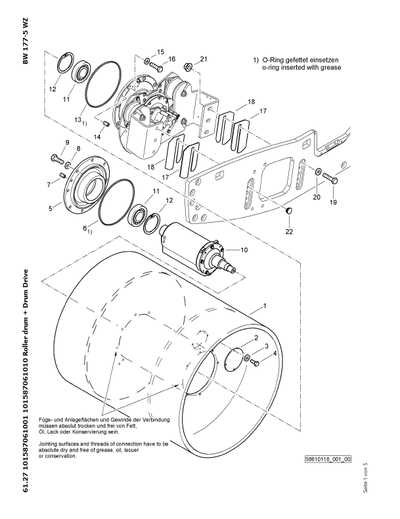

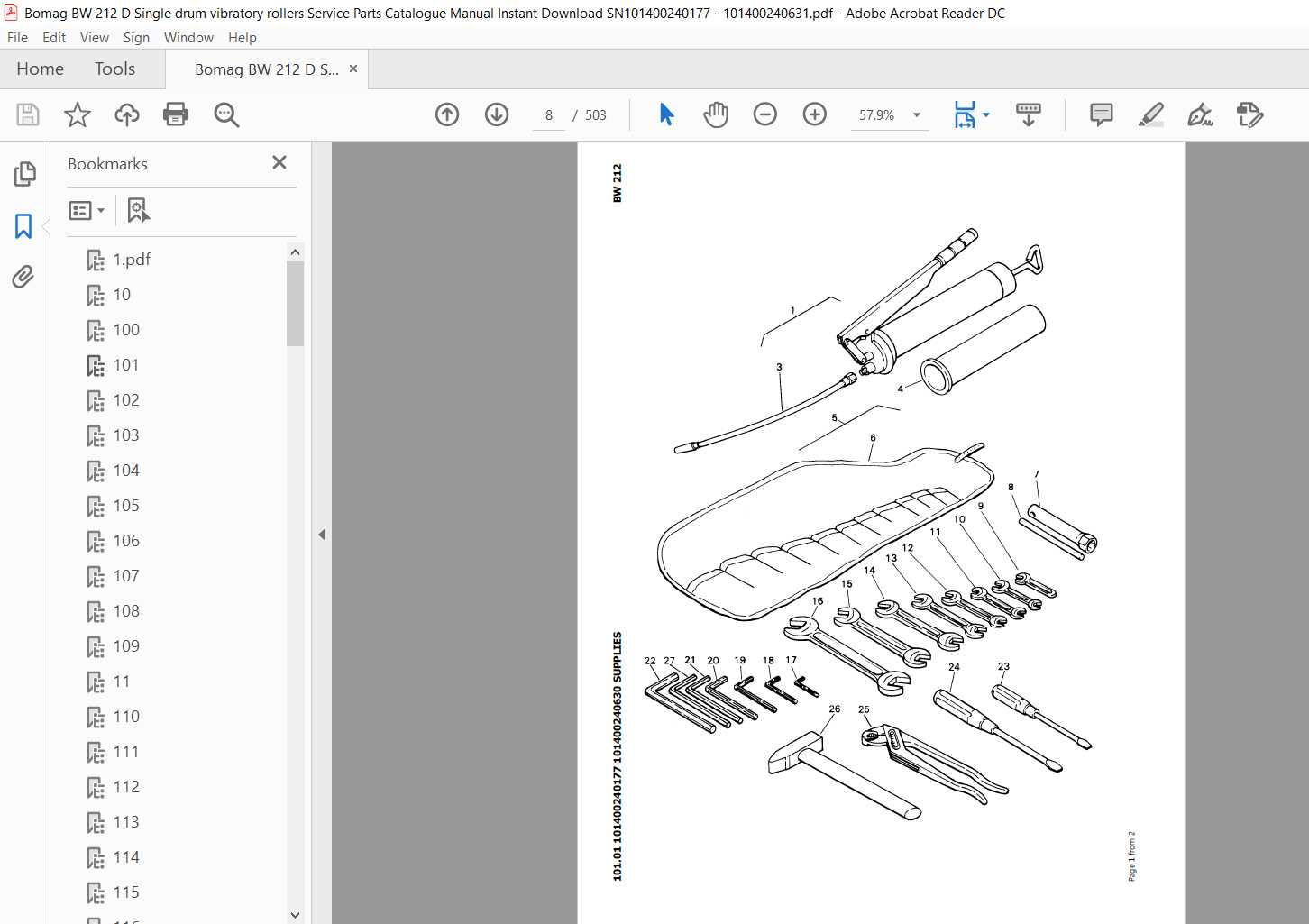

Maintaining construction machinery requires a thorough understanding of its various elements and how they interact. Identifying individual components within complex systems can be challenging without proper visual aids, especially when dealing with large industrial equipment. A detailed schematic provides an invaluable tool for navigating these intricate assemblies.

Component schematics allow technicians to quickly identify key elements and their locations, making repairs and maintenance tasks more efficient. Each section is mapped out to show how different pieces fit together, ensuring clarity during troubleshooting or part replacement.

Using these illustrations not only helps in diagnosing mechanical issues but also aids in understanding the structure of the machinery. By studying the arrangement and connections, one can gain insights into potential wear points and optimize upkeep procedures for bet

Understanding Bomag Roller Components

When examining the machinery used for compaction tasks, it’s essential to recognize the individual elements that contribute to its overall performance. Each component plays a crucial role in ensuring effective operation, from structural stability to the seamless execution of compression tasks.

Core Mechanical Elements

The main structural units work together to provide balance and maintain uniform ground contact. These elements are engineered to handle varying load conditions, distribute weight evenly, and enhance the equipment’s ability to adjust to different surfaces, thereby maximizing the compaction effect.

Hy

Key Features of Bomag Rollers

The equipment in question is known for its robust performance and ability to handle various surfaces. Its design focuses on durability, providing consistent results even under demanding conditions. The machinery incorporates advanced technologies to enhance operational efficiency and deliver optimal compaction quality.

High-Performance Compaction

These machines are engineered to deliver excellent compaction results across different types of materials, including asphalt, gravel, and soil. The equipment’s compaction capabilities are supported by adjustable settings that allow operators to fine-tune the pressure for specific tasks, ensuring uniform density and a smoother surface finish.

Operator Comfort and Safety

To maximize productivity, the machinery is designed with features that improve operator comfort

Importance of Parts Diagrams

Understanding the layout and relationships between various components is crucial for effective maintenance and repairs. Visual representations help identify specific elements, simplifying the process of locating the right piece. These illustrations provide clarity, reducing confusion when dealing with complex assemblies.

Such graphical guides also play a key role in ensuring accuracy during replacements. With a visual reference, technicians can confirm compatibility and proper fitment, minimizing the risk of installing incorrect items. This results in smoother servicing and extended equipment life.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Common Bomag Roller Models Overview

Various compaction equipment models cater to different construction needs, offering a range of options for soil and asphalt applications. Each model provides unique features and capabilities designed to meet specific project requirements, ensuring efficient performance across various environments. Understanding the key characteristics of these machines can help identify the best fit for different tasks. Lightweight Models for Small Projects

Smaller units are ideal for tasks such as landscaping, driveway maintenance, or minor road repairs. These machines are known for their maneuverability and ease of use in confined spaces, making them suitable for urban areas or projects where precision is crucial. They often come equipped with user-friendly controls and adjustable Maintenance Tips for Bomag RollersRegular upkeep is crucial for ensuring the long-term performance and durability of construction machinery. By adopting a consistent maintenance routine, operators can minimize unexpected downtime and extend the equipment’s service life. Paying attention to key areas can help detect potential issues early, allowing for timely repairs and reducing operational costs. Check Fluid Levels RegularlyMaintaining proper fluid levels, such as engine oil, hydraulic fluid, and coolant, is essential for the smooth operation of the machine. Low or contaminated fluids can lead to overheating or mechanical damage. Always inspect these levels before starting work, and top them off if needed, using the correct type recommended for the equipment. Identifying Roller Parts and FunctionsUnderstanding the components and their roles in a compaction machine is essential for proper maintenance and efficient operation. Each element contributes to the overall functionality, ensuring smooth performance on various terrains. Recognizing these elements helps in troubleshooting issues and optimizing the equipment’s use. Main Structural Components

|