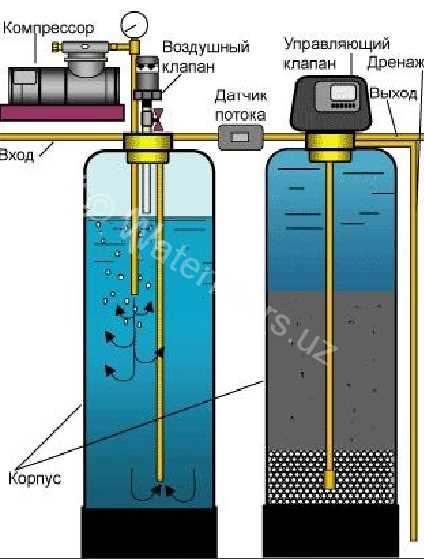

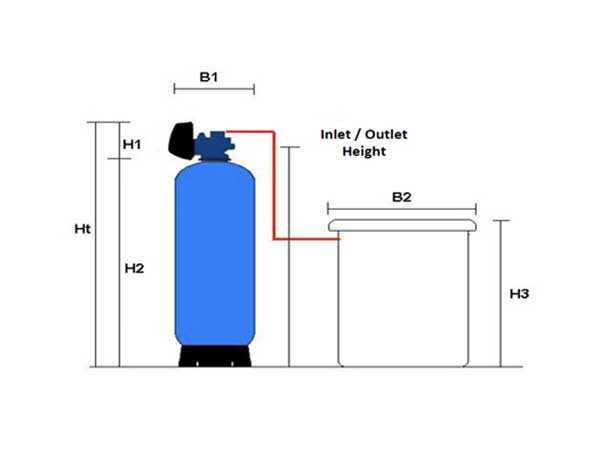

In the realm of mechanical systems, comprehending the arrangement of individual elements is crucial for effective maintenance and troubleshooting. Each component plays a specific role, contributing to the overall functionality of the system. Familiarity with these layouts empowers users to make informed decisions regarding repairs and enhancements.

Visual representations serve as invaluable tools for deciphering the complex interactions between various parts. By examining these illustrations, one can gain insight into the design intricacies and operational flow of the assembly. This knowledge not only aids in identifying potential issues but also enhances the efficiency of routine checks.

Moreover, understanding the connections and configurations of each element fosters a deeper appreciation for the engineering behind the system. It opens the door to exploring upgrades and modifications, enabling users to optimize performance and extend the lifespan of their equipment. A thorough grasp of the internal workings ultimately leads to more confident and skilled handling of the machinery.

Understanding Clack WS1 Components

This section aims to explore the various elements that comprise a specific water treatment system, highlighting their functions and importance in ensuring optimal performance.

- Valves: Essential for regulating water flow and pressure.

- Filters: Key components for removing impurities from the water.

- Control Systems: Critical for monitoring and adjusting the treatment process.

- Resins: Vital for softening water and enhancing quality.

- Housings: Provide structural support and protection for internal components.

Each of these elements works in harmony to deliver efficient water purification, ultimately contributing to a reliable and effective system.

Overview of Clack WS1 System

The system in question is designed for efficient management and treatment of water, ensuring optimal quality for various applications. Its innovative design encompasses multiple components that work in harmony to deliver superior performance and reliability.

This advanced setup is tailored for both residential and commercial use, featuring automated processes that simplify operation and maintenance. Each element plays a crucial role in enhancing the overall functionality, from filtration to regeneration, making it a comprehensive solution for water purification.

Moreover, the integration of smart technology allows for seamless monitoring and adjustments, ensuring that users have ultimate control over their water quality. This adaptability not only increases efficiency but also promotes sustainability, aligning with modern environmental standards.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate details of any system. They serve as invaluable tools for both novice and experienced individuals, allowing for a clearer grasp of functionality and interconnections.

These illustrations not only enhance comprehension but also streamline the maintenance and repair processes. By providing a comprehensive overview, they enable users to identify issues swiftly and efficiently.

Furthermore, well-structured visuals foster effective communication among team members, ensuring everyone is aligned in their understanding and approach to tasks. In essence, these visual aids are fundamental in promoting accuracy and efficiency in any mechanical endeavor.

Main Components of the WS1

This section delves into the essential elements that comprise the system, highlighting their functions and interconnections. Each component plays a critical role in ensuring optimal performance and reliability, contributing to the overall effectiveness of the unit.

Core Elements

The primary constituents include the housing, which protects internal mechanisms, and the control unit that manages operations. Additionally, the filtration system is vital for maintaining water purity, while the regeneration mechanism ensures longevity and efficiency.

Supporting Mechanisms

Other notable components are the valves that regulate flow and pressure, as well as the sensors that monitor performance metrics. Together, these elements work harmoniously to enhance functionality and user experience, making the system both effective and user-friendly.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and assembly. These illustrations provide a clear overview of individual elements and their interconnections, enabling users to grasp complex systems intuitively.

Identifying Key Elements

Begin by locating the legend, which typically explains symbols and codes used in the illustration. This crucial reference helps you decipher the meaning of various components, ensuring accurate identification and understanding.

Interpreting Relationships

Focus on how elements interact with one another. Arrows and lines often indicate connections, while numerical references may suggest assembly order. By analyzing these relationships, you can gain insights into the ultimate functionality of the system.

Common Issues with WS1 Parts

Understanding frequent challenges related to specific components is essential for maintaining optimal performance. These obstacles can arise from various factors, impacting functionality and longevity.

- Wear and Tear: Over time, certain elements may degrade, leading to inefficiency.

- Improper Installation: Incorrect fitting can result in leaks or malfunctions.

- Environmental Factors: Exposure to extreme conditions can affect durability.

To address these concerns, regular maintenance and timely replacements are crucial. Users should be aware of signs indicating potential issues to ensure effective operation.

Maintenance Tips for Clack Systems

Regular upkeep is essential for ensuring the longevity and efficiency of your water treatment equipment. Proper maintenance not only enhances performance but also prevents costly repairs and downtime. Following a few key practices can keep your system operating smoothly.

Routine Checks

Conducting frequent inspections is crucial. Examine the unit for any signs of wear or damage. Pay close attention to seals and connections, as leaks can lead to significant issues. Ensure that the salt levels are adequate and check the brine tank regularly to avoid any operational interruptions.

Cleaning Procedures

Regular cleaning is vital to maintain optimal performance. Remove any accumulated debris and ensure that the filters are clean. A buildup of minerals or contaminants can affect efficiency, so consider rinsing and cleaning components according to the manufacturer’s recommendations. This proactive approach will help maintain peak functionality.

Remember: Consistency in maintenance can greatly extend the lifespan of your system and enhance its overall efficiency.

Replacing WS1 Components Effectively

Understanding how to efficiently substitute essential elements in a system is crucial for maintaining optimal performance. This process not only ensures longevity but also enhances the overall functionality of the unit. Proper techniques and knowledge about the components are vital for a successful replacement.

Essential Steps for Replacement

To achieve effective substitutions, follow these key steps:

| Step | Description |

|---|---|

| 1 | Identify the component that requires replacement and gather necessary tools. |

| 2 | Carefully disassemble the unit, taking note of the arrangement. |

| 3 | Replace the faulty part with a compatible substitute, ensuring a secure fit. |

| 4 | Reassemble the unit and test its functionality before finalizing. |

Common Components to Consider

Familiarize yourself with typical elements that often require attention, such as valves, seals, and control mechanisms. Regular maintenance checks can help identify wear and tear early, allowing for timely interventions and ensuring peak performance.

Comparing WS1 Parts with Alternatives

When evaluating components for water treatment systems, it is essential to explore various options available on the market. This analysis not only highlights the unique features of each item but also uncovers potential advantages that alternatives might offer. By examining these elements, users can make informed decisions that best suit their specific requirements.

Compatibility is a crucial factor to consider. While some components are designed to fit seamlessly with specific systems, others may provide greater versatility, allowing for integration into different setups. Durability also plays a significant role; alternatives might utilize superior materials that extend lifespan and enhance performance.

Additionally, the cost-effectiveness of substitutes can be attractive. Many options deliver similar functionalities at a lower price point, making them an appealing choice for budget-conscious consumers. However, it is vital to assess long-term value over initial savings to ensure the best investment.

Ultimately, conducting a thorough comparison enables users to delve deeper into what each alternative offers, ensuring that the final selection aligns perfectly with operational goals and performance expectations.

Benefits of Proper Component Identification

Accurate recognition of individual elements within a system plays a crucial role in enhancing functionality and efficiency. When each component is clearly understood and defined, it facilitates smoother operations and reduces the likelihood of errors during maintenance or upgrades.

Enhanced Efficiency

Identifying each piece correctly allows for quicker troubleshooting and repairs. When technicians can easily locate and comprehend the elements involved, they can address issues more effectively, minimizing downtime and optimizing performance.

Informed Decision-Making

Proper identification empowers stakeholders to make knowledgeable choices regarding upgrades and replacements. Understanding the role of each part ensures that any modifications made will ultimately benefit the system, leading to improved longevity and reliability.

Where to Find Quality Diagrams

Accessing high-quality visual representations is crucial for anyone looking to understand complex systems or components. These resources provide detailed insights and can significantly aid in maintenance or assembly tasks. Here are some reliable sources to explore for exceptional visuals:

- Manufacturer Websites: Many manufacturers offer comprehensive resources on their official sites, including user manuals and technical illustrations.

- Online Forums: Communities dedicated to specific industries often share valuable resources. Engaging in discussions can lead to discovering rare visuals.

- Technical Publications: Journals and magazines focused on particular fields frequently publish detailed illustrations that accompany articles.

- Educational Platforms: Websites that provide courses or tutorials may include well-crafted visuals as part of their learning materials.

- Social Media Groups: Joining relevant groups on platforms like Facebook or Reddit can connect you with enthusiasts who share resources.

When seeking visuals, ensure to verify the credibility of the source to guarantee accuracy and quality. By exploring these avenues, you can find the illustrations you need to enhance your understanding and improve your projects.

Ultimate Guide to Clack WS1 Repairs

This comprehensive guide is designed to assist you in understanding the intricacies of maintenance and troubleshooting for your water treatment system. Whether you’re a seasoned technician or a curious homeowner, having a solid grasp of repair processes can enhance the longevity and efficiency of your equipment.

Identifying Common Issues

Before diving into repairs, it’s essential to recognize frequent problems that may arise. These can include irregular flow rates, unusual noises, or leaks. By pinpointing the symptoms, you can address the underlying issues more effectively.

Essential Tools and Materials

Having the right tools at your disposal is crucial for successful repairs. Basic items like wrenches, screwdrivers, and replacement seals can make a significant difference. Additionally, keeping a well-stocked inventory of maintenance supplies ensures you’re prepared for unexpected challenges.

Step-by-Step Repair Process

Once you’ve diagnosed the issue, follow a structured approach to resolve it. Begin by turning off the system and disconnecting any power sources. Carefully disassemble the necessary components, making sure to document your steps for reassembly. Replace any damaged parts and clean all surfaces thoroughly before reassembling.

Testing and Troubleshooting

After completing the repairs, it’s important to conduct a thorough test. Check for leaks, ensure proper flow, and listen for any unusual sounds. If problems persist, revisit your steps to troubleshoot further, confirming that all components are functioning as intended.

Regular Maintenance Tips

To prevent future issues, implement a routine maintenance schedule. Regularly check for wear and tear, clean filters, and replace any necessary components. Keeping an eye on the system’s performance can help you catch potential problems early, saving time and resources in the long run.

By following this guide, you can confidently tackle repairs and ensure your water treatment system operates efficiently for years to come.