The functionality of a vehicle’s braking mechanism relies on a collection of essential elements that work in unison to ensure safety and performance. Each component plays a critical role in the overall effectiveness of the system, contributing to a smooth and reliable stopping experience.

Identifying these elements is key to comprehending how they interact and function together. A thorough exploration of these components provides insights into their specific responsibilities, as well as potential issues that may arise if any part becomes compromised.

By delving into the intricate relationships among these components, one can appreciate the engineering and design that goes into creating a dependable stopping mechanism. Understanding these connections is vital for both maintenance and enhancement of vehicle performance.

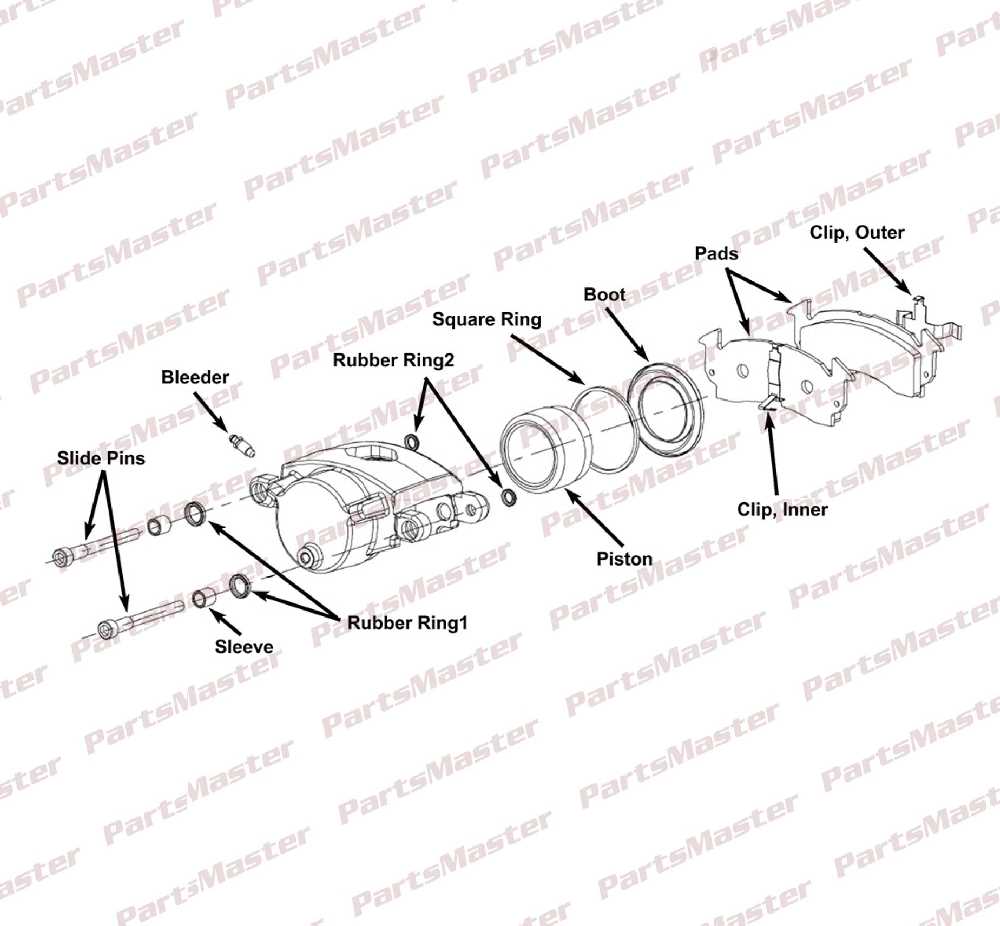

Understanding Caliper Components

Grasping the essential elements of braking mechanisms is vital for effective maintenance and performance. Each component plays a crucial role in ensuring that the system operates smoothly and safely, influencing the overall functionality of the vehicle.

Key Elements: Within this system, various elements collaborate to provide optimal stopping power. These include devices responsible for pressure distribution, friction generation, and adjustment to varying driving conditions.

Functionality Insights: Analyzing these components reveals how they interact under pressure, enhancing safety and control during operation. Understanding their roles can aid in troubleshooting and improving system reliability.

Maintenance Importance: Regular inspection and knowledge of these components can prevent wear and tear, ensuring longevity and efficiency in braking performance.

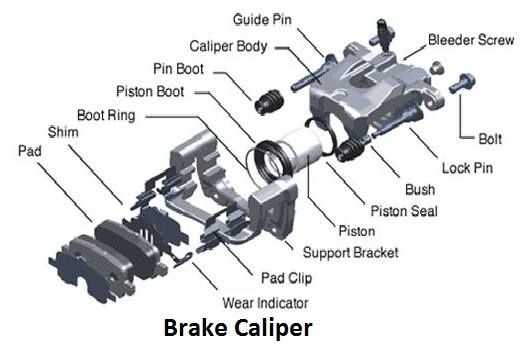

Key Parts of a Brake Caliper

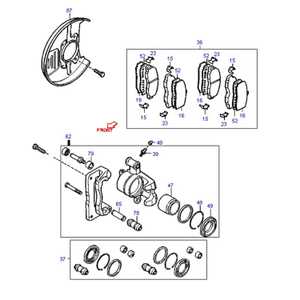

The essential components involved in the braking system play a crucial role in ensuring effective vehicle deceleration. Understanding their functions is vital for proper maintenance and performance.

Piston: The primary actuator that generates hydraulic pressure, pushing the friction material against the rotor to create stopping power.

Friction Material: This is the surface that contacts the rotor, designed to create friction when pressure is applied, thus slowing down the vehicle.

Housing: The outer shell that encloses the internal mechanisms, providing structural integrity and protection from environmental factors.

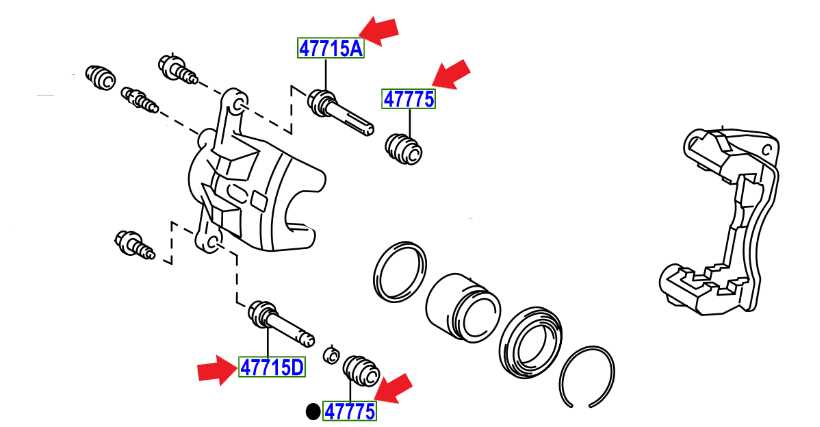

Guide Pins: These components allow for smooth movement and alignment of the assembly during operation, ensuring consistent contact with the rotor.

Brake Line Connection: The link that facilitates the flow of hydraulic fluid, essential for transferring force from the pedal to the piston.

Functionality of Each Component

This section explores the various elements of a braking mechanism and their specific roles in ensuring optimal performance. Understanding the functionality of each element is crucial for maintaining efficiency and safety in automotive systems.

| Component | Function |

|---|---|

| Piston | Applies pressure to the friction material, creating the necessary force to halt movement. |

| Friction Material | Engages with the rotor to generate friction, effectively slowing down the vehicle. |

| Housing | Encases the internal components, providing structural support and protecting them from external elements. |

| Bleeder Valve | Facilitates the removal of air from the hydraulic system, ensuring effective pressure transfer. |

| Mounting Bracket | Secures the assembly to the vehicle, maintaining proper alignment and stability during operation. |

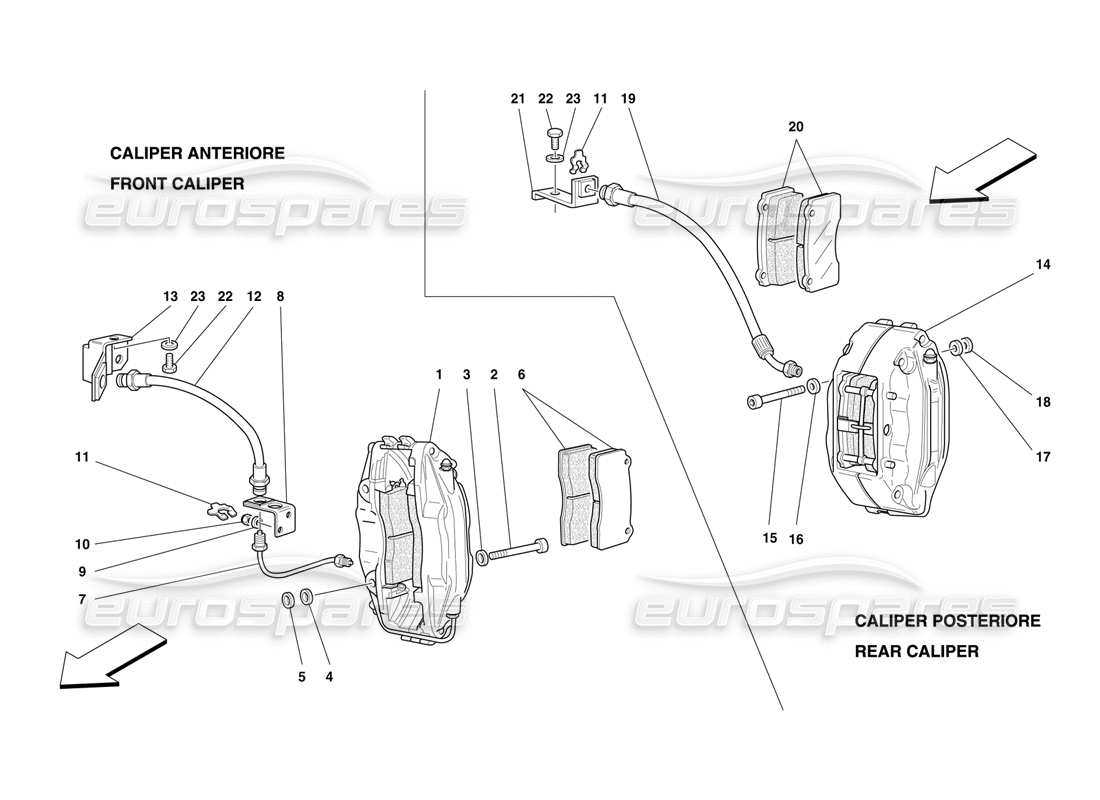

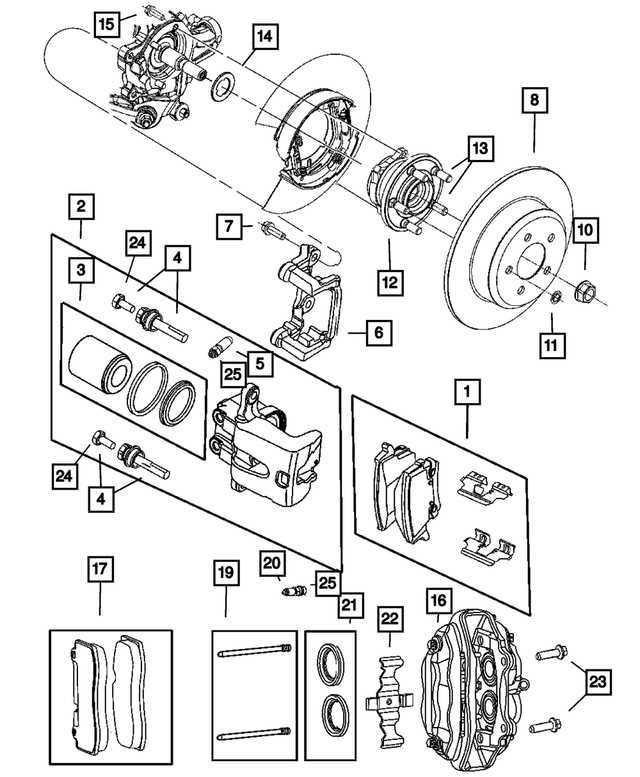

Identifying Common Caliper Types

Understanding the various types of braking components is essential for effective maintenance and repair. Each variant serves specific functions and exhibits unique characteristics that influence vehicle performance and safety. Recognizing these differences aids in selecting the appropriate replacement or upgrade.

Below is a summary of the most prevalent designs found in modern vehicles:

| Type | Description | Common Applications |

|---|---|---|

| Floating | Utilizes a single piston and allows movement to ensure even pressure distribution. | Standard passenger vehicles |

| Fixed | Features multiple pistons that provide consistent and reliable force, enhancing stopping power. | High-performance and sports cars |

| Radial | Employs pistons arranged radially for improved strength and performance under heavy loads. | Racing applications |

| Pin | Incorporates a pin system for smooth operation and ease of installation. | Compact vehicles and light trucks |

Materials Used in Caliper Manufacturing

The construction of braking devices involves a variety of materials that enhance performance, durability, and safety. Each component requires specific properties to withstand operational stresses and environmental factors. Understanding these materials is crucial for optimizing functionality and longevity.

Common Materials

- Aluminum: Lightweight and resistant to corrosion, aluminum is often used for housing, providing effective heat dissipation.

- Cast Iron: Known for its strength and durability, cast iron is frequently utilized in high-performance applications.

- Composite Materials: These materials offer a balance of weight and strength, commonly found in specialized applications.

- Steel: Valued for its toughness, steel is used in various components, ensuring reliability under heavy loads.

Coatings and Treatments

- Powder Coating: Applied to enhance resistance to corrosion and wear.

- Anodizing: A process that increases surface hardness and improves corrosion resistance, particularly for aluminum parts.

- Plating: Techniques such as nickel or chrome plating provide additional protection and aesthetic appeal.

Maintenance Tips for Calipers

Regular upkeep of your braking system components is essential for ensuring optimal performance and safety. By following these straightforward guidelines, you can prolong the lifespan of your equipment and enhance overall functionality.

Routine Inspections

Frequent examinations are crucial to identify any wear or damage. Check for fluid leaks, corrosion, or unusual noises during operation. Addressing these issues promptly can prevent more significant problems down the line.

Cleaning Procedures

Keep components free from dirt and debris to maintain efficiency. Use a soft cloth and appropriate cleaning solutions to remove contaminants. Ensure all moving elements are properly lubricated to reduce friction and enhance performance.

| Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Cleaning | Every 3 Months |

| Fluid Check | Every 6 Months |

Common Issues and Troubleshooting

This section addresses frequent challenges encountered during maintenance and provides solutions to enhance performance and reliability. Understanding potential problems can significantly aid in preventing costly repairs and ensuring optimal functionality.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Leaking Fluid | Fluid spots under the assembly | Inspect seals for damage; replace if necessary. |

| Uneven Wear | Worn surfaces on one side | Check alignment; adjust if needed. |

| Noise During Operation | Unusual sounds while in use | Inspect components for wear; lubricate or replace parts. |

| Reduced Performance | Sluggish response | Examine fluid levels and quality; refill or change fluid. |

How to Replace Caliper Parts

Replacing components of the braking system can significantly enhance vehicle performance and safety. This process typically involves several key steps that ensure each element is correctly installed and functions effectively.

Begin by elevating the vehicle and securely supporting it on jack stands. Remove the wheel to access the assembly, then carefully detach the existing components, taking note of their arrangement for proper reinstallation. It’s crucial to inspect all surfaces for wear or damage before placing new elements in their designated locations.

Once the new pieces are in place, reassemble the system meticulously, ensuring all fasteners are tightened to the manufacturer’s specifications. Finally, bleed the braking system to eliminate any air pockets, restoring optimal functionality. Remember to test the system before driving to confirm everything operates as intended.

Comparing Floating and Fixed Calipers

When it comes to braking systems, understanding the distinctions between different designs can greatly enhance performance and reliability. The choice between movable and stationary assemblies can impact various aspects of vehicle handling and safety. This section delves into the characteristics of these two approaches, highlighting their advantages and disadvantages.

| Feature | Movable Assembly | Stationary Assembly |

|---|---|---|

| Design | Utilizes a sliding mechanism that allows movement | Remains fixed in one position during operation |

| Weight | Generally lighter due to fewer components | Often heavier due to more robust construction |

| Cost | Typically less expensive to manufacture | Can be more costly due to complexity |

| Heat Dissipation | May experience uneven cooling | Often provides better heat management |

| Performance | Can offer responsive braking under certain conditions | Delivers consistent braking force and stability |

Importance of Caliper Assembly

The assembly of braking components plays a crucial role in the overall functionality of a vehicle’s stopping system. Its design and arrangement ensure effective friction and precise movement, contributing significantly to safety and performance.

Reliable operation of this assembly directly affects the vehicle’s ability to slow down or halt, making it essential for preventing accidents. A well-functioning unit allows for consistent responsiveness under various driving conditions, enhancing the driver’s control.

Moreover, maintaining the integrity of this assembly can lead to longer service life of the entire braking system. Regular inspections and timely replacements help avoid costly repairs and ensure that the vehicle remains in optimal condition.

Caliper Performance and Vehicle Safety

Efficient braking components are crucial for optimal vehicle performance and ensuring safety on the road. Their reliability directly affects stopping power, response time, and overall driving experience, making it essential to understand their role in automotive functionality.

Importance of Quality Components

High-quality braking mechanisms enhance stability and control, reducing the risk of accidents. Regular maintenance and timely replacements of these mechanisms contribute significantly to vehicle safety, preventing potential failures during operation.

Factors Influencing Effectiveness

Several aspects can influence the effectiveness of braking systems, including design, material durability, and environmental conditions. Monitoring these factors ensures consistent performance and maximizes the safety of the vehicle.

| Factor | Impact on Performance |

|---|---|

| Material Quality | Improves durability and resistance to wear |

| Design Efficiency | Enhances response time and stopping distance |

| Environmental Conditions | Affects performance under varying temperatures and surfaces |

Innovations in Caliper Design

Recent advancements in braking system technology have led to significant enhancements in the overall functionality and efficiency of braking mechanisms. These innovations focus on improving performance, safety, and durability while ensuring a lighter weight and more compact design.

Key Technological Advancements

- Materials: The introduction of lightweight composite materials enhances strength while reducing weight, contributing to better fuel efficiency.

- Heat Dissipation: Enhanced cooling designs mitigate heat buildup, improving performance during prolonged use.

- Integration: Advanced integration with electronic control systems allows for smarter braking functions, improving responsiveness and safety.

Design Enhancements

- Modular construction simplifies maintenance and repair, reducing downtime.

- Ergonomic shapes improve handling and reduce operator fatigue.

- Customizable options allow for tailored solutions, meeting diverse performance requirements.