In this section, we explore the detailed structure and organization of essential elements within a compact and efficient construction vehicle. This guide provides an overview of the main components, their alignment, and the way they connect to form a fully functional system.

The following segments delve into the specific modules and their configurations. By examining each segment’s placement and role, one can gain a deeper appreciation for the engineering precision behind the machinery. This examination not only highlights the importance of each part but also helps to identify and understand the interconnected nature of the entire system.

Efficient maintenance and troubleshooting become more manageable when there’s clarity on how every section is structured. Our aim is to present this information in a straightforward manner, ensuring

Cat 257B Parts Overview

This section provides a comprehensive look at the key elements and components that make up this compact track loader. Understanding the various pieces and how they interact is essential for maintaining and ensuring the efficient operation of the machine.

The design includes a variety of systems working together, such as the hydraulic assembly, undercarriage structure, and power transmission units. Each system has its own set of elements that are engineered to work in harmony, providing stability, mobility, and power.

The internal structure is supported by a robust chassis, housing critical systems like the drive train and engine compartment. The external framework includes attachments and linkage elements, enabling the machine to perform a wide range of tasks effectively. These components are designed for durability, ensuring long-term operation under demanding conditions.

Understanding the Cat 257B Structure

The design and configuration of this compact machine are crucial for its efficiency and functionality. This section provides an overview of its framework, highlighting the main elements that contribute to its stability and versatility in various tasks.

The framework of the machine includes multiple interconnected components, each serving a specific purpose to support performance and maneuverability. Understanding these elements helps operators maintain and optimize the equipment’s use over time.

- Chassis and Frame: The base structure provides support and houses essential parts, ensuring durability and balance during operation.

- Hydraulic System: A complex network that powers the movement and functions of the machine, allowing for efficient and precise control.

- Track System: Engineered to offer traction and stability, the tracks enable smooth movement across various surfaces, enhancing mobility and adaptability.

- Operator Cabin:

Key Components of the Cat 257B

The essential elements of this machinery are designed to ensure efficient operation, durability, and versatility in various tasks. Each part plays a critical role, contributing to the overall functionality and performance. Below is a breakdown of these crucial elements, which help maintain stability, maneuverability, and power during operation.

Component Description Hydraulic System A complex network responsible for transferring power through pressurized fluid, enabling smooth movement and operation of attachments. Track Assembly Offers traction and stability on various terrains, providing support and ensuring the equipment remains balanced during use. Hydraulic System Breakdown

The hydraulic mechanism is crucial for the efficient operation of heavy machinery, providing the necessary power for various functions. This section offers an overview of how the fluid power system operates, including key components and their roles in ensuring effective performance.

Key Components and Functions

The hydraulic system comprises several essential elements that work together to deliver controlled movement and force. These components include pumps, valves, cylinders, and hoses, each with a specific function within the system. Proper maintenance and understanding of these parts are vital for maximizing the machine’s efficiency and longevity.

Common Hydraulic Elements

Component Function Engine and Transmission Details

The power and movement system is crucial for the overall performance and functionality of this machine. Understanding the core components of the engine and its transmission system helps in maintaining efficiency and ensuring longevity. Below, we explore the primary features and functions that drive this machinery, including how different elements interact for optimal performance.

Engine Specifications: The engine serves as the main power source, providing the energy needed for various operations. It is designed with precision to offer maximum power output while maintaining fuel efficiency. Key elements include the combustion system, cooling mechanisms, and emission control technologies, all working together to create a balanced and efficient power delivery.

Transmission System: This system is responsible for transferring power from the engine to the wheels, enabling smooth and controlled movement. It consists of

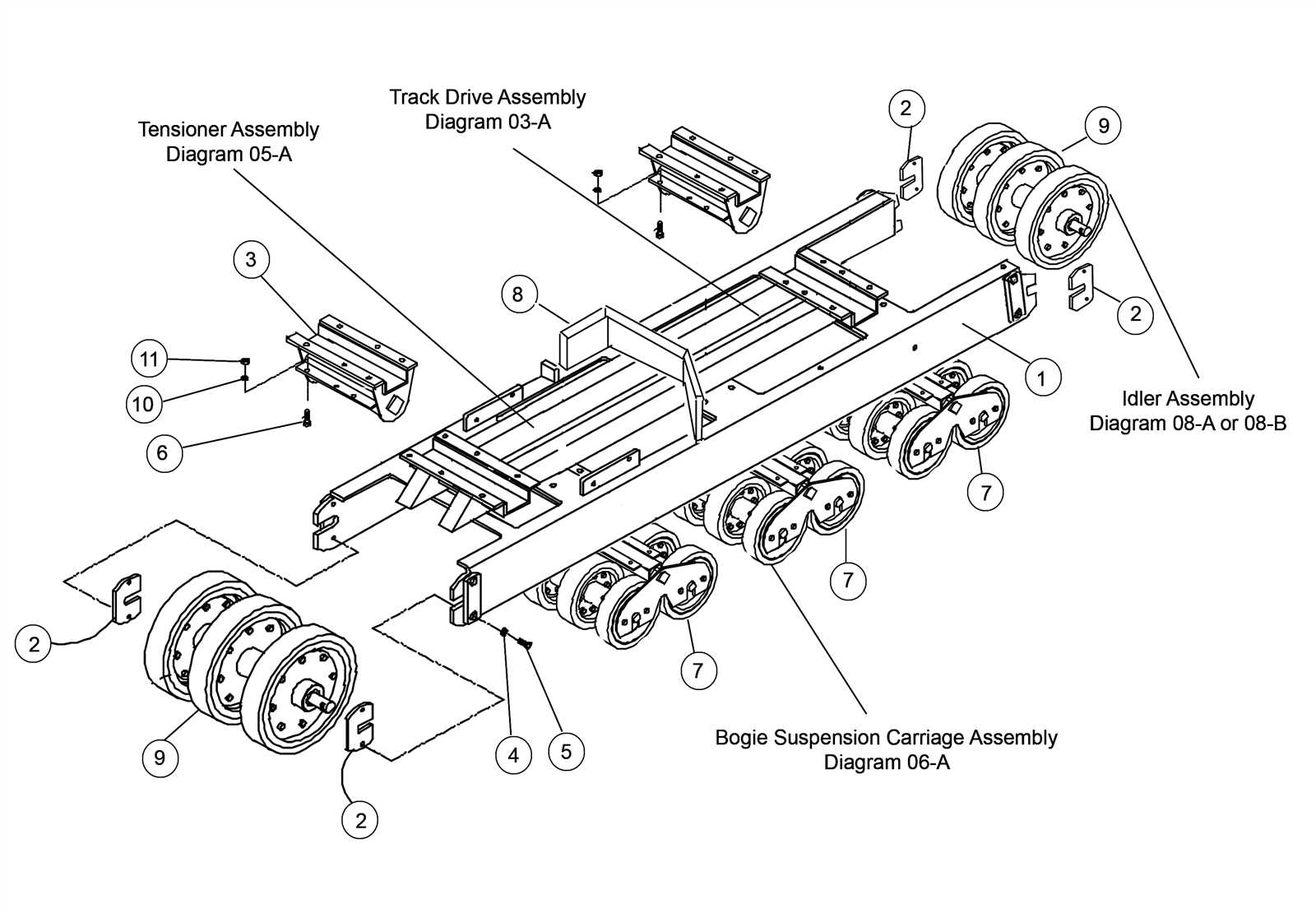

Track System and Undercarriage

The track system and undercarriage

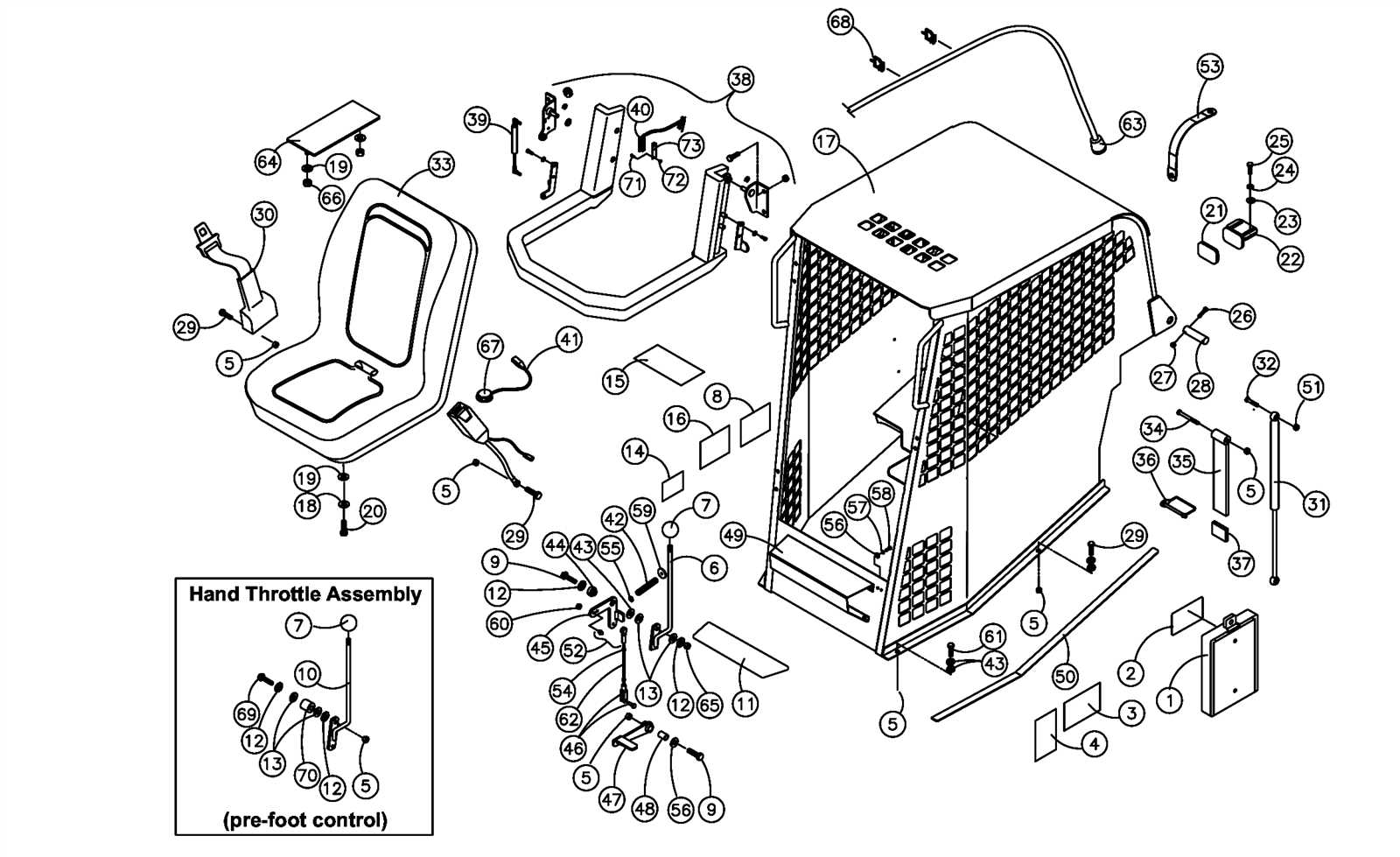

Cab and Operator Controls

The operator’s cabin serves as the central hub for interaction between the user and the machinery, designed to optimize both comfort and functionality. It is essential for the operator to have access to intuitive controls and clear visibility to ensure efficient operation and safety while navigating various tasks.

Control Layout and Functionality

The layout of the controls is meticulously arranged to facilitate easy access and minimize the need for the operator to shift their focus from the task at hand. Key functions are often grouped together, with clearly labeled switches and levers, enabling seamless transitions between operations. The ergonomic design of the control interface enhances user experience, allowing operators to perform their duties with precision and confidence.

Visibility and Comfort

Visibility from the cabin is crucial for safe operation. Large windows and strategically placed mirrors provide an unobstructed view of the working environment, reducing blind spots. Additionally, adjustable seating and climate controls contribute to the operator’s comfort during extended periods of use, enhancing overall productivity.

In summary, the cabin and operator controls are integral components that significantly influence the effectiveness and safety of the equipment. Attention to detail in design ensures that operators can perform their tasks efficiently while maintaining comfort and control.

Maintenance Tips for Cat 257B

Proper upkeep of your machinery is essential for ensuring optimal performance and longevity. Regular maintenance can help prevent breakdowns, enhance efficiency, and reduce operational costs. This section provides practical guidance to keep your equipment running smoothly and effectively.

1. Regular Inspection: Conduct frequent checks to identify any signs of wear or damage. Look for leaks, unusual noises, and loose components. Addressing these issues early can prevent more significant problems in the future.

2. Fluid Levels: Maintain proper fluid levels for hydraulic systems, engine oil, and coolant. Regularly check and replace fluids as needed to ensure the machinery operates efficiently.

3. Cleanliness: Keep the equipment clean to avoid dirt and debris accumulation, which can lead to wear and tear. Use a pressure washer or air compressor to remove grime from surfaces and components.

4. Filter Replacement: Replace filters on a regular schedule to ensure optimal performance. Clogged filters can reduce efficiency and lead to engine damage.

5. Tire Maintenance: Regularly inspect tires for wear and maintain proper air pressure. Well-maintained tires improve traction and reduce fuel consumption.

6. Scheduled Servicing: Follow the manufacturer’s recommended service intervals. Scheduled servicing helps identify potential issues before they escalate, ensuring that the machinery remains in peak condition.

By following these maintenance tips, you can enhance the performance and reliability of your equipment, ultimately leading to better productivity and reduced downtime.

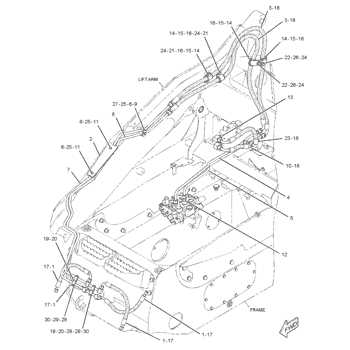

Electrical Wiring and Connections

This section explores the intricacies of electrical systems and their vital role in the operation of machinery. Proper wiring and secure connections are essential for ensuring that electrical components function efficiently and reliably.

Understanding the wiring layout is crucial for troubleshooting and maintenance. Each component is interconnected, forming a complex network that powers various functions. Familiarity with the electrical schematics allows operators to identify potential issues and make informed decisions during repairs.

Secure connections play a significant role in preventing electrical failures. Loose or corroded connections can lead to malfunctions, posing safety risks and increasing downtime. Regular inspection and maintenance of wiring systems help maintain optimal performance and extend the lifespan of the equipment.

In addition, correct wire gauge and insulation are critical factors in preventing overheating and ensuring efficient current flow. Understanding these specifications aids in making appropriate replacements and modifications when necessary.

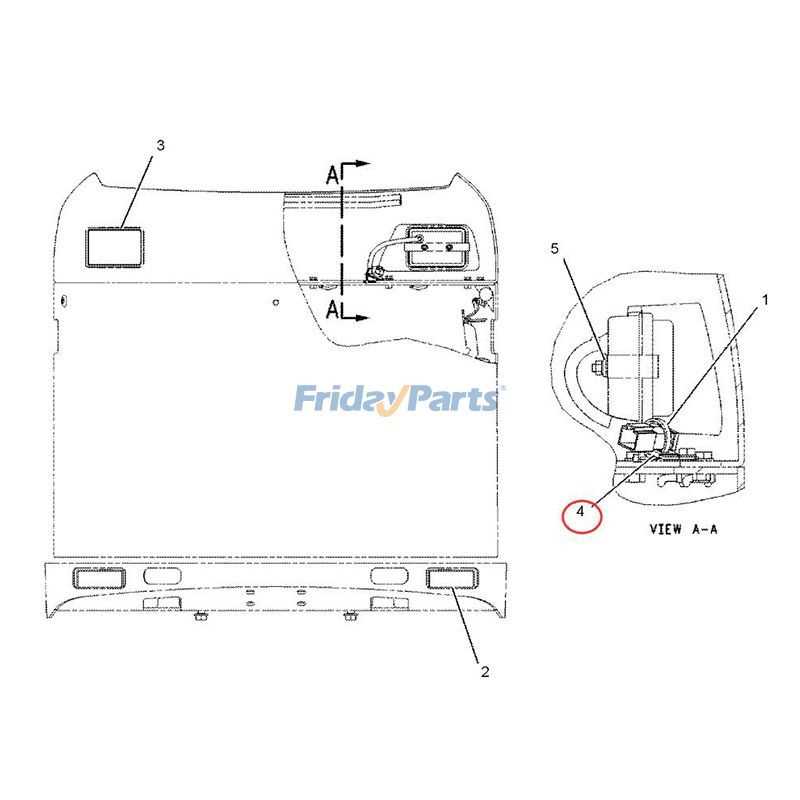

Hydraulic Fluid and Filter Locations

Understanding the placement of hydraulic fluid and filter components is essential for maintaining optimal performance and efficiency in your machinery. Proper knowledge of these locations helps in conducting regular inspections and timely replacements, which can prevent serious operational issues.

Fluid Reservoir Location

The hydraulic fluid reservoir is typically situated in a designated compartment accessible from the machine’s exterior. This location allows for easy filling and monitoring of fluid levels.

- Check the reservoir regularly for leaks.

- Ensure the fluid is filled to the recommended level.

- Look for any signs of contamination or debris in the fluid.

Filter Placement

The hydraulic filter is usually located near the hydraulic pump, designed to remove impurities from the fluid. Accessing this filter is crucial for routine maintenance and ensuring the longevity of the hydraulic system.

- Regularly inspect the filter for signs of clogging.

- Replace the filter according to the manufacturer’s recommendations.

- Use only compatible filters to maintain system integrity.

Attachments Compatibility for Cat 257B

Understanding the compatibility of various attachments with compact track loaders is essential for maximizing efficiency and versatility in different tasks. Each model can accommodate a range of tools that enhance functionality, making it vital to know which implements are suitable for specific equipment.

Common Compatible Attachments

Several implements are widely recognized for their effectiveness when paired with this type of machinery. These include:

- Bucket Attachments: Ideal for moving materials like dirt, gravel, and snow.

- Forks: Useful for lifting pallets and other heavy objects.

- Grapples: Excellent for handling debris and bulky materials.

- Hammers: Suitable for demolition tasks and breaking up concrete.

Factors to Consider

When selecting attachments, it’s crucial to evaluate compatibility based on factors such as weight, hydraulic requirements, and mounting systems. Always consult the manufacturer’s guidelines to ensure optimal performance and safety.

Replacement Part Identification Guide

This section aims to assist users in recognizing and locating specific components needed for their machinery maintenance and repair. Understanding the different elements of the equipment is crucial for ensuring optimal functionality and longevity.

When looking for a replacement, it’s essential to refer to an identification guide that categorizes each component according to its function and location within the system. This will streamline the process of finding the correct item and reduce the risk of errors during replacement.

Component Name Description Location Hydraulic Cylinder Used for lifting and lowering attachments. Front left of the chassis. Drive Motor Responsible for powering the movement of the unit. Located at the rear section. Control Valve Regulates hydraulic fluid flow. Near the operator’s cabin. Filter Element Removes contaminants from hydraulic fluid. In the hydraulic system compartment. Track Roller Facilitates smooth movement over various terrains. Underneath the side frames.