When exploring the intricacies of a sophisticated apparatus, it’s essential to have a clear visual representation of its individual elements. Each section plays a pivotal role in ensuring optimal functionality and efficiency. By breaking down the various components, one can gain insights into the overall mechanics and design principles at play.

Such representations not only enhance comprehension but also aid in identifying potential issues during maintenance or upgrades. Understanding how each piece interacts can ultimately lead to more informed decisions regarding repairs or enhancements. This comprehensive overview serves as a guide for enthusiasts and professionals alike.

Furthermore, a detailed breakdown allows for a deeper appreciation of the engineering involved. It is through this meticulous examination that one can truly delve into the ultimate workings of the machine, revealing the harmony of form and function in every aspect.

Understanding the Br700 Parts Diagram

Grasping the intricacies of mechanical assemblies is crucial for efficient maintenance and operation. A detailed visual representation helps users identify components and their relationships, ensuring a comprehensive understanding of the overall structure. This knowledge enhances troubleshooting and repair processes, ultimately improving functionality and longevity.

| Component | Description | Function |

|---|---|---|

| Element A | Main structural unit | Provides support and stability |

| Element B | Connecting part | Links various sections together |

| Element C | Operational mechanism | Facilitates movement and function |

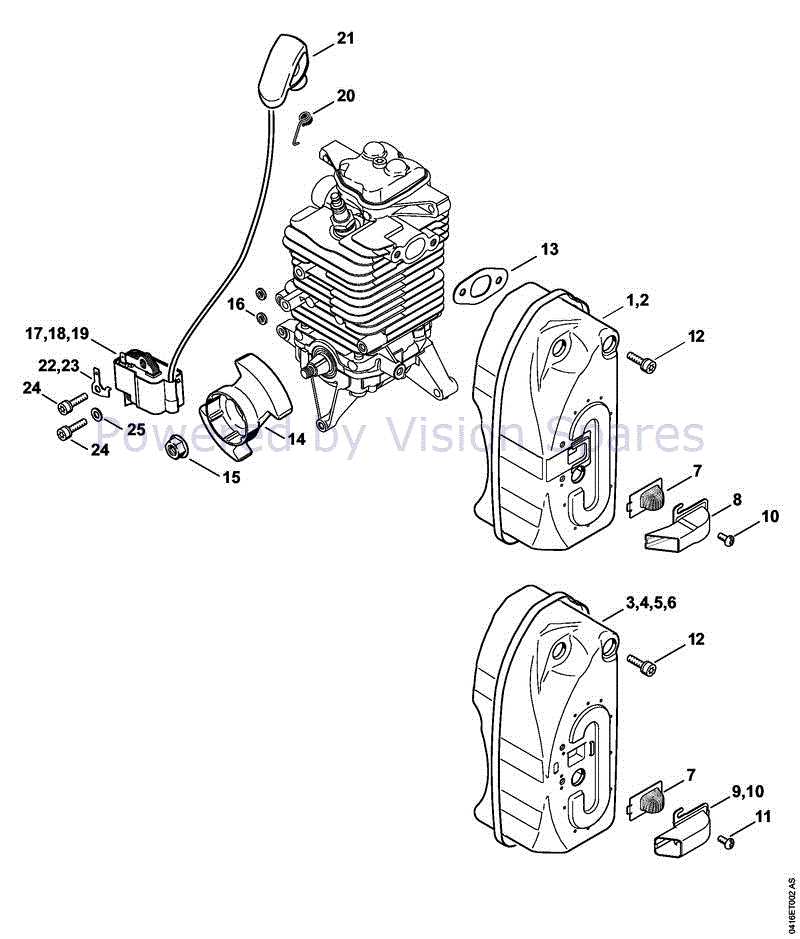

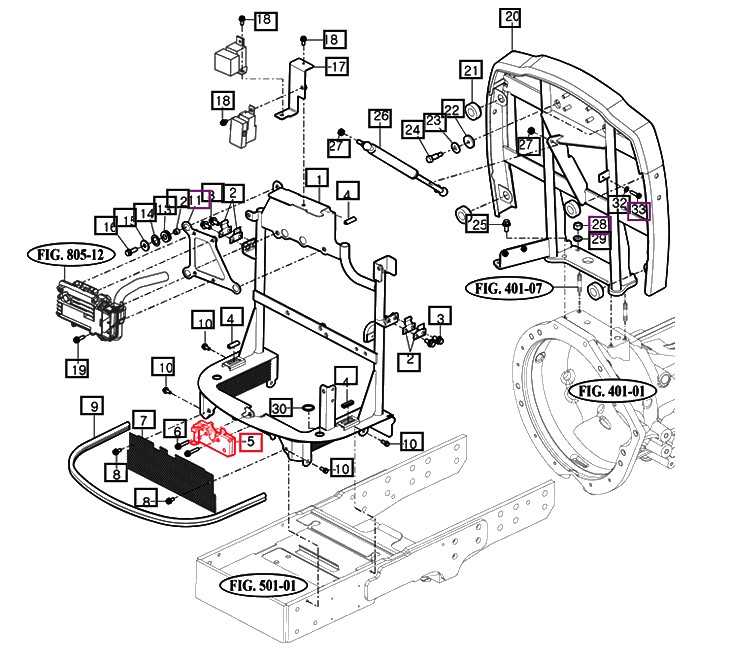

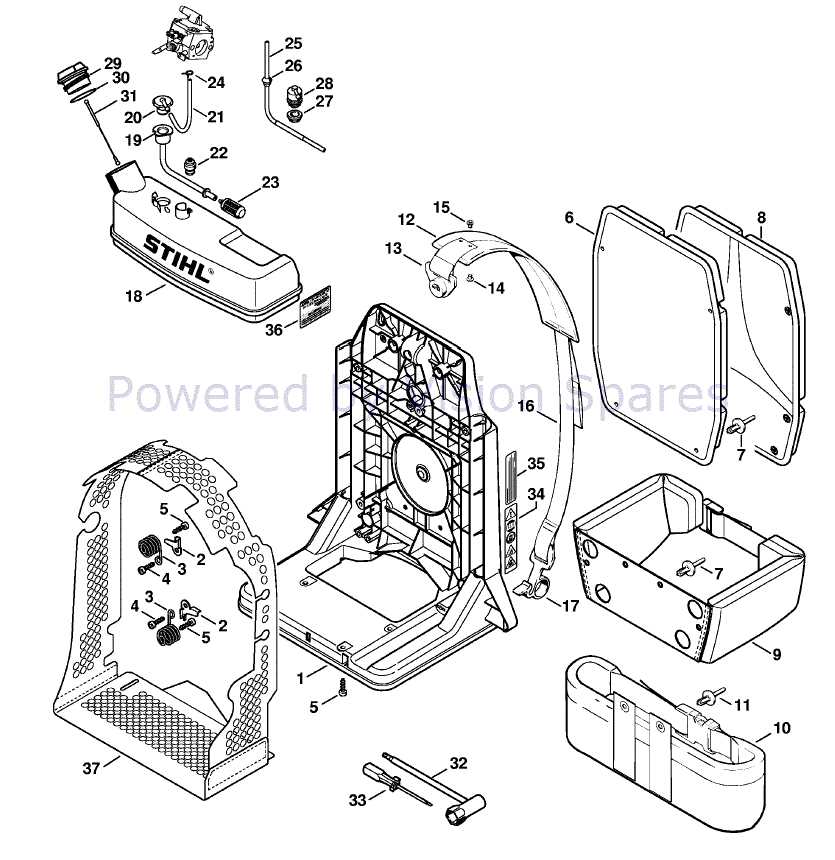

Key Components of the Br700

This section delves into the essential elements that make up this advanced device. Understanding these critical components is vital for comprehending how the system operates and performs its intended functions efficiently.

Core Elements

At the heart of the mechanism lies a robust engine, engineered for optimal performance. This unit is complemented by a sophisticated control system that regulates various operations, ensuring precision and reliability. Additionally, a high-quality filtration system plays a crucial role in maintaining efficiency by removing impurities from the airflow.

Supporting Structures

Supporting the main engine are various structural components designed for durability and stability. These include a well-crafted chassis that enhances overall integrity and a series of mounts that secure the engine and other essential units in place. Regular maintenance of these parts is necessary to ensure the longevity and performance of the entire system. Furthermore, accessory units contribute significantly to the functionality, enabling a range of operations that enhance user experience.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication and understanding in any technical field. These illustrations serve as essential tools for users, facilitating navigation through complex structures and enhancing comprehension of intricate systems.

Enhancing Clarity

Clear illustrations help eliminate confusion, allowing users to quickly identify components and their functions. When visuals are precise, it minimizes the risk of errors during assembly or maintenance, ultimately leading to improved efficiency.

Supporting Training and Development

Accurate visuals also play a vital role in educational contexts. They are invaluable resources for training new personnel, providing a reference that aids in mastering the intricacies of a system. With well-crafted representations, learners can delve deeper into their studies, fostering a stronger understanding.

Common Issues with Br700 Parts

When dealing with complex machinery, certain components often exhibit recurring problems that can hinder performance and efficiency. Identifying these challenges early can lead to more effective maintenance and prolonged lifespan of the equipment.

Wear and Tear: Over time, essential components may experience deterioration due to frequent use, leading to reduced functionality. Regular inspections are crucial to detect these issues.

Improper Installation: Errors during assembly can result in misalignment or inadequate connections, causing malfunctions. Ensuring precise installation is vital for optimal operation.

Material Fatigue: Continuous exposure to stress can cause some materials to weaken, resulting in fractures or failures. Monitoring stress levels is essential to prevent unexpected breakdowns.

Contamination: Dirt, dust, and other contaminants can accumulate, affecting the efficiency of crucial components. Routine cleaning and maintenance help mitigate this risk.

Incompatibility: Using non-standard or mismatched components can lead to operational issues. It’s important to verify compatibility before replacements.

How to Read the Diagram

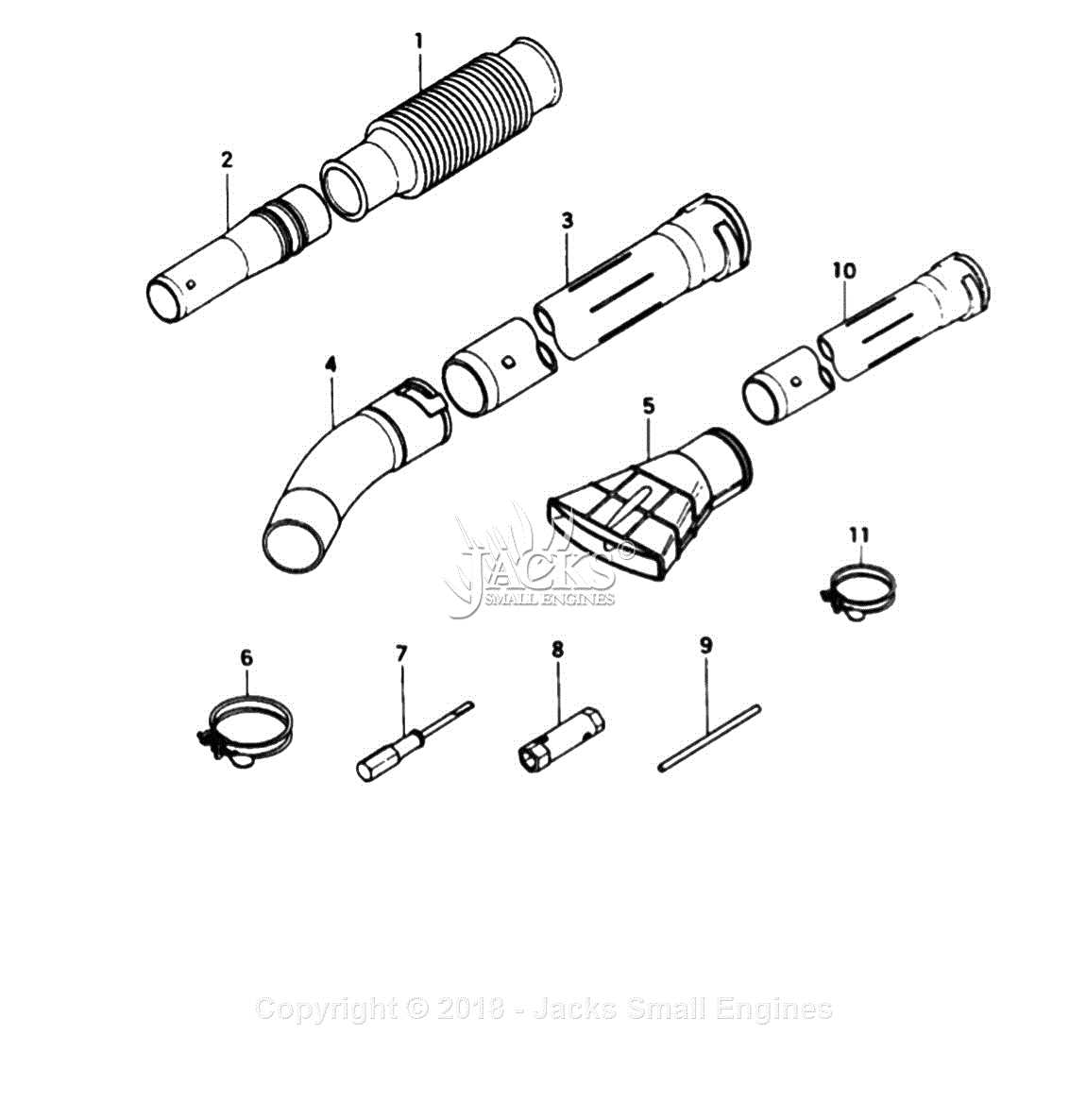

Understanding a visual representation of components can significantly enhance your comprehension of their relationships and functions. This process involves interpreting symbols, lines, and annotations that collectively convey essential information.

First, familiarize yourself with the key. It often includes explanations of the symbols used, which can represent different types of elements, such as connectors or mechanical parts. Pay close attention to these notations as they serve as the foundation for further analysis.

Next, examine the layout. Components are typically organized in a logical manner, often indicating how they interact with each other. Tracing connections can help you visualize the flow of processes or the assembly order.

Lastly, take note of any accompanying notes or specifications. These annotations provide crucial details that can clarify the purpose and functionality of each element, ensuring you grasp the ultimate objectives of the schematic.

Maintenance Tips for Br700 Parts

Proper upkeep is essential for ensuring longevity and optimal performance of your machinery components. Regular attention to detail can prevent costly repairs and enhance efficiency. Here are some strategies to keep everything running smoothly.

Regular Inspections

Routine checks allow you to identify wear and tear early. Focus on key areas prone to deterioration. Ensure all connections are secure and components are free from debris.

Lubrication and Cleaning

Maintaining cleanliness and appropriate lubrication is vital. This helps minimize friction and prolongs the lifespan of moving elements. Use recommended lubricants for best results.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Look for signs of wear or damage. |

| Cleaning | Monthly | Remove dust and debris. |

| Lubrication | Every 3 Months | Use manufacturer-recommended products. |

Comparative Analysis with Similar Models

This section aims to explore and contrast a specific model with its counterparts in the industry. By examining their features, functionalities, and overall performance, we can uncover insights that highlight the strengths and weaknesses of each variant.

Key Features Comparison

- Performance metrics

- Design and build quality

- Technological advancements

- User feedback and satisfaction

Advantages and Disadvantages

- Model A:

- Advantages: Enhanced efficiency, compact size

- Disadvantages: Higher maintenance costs

- Model B:

- Advantages: Cost-effective, robust design

- Disadvantages: Limited features compared to others

In conclusion, analyzing these models reveals a spectrum of options that cater to different needs and preferences, allowing users to make informed decisions based on their specific requirements.

Replacement Part Options Available

When it comes to maintaining and enhancing the performance of specialized equipment, understanding the variety of available components is essential. This section explores the different alternatives you can consider to ensure optimal functionality and longevity.

Types of Components

There are numerous types of replacements that cater to various needs. From high-quality OEM selections that ensure compatibility to aftermarket solutions that often provide cost-effective alternatives, users have a broad spectrum of options. Choosing the right type depends on factors such as budget, intended use, and specific performance requirements.

Where to Source Components

Finding reliable suppliers is crucial for acquiring suitable replacements. Many online platforms and local distributors offer a wide range of choices, ensuring you can access the necessary items conveniently. Always verify the credibility of the seller and consider reading reviews to make informed decisions.

Common Modifications and Upgrades

In the realm of enhancing aircraft performance and functionality, enthusiasts often explore various improvements to optimize their experience. These upgrades can range from minor tweaks to substantial alterations, aiming to enhance efficiency, safety, and comfort.

Performance Enhancements

- Engine tuning for increased power output.

- Weight reduction through the use of lightweight materials.

- Improved aerodynamics via streamlined components.

Comfort and Convenience

- Upgrading the cockpit with advanced avionics.

- Installing modern seating for enhanced passenger comfort.

- Implementing noise reduction systems for a quieter cabin.

Finding Quality Parts Suppliers

Identifying reliable vendors for essential components is crucial for maintaining operational efficiency and safety. The selection process requires careful consideration of various factors to ensure optimal performance and longevity of the items sourced.

Research plays a significant role in uncovering trustworthy providers. Online reviews, testimonials, and industry recommendations can help gauge a supplier’s reputation. Additionally, establishing communication with potential vendors allows for assessing their responsiveness and willingness to assist with inquiries.

Evaluating quality assurance measures is also vital. Suppliers should adhere to industry standards and provide documentation that verifies the integrity of their offerings. This step not only ensures compliance but also fosters confidence in the durability of the products acquired.

Lastly, consider the logistical aspects of procurement. Timeliness, delivery options, and after-sales support are key factors that contribute to a seamless purchasing experience. Prioritizing these elements will ultimately enhance your operational workflow.

Expert Insights on Br700 Functionality

The intricate design of this device showcases a remarkable interplay of components, each serving a critical role in its overall operation. Understanding how these elements interact is essential for maximizing efficiency and performance.

Specialists emphasize the importance of maintaining a keen awareness of the various functionalities embedded within the system. Each feature is tailored to enhance user experience and reliability, making it vital to delve into their individual purposes.

Moreover, expert analysis reveals that regular assessments can significantly prolong the lifespan of the apparatus. By identifying potential issues early, users can ensure that all components work harmoniously, thereby achieving ultimate effectiveness.

Future Trends in Br700 Design

The evolving landscape of design within this innovative realm is set to revolutionize the way components are structured and utilized. As technology advances, the focus shifts toward enhancing efficiency, sustainability, and user experience, ultimately transforming the industry.

Innovative Materials

- Incorporation of lightweight composites

- Utilization of recyclable materials

- Enhanced durability through nanotechnology

Smart Integration

- Integration of IoT for real-time monitoring

- Adaptive systems for improved functionality

- Data analytics for predictive maintenance

These trends will not only streamline production processes but also elevate performance standards, marking a new era of design excellence.