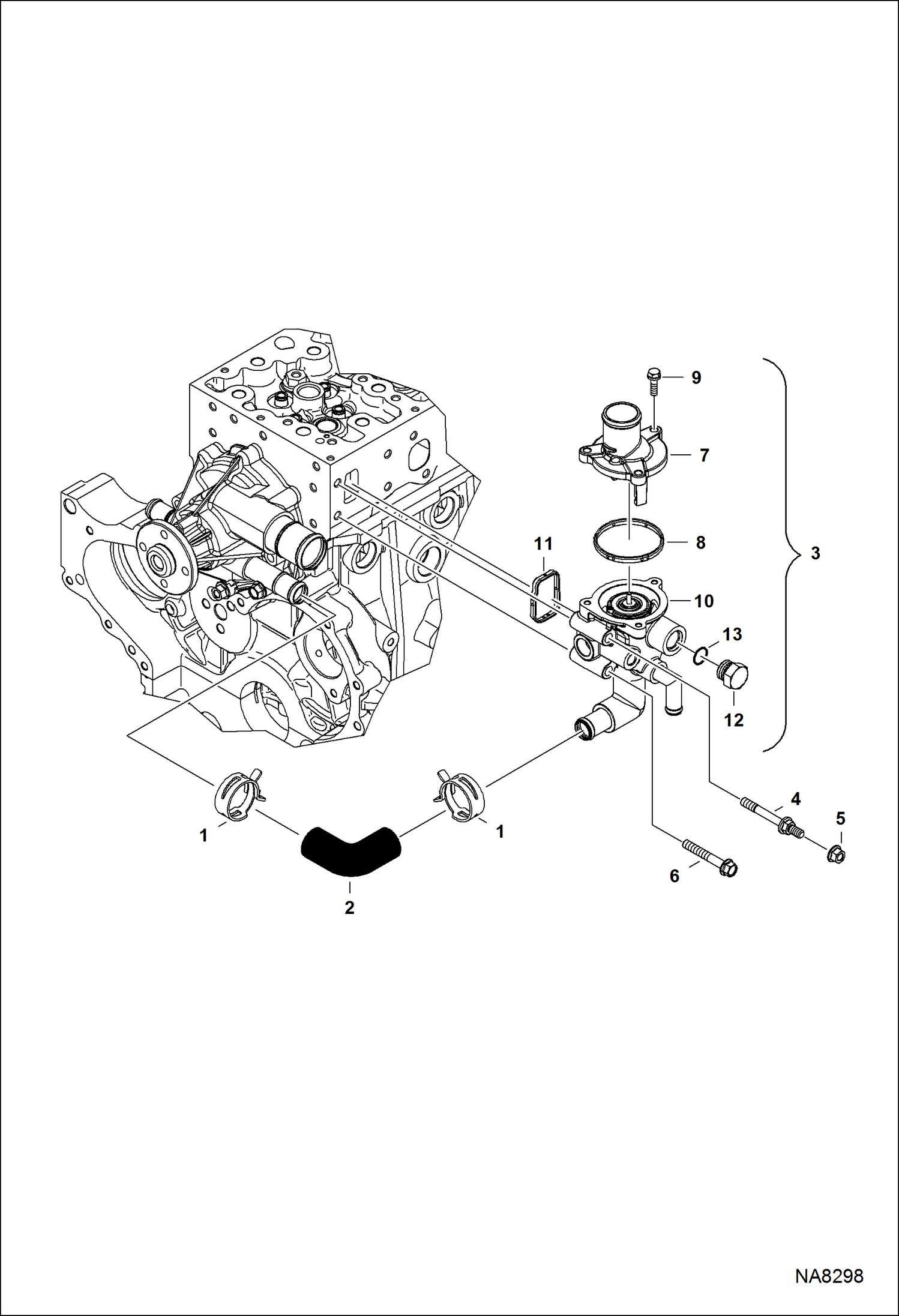

The engine compartment of modern machinery plays a critical role in housing and protecting the core power system. Its design is crafted with both functionality and maintenance in mind, ensuring that key components are easily accessible for service while maintaining a compact and efficient layout. This thoughtful arrangement supports optimal performance and durability, even in demanding working environments. Accessibility and Layout are essential factors in this space. The compartment is structured to provide quick access to essential elements, minimizing downtime during routine inspections or repairs. Well-placed panels and latches offer seamless entry, allowing technicians to work efficiently. In addition to accessibility, the ventilation system within the compartment is des Analyzing the Cooling System Components

The cooling system is a vital part of any equipment, ensuring that the internal mechanisms operate within the proper temperature range. By keeping the engine cool and preventing overheating, it safeguards the longevity of various mechanical elements. This section explores the primary components involved in maintaining temperature stability and their roles within the system. Main Elements of the Cooling System

Several essential elements work together to regulate temperature. These components ensure that heat generated during operation is efficiently dispersed. Proper maintenance of these components is crucial to prevent failures caused by excessive heat buildup.

|