The intricate mechanisms of heavy machinery play a crucial role in their functionality and efficiency. By examining the layout and arrangement of these essential elements, one can gain valuable insights into how these machines operate. A comprehensive overview of the various components provides clarity on their interactions and contributions to overall performance.

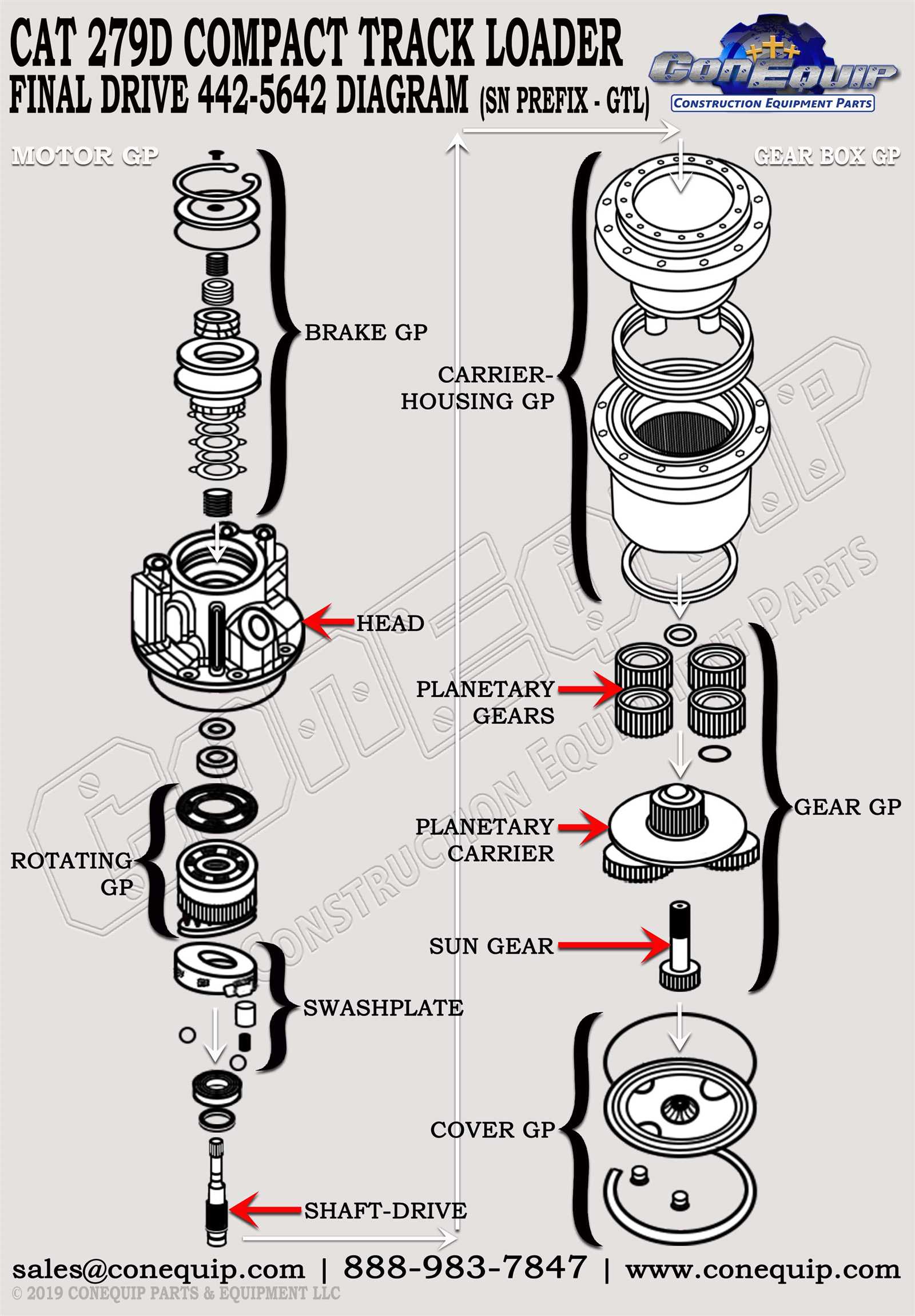

Visual representations of machinery components serve as a practical guide for operators and technicians alike. These illustrations not only enhance understanding but also facilitate maintenance and repair processes. Recognizing the significance of each component helps ensure that machinery operates at its best.

Moreover, a thorough exploration of these components empowers users to make informed decisions regarding equipment management. Knowledge of the different parts can lead to improved troubleshooting, ultimately extending the lifespan of the machinery. By investing time in understanding the structural details, operators can optimize their workflow and enhance productivity.

Caterpillar Dozer Parts Overview

This section provides a comprehensive look at the essential components that make up heavy machinery designed for earth-moving tasks. Understanding the functionality and interrelation of these elements is crucial for effective maintenance and operation.

The machinery is built with a variety of crucial elements, each playing a vital role in its performance. Engine systems provide the necessary power, while the transmission facilitates smooth movement. Additionally, track assemblies ensure stability and traction on diverse terrains.

Other significant components include the hydraulic systems, which enable precise control over various attachments, and the frame, which supports the overall structure and withstands heavy loads. A thorough understanding of these elements is essential for optimal functionality.

Importance of Dozer Parts Diagrams

Understanding the layout and components of heavy machinery is crucial for effective maintenance and repair. Visual representations of these elements serve as essential tools for operators and technicians, enabling them to identify and locate individual components swiftly. This knowledge not only facilitates timely interventions but also enhances the overall efficiency of the equipment.

Enhancing Maintenance Efficiency

When professionals have access to clear visual guides, they can perform servicing tasks more effectively. By pinpointing specific elements and their connections, workers can minimize downtime and reduce the risk of errors during repairs. This clarity is vital in ensuring that machinery operates optimally, leading to prolonged service life.

Facilitating Training and Safety

Training new operators is simplified with well-structured visual aids. These resources help newcomers grasp the complexities of machinery quickly, fostering a safer working environment. With a comprehensive understanding of the equipment’s design, operators can navigate their tasks with confidence, ultimately contributing to safer operational practices.

Common Components in Dozers

Heavy machinery is composed of several essential elements that work together to ensure optimal performance and efficiency. Understanding these key components is crucial for effective operation and maintenance.

- Blade: This is the primary attachment used for pushing material, featuring different designs for various tasks.

- Track System: A series of interconnected links that provide traction and stability, enabling movement over various terrains.

- Engine: The power source that drives all functions, available in various configurations to meet different power requirements.

- Hydraulic System: This system controls the movement of attachments and adjustments to the blade angle and height.

- Cab: The operator’s area, designed for comfort and visibility, often equipped with advanced controls and displays.

Familiarity with these elements not only aids in operation but also assists in troubleshooting and repairs, ultimately enhancing the machine’s longevity and productivity.

How to Read Parts Diagrams

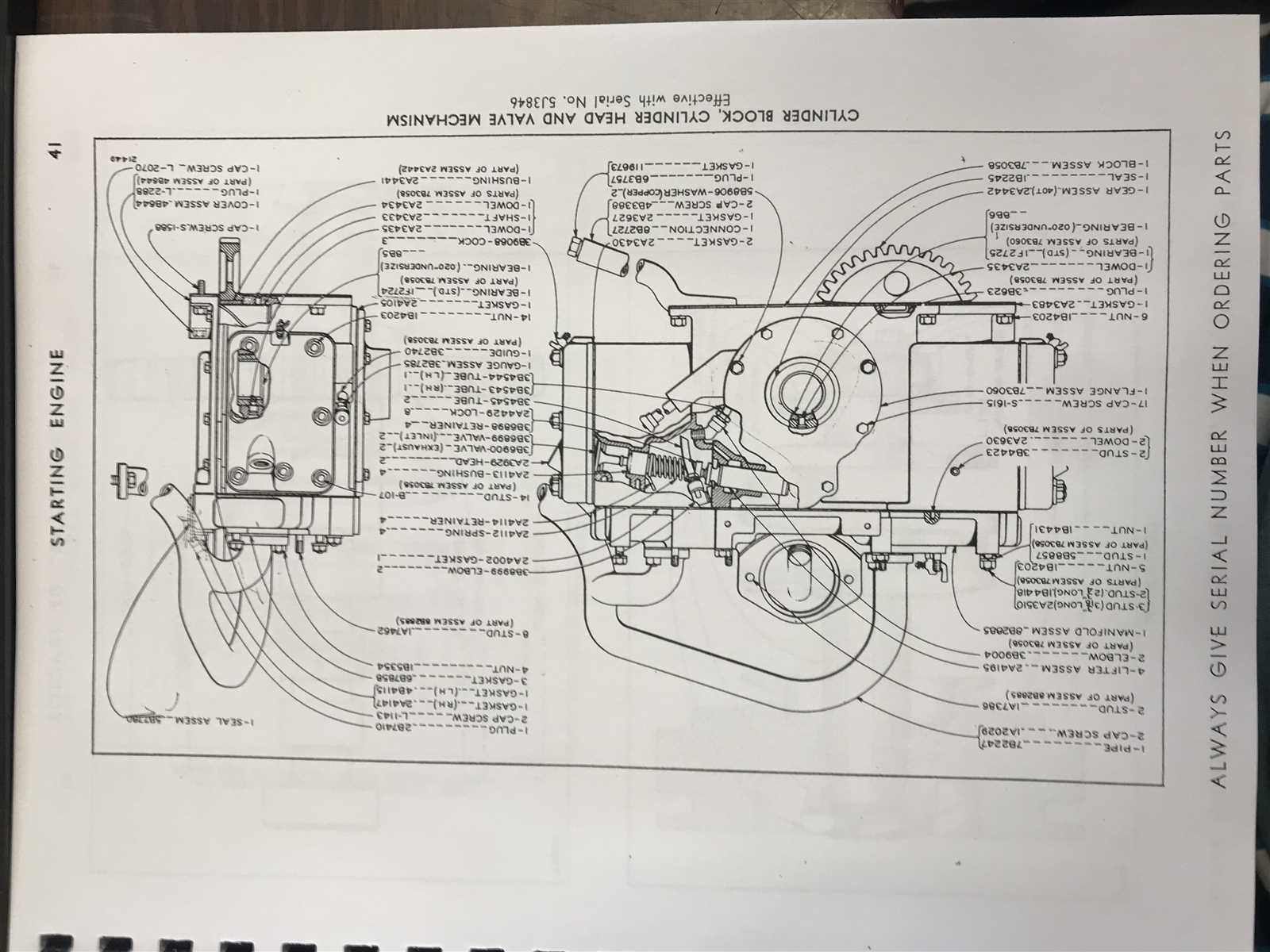

Understanding visual representations of components is essential for efficient maintenance and repair. These illustrations provide a systematic overview of various elements, helping users identify parts and their connections. Familiarity with these visuals enhances problem-solving skills and ensures accurate assembly or disassembly.

Interpreting Symbols and Notations

Each visual may include unique symbols or annotations that indicate specific functions or relationships between components. Recognizing these symbols is crucial for accurate interpretation. Pay attention to legends or keys that accompany the illustrations, as they provide valuable information regarding the meaning of each element.

Analyzing Layout and Structure

The arrangement of elements within the visual representation often reflects their physical configuration. Observe how components are grouped and connected, as this can reveal important insights about their interactions. Identifying patterns in the layout helps in comprehending the overall system and aids in troubleshooting effectively.

Identifying Key Assembly Sections

Understanding the fundamental components of heavy machinery is crucial for effective maintenance and repair. Each major assembly is designed to work seamlessly with others, contributing to the overall functionality of the equipment. Recognizing these sections allows operators and technicians to troubleshoot issues efficiently and perform necessary replacements or upgrades.

Among the primary components are the hydraulic system, which controls movement and power distribution; the undercarriage, essential for mobility and stability; and the engine assembly, which provides the necessary power for operation. Familiarity with these sections not only aids in identifying potential problems but also enhances the ability to ensure optimal performance.

Moreover, visual aids such as schematics or models can significantly assist in grasping the layout and interconnections of these assemblies. By focusing on these key areas, individuals can develop a deeper understanding of the machinery, leading to improved efficiency and longevity.

Maintenance Tips for Dozer Parts

Ensuring the longevity and efficiency of heavy machinery requires regular attention to its components. Proper upkeep not only enhances performance but also prevents costly repairs. Here are some essential strategies to keep your equipment in top condition.

Regularly inspecting the machinery is crucial. Check for signs of wear and tear, including cracks or loose connections. Early detection can prevent further damage and extend the lifespan of vital components.

Lubrication plays a significant role in maintaining smooth operation. Ensure that all moving elements are adequately greased to minimize friction and avoid premature wear. Follow the manufacturer’s recommendations for lubricant types and application intervals.

Keep the equipment clean. Dirt and debris can accumulate and hinder performance. Regularly wash down the exterior and check for buildup in critical areas. A clean machine not only looks better but also operates more efficiently.

Finally, schedule routine servicing with professionals. Expert technicians can provide insights into potential issues and recommend necessary adjustments. Investing in professional maintenance can save time and money in the long run.

Repairing Common Dozer Issues

Maintaining heavy machinery is crucial for optimal performance and longevity. Identifying and addressing frequent problems can significantly enhance efficiency and reduce downtime. This section explores common challenges faced by operators and offers solutions for effective repairs.

Identifying Common Problems

- Hydraulic leaks

- Engine overheating

- Track alignment issues

- Unresponsive controls

Solutions for Effective Repairs

- Regularly inspect hydraulic lines for wear and tear, replacing any damaged components.

- Monitor coolant levels and ensure proper airflow to prevent overheating.

- Adjust tracks to maintain proper alignment, checking tension frequently.

- Test and calibrate control systems to ensure responsiveness and accuracy.

Ordering Replacement Components Effectively

When it comes to maintaining heavy machinery, ensuring the timely acquisition of necessary components is crucial for optimal performance. Understanding how to efficiently order replacements can significantly reduce downtime and enhance operational productivity.

Here are some key strategies for effective ordering:

- Research Suppliers: Identify reputable vendors who specialize in industrial machinery components. Compare their offerings and check reviews to ensure reliability.

- Know Your Needs: Before placing an order, thoroughly assess which components are required. Create a detailed list to avoid confusion.

- Verify Compatibility: Ensure that the items you are ordering are compatible with your equipment model. This prevents issues related to fitting and functionality.

- Consider Lead Times: Factor in delivery times when planning maintenance schedules. Early ordering can mitigate delays in operations.

- Request Bulk Discounts: If you anticipate needing multiple items, inquire about bulk purchasing options, which can lead to cost savings.

By implementing these strategies, you can streamline the process of sourcing essential components, thereby supporting the efficiency and longevity of your machinery.

Understanding Dozer Hydraulic Systems

The hydraulic systems in heavy machinery play a crucial role in enhancing operational efficiency and maneuverability. These systems are responsible for transmitting power through the controlled flow of hydraulic fluid, enabling the machine to perform various tasks with precision and strength.

Components of Hydraulic Systems

A well-functioning hydraulic system comprises several key elements:

- Pump: Generates hydraulic pressure, driving fluid through the system.

- Valves: Control the direction and flow rate of the fluid, ensuring that the desired action occurs at the right time.

- Cylinders: Convert hydraulic energy into mechanical force, performing tasks such as lifting and tilting.

- Fluid: Serves as the medium for power transfer, requiring proper maintenance to prevent contamination.

Operating Principles

The efficiency of hydraulic systems relies on several operating principles:

- Pressure Generation: The pump creates a pressure differential, allowing fluid to move through the system.

- Fluid Dynamics: The flow of hydraulic fluid is influenced by resistance within the system, affecting performance.

- System Monitoring: Regular checks of fluid levels and component functionality are essential to maintain optimal operation.

Safety Practices for Dozer Maintenance

Maintaining heavy machinery is crucial for ensuring safe and efficient operation. Implementing effective safety measures can prevent accidents and equipment failures. Understanding best practices helps operators and technicians minimize risks during maintenance tasks.

Prioritizing safety begins with proper training and awareness of potential hazards. Operators should always wear appropriate personal protective equipment (PPE) and follow established protocols. Regular inspections and maintenance schedules contribute significantly to the overall safety of the machinery.

| Safety Practice | Description |

|---|---|

| Personal Protective Equipment | Ensure that all personnel wear helmets, gloves, and steel-toed boots during maintenance. |

| Lockout/Tagout Procedures | Implement procedures to ensure that machinery is properly shut off and cannot be started while maintenance is being performed. |

| Work Area Inspection | Regularly inspect the work area for hazards, such as spills or obstacles, to create a safe working environment. |

| Emergency Preparedness | Have emergency procedures in place and ensure all personnel are trained to respond to incidents. |

By adhering to these safety practices, operators can significantly enhance the maintenance process and ensure the longevity of their machinery.

Resources for Dozer Parts Information

Accessing reliable sources for machinery components is essential for maintaining efficiency and performance. Understanding where to find detailed references can help operators and mechanics alike to identify and source the necessary elements for optimal operation.

Online Databases

Numerous online platforms provide comprehensive catalogs, allowing users to search for components based on various criteria. These databases often include specifications, images, and compatibility information to facilitate informed purchasing decisions.

Manufacturer Publications

Official publications from manufacturers are invaluable resources. These documents often include detailed descriptions and schematics, ensuring accurate identification of elements required for repairs or upgrades.

| Resource Type | Description | Benefits |

|---|---|---|

| Online Catalogs | Web-based platforms with searchable inventories. | Easy access and extensive options. |

| Technical Manuals | Official guides with detailed information. | Accurate and reliable data. |

| Forums and Communities | Online spaces for user discussions. | Insights from experienced operators. |