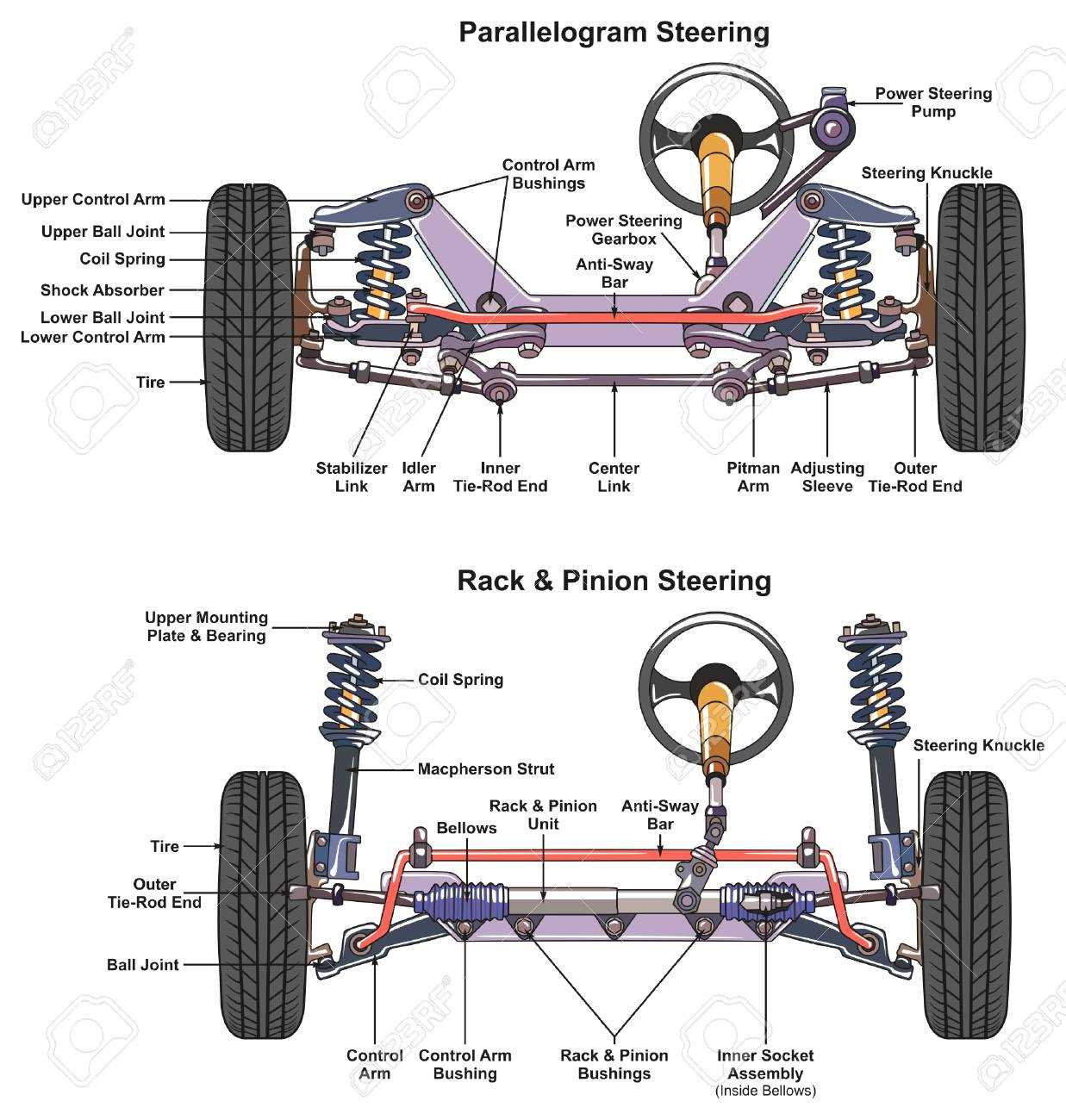

Exploring the various elements that make up a vehicle’s rolling apparatus is essential for maintenance and performance. Each component plays a vital role in ensuring safety, stability, and efficient operation on the road.

The intricate assembly includes a variety of segments that work in harmony to provide optimal functionality. Understanding these elements helps in diagnosing issues and enhancing the overall driving experience.

Familiarity with the structure and function of these components can empower vehicle owners to make informed decisions regarding upkeep and replacements. A comprehensive grasp of these mechanisms not only promotes longevity but also contributes to enhanced performance.

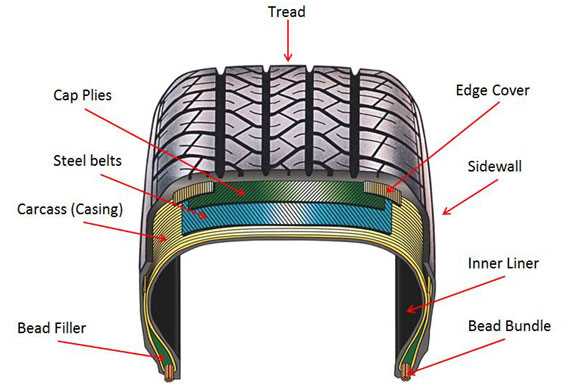

The bead is a crucial component within a wheel structure, playing a vital role in maintaining overall integrity and performance. This element is designed to create a secure interface between the wheel and the surrounding environment, ensuring stability and safety during operation.

Key Functions of the Bead

- Sealing: The bead helps in preventing air leakage, which is essential for optimal performance.

- Attachment: It securely connects the wheel to the surrounding framework, facilitating effective handling and maneuverability.

- Flexibility: The design allows for slight movements, accommodating various road conditions while maintaining control.

Importance of Proper Maintenance

Regular checks on the bead’s condition are crucial for ensuring longevity and functionality. Issues such as wear and tear can compromise safety and performance, making timely inspections and replacements essential for optimal operation.

Understanding Tire Belts

The construction of a wheel’s outer layer involves various components that play crucial roles in performance and durability. Among these, the belts provide essential strength and stability, enhancing the overall functionality of the structure.

Belts are typically composed of layers of materials designed to withstand forces exerted during operation. Their primary function is to reinforce the outer casing, ensuring that it maintains its shape under pressure. This reinforcement is vital for the longevity and safety of the wheel during use.

Furthermore, the arrangement and composition of these belts can significantly influence traction and handling. Different designs cater to specific conditions, balancing aspects like flexibility and rigidity to optimize performance.

Overview of Tire Casing

The casing serves as the fundamental structure that provides stability and support for the overall assembly. It plays a crucial role in ensuring performance and safety on various surfaces.

- Structure: The casing is composed of several layers, each designed to enhance durability and flexibility.

- Materials: Typically made from a combination of synthetic and natural fibers, these materials contribute to the strength and resilience of the structure.

- Functionality: This component is vital for maintaining shape under pressure and absorbing shocks from the road, which enhances comfort during use.

Understanding the significance of the casing helps in appreciating its role in enhancing performance, longevity, and safety of the entire assembly.

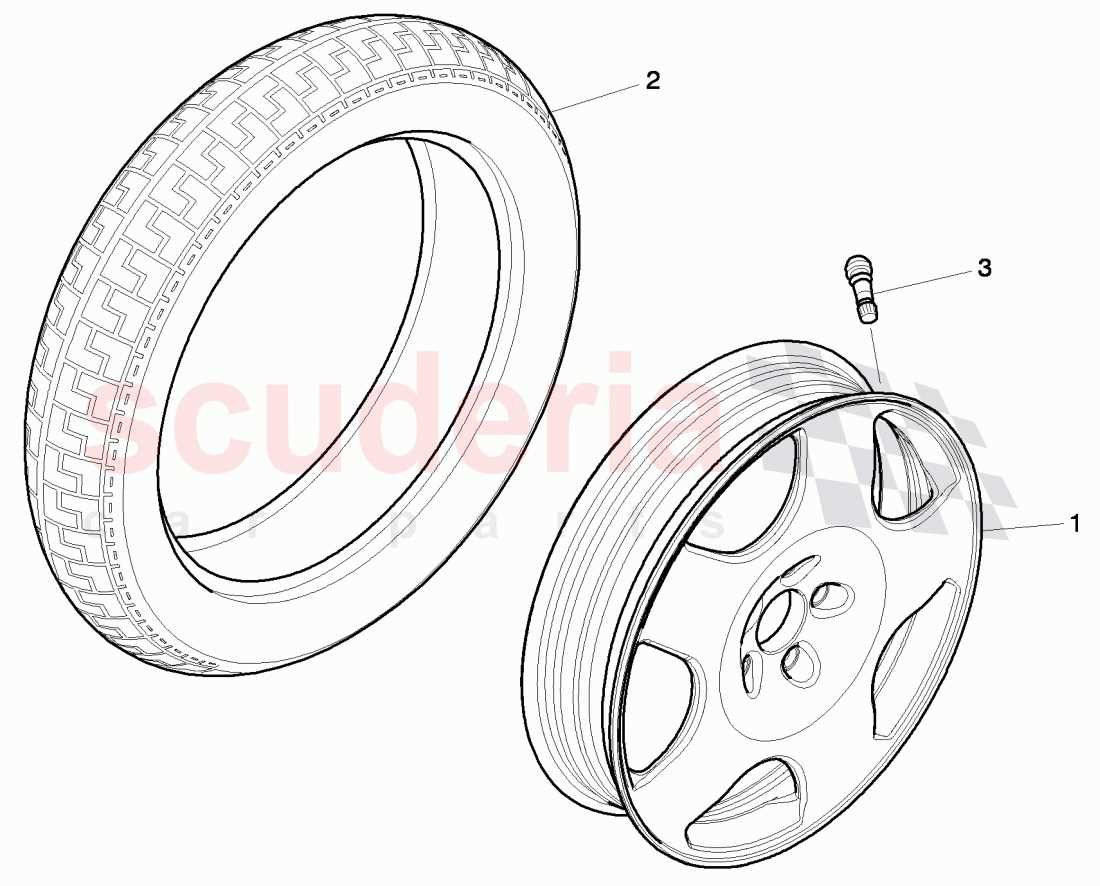

Why Tires Need Valves

Valves play a crucial role in maintaining the integrity and functionality of inflatable structures. These components ensure that the air remains contained, allowing for optimal performance and safety. Without them, the risk of deflation increases significantly, which can lead to various issues during operation.

Maintaining Air Pressure

One of the primary functions of valves is to regulate and maintain air pressure within the structure. Proper inflation is essential for achieving the right balance between comfort and handling. Valves prevent air from escaping, ensuring that the correct pressure is sustained over time.

Facilitating Inflation and Deflation

Another important aspect is that valves enable easy inflation and deflation. They allow users to adjust the air levels as needed, whether for seasonal changes or specific conditions. This adaptability contributes to enhanced performance and longevity of the inflatable components.

The Impact of Tread Depth

The depth of the grooves on a vehicle’s contact surface plays a crucial role in ensuring optimal performance and safety. It affects traction, handling, and the overall ability to navigate various road conditions. Understanding how this aspect influences driving can significantly enhance the experience and reduce risks.

Safety Considerations

Adequate groove depth is essential for maintaining grip, especially in wet or slippery environments. Insufficient depth can lead to hydroplaning, where the vehicle loses contact with the road, resulting in a dangerous loss of control. Regularly checking and maintaining the proper depth is vital for safe driving.

Performance and Longevity

Not only does groove depth impact safety, but it also influences the longevity of the surface. A well-maintained depth can lead to even wear, promoting durability and performance efficiency. Investing in proper maintenance can ultimately save costs and enhance the vehicle’s operational life.

Different Types of Tire Materials

Various compositions are employed in the manufacturing of vehicle wheels, each offering distinct characteristics that enhance performance and durability. Understanding these materials is essential for making informed choices regarding quality and suitability.

- Natural Rubber: Sourced from rubber trees, this material provides excellent elasticity and traction.

- Synthetic Rubber: Engineered through chemical processes, it offers enhanced resistance to wear and temperature variations.

- Textiles: Fabrics such as polyester and nylon are utilized for reinforcement, contributing to structural integrity and flexibility.

- Steel Belts: Incorporating steel belts improves strength and stability, especially under heavy loads.

- Silica: Used in tread compounds, silica enhances grip and reduces rolling resistance, contributing to better fuel efficiency.

Each material plays a crucial role in determining the overall performance, safety, and lifespan of the wheel, making material selection an important factor in automotive design and engineering.

Identifying Tire Defects

Recognizing imperfections in rubber wheels is essential for ensuring safety and performance. Various types of damage can compromise their integrity, leading to potential hazards on the road. Regular inspections help in detecting issues early, allowing for timely repairs or replacements.

Common indicators of damage include uneven wear patterns, bulges, or cuts on the surface. These anomalies may signal underlying problems, such as improper inflation or misalignment. Furthermore, checking for foreign objects lodged in the tread can prevent further complications.

Understanding these signs and their implications enables vehicle owners to maintain optimal functionality and extend the lifespan of their rubber wheels. Consistent attention to potential defects not only enhances safety but also contributes to a smoother driving experience.

Seasonal Variations in Tire Design

Adapting to changing weather conditions is essential for optimal performance and safety. Designs often vary significantly based on seasonal demands, enhancing traction, stability, and durability across diverse environments.

Key factors influencing design include:

- Temperature: Materials are selected based on their ability to withstand heat and cold.

- Weather Conditions: Tread patterns are engineered for wet, dry, or snowy surfaces.

- Usage Patterns: Consideration of how and where the vehicle will be used throughout different seasons.

As a result, consumers can expect distinct characteristics tailored to enhance performance year-round. Understanding these variations helps in making informed choices for safety and efficiency.