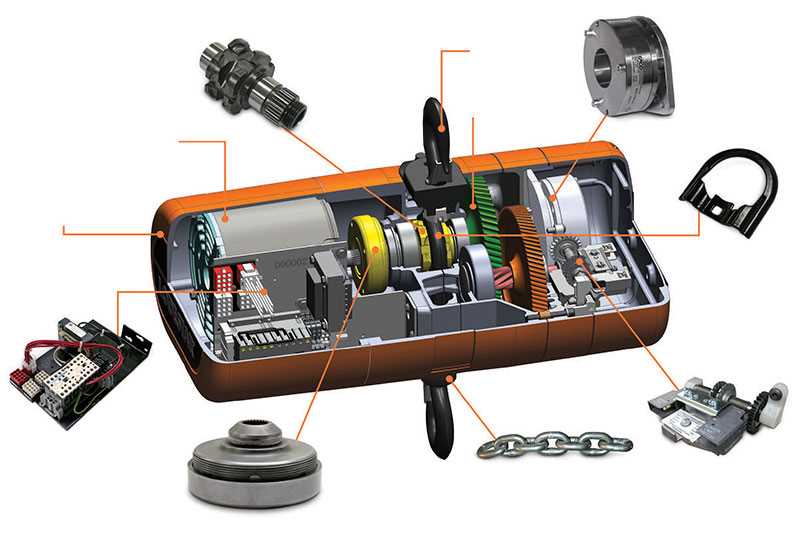

The efficient functioning of lifting devices relies on a comprehensive understanding of their intricate components. Each element plays a vital role in ensuring smooth operation and safety during material handling tasks. By exploring the various sections of these mechanisms, users can enhance their knowledge and improve maintenance practices.

Examining the individual segments reveals the significance of design and engineering in creating robust systems. Familiarity with these components enables operators and technicians to identify potential issues and implement necessary repairs promptly. This proactive approach not only extends the lifespan of the equipment but also enhances overall performance.

In summary, a thorough grasp of the essential elements of lifting equipment is crucial for effective usage and maintenance. Gaining insights into the configuration and interaction of these segments empowers users to optimize operations and ensure a safer working environment.

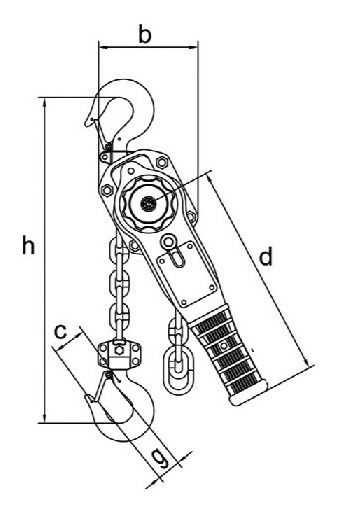

The lifting mechanism plays a crucial role in various industries, providing the necessary support and efficiency for moving heavy loads. This system is designed to ensure that objects can be elevated with ease, utilizing mechanical principles that enhance safety and functionality. By comprehending the components and their interactions, one can appreciate how this technology simplifies tasks that would otherwise require significant physical effort.

At the heart of this lifting system lies a series of interrelated elements that work together to achieve optimal performance. These components include the drive mechanism, which initiates movement, and the supporting framework that bears the load’s weight. Additionally, the efficiency of this system is enhanced by utilizing pulleys and gears that modify force and direction, making it possible to lift objects of varying sizes and weights.

| Component | Function |

|---|---|

| Drive Mechanism | Initiates lifting motion. |

| Supporting Framework | Holds and stabilizes the load. |

| Pulleys | Change the direction of force applied. |

| Gears | Modify speed and torque for lifting. |

Understanding the intricacies of this lifting system allows operators and engineers to enhance safety measures and optimize performance. By regularly maintaining and inspecting the individual components, the longevity and efficiency of the entire assembly can be ensured, ultimately leading to more successful operations.

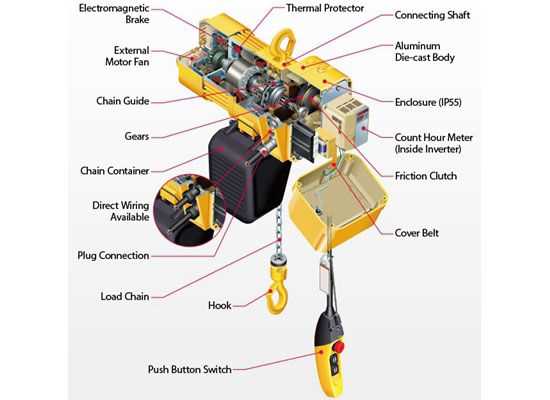

Key Parts of Chain Hoists

This section explores the essential components of lifting devices commonly used in various industries. Understanding these elements is crucial for effective operation and maintenance, ensuring safety and efficiency during lifting tasks.

| Component | Description |

|---|---|

| Lift Mechanism | This mechanism facilitates the elevation and lowering of loads, utilizing a system of pulleys and gears. |

| Load Chain | This durable chain is responsible for carrying the weight, designed to withstand heavy loads and repetitive use. |

| Hook | Attached to the end of the lifting system, this component securely holds the load, ensuring stability during operation. |

| Brake System | This safety feature prevents accidental descent, providing control over the lifting process and ensuring load security. |

| Frame | This sturdy structure supports the entire mechanism, designed to withstand the stresses involved during lifting operations. |

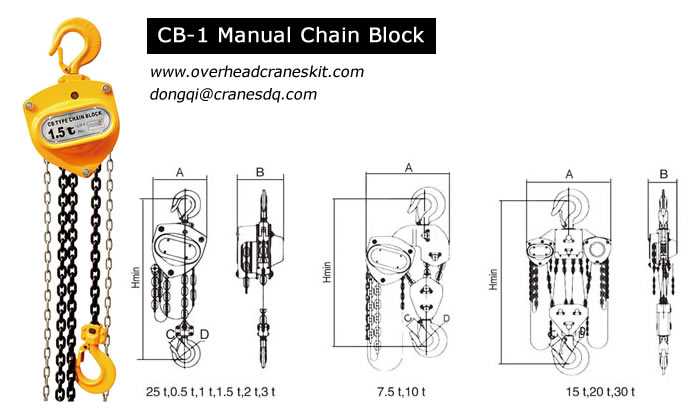

Types of Chain Hoists Explained

Various lifting devices serve distinct purposes in industrial and construction settings. Each type is designed to meet specific operational needs, ensuring efficiency and safety during material handling. Understanding the differences among these mechanisms can help users select the appropriate tool for their tasks.

Among the most common variations are electric and manual mechanisms. Electric versions rely on power sources for operation, offering speed and ease. In contrast, manual variants depend on human effort, providing simplicity and portability.

| Type | Operation | Typical Applications |

|---|---|---|

| Electric Model | Powered by electricity | Warehouse loading, construction |

| Manual Model | Operated by hand | Light lifting tasks, maintenance |

| Pneumatic Model | Uses compressed air | Assembly lines, heavy equipment |

| Portable Model | Compact and lightweight | Temporary setups, fieldwork |

Importance of Proper Maintenance

Regular upkeep of equipment is essential for ensuring optimal performance and longevity. Neglecting this crucial aspect can lead to unexpected failures and costly repairs. By implementing a systematic maintenance routine, operators can identify potential issues early, enhancing the reliability and efficiency of their systems.

Moreover, well-maintained machinery operates safely, reducing the risk of accidents in the workplace. Frequent inspections and timely interventions not only protect the investment but also foster a culture of safety and responsibility among team members. This proactive approach ultimately contributes to a more productive and secure work environment.

Additionally, adhering to maintenance schedules helps to uphold the manufacturer’s warranty, ensuring that any necessary support remains available. Understanding the significance of regular servicing empowers users to take charge of their equipment’s health, promoting a more sustainable and efficient operation overall.

Identifying Common Issues

Understanding potential problems that can arise with lifting equipment is essential for maintaining safety and efficiency. By recognizing the signs of malfunction or wear, operators can take proactive steps to ensure smooth operation and longevity of the system.

Common Symptoms of Malfunction

- Unusual noises during operation, such as grinding or squeaking.

- Difficulty in raising or lowering the load.

- Visible wear on components, including frayed cables or damaged fittings.

- Inconsistent movement, which may indicate a problem with the mechanism.

- Overheating of the device during use.

Recommended Inspection Practices

- Regularly check for signs of wear and tear on all components.

- Listen for abnormal sounds and assess if they correlate with performance issues.

- Ensure that all fasteners and connections are secure and in good condition.

- Consult the manufacturer’s guidelines for specific maintenance routines.

- Document any irregularities to track recurring issues over time.

Safety Features in Hoists

Ensuring the safety of lifting mechanisms is crucial for preventing accidents and protecting both operators and equipment. Various safety elements are integrated into these systems to enhance operational security and reliability. These features serve as essential safeguards, enabling safe lifting and lowering processes in various environments.

Load Limiters play a vital role in preventing overload situations, which can lead to mechanical failure. By automatically stopping the operation when the weight exceeds a predetermined limit, these devices help maintain safety and prolong the lifespan of the equipment.

Emergency Stop Systems are critical for immediate response in case of malfunction or unexpected situations. Operators can quickly disengage the lifting mechanism, minimizing risks and ensuring prompt action during emergencies.

Braking Systems provide additional security by preventing unintended movement of the load when it is in a suspended position. Reliable brakes ensure that the load remains securely in place, reducing the chances of accidents during handling or maintenance.

Periodic Inspections are essential for maintaining the integrity of safety features. Regular checks ensure that all components function correctly and that any potential issues are identified and addressed promptly, enhancing overall safety during operations.

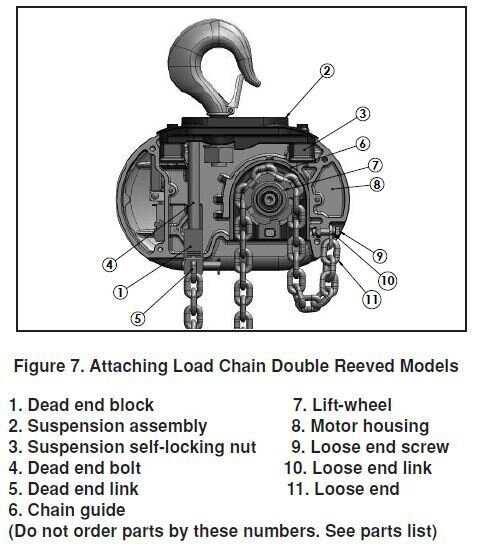

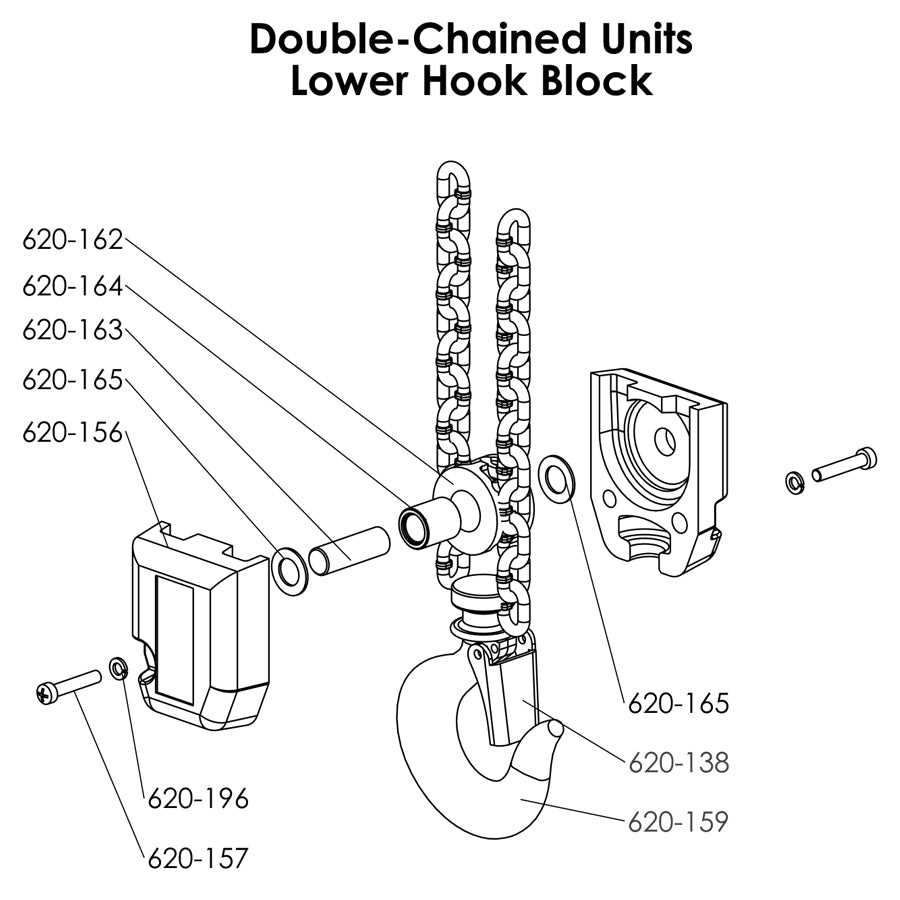

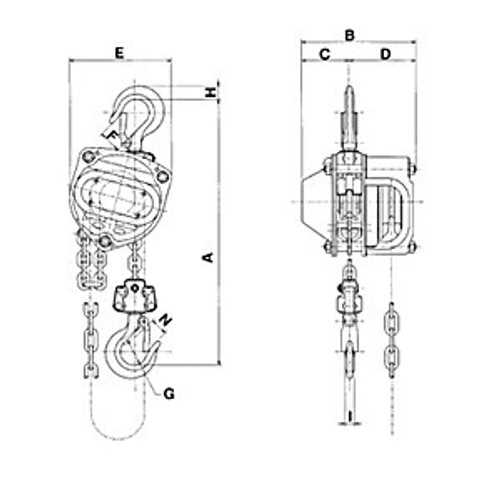

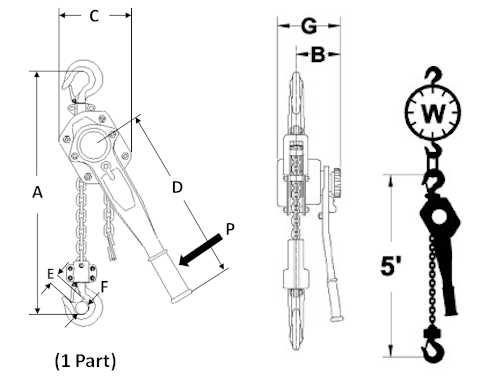

How to Read a Parts Diagram

Understanding a component layout is essential for anyone working with machinery. This visual representation provides insights into the various elements involved, helping users identify each component’s role and its relationship with others. Mastering this skill can greatly enhance your maintenance and troubleshooting abilities.

To effectively interpret the layout, start by familiarizing yourself with the symbols and notations used. Each symbol corresponds to a specific element, and often, a legend accompanies the illustration to clarify these representations. Pay attention to the connections between components; lines or arrows typically indicate how different parts interact.

Another critical aspect is to note any annotations or specifications accompanying the illustration. These notes can provide valuable information about sizes, materials, and assembly instructions. Taking the time to review these details can save significant effort during repairs or assembly.

Lastly, practice is key. The more you work with such visual aids, the more intuitive it will become to interpret them quickly and accurately. Regularly consulting these layouts while performing maintenance tasks will strengthen your understanding and efficiency.

Choosing the Right Replacement Parts

When it comes to maintaining equipment, selecting suitable components is essential for ensuring optimal functionality and longevity. Understanding the significance of quality and compatibility can greatly impact the overall performance of your machinery.

Here are some key considerations to keep in mind when making your selection:

- Compatibility: Ensure that the components you choose are designed to work with your specific model. This helps prevent operational issues and extends the lifespan of the equipment.

- Quality: Opt for high-quality components that are built to withstand the demands of your operations. Durable materials can reduce the frequency of replacements.

- Manufacturer Reputation: Consider parts from reputable manufacturers known for their reliability. Research customer reviews and testimonials to gauge their performance.

- Cost-effectiveness: While it’s important to stick to a budget, be cautious of excessively cheap options. Investing in reliable components can save you money in the long run.

- Availability: Check the availability of the components you need. It’s advisable to source them from suppliers that offer prompt delivery to minimize downtime.

By focusing on these aspects, you can ensure that your machinery operates efficiently and remains in good condition for years to come.

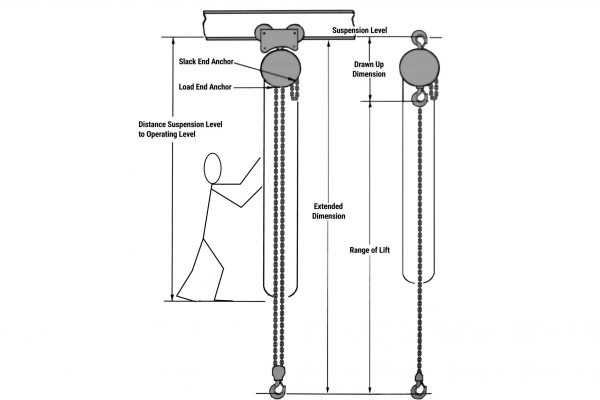

Installation Guidelines for Components

Proper assembly of lifting equipment is crucial for optimal performance and safety. This section provides essential instructions to ensure that all elements are securely installed and function as intended. Following these guidelines will help to enhance the durability and reliability of the system.

Before beginning the installation process, ensure that all necessary tools and components are readily available. Familiarize yourself with each component to understand its role in the overall mechanism. It is advisable to follow the manufacturer’s recommendations closely to achieve the best results.

Start by securely positioning the base unit on a stable surface. Ensure that it is level and capable of bearing the load. Next, attach the lifting mechanism, making certain that all fasteners are tightened to the specified torque settings. It is essential to double-check the alignment of each component to prevent operational issues.

Once the primary elements are in place, proceed to connect any additional accessories or safety features. These may include limit switches or safety latches, which play a vital role in preventing accidents. Ensure that all connections are made correctly and that wiring is protected from wear and tear.

After installation, perform a thorough inspection of the entire setup. Conduct a test run without a load to verify that everything operates smoothly. Listen for any unusual sounds and observe for any irregular movements. This step is critical for ensuring that the system is ready for safe and effective use.

Resources for Further Learning

Enhancing your understanding of lifting mechanisms and their components can greatly improve your operational efficiency and safety. A variety of resources are available to deepen your knowledge, including books, online courses, and technical manuals. Engaging with these materials will provide insights into the functionality and maintenance of these essential tools.

Books and Manuals

- Understanding Mechanical Systems: This book offers comprehensive information on the principles governing lifting devices.

- Maintenance and Safety Practices: A detailed manual focusing on best practices for ensuring operational safety.

- Engineering Fundamentals: A resource that covers the basics of mechanical engineering relevant to lifting equipment.

Online Courses and Tutorials

- Introduction to Lifting Equipment: An online course that provides foundational knowledge.

- Advanced Maintenance Techniques: A series of tutorials focused on the upkeep of lifting devices.

- Safety Protocols in Equipment Handling: An informative course emphasizing safety standards.

Utilizing these resources will not only broaden your comprehension but also empower you to apply best practices in real-world scenarios.