In the realm of industrial equipment, having a clear understanding of the individual elements that make up a system is crucial for optimal performance and maintenance. Each component serves a specific function, contributing to the overall efficiency of the equipment. A comprehensive overview of these elements enables users to make informed decisions regarding repairs, replacements, and upgrades.

When dealing with winding mechanisms, it’s important to recognize the significance of each piece involved in the operation. From the housing that protects the internal mechanisms to the retractable cords that ensure ease of use, familiarity with these components enhances user experience. A detailed exploration can help in troubleshooting common issues and improving the functionality of the equipment.

Furthermore, understanding the relationships between these parts can lead to more efficient workflows. By mastering the intricacies of each segment, operators can effectively manage and utilize their equipment, ensuring longevity and reliability. This knowledge not only facilitates smoother operations but also empowers users to tackle challenges confidently.

Understanding Coxreels Components

The various elements of hose reels play a crucial role in their overall functionality and performance. These components work together to ensure efficient operation, ease of use, and durability in different environments. By gaining insights into these essential parts, users can make informed decisions regarding maintenance, upgrades, and replacements.

Core Elements: At the heart of these devices are the primary components, which include the frame, reel, and mounting brackets. The frame provides structural integrity, while the reel facilitates the smooth winding and unwinding of hoses. Proper selection of these core elements is vital for achieving optimal performance and longevity.

Mechanical Features: Mechanical aspects, such as the rewind mechanism and locking systems, contribute significantly to user experience. A reliable rewind mechanism ensures that the hose retracts smoothly, while effective locking systems prevent accidental unwinding. Understanding these features allows users to choose the right setup for their specific applications.

Accessories and Enhancements: Additional elements like swivel joints, hose guides, and protective covers can enhance functionality. These accessories not only improve ease of use but also protect the equipment from wear and tear. Familiarity with available enhancements can lead to better operational efficiency and increased equipment lifespan.

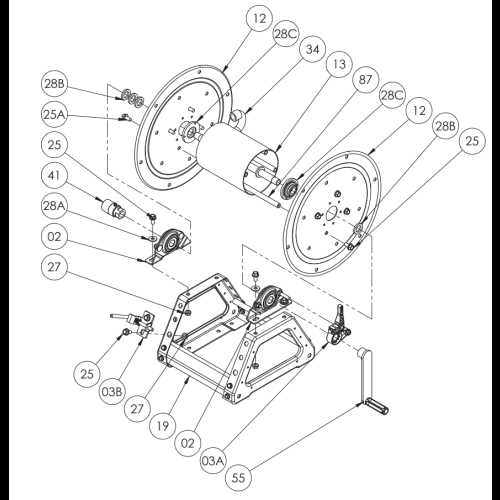

Overview of Reel Assembly

The assembly of a winding device involves several crucial components working in harmony to ensure optimal performance and longevity. Understanding the layout and function of each segment is essential for efficient operation and maintenance. This overview highlights the key elements that contribute to the effective functioning of the reel.

Key Components

At the heart of the winding mechanism lies the drum, which serves as the main housing for the material being wound. Attached to this are various supports and brackets that provide structural integrity and stability. Additionally, a spring mechanism is often included to assist with retraction, ensuring that the material is neatly stored when not in use.

Assembly Considerations

When assembling these components, careful attention must be given to alignment and fit. Misalignment can lead to premature wear and operational issues. Regular inspection of the assembly will help identify potential problems, allowing for timely adjustments and replacements to maintain peak functionality.

Identifying Key Parts and Functions

Understanding the essential components and their roles is crucial for the effective operation of any equipment. Each element serves a specific purpose, contributing to the overall functionality and efficiency of the system. By familiarizing oneself with these elements, users can better appreciate how they interact and influence performance.

The first crucial component is the reel, which is designed to store and manage flexible lines, ensuring they are neatly coiled and easily accessible. Alongside the reel, the housing plays a protective role, safeguarding internal mechanisms from external damage and environmental factors. The handle is another vital element, enabling users to effortlessly operate the equipment and rewind or deploy the line as needed.

Another significant part is the swivel, which allows for smooth rotation of the line without tangling, enhancing maneuverability. Additionally, the brake system is essential for controlling the unwinding speed, providing users with the ability to manage the line tension effectively. Understanding these key components not only aids in efficient operation but also helps in diagnosing issues that may arise during use.

Maintenance Tips for Coxreels

Regular upkeep is essential for ensuring the longevity and efficiency of any equipment. By following a few straightforward practices, users can significantly enhance performance and avoid potential issues down the line. This section outlines key strategies to maintain your equipment effectively, helping to optimize functionality and extend its lifespan.

Routine Inspection

Conducting regular checks of the machinery is crucial. Look for signs of wear and tear, and ensure that all components are functioning smoothly. Pay particular attention to any unusual noises or movements that may indicate underlying problems. Early detection can prevent more severe damage and costly repairs.

Proper Lubrication

Applying the right lubricant to moving parts is vital for reducing friction and wear. Ensure to use the recommended type for your specific equipment to achieve optimal results. Additionally, remember to clean any excess lubricant to prevent dirt accumulation, which could hinder performance.

Common Issues with Reel Components

Mechanical devices designed for winding and unwinding flexible materials can encounter a variety of challenges over time. These complications can arise from wear and tear, improper maintenance, or environmental factors. Understanding these common problems is essential for ensuring efficient operation and longevity.

Wear and Tear of Mechanical Parts

One of the most frequent issues involves the deterioration of mechanical elements due to constant use. Friction between moving components can lead to reduced efficiency and increased resistance, affecting overall performance. Regular inspections can help identify signs of wear, allowing for timely replacements before failures occur.

Environmental Impact

Exposure to harsh weather conditions can significantly affect the functionality of these devices. Corrosion from moisture or rust from prolonged exposure to the elements can weaken structural integrity. Implementing protective measures, such as proper storage and using weather-resistant materials, can mitigate these risks and enhance durability.

Repairing Damaged Parts Effectively

Restoring components to their original functionality is a crucial aspect of maintaining equipment longevity and performance. Proper techniques can ensure that even severely worn or broken elements can be efficiently revitalized, saving both time and resources. Understanding the right approaches to repair can make a significant difference in achieving durable and reliable results.

Assessment of Damage

Before initiating any repair process, it is essential to evaluate the extent of the damage. A thorough inspection allows for the identification of specific issues that need addressing. This assessment guides the selection of appropriate repair methods and materials.

Repair Techniques

Once the damage is assessed, various techniques can be employed to restore the functionality of the components. Below is a table outlining common repair methods and their applications:

| Repair Method | Description | Best Suited For |

|---|---|---|

| Welding | Joining two materials using high heat to melt and fuse them together. | Metal components with breaks or cracks. |

| Adhesive Bonding | Using specialized adhesives to bond materials together. | Non-metal components and lighter assemblies. |

| Replacement | Substituting a damaged element with a new or refurbished part. | Severely damaged components beyond repair. |

| Reinforcement | Adding extra material or support to strengthen weakened areas. | Components under significant stress or wear. |

How to Upgrade Your Coxreels

Enhancing your reel system can significantly improve its functionality and longevity. By making specific adjustments and replacements, you can ensure that your equipment operates more efficiently, saving both time and effort. This guide will walk you through essential upgrades that can elevate the performance of your reel setup.

1. Evaluate Your Current Setup

Before diving into modifications, assess your existing equipment thoroughly. Check for any signs of wear and tear, such as frayed hoses or rusted components. Identifying weaknesses will help you prioritize upgrades and make informed decisions about necessary enhancements.

2. Consider Replacement Components

Upgrading individual components can greatly enhance your system’s overall performance. Look for high-quality alternatives to existing elements, such as stronger springs or more durable hoses. Investing in superior materials can lead to increased efficiency and reduced maintenance over time. Additionally, consider adding features like swivel joints for improved maneuverability.

Choosing the Right Accessories

Selecting appropriate add-ons is crucial for optimizing functionality and enhancing performance. The right components can significantly impact efficiency, usability, and the overall user experience. Understanding the available options helps in making informed decisions that align with specific needs.

When considering which accessories to incorporate, keep the following factors in mind:

- Compatibility: Ensure that the selected add-ons are suitable for the primary equipment. Compatibility guarantees seamless operation and minimizes potential issues.

- Functionality: Identify the specific functions required. Accessories that enhance performance, such as hoses or reels, should be prioritized based on their intended use.

- Durability: Opt for high-quality materials that withstand environmental factors and daily wear. Investing in robust accessories can lead to long-term savings and reduced maintenance.

- Ease of Installation: Choose components that are simple to install. User-friendly add-ons can save time and reduce frustration during setup.

- Cost-Effectiveness: Assess the price against the value provided. Sometimes, higher initial costs can lead to better performance and longevity, making them worthwhile investments.

In conclusion, the selection of appropriate accessories plays a vital role in achieving optimal results. Careful consideration of the above factors ensures that users make choices that enhance their equipment’s efficiency and overall performance.

Safety Precautions During Use

When operating equipment designed for winding and unwinding flexible materials, it is essential to adhere to specific safety guidelines. These measures ensure the protection of both the user and the surrounding environment, minimizing the risk of accidents and injuries.

1. Personal Protective Equipment (PPE): Always wear appropriate protective gear, including gloves, safety glasses, and steel-toed boots. This equipment safeguards against potential hazards, such as sharp edges or accidental impacts.

2. Work Area Inspection: Before beginning operations, inspect the workspace for any obstructions or hazards. Ensure that the area is clear of debris and that the surface is stable to prevent slips and falls.

3. Proper Handling Techniques: Use the correct lifting and maneuvering techniques when moving the apparatus. Always lift with your legs, not your back, to avoid strain and injury.

4. Regular Maintenance: Conduct routine checks and maintenance on the equipment to ensure it is functioning correctly. Address any issues immediately to prevent malfunctions during operation.

5. Awareness of Surroundings: Stay vigilant and aware of your surroundings while in use. Be mindful of other personnel nearby and communicate effectively to avoid accidents.

6. Emergency Procedures: Familiarize yourself with emergency procedures and the location of first aid kits. Knowing how to respond in case of an emergency can significantly reduce the severity of injuries.

By following these safety precautions, users can operate their equipment confidently and effectively, ensuring a secure working environment.

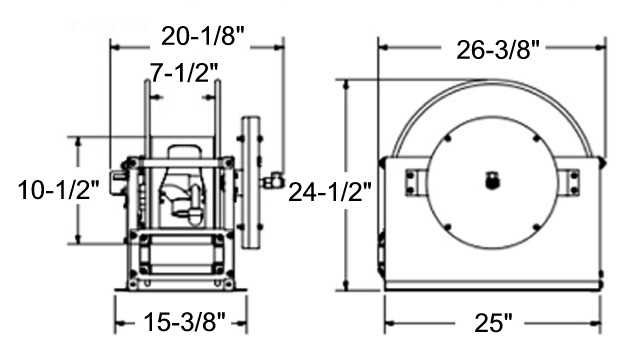

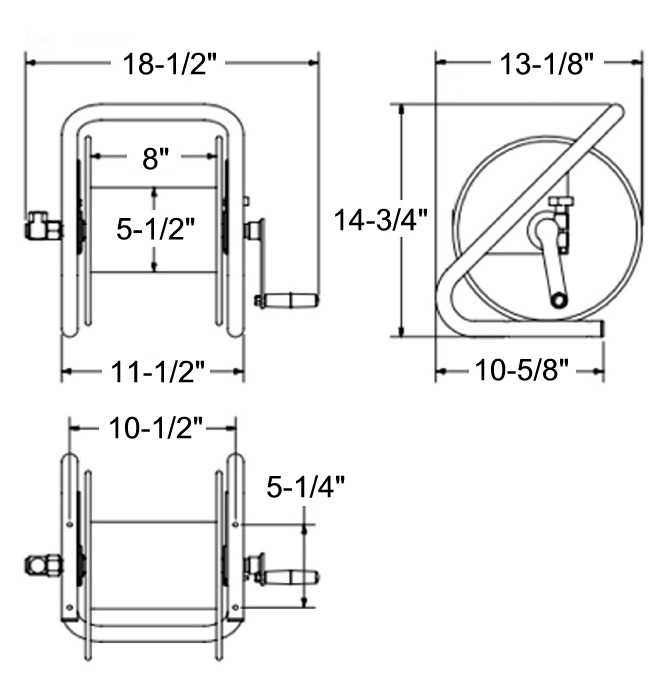

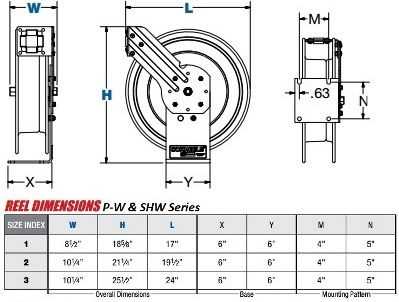

Comparing Different Coxreels Models

This section explores various models of a renowned brand specializing in hose reels, focusing on their distinct features, applications, and advantages. By understanding these variations, users can make informed decisions when selecting the right model for their needs.

Key Features to Consider

- Material Quality: Different models may utilize varying materials, affecting durability and resistance to environmental factors.

- Reel Size: Available sizes can influence the amount of hose accommodated, catering to diverse user requirements.

- Mounting Options: Some variants offer wall or floor mounting, providing flexibility in installation.

- Hose Capacity: Each model has a specific capacity, determining how much hose can be stored and used efficiently.

- Retrieval Mechanism: The winding system varies among models, impacting ease of use and efficiency.

Model Comparisons

- Model A: Known for its robust design, this variant is ideal for industrial applications, featuring high hose capacity and sturdy construction.

- Model B: A more compact option suitable for residential use, it offers convenient mounting solutions and ease of maneuverability.

- Model C: This model is designed for versatility, accommodating various hose types and lengths, making it popular among professional users.

- Model D: With advanced features like automatic retrieval, this option appeals to those seeking efficiency and time-saving solutions.

Exploring Parts Availability and Support

Access to quality components is crucial for maintaining the efficiency and longevity of any equipment. Understanding the resources available for obtaining these essential elements can significantly enhance user experience. Various channels exist for acquiring the necessary items, ensuring that functionality is preserved and downtime is minimized.

Manufacturers often provide extensive resources, including online catalogs and dedicated customer service teams, to assist customers in locating the right components. Their websites typically feature detailed information about the items they offer, making it easier to identify and procure what is needed. Additionally, they may have a support network in place to address any queries or concerns that may arise during the selection process.

Distributors also play a vital role in the supply chain by offering a range of options and facilitating quicker access to required items. They often maintain a stock of popular selections, making it more convenient for users to find what they need without delay. Furthermore, many distributors have knowledgeable staff who can provide guidance on selecting the best solutions for specific applications.

Online marketplaces can serve as another valuable resource, where users can explore a wide array of options from various suppliers. These platforms allow for easy comparison of prices and availability, helping users make informed decisions. Reviews and ratings can further aid in assessing the reliability of both products and sellers, ensuring confidence in purchases.

Ultimately, understanding where to find necessary components and the support available can significantly impact the efficiency of operations. By leveraging multiple sources, users can ensure that they have access to the essential elements required to keep their equipment functioning optimally.