The intricate workings of heavy machinery play a crucial role in various industries, facilitating efficient operations and enhancing productivity. Analyzing the structural elements of these powerful machines allows operators and technicians to grasp their functionality and maintenance requirements.

Familiarity with the assembly of such equipment is essential for anyone involved in their operation or repair. Comprehensive insights into each component can lead to improved performance and longevity, ensuring that these robust machines can handle demanding tasks.

In this exploration, we will delve into the essential elements that comprise a specific model, providing a clear representation of how each part interacts within the whole system. This knowledge ultimately empowers users to make informed decisions about upkeep and repairs, maximizing the equipment’s capabilities.

Understanding Bobcat T870 Parts

This section delves into the intricate components of a compact track loader, highlighting the essential elements that contribute to its efficiency and functionality. Recognizing the various segments and their respective roles can significantly enhance maintenance practices and operational performance.

Key Components

- Engine: The heart of the machine, providing the necessary power for all operations.

- Hydraulic System: Responsible for lifting and maneuvering attachments, crucial for versatility.

- Tracks: These enable movement across diverse terrains while ensuring stability.

- Cabin: The operator’s control center, designed for comfort and visibility.

- Attachment Interface: Facilitates the quick connection of various tools for specific tasks.

Maintenance Considerations

- Regular inspections of the hydraulic lines to prevent leaks and maintain efficiency.

- Monitoring the condition of tracks to ensure optimal traction and prevent damage.

- Routine checks of the engine oil and filters to promote longevity and performance.

- Cleaning the cabin area to maintain a clear line of sight and a comfortable working environment.

By familiarizing oneself with these critical elements, operators can ensure optimal performance and longevity of their machinery.

Overview of Bobcat T870 Features

This section explores the remarkable capabilities and functionalities of a cutting-edge compact track loader, emphasizing its versatility and performance in various applications. Designed to meet the demands of both construction and landscaping tasks, this machine combines power with agility, making it an indispensable tool for professionals.

Key Specifications

| Feature | Details |

|---|---|

| Engine Power | More than 90 horsepower for robust performance |

| Operating Weight | Approximately 10,000 lbs for stability |

| Lift Capacity | Over 3,500 lbs for heavy lifting |

| Track Width | Wide tracks for enhanced ground contact |

Operational Advantages

This loader is engineered for superior maneuverability, allowing it to navigate tight spaces effortlessly. Its advanced hydraulic system ensures precise control, making it ideal for tasks that require accuracy. Furthermore, the operator-friendly cab enhances comfort and visibility, promoting productivity throughout long workdays.

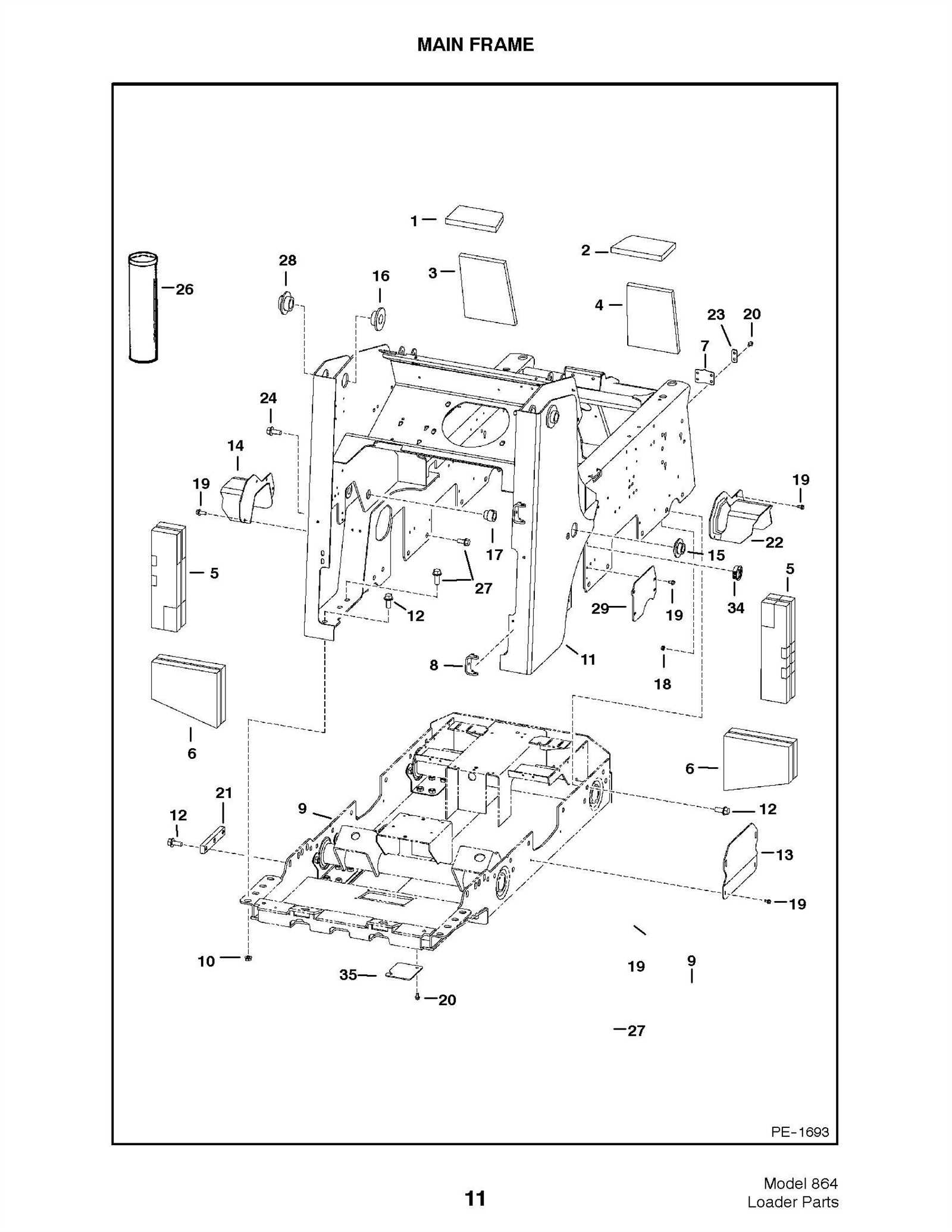

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that simplify the identification and organization of various elements, allowing operators to navigate complexities with ease.

| Benefit | Description |

|---|---|

| Enhanced Clarity | Visual aids provide a clear overview, making it easier to locate specific components. |

| Efficient Repairs | By having a detailed layout, repairs can be performed more swiftly and accurately. |

| Streamlined Maintenance | Regular upkeep becomes simpler, as users can refer to the visual guide for routine checks. |

| Training Resource | These visual tools are invaluable for educating new personnel on machinery intricacies. |

Main Components of the T870

This section provides an overview of the key elements that contribute to the functionality and performance of the machine. Understanding these components is essential for effective operation and maintenance.

- Engine: Powers the entire unit and ensures optimal performance.

- Hydraulic System: Controls movement and operation of attachments.

- Chassis: The framework that supports all components and provides stability.

- Cab: The operator’s area, designed for comfort and visibility.

- Tracks: Facilitate movement over various terrains, enhancing maneuverability.

Each of these elements plays a crucial role in achieving the ultimate efficiency and effectiveness of the equipment.

Common Wear Parts to Monitor

Regular maintenance is essential for the longevity and efficiency of heavy machinery. Among the various components, certain elements are prone to wear and tear, requiring close attention. Monitoring these areas not only ensures optimal performance but also helps prevent costly repairs.

1. Tracks and Tires: These elements are critical for mobility. Over time, they can develop cracks or wear down, leading to reduced traction and efficiency. Regular inspection for signs of damage is vital.

2. Filters: Air and oil filters play a crucial role in maintaining the health of the engine. Clogged filters can impede airflow and fluid circulation, potentially causing overheating and engine strain. Schedule routine replacements to avoid issues.

3. Hydraulic Hoses: These flexible conduits are essential for fluid transfer in the hydraulic system. Regular checks for leaks, abrasions, or bulges can prevent sudden failures that may halt operations.

4. Teeth and Cutting Edges: For attachments like buckets and blades, the cutting edges are subject to intense wear. Dull or damaged teeth can reduce productivity and increase strain on the machine. Replacing them in a timely manner is crucial.

5. Pins and Bushings: These components connect moving parts and are critical for maintaining proper alignment and function. Over time, they can wear out, leading to increased play and reduced efficiency. Regular lubrication and inspection are recommended.

By focusing on these commonly worn components, operators can enhance the performance and lifespan of their machinery, ensuring that it remains reliable and efficient for years to come.

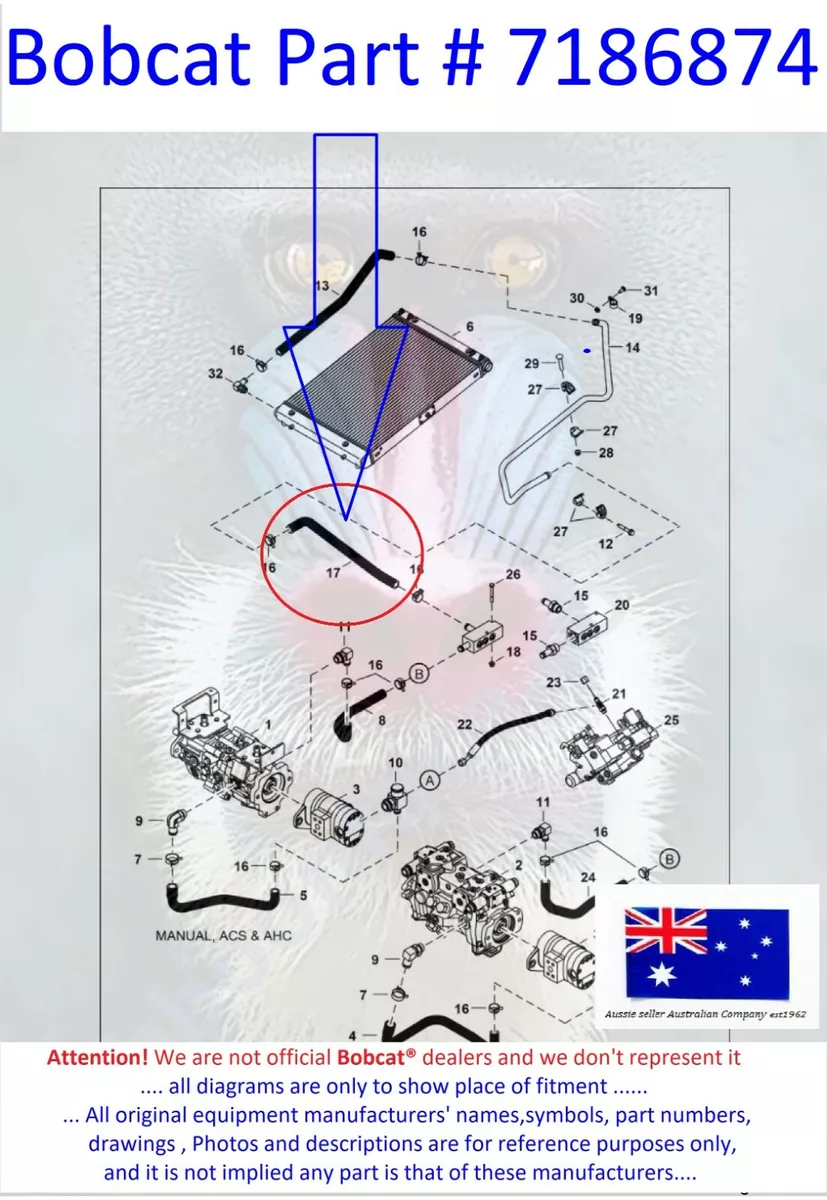

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance maintenance and repair efforts. By mastering these illustrations, you can identify necessary items and their specific locations within machinery.

Follow these steps to effectively interpret these visuals:

- Familiarize with the Layout: Recognize how the illustration is structured, including sections and groups of components.

- Identify Labels: Pay attention to numerical or alphabetical identifiers that correlate with lists or tables.

- Observe Connections: Note how elements are linked, which can indicate assembly order or relationships.

- Use a Reference Guide: Keep a manual or resource handy that provides explanations for symbols and codes used.

By employing these techniques, you can delve deeper into the inner workings of your equipment, ensuring efficient repairs and maintenance.

Finding OEM vs Aftermarket Parts

When it comes to maintaining heavy machinery, the choice between original equipment manufacturer components and those produced by third-party suppliers can significantly impact performance and longevity. Understanding the differences and benefits of each option is crucial for making informed decisions.

Original equipment manufacturer components are designed specifically for a particular machine, ensuring compatibility and adherence to strict quality standards. In contrast, third-party alternatives often provide cost-effective solutions but may vary in quality and reliability.

- Advantages of OEM Components:

- Guaranteed compatibility with existing machinery.

- Higher assurance of quality and durability.

- Warranty protection often provided by the manufacturer.

- Benefits of Aftermarket Options:

- Potential for significant cost savings.

- A wider range of choices and features available.

- Innovative designs and improvements over original models.

Ultimately, the decision should be based on individual needs, budget considerations, and the specific requirements of the equipment. Careful evaluation of both choices can lead to optimal performance and satisfaction.

Maintenance Tips for T870 Owners

Proper upkeep is essential for maximizing the lifespan and efficiency of your equipment. Regular attention to key components can prevent costly repairs and ensure smooth operation during demanding tasks.

Begin with routine inspections, checking for signs of wear and tear. Pay close attention to hydraulic systems, as leaks can lead to performance issues. Keeping the filters clean is vital to avoid dirt and debris clogging vital areas.

Next, schedule regular fluid changes, including oil and coolant, to maintain optimal performance. This practice not only enhances efficiency but also safeguards critical parts from premature failure.

Don’t forget about the importance of greasing moving parts to reduce friction and wear. Maintaining tire pressure and tread can also significantly improve stability and traction on various terrains.

Lastly, always consult the manufacturer’s guidelines for specific maintenance schedules and recommendations. Staying proactive will ultimately result in a more reliable and effective machine.

Identifying Part Numbers Easily

Locating specific identifiers for machinery components can be a straightforward process with the right approach. Understanding how to navigate catalogs and resources will streamline the task of finding the necessary elements for maintenance or repair. This section outlines effective strategies to simplify the identification of these crucial identifiers.

Utilizing Online Resources

- Visit manufacturer websites for comprehensive listings.

- Use search functions to quickly access the required sections.

- Engage with online forums or communities for shared experiences.

Consulting Maintenance Manuals

- Refer to the official manuals provided with the equipment.

- Look for sections that detail component breakdowns.

- Take note of diagrams that visually represent the assembly.

By employing these methods, identifying the right component identifiers becomes much more efficient, ensuring that repairs or replacements are handled promptly and accurately.

Resources for Parts Replacement

When it comes to maintaining machinery, having access to reliable resources is essential for effective component replacement. Understanding where to find quality materials and detailed information can streamline the repair process, ensuring that equipment operates efficiently and reliably. Below are some recommended sources that can aid in obtaining necessary replacements.

| Resource Type | Description | Website/Contact |

|---|---|---|

| Manufacturer’s Website | Official site often includes a catalog of components, specifications, and installation guides. | www.manufacturerwebsite.com |

| Authorized Dealers | Local dealers provide genuine items and expert advice tailored to specific equipment. | Find a dealer near you |

| Online Marketplaces | Platforms where various suppliers offer a wide range of replacement items, often with customer reviews. | www.marketplace.com |

| Repair Manuals | Comprehensive guides that provide detailed instructions on how to replace components effectively. | Available for purchase or download from various retailers |

| Forums and Community Groups | Online communities where users share experiences, tips, and recommendations for sourcing replacements. | www.forumwebsite.com |

Benefits of Using Genuine Parts

Opting for authentic components is crucial for maintaining equipment efficiency and longevity. These elements are specifically designed to meet the exact specifications of the machinery, ensuring optimal performance and reliability.

Enhanced Durability

Genuine components undergo rigorous testing to guarantee they can withstand demanding conditions. This leads to a longer lifespan and reduced frequency of replacements, ultimately saving time and resources.

Improved Performance

When using original elements, you can expect ultimate compatibility with your machinery. This ensures that every function operates smoothly, contributing to overall productivity and reducing the risk of malfunctions.

FAQs About Bobcat T870 Parts

This section aims to address common inquiries regarding components and their maintenance for a specific model of heavy machinery. Understanding the essential elements can help ensure optimal performance and longevity of the equipment.

What are the most commonly replaced components?

The most frequently replaced elements include hydraulic filters, drive belts, and undercarriage parts. Regular inspections can help identify wear and tear early, allowing for timely replacements.

How can I ensure I’m purchasing quality replacements?

To guarantee high-quality replacements, consider sourcing from reputable suppliers, checking for OEM certification, and reading customer reviews. Prioritizing trusted brands often leads to better durability and performance.