Understanding the layout and interconnection of various mechanical elements is essential for maintaining and optimizing the performance of industrial machinery. Each piece serves a specific role in ensuring the smooth operation of complex systems, where precision and reliability are key.

When dealing with heavy-duty equipment, having a clear understanding of the internal structure can significantly aid in troubleshooting, repairs, and upgrades. By recognizing how individual elements are linked, professionals can easily identify potential issues and enhance overall efficiency.

In this guide, we will delve into the intricate configuration of vital mechanical components. Whether it’s for routine maintenance or detailed repairs, knowing the positioning and function of each element is crucial for keeping equipment running efficiently and safely.

Daewoo Forklift Parts Diagram Overview

The structural breakdown of heavy equipment components provides a clear understanding of how various elements interact within a complex machinery system. Each individual piece plays a crucial role in ensuring optimal performance and safety. By examining these configurations, operators and technicians can effectively maintain and repair equipment.

Key elements to explore include:

- The system responsible for lifting and lowering loads

- The mechanisms that ensure smooth operation and movement

- The power source and its integration with control elements

- Safety features that protect both the machine and its operators

Understanding these critical connections helps streamline maintenance tasks and reduces downtime, ensuring efficient and reliable operation.

Understanding the Mechanical Components

The arrangement of various elements within a machine plays a vital role in its functionality and overall performance. Every piece works together to ensure smooth operation, contributing to the efficient movement and handling of loads. Recognizing the purpose of each mechanical element is key to maintaining and optimizing performance.

| Component | Function | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydraulic System | Responsible for powering lifting and lowering mechanisms through fluid pressure. | ||||||||||||||||||||||

| Chassis | Acts as the foundational frame supporting the overall structure. | ||||||||||||||||||||||

| Transmission | Transfers power from the engine to the wheels, enabling controlled movement. | ||||||||||||||||||||||

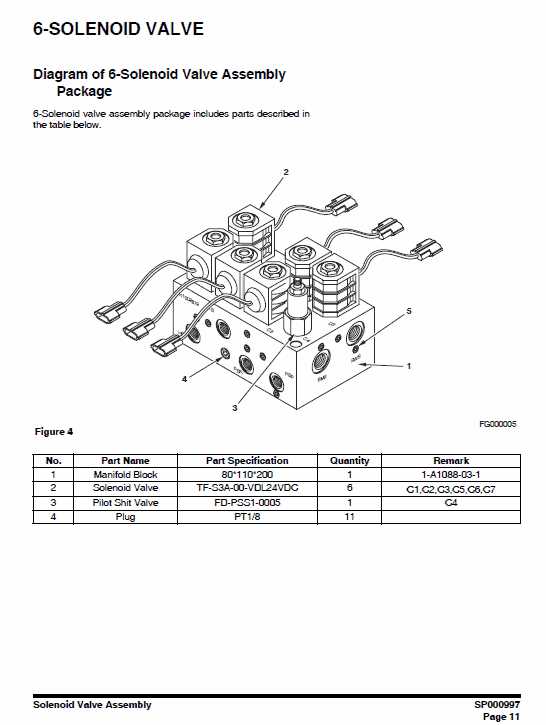

| Detailed View of Hydraulic System

The hydraulic mechanism plays a crucial role in the operation of lifting equipment, enabling smooth and precise movement by using fluid power. This system ensures that various components work in harmony to lift, lower, and maneuver loads efficiently. By transferring force through pressurized liquid, the machinery operates with minimal effort from the user, providing optimal control and stability. Main Components of the Hydraulic SetupThe system is composed of several key elements that work together to generate and regulate power. These include the pump, which creates the necessary pressure, the valves that control the flow of fluid, and the cylinders responsible for converting hydraulic energy into mechanical action. Electrical Layout and Connections

The structure of the electrical system is essential for ensuring the efficient operation of any machinery. Understanding how different components interconnect within the framework is vital for proper functioning and maintenance. Each section of the system plays a critical role in transferring power and signals, making it crucial to comprehend the overall arrangement of these elements. Core Electrical ComponentsKey elements in the electrical design include power sources, control units, and various pathways that link them. These pathways allow for the smooth transmission of energy, ensuring that each section of the machinery operates harmoniously. By mapping these connections, one can easily troubleshoot and optimize performance. Connection Points Overview

Cooling System StructureThe cooling system plays a crucial role in maintaining optimal operating temperatures within machinery, ensuring efficient performance and longevity. This setup is designed to regulate heat generated during operation, preventing overheating and potential damage. By circulating a cooling medium, it dissipates excess heat, allowing various components to function effectively. Components of the Cooling System

The structure of the cooling mechanism comprises several essential components that work together to manage temperature. Each element contributes to the overall efficiency of the system, ensuring smooth operation and preventing failures.

Importance of Regular MaintenanceTo ensure the effectiveness of the cooling system, regular maintenance is vital. This includes checking coolant levels, inspecting components for wear, and flushing the system periodically. Proper upkeep enhances performance, reduces the risk of overheating, and extends the lifespan of machinery. Load Handling Mechanism ComponentsThe system responsible for managing and maneuvering loads plays a crucial role in various industrial applications. This arrangement comprises several elements that work in unison to facilitate the safe and efficient movement of materials. Understanding these components is essential for optimizing operations and ensuring longevity in performance. Key Elements of Load ManagementAmong the primary components are the lifting apparatus, which provides the necessary force to elevate loads, and the attachment mechanisms that secure items during transportation. Additionally, the control systems enable operators to maneuver and position the loads accurately, while safety features ensure the stability of the entire setup. Importance of Quality ComponentsUtilizing high-quality components is vital for maintaining operational efficiency and minimizing downtime. Durability and reliability are paramount, as they contribute to the overall effectiveness of load handling operations. Regular maintenance and the use of original equipment will further enhance performance and safety in material management tasks. Troubleshooting Common Forklift PartsUnderstanding the typical challenges encountered with lifting machinery is essential for maintaining optimal performance. Various components can exhibit issues that impact functionality, leading to reduced efficiency and safety concerns. By identifying these common problems, operators can take proactive measures to ensure smooth operation and prevent costly downtime. Identifying Hydraulic System IssuesOne of the most critical systems in lifting machinery is the hydraulic mechanism. Problems here often manifest as sluggish operation or complete failure to lift. Signs of hydraulic issues may include:

Regularly checking fluid levels and inspecting hoses can help maintain system integrity and performance. Assessing Electrical Components

The electrical system plays a vital role in the operation of lifting machines. Common electrical challenges might arise, affecting functionality. Key indicators of electrical problems include:

Routine inspections and timely replacements of worn-out components can prevent unexpected failures and prolong the lifespan of the equipment. Maintenance Tips for Daewoo ForkliftsEnsuring optimal performance and longevity of handling equipment requires consistent care and attention. Regular upkeep not only enhances efficiency but also minimizes the risk of unexpected breakdowns. This section outlines essential practices to maintain the functionality and reliability of your machinery. Routine InspectionsConducting frequent assessments is vital to identify potential issues before they escalate. Check fluid levels, tire conditions, and overall structural integrity. Regular inspections help in spotting wear and tear, enabling timely repairs and replacements. Proper CleaningMaintaining cleanliness is crucial for the effective operation of handling devices. Accumulated debris can lead to malfunctions and reduced efficiency. Ensure that all components, especially moving parts, are kept free of dirt and grime to promote optimal functionality. |