When it comes to maintaining and operating farming machinery, comprehending the various elements that comprise these tools is essential. This knowledge not only ensures efficient functioning but also aids in troubleshooting potential issues that may arise during usage. By familiarizing oneself with the intricate structures and functions of these components, operators can achieve optimal performance and longevity of their equipment.

In this exploration, we delve into the specific configurations and arrangements that define a particular model of mowing apparatus. The detailed representations of these elements provide valuable insights into how each piece contributes to the overall functionality. Such understanding empowers users to make informed decisions regarding maintenance, repairs, and upgrades, enhancing their productivity in the field.

Furthermore, a thorough grasp of the layout and interconnectivity of the various sections allows for easier identification of wear and tear. This proactive approach to machinery care can lead to improved efficiency, reducing downtime and ensuring that operations run smoothly. Whether you are a seasoned operator or a newcomer to the agricultural scene, this information will prove beneficial in navigating the complexities of modern farming equipment.

Exploring the Anatomy of the M2561 Machinery Components

In this section, we delve into the intricate details of the essential elements that constitute the M2561 equipment. We aim to provide a comprehensive view of its internal structure, highlighting key components without resorting to overly technical jargon.

| Main Frame | The sturdy foundation of the machinery, supporting all operational components. |

| Blade Assembly | Responsible for the cutting and shredding tasks, ensuring efficient performance. |

| Hydraulic System | Controls the movements and functionalities of various mechanical parts. |

| Power Transmission | Transfers engine power to operational components with minimal energy loss. |

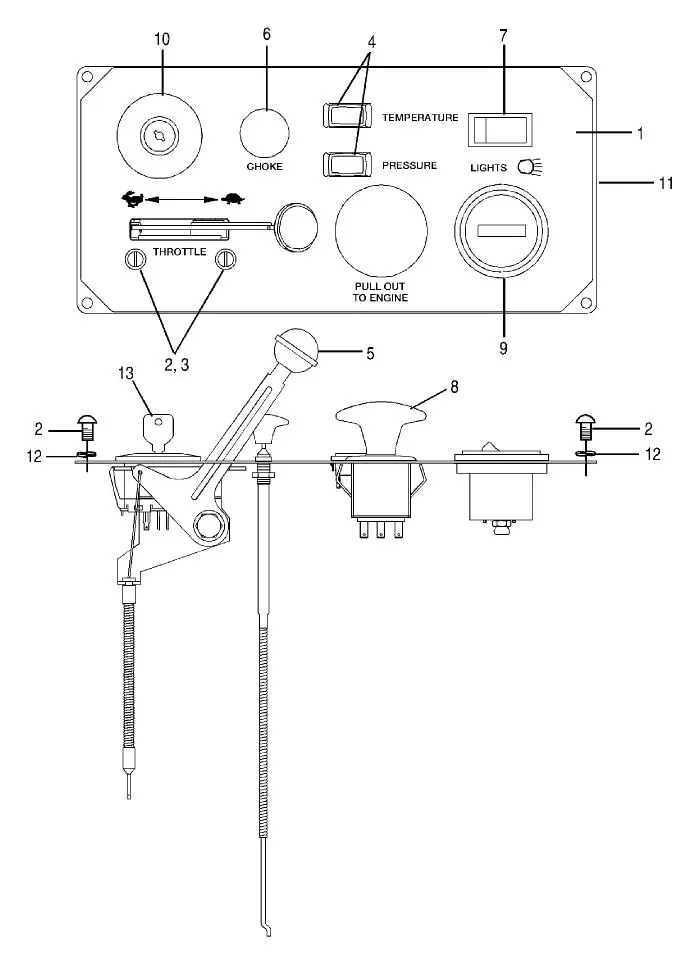

| Control Panel | Allows operators to manage and adjust the machine’s settings for optimal use. |

Each component plays a crucial role in the seamless operation of the M2561, contributing to its overall efficiency and durability. Understanding these parts enhances not only maintenance efforts but also facilitates better utilization of the equipment in various agricultural tasks.

Understanding the Bush Hog M2561 Model

In this section, we delve into the intricacies of the M2561 model, exploring its components and functionality without delving into specific part names or detailed schematics. The M2561 is a robust agricultural implement known for its efficiency and durability in field operations.

Key Features and Components

- Essential elements that contribute to its operational prowess

- Main components that define its functionality

- Structural aspects crucial for its performance in agricultural settings

Operational Insights

- How the M2561 model functions in various agricultural tasks

- Key operational considerations for maximizing efficiency

- Performance metrics and capabilities in real-world scenarios

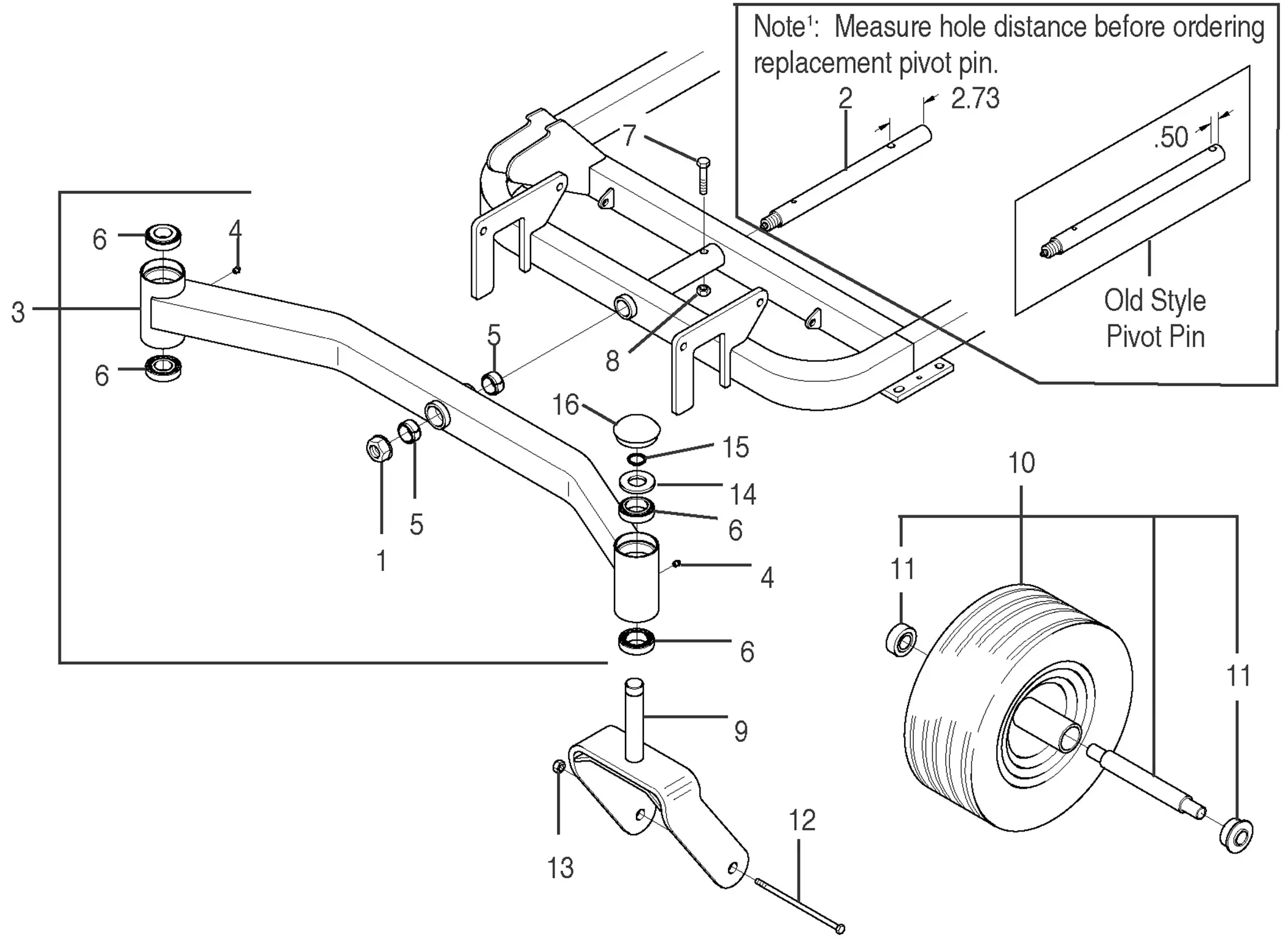

Locating Key Components on the Bush Hog M2561

In this section, we will explore the essential elements that make up the operational framework of the M2561 equipment. Understanding these crucial parts facilitates a comprehensive grasp of its functionality and maintenance requirements.

- Main Assembly: The core structure housing vital mechanisms essential for operation.

- Power Transmission Unit: Facilitates the transfer of power from the engine to operational components.

- Cutting Mechanism: Includes the blade assembly responsible for cutting and mulching tasks.

- Hydraulic System: Controls the operation of various moving parts and implements.

- Control Panel: Interface for monitoring and adjusting operational settings.

Each component plays a pivotal role in ensuring the effectiveness and durability of the M2561, making it essential to identify and understand their functions within the equipment.

Exploring the Blade Assembly in Detail

The cutting mechanism is a critical component that ensures effective operation, transforming raw power into precise action. This section focuses on the intricacies of the blade setup, its role in providing clean and consistent performance, and the various factors that influence its longevity and efficiency.

Material selection plays a key role in determining the durability of the cutting edge. Blades made from high-quality metals are better suited to withstand the stresses of heavy-duty tasks, offering a longer lifespan and improved reliability.

Another crucial aspect is the mounting system. A well-engineered attachment ensures stability and reduces wear on the blade itself. Proper alignment and secure fastening not only extend the life of the blade but also contribute to smoother, more efficient cutting.

Lastly, regular maintenance is essential for keeping the cutting mechanism in optimal condition. Sharpening and balancing the blades periodically prevents performance issues, ensuring a c

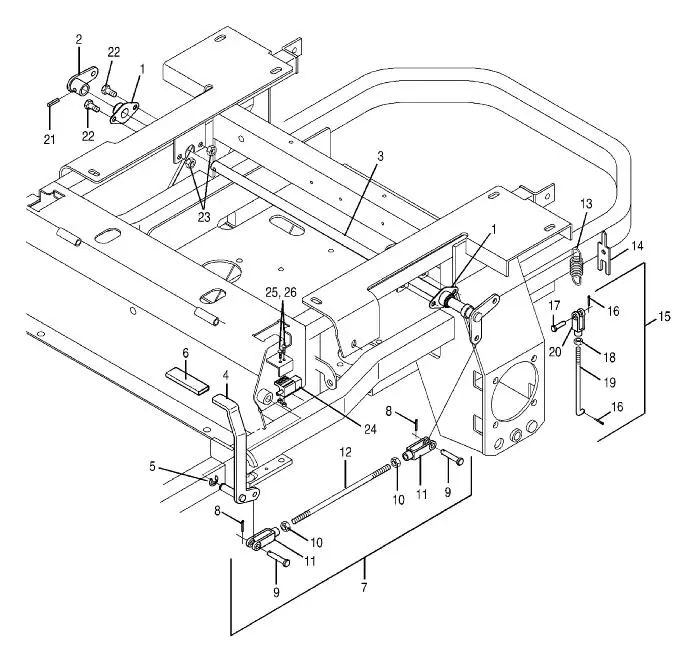

Identifying Drive System Components

Understanding the elements of a drive mechanism is crucial for maintaining optimal functionality in machinery. These components work in harmony to ensure effective power transmission and operational efficiency. By familiarizing yourself with these elements, you can enhance performance and address any potential issues that may arise during use.

Key Elements of the Drive System

The primary components of a drive system include the transmission unit, drive shafts, and coupling mechanisms. The transmission unit is responsible for modifying the speed and torque output, while drive shafts facilitate the transfer of energy between the engine and other machinery parts. Couplings play a vital role in connecting these shafts, allowing for smooth operation and minimizing wear and tear.

Common Issues and Solutions

Problems within the drive system can manifest in various ways, such as unusual noises or reduced efficiency. Regular inspection of the transmission unit and drive shafts can help identify wear or misalignment early. Ensuring proper lubrication and timely replacement of worn components will significantly extend the lifespan of the drive mechanism and maintain overall equipment reliability.

Examining the Gearbox and Gear Train

The gearbox and gear train are essential components in the machinery, responsible for transmitting power and ensuring efficient operation. Their design plays a crucial role in converting input speed and torque into usable output, which ultimately affects the performance and reliability of the equipment.

Within the gearbox, various gears work together to optimize the mechanical advantage, allowing for smoother transitions between different operational states. The arrangement of these gears determines how force is distributed and modified, enabling the machinery to tackle varying tasks effectively.

Regular inspection of these components is vital to maintain functionality and prevent potential failures. Identifying wear and tear on gears or misalignment in the gear train can lead to significant improvements in efficiency and longevity. Understanding the intricacies of the gearbox system is fundamental for operators and technicians alike.

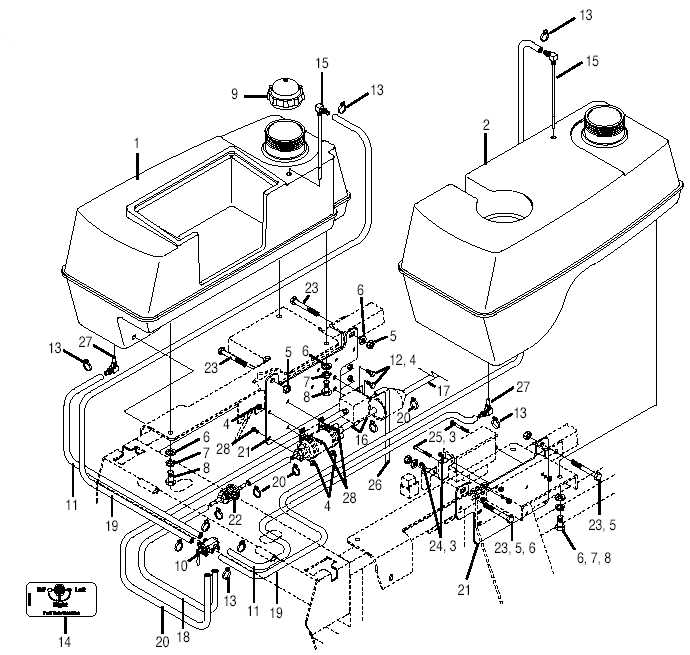

Analyzing the Hydraulic System Layout

The hydraulic system is a crucial component in various machinery, providing the necessary force and motion for effective operation. Understanding its configuration is essential for maintenance and troubleshooting. This section delves into the key elements of the hydraulic system, highlighting their roles and interconnections.

Main Components

- Hydraulic Pump: This device converts mechanical energy into hydraulic energy, creating the fluid pressure required for operation.

- Control Valves: These components regulate fluid flow and direction, allowing for precise control of the system’s functions.

- Actuators: Often in the form of cylinders or motors, actuators convert hydraulic energy back into mechanical motion.

- Reservoir: The storage tank holds hydraulic fluid, ensuring that the system has a sufficient supply for continuous operation.

- Filters: Essential for maintaining fluid cleanliness, filters prevent contaminants from damaging sensitive components.

System Interconnections

The interconnections between these components are vital for the system’s efficiency. Properly designed hydraulic circuits ensure optimal fluid flow and pressure management. Here are some key aspects:

- Flow Paths: Each component must be strategically placed to facilitate smooth fluid movement throughout the system.

- Pressure Points: Identifying critical areas where pressure is generated and utilized helps in understanding potential points of failure.

- Return Lines: Properly configured return lines are necessary for maintaining fluid circulation and system balance.

By examining these elements and their configurations, operators can ensure efficient performance and prolong the lifespan of hydraulic systems.

Inspecting the Frame and Structural Components

Thorough examination of the chassis and its essential elements is crucial for maintaining optimal functionality and safety. This process involves assessing various structural aspects to ensure that they are intact, secure, and free from any signs of wear or damage. Proper inspection not only enhances the durability of the equipment but also prolongs its operational lifespan.

Key Areas to Examine

- Chassis Integrity: Check for any cracks or bends that could compromise stability.

- Welds and Connections: Inspect welds for signs of fatigue and ensure all connections are tight.

- Mounting Points: Evaluate the condition of mounting brackets and bolts to prevent loosening during operation.

Signs of Wear and Damage

- Rust or corrosion on metal surfaces.

- Uneven wear patterns indicating misalignment.

- Excessive vibration or noise during operation.

Regular inspections help identify potential issues early, allowing for timely repairs and adjustments. Maintaining the structural integrity of the machinery is essential for safe and efficient operation.

Understanding Electrical Connections and Components

The functionality of any machinery relies heavily on its electrical framework. This intricate network of connections and devices serves as the brain of the operation, facilitating communication between various elements. Recognizing how these components interact is essential for effective maintenance and troubleshooting.

Electrical connections are vital pathways that allow for the transfer of energy and signals throughout the system. Understanding these pathways involves examining various types of wiring, connectors, and terminals that link the different parts together. Proper connections ensure a seamless flow of electricity, preventing issues such as short circuits or component failure.

Components within the electrical system include switches, fuses, and relays, each playing a specific role in the overall operation. Switches control the flow of electricity, while fuses protect the system from overloads. Relays serve as intermediaries, allowing low-power signals to control higher-power circuits. Familiarity with these elements is crucial for anyone looking to maintain or repair equipment effectively.

Regular inspection and understanding of electrical connections and components can significantly enhance the longevity and performance of machinery. By prioritizing this knowledge, operators can ensure their systems run efficiently and with minimal interruptions.

Reviewing Safety Features and Guards

When operating any agricultural machinery, ensuring safety is paramount. This section focuses on the various protective elements and features integrated into equipment, designed to minimize risks and enhance user security. Properly functioning safety mechanisms are crucial in preventing accidents during operation and maintenance.

Importance of Protective Barriers

Protective barriers play a significant role in safeguarding users from potential hazards associated with moving parts. These features are engineered to limit access to dangerous areas, ensuring that individuals remain at a safe distance while the equipment is in operation. Regular inspection and maintenance of these barriers are essential to uphold their effectiveness and reliability.

Emergency Shut-off Systems

Incorporating emergency shut-off systems is another vital safety aspect. These mechanisms allow operators to quickly deactivate the machinery in case of an unexpected situation, providing an essential layer of protection. Familiarizing oneself with the location and function of these shut-off features is crucial for anyone using the equipment.

Exploring Options for Maintenance and Lubrication

Regular upkeep and effective lubrication are essential for ensuring optimal performance and longevity of machinery. By adhering to recommended practices, users can significantly enhance the operational efficiency and reliability of their equipment. This section delves into various strategies and solutions for maintaining and lubricating machinery, highlighting the importance of proactive care.

Understanding Maintenance Techniques

Implementing a structured maintenance schedule can prevent unexpected breakdowns and prolong the life of machinery. Routine inspections, cleaning, and timely repairs are vital components of a successful maintenance plan. Users should familiarize themselves with the specific requirements of their equipment, ensuring that all components are functioning correctly and efficiently.

Effective Lubrication Practices

Proper lubrication is crucial for minimizing friction and wear between moving parts. Utilizing the right type of lubricant, whether oil or grease, can make a significant difference in performance. Regularly checking and replenishing lubrication levels will help maintain smooth operation and reduce the risk of damage. It is also advisable to follow manufacturer guidelines to determine optimal lubrication intervals and quantities.

Referencing the Bush Hog M2561 Parts Manual

Accessing the manual dedicated to your equipment is essential for maintaining its functionality and ensuring its longevity. This comprehensive guide provides an invaluable resource for understanding the components and their respective roles within the machine. By familiarizing yourself with the layout and descriptions offered in this reference, you can enhance your troubleshooting and repair skills effectively.

Understanding the Importance of the Manual

Having a detailed resource at your disposal allows you to identify the various elements crucial for operation. Each section meticulously outlines the necessary components, enabling users to pinpoint issues quickly and effectively. This knowledge empowers you to conduct repairs independently, saving both time and costs associated with professional assistance.

Utilizing the Reference for Maintenance

Regular upkeep is vital for optimal performance. The manual serves as a step-by-step guide, illustrating the proper procedures for inspections and replacements. By adhering to the instructions, you can ensure that your machinery remains in peak condition, reducing the risk of unexpected failures and enhancing overall efficiency.

Ordering Replacement Parts and Accessories

When it comes to maintaining your equipment, acquiring the necessary components and add-ons is crucial for optimal performance. Understanding how to effectively source these items can enhance the longevity and functionality of your machine. Whether you’re replacing worn-out elements or upgrading features, having a reliable process in place is essential.

Finding Reliable Suppliers

Begin your search by identifying trustworthy vendors that specialize in machinery components. Research online platforms and local distributors that offer a wide range of options. Customer reviews and ratings can provide valuable insights into the reliability of these suppliers. Make sure to compare prices and availability to ensure you get the best deal.

Placing Your Order

Once you have selected a supplier, gather all necessary information regarding the components you need. This includes part numbers, descriptions, and any additional specifications. When placing your order, consider whether you prefer to do so online or via direct communication with the supplier. Ensure that you double-check all details to avoid delays or incorrect shipments. Promptly follow up on your order to confirm processing and delivery timelines.