In the realm of tire maintenance and repair, a comprehensive knowledge of machinery is essential. This section aims to provide insights into the intricate elements that contribute to the efficiency and functionality of tire-changing apparatus. By examining these individual components, users can better appreciate their roles and interactions.

Whether you are a technician or a hobbyist, familiarizing yourself with the structure of such equipment can enhance your operational skills. Each piece plays a critical role in ensuring seamless performance, making it vital to understand their specific functions and configurations.

By delving into the assembly of these tools, one can uncover the ultimate balance between efficiency and reliability. This exploration will not only aid in troubleshooting but also in making informed decisions regarding maintenance and repairs.

Understanding Coats 5060EX Parts

This section delves into the intricate components of a renowned tire changer model, highlighting the significance of each element in ensuring optimal performance. Familiarity with these individual pieces enhances the user’s ability to maintain and troubleshoot the machine effectively.

Key Components and Their Functions

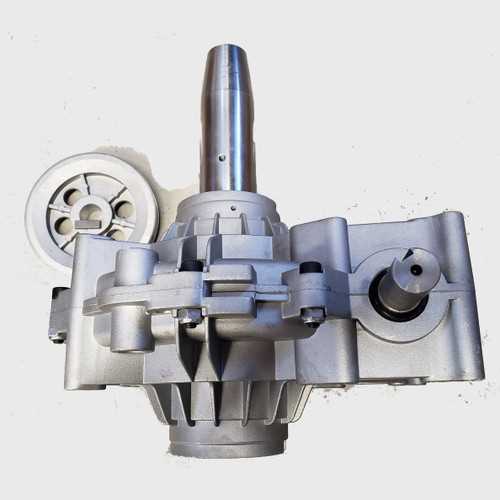

Each component plays a vital role in the overall operation of the equipment. For instance, the motor is responsible for driving the mechanism, while the clamps secure the tire firmly in place during the changing process. Understanding how these parts interact allows for better diagnostics and efficient maintenance.

Maintenance and Troubleshooting Tips

Regular upkeep is essential for prolonging the lifespan of the device. Regularly inspecting the critical elements, such as the hydraulic system and electronic controls, can prevent minor issues from escalating. If malfunctions occur, knowing the specific roles of various components aids in pinpointing the problem quickly and accurately.

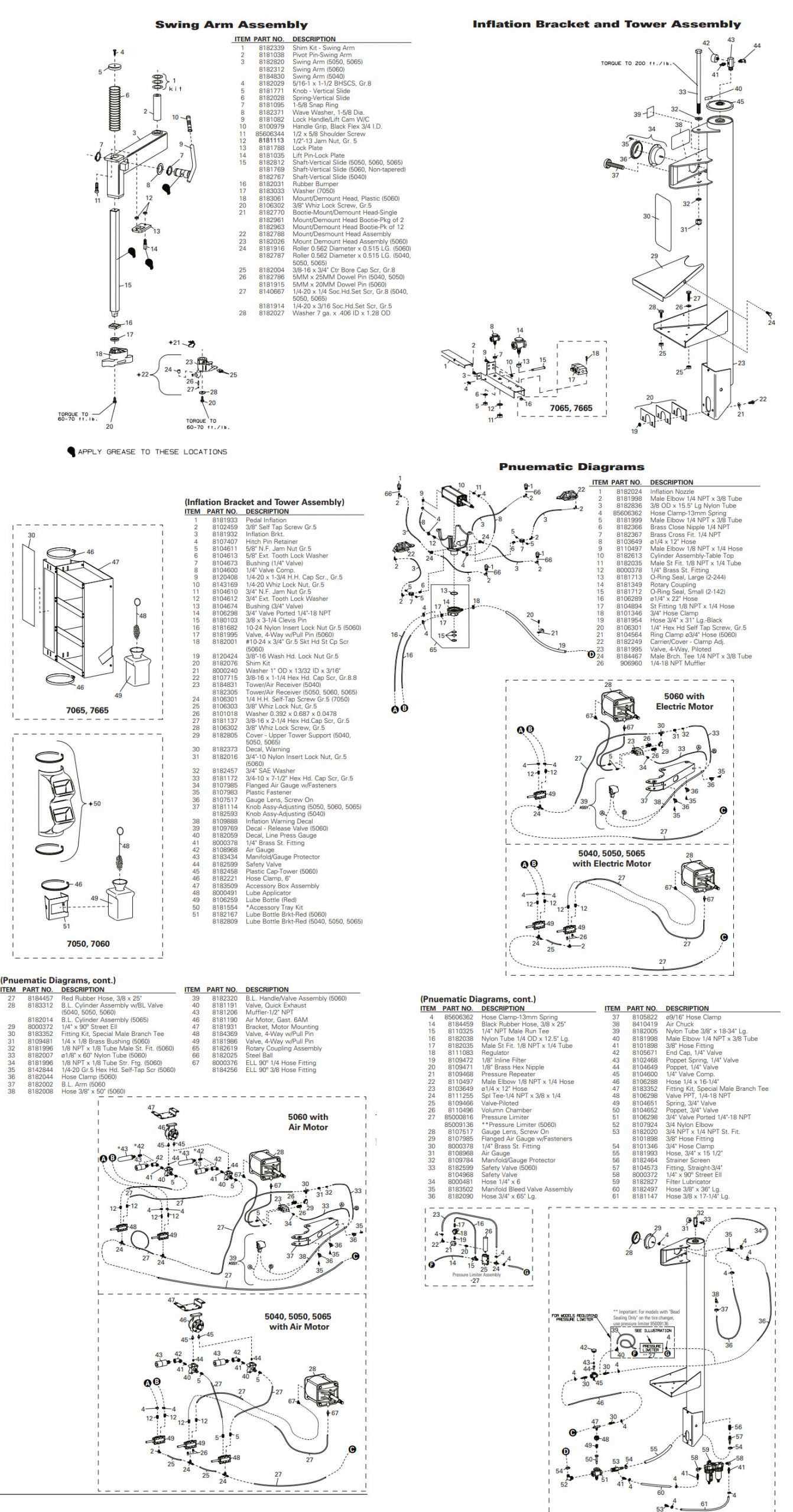

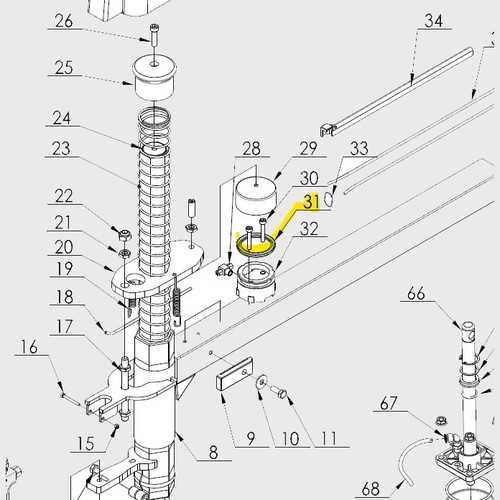

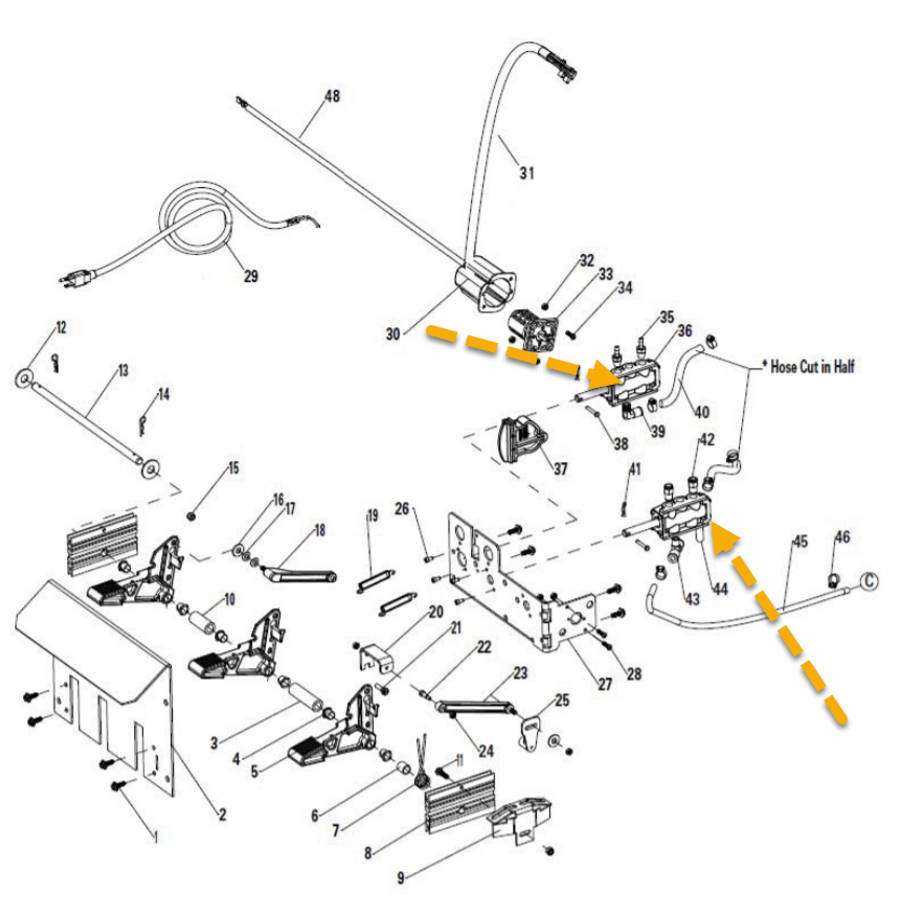

Importance of Parts Diagrams

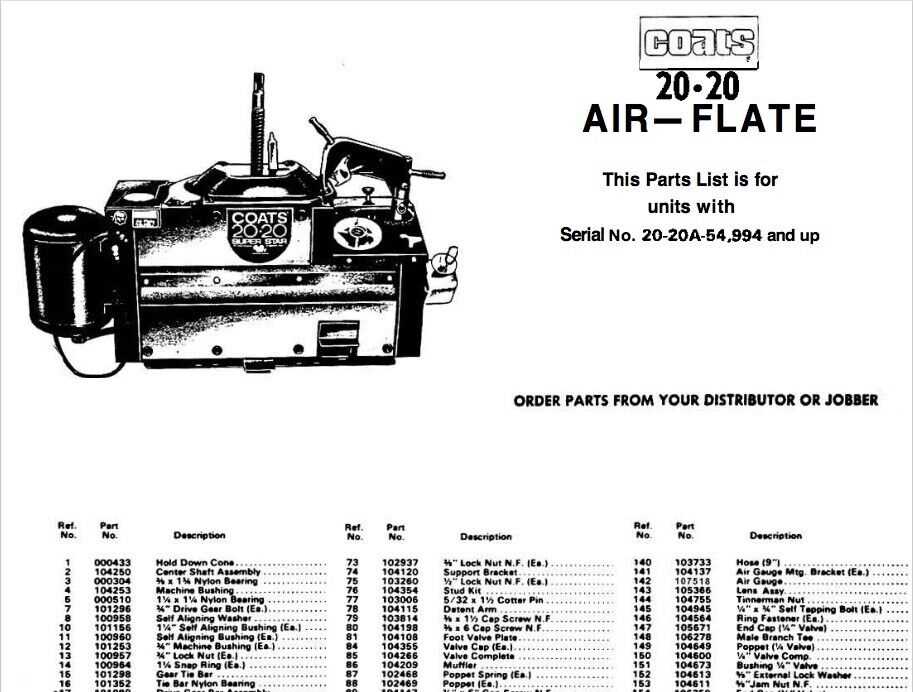

Visual representations of components are essential tools in various industries. They offer a clear and structured way to understand the intricate relationships between different elements of a machine or system. By breaking down complex assemblies into manageable parts, these illustrations facilitate both maintenance and repair processes.

Enhanced Understanding: Such visuals provide clarity, allowing technicians and operators to grasp the configuration and functionality of each element. This comprehensive understanding is crucial for troubleshooting and effective servicing.

Efficiency in Repair: When issues arise, having a detailed reference enables faster diagnostics and repairs. Technicians can quickly identify the necessary components, reducing downtime and improving overall operational efficiency.

Training and Development: These representations serve as valuable educational resources. They can help new employees familiarize themselves with machinery and systems, promoting safer and more effective work practices.

Ordering and Inventory: For procurement and inventory management, clear visual guides simplify the process of ordering replacements. Knowing exactly what is needed reduces errors and ensures that the correct items are acquired promptly.

In conclusion, visual representations of components play a vital role in the maintenance, repair, and education surrounding machinery, ultimately contributing to improved productivity and safety in the workplace.

Common Issues with Coats 5060EX

In the realm of tire changing machines, certain recurring challenges can affect performance and efficiency. Understanding these problems is crucial for maintaining optimal operation and prolonging the lifespan of the equipment.

- Air Leaks: Insufficient sealing may lead to pressure loss, impacting the machine’s effectiveness.

- Electrical Malfunctions: Faulty wiring or connectors can cause erratic behavior or complete failure of controls.

- Hydraulic Issues: Low fluid levels or leaks can diminish lifting power, affecting functionality.

- Wear and Tear: Components such as clamps or arms may degrade over time, requiring timely replacements.

- Alignment Problems: Improper setup can lead to uneven tire mounting, increasing wear on both the machine and tires.

Regular maintenance and careful observation can help identify these common issues early, ensuring smoother operation and reducing downtime.

How to Read Parts Diagrams

Understanding the visual representations of components is essential for efficient maintenance and repair. These illustrations serve as guides, offering a clear view of how each element fits into the larger assembly. Mastering this skill can enhance your troubleshooting abilities and streamline your repair processes.

First, familiarize yourself with the layout. Typically, these visuals are organized logically, showcasing the assembly’s structure. Next, pay attention to the labels and numbers associated with each piece; they provide crucial identification that corresponds to detailed lists. Finally, cross-reference the information with manuals or resources to ensure comprehensive understanding.

By taking the time to delve into these illustrations, you can greatly improve your repair efficiency and ultimately save time and resources.

Key Components of Coats 5060EX

The effectiveness of a tire-changing machine relies heavily on its core elements, which are meticulously designed to ensure optimal performance and durability. Understanding these fundamental components allows operators to maintain the equipment efficiently and achieve the best results during tire service tasks.

Motor: The heart of the system, the motor provides the necessary power to drive various functions. A robust motor ensures swift operation and minimizes downtime during tire changes.

Rim Clamp: This essential element securely holds the wheel in place, preventing any movement during the tire fitting process. A reliable rim clamp minimizes the risk of damage to both the wheel and the tire.

Bead Breaker: The bead breaker is crucial for separating the tire from the rim. Its design allows for efficient operation, enabling technicians to remove tires without excessive effort or risk of damage.

Tool Arm: This component is responsible for guiding tools during the tire change process. A well-engineered tool arm enhances precision and control, ensuring that every action is executed smoothly.

Control Panel: The interface for operators, the control panel provides intuitive access to various functions of the machine. An ergonomic layout and clear labeling improve usability and efficiency during operation.

Inflation System: This system is designed to ensure that tires are properly inflated after installation. An accurate inflation mechanism contributes to the overall safety and performance of the vehicle.

By familiarizing oneself with these key components, users can optimize the functionality of their tire-changing equipment, ensuring a seamless and effective tire service experience.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular upkeep and attention. By following a few essential practices, you can significantly extend the lifespan of your machinery and enhance its performance over time.

Regular Cleaning

Keeping your tools clean is vital. Dust, debris, and grime can accumulate and lead to operational issues. Use appropriate cleaning solutions and methods to maintain a pristine working environment.

Routine Inspections

Conducting frequent checks for wear and tear can prevent major breakdowns. Look for signs of damage or irregularities, and address them promptly to avoid costly repairs down the line.

Replacing Worn-Out Parts Effectively

Maintaining equipment in peak condition is essential for optimal performance and longevity. When components show signs of wear, timely replacement can prevent further damage and ensure seamless operation. Understanding the right approach to substituting these elements is crucial for efficiency and cost-effectiveness.

Assessment is the first step in this process. Regular inspections help identify which items require attention. Look for signs such as unusual noises, decreased functionality, or visible damage. By pinpointing the specific components that need replacement, you can avoid unnecessary work and expenses.

Once you’ve identified the affected elements, sourcing quality replacements becomes vital. Choosing reliable suppliers ensures that you obtain parts that meet the required specifications. Look for items that offer durability and compatibility with your existing system, as this can enhance overall performance.

When you’re ready to proceed with the substitution, following a systematic approach is essential. Begin by ensuring the equipment is powered down and secure. Refer to the manufacturer’s guidelines for proper disassembly procedures. Take your time during this phase to avoid damaging surrounding components.

After removing the worn parts, install the new ones carefully. Make sure they fit snugly and are properly aligned. Once in place, reassemble everything according to the specified instructions. After completing the installation, conduct a thorough functional check to confirm that the equipment operates smoothly.

Finally, maintaining a record of replacements can help track the lifespan of various components and streamline future maintenance efforts. Regularly updating your inventory ensures that you are always prepared for the next wear-and-tear situation.

Where to Find Replacement Parts

Locating essential components for your machinery can significantly enhance its longevity and performance. Various sources cater to different needs, whether you seek original equipment or compatible alternatives. Understanding where to source these items ensures that you can maintain optimal functionality without unnecessary delays.

One effective avenue is to explore authorized dealers who specialize in specific brands. These suppliers often carry a wide array of items and can provide guidance on compatibility. Additionally, online marketplaces offer a vast selection, allowing you to compare prices and read reviews, ensuring you choose a reliable option.

Local repair shops can also be valuable resources, as they may have insights into the best suppliers and can sometimes order parts directly for you. Furthermore, online forums and communities focused on machinery maintenance can offer recommendations based on firsthand experiences, giving you a deeper understanding of where to turn for your specific requirements.

For those interested in budget-friendly options, consider salvage yards or resale sites, which often have used items in good condition. Ultimately, knowing the right places to search will streamline your process and help you find what you need efficiently.

Tools Required for Repairs

Effective maintenance of machinery relies heavily on the appropriate tools. Having the right instruments at hand not only streamlines the repair process but also ensures safety and precision. This section outlines essential equipment that should be gathered before commencing any repair work.

Essential Hand Tools

Basic hand tools are crucial for disassembly and assembly tasks. Common items include:

- Wrenches: These are vital for loosening and tightening bolts and nuts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will cover most fastening needs.

- Pliers: Useful for gripping, twisting, and cutting wires.

Power Tools and Equipment

In addition to hand tools, power tools can significantly enhance efficiency. Consider the following:

- Drill: Essential for creating holes and driving screws quickly.

- Impact wrench: Great for high-torque applications, particularly in tightening or loosening stubborn fasteners.

- Multimeter: Important for diagnosing electrical issues and ensuring proper functioning.

By preparing these tools in advance, the repair process will be more organized, efficient, and successful.

Safety Precautions During Repairs

When undertaking maintenance or repair tasks, ensuring a safe working environment is paramount. Adhering to specific safety measures not only protects the individual performing the work but also extends the life of the equipment involved. Understanding and implementing these precautions can prevent accidents and facilitate a more efficient workflow.

Personal Protective Equipment (PPE)

The use of appropriate personal protective gear is essential in minimizing risks. This includes items such as gloves, goggles, and protective footwear. Each type of equipment plays a crucial role in shielding against potential hazards present during repairs.

| Type of PPE | Purpose |

|---|---|

| Gloves | Protects hands from sharp objects and chemicals |

| Goggles | Prevents eye injuries from debris and harmful substances |

| Steel-toed Boots | Offers foot protection from heavy items |

Work Environment Considerations

A well-organized and clutter-free workspace is vital for safe operations. Ensuring that tools are readily accessible and that the area is well-lit can significantly reduce the likelihood of accidents. Additionally, being aware of surrounding conditions, such as electrical hazards or slip risks, further enhances safety during the repair process.

FAQs About Coats 5060EX Parts

This section addresses common inquiries related to components of a well-known tire changing machine. Users often have similar concerns regarding maintenance, compatibility, and troubleshooting, and we aim to provide clear and concise answers to enhance understanding and ensure proper usage.

- What should I do if a component breaks?

- Assess the damage and consult the user manual for specific guidance.

- Consider sourcing a replacement from a trusted supplier.

- Reach out to a professional for assistance if needed.

- How can I identify the correct replacement parts?

- Refer to the machine’s manual for part numbers and specifications.

- Contact the manufacturer or an authorized dealer for assistance.

- Join online forums or groups dedicated to tire service equipment for recommendations.

- Are there maintenance tips for extending the lifespan of components?

- Regularly clean and lubricate moving parts.

- Check for wear and tear on a routine basis.

- Follow the manufacturer’s guidelines for servicing and replacements.

- What should I do if the machine is not functioning properly?

- Verify that all components are correctly installed and secured.

- Look for any visible signs of damage or misalignment.

- Consult the troubleshooting section of the manual for specific issues.