When engaging with intricate machinery, comprehending the layout of its components is essential for effective operation and maintenance. This understanding not only enhances functionality but also ensures safety during usage. Each segment plays a vital role in the overall performance, making it crucial to familiarize oneself with their arrangement and purpose.

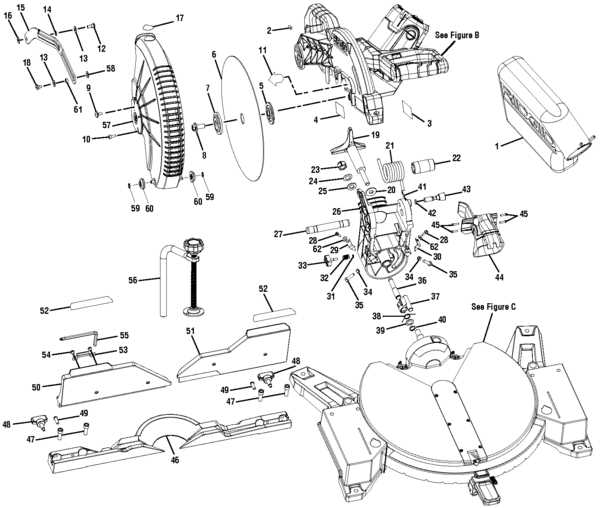

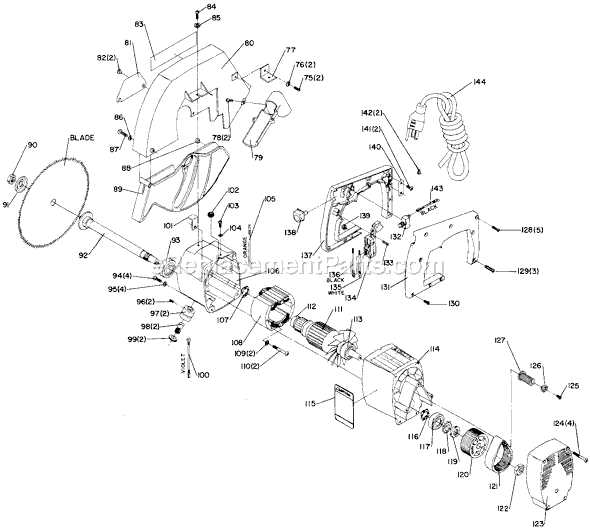

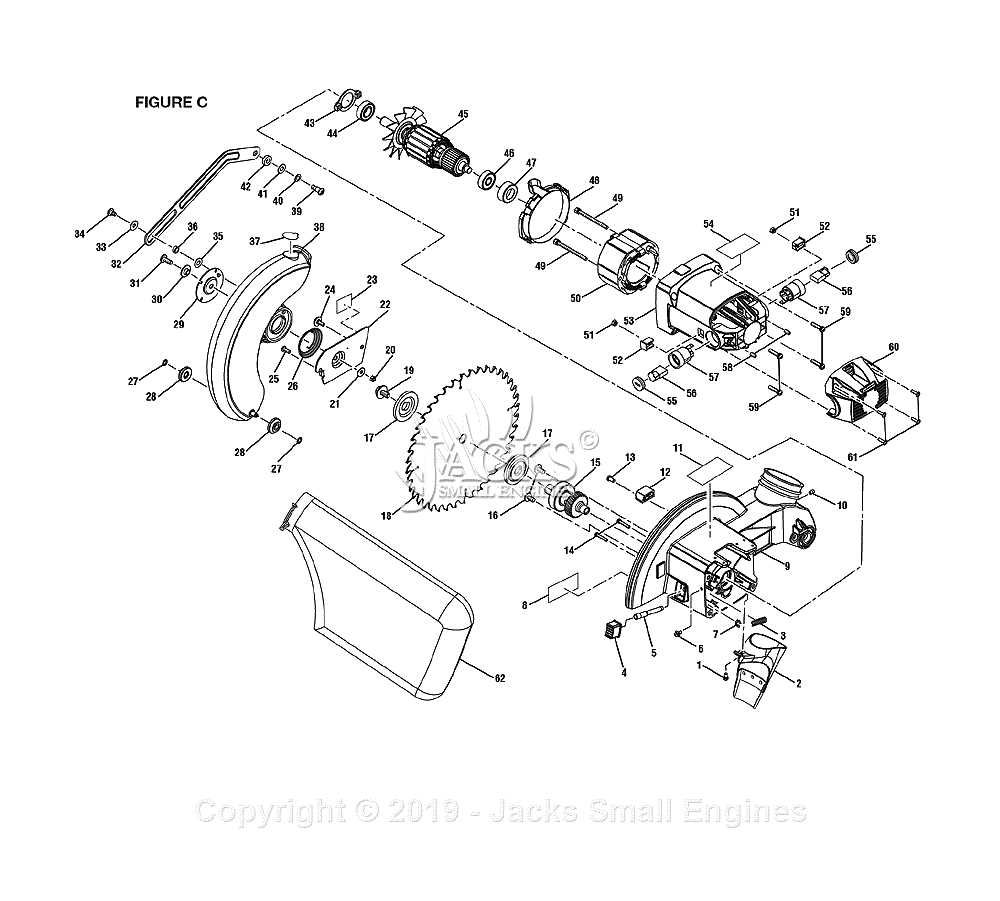

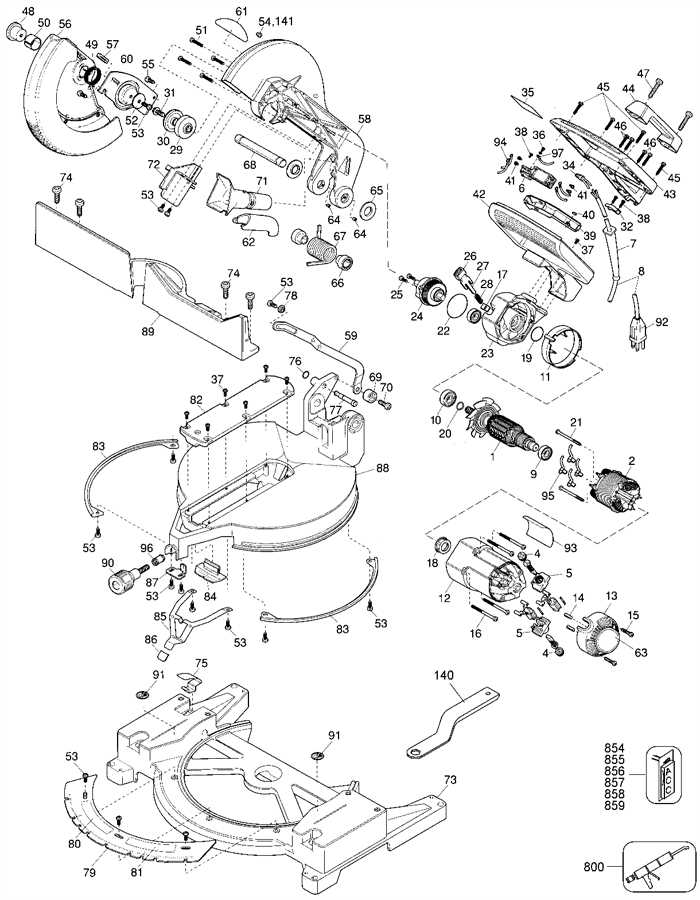

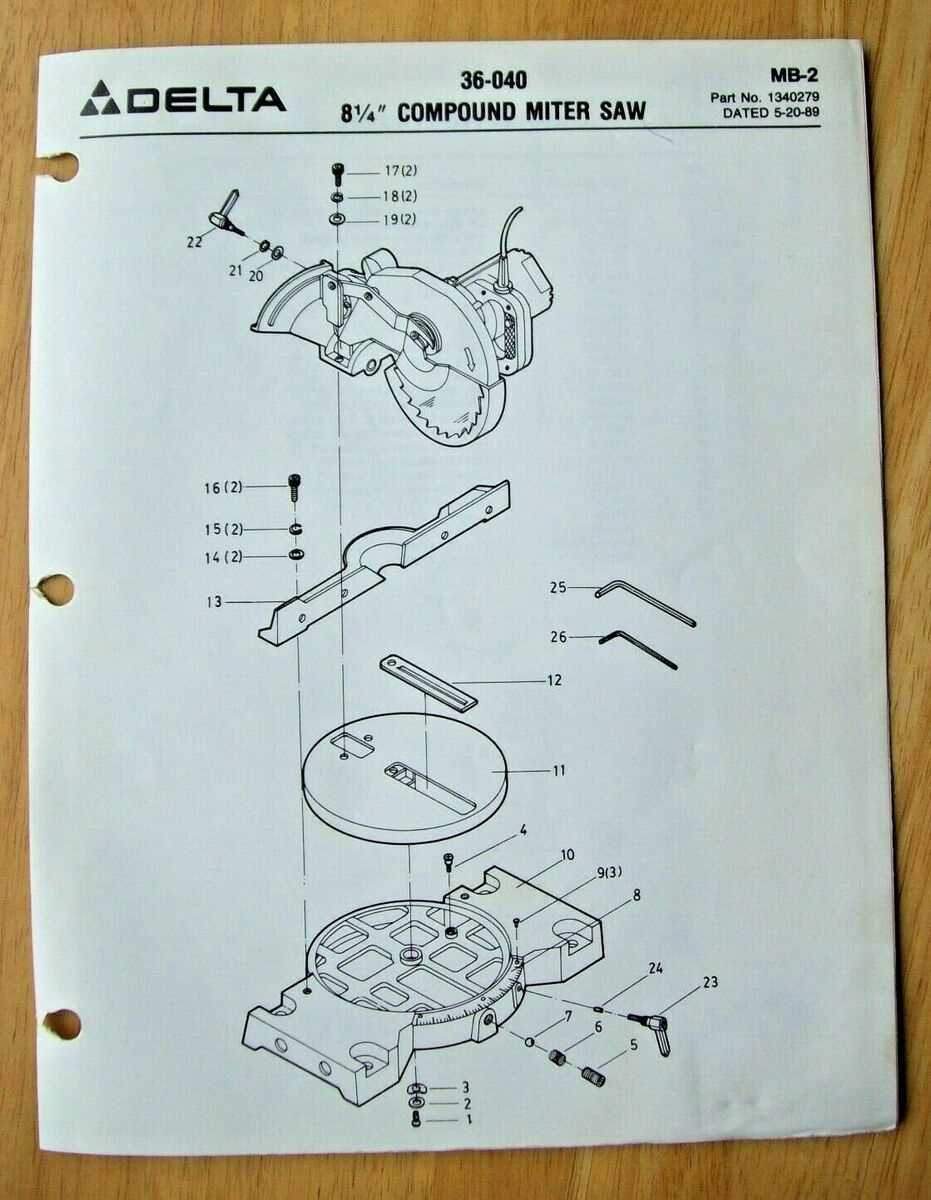

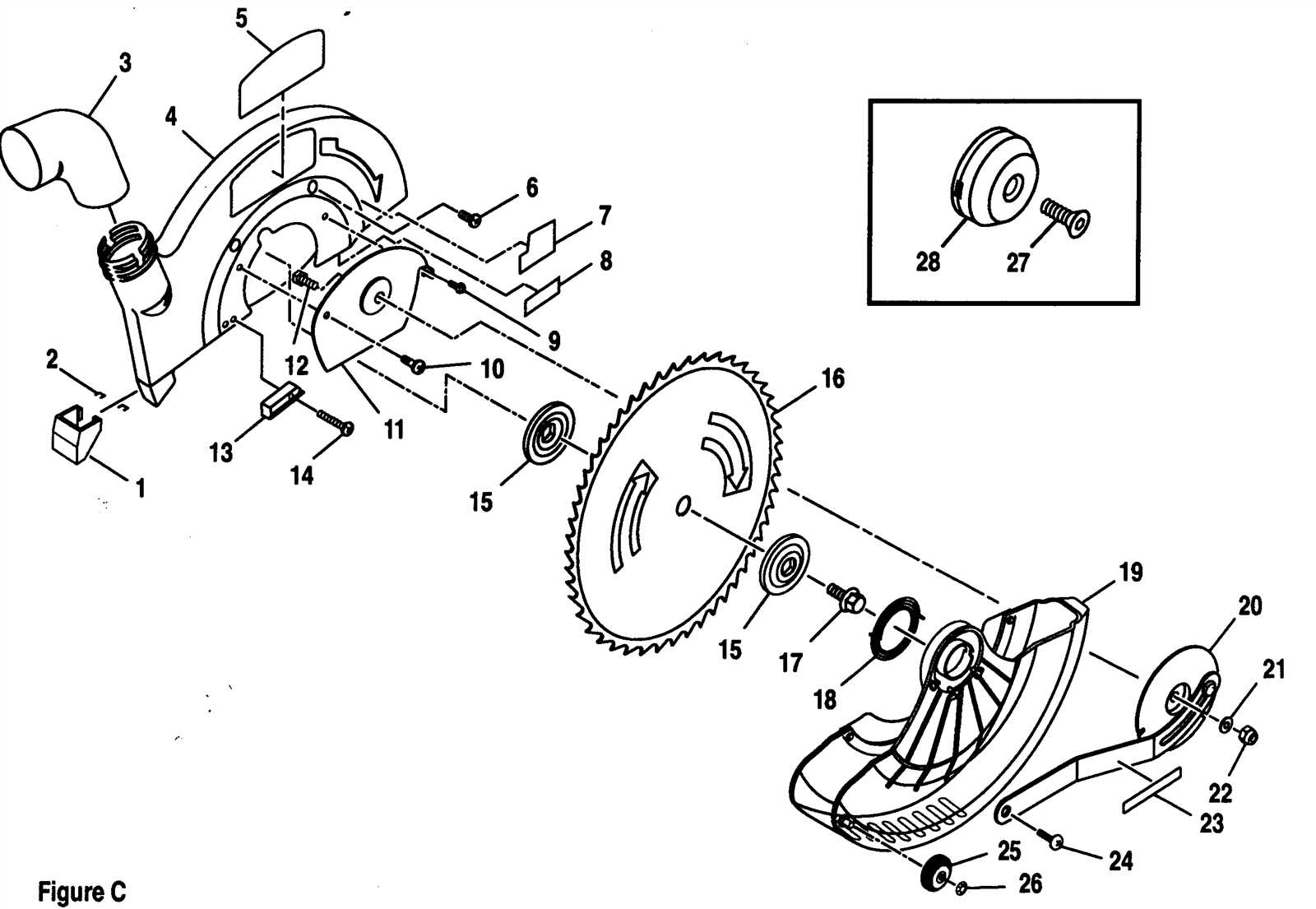

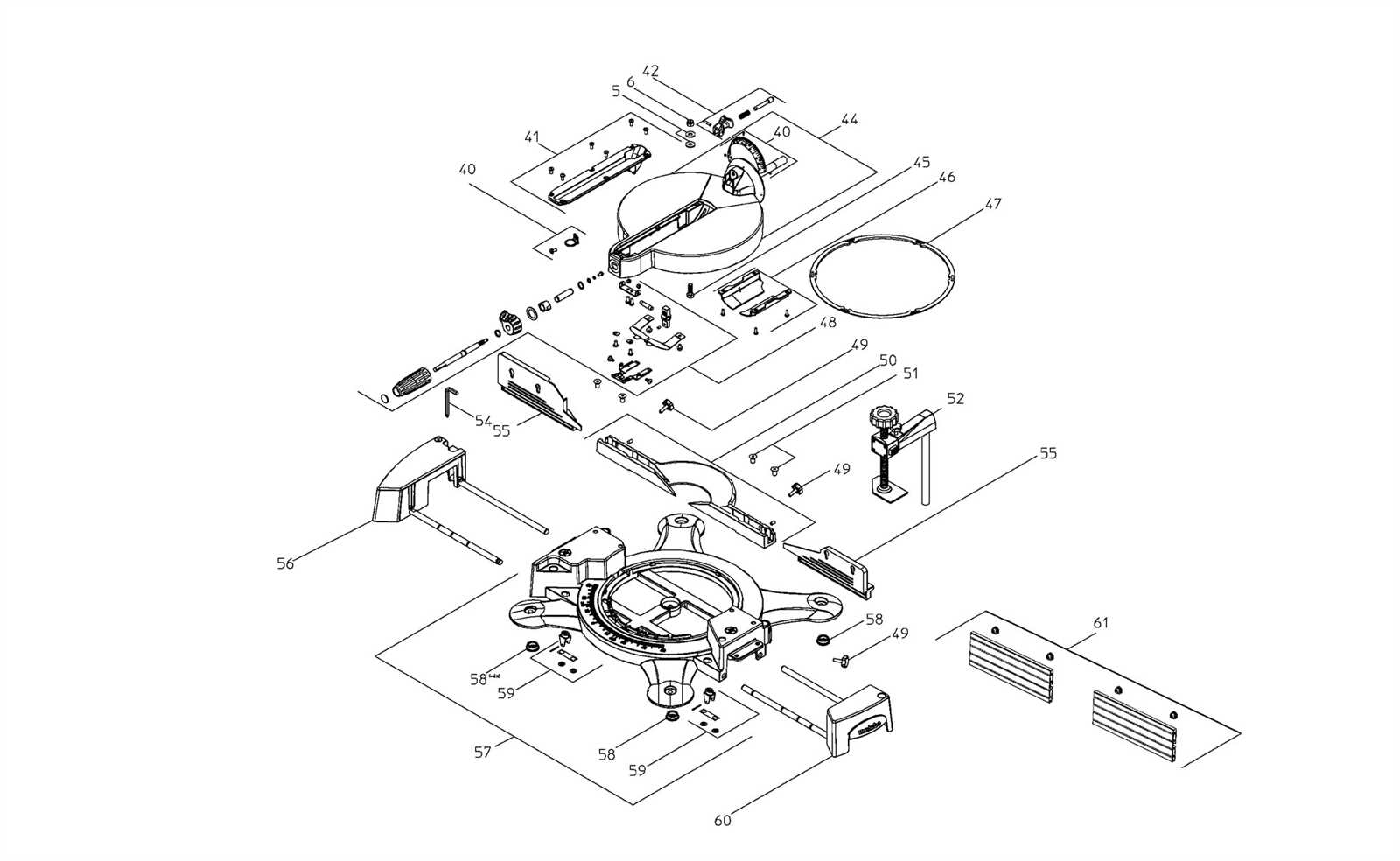

The visual representation of these elements allows users to quickly identify each section, facilitating easier repairs and upgrades. By examining how various pieces interconnect, one gains insights into the operational dynamics and potential troubleshooting paths. Knowledge of these configurations empowers users to maximize efficiency and extend the life of the equipment.

Moreover, this awareness fosters confidence in handling the machinery, making it simpler to address any issues that arise. A clear understanding of the layout encourages proactive maintenance practices, ultimately leading to a smoother and more productive experience with the tool.

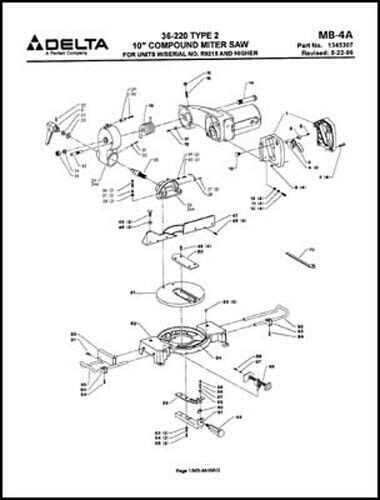

Understanding Delta Miter Saw Components

This section explores the essential elements of a precision cutting tool, focusing on their functions and how they contribute to overall performance. Recognizing these components is vital for efficient operation and maintenance.

Main Elements of the Tool

The primary structure typically includes a robust frame, which provides stability during use. Additionally, a rotating arm allows for angled cuts, making it easier to achieve various project specifications.

Another critical feature is the adjustable cutting mechanism, which ensures accurate depth and angle adjustments. Understanding these aspects enhances the user experience, leading to superior results in woodworking tasks. Proper maintenance of these components can significantly extend the tool’s lifespan.

Key Parts of a Miter Saw

Understanding the essential components of a cutting tool can enhance its effective use and maintenance. Each element plays a vital role in ensuring precise cuts and overall performance.

Essential Components

- Base: Provides stability and support during operation.

- Blade: The cutting edge that performs the actual cutting.

- Arm: The mechanism that holds and moves the blade.

- Fence: A guide to ensure accurate alignment of the material being cut.

- Handle: Facilitates control and maneuverability.

Additional Features

- Bevel Adjustment: Allows for angled cuts.

- Blade Guard: Enhances safety by covering the blade.

- Power Switch: Provides an easy way to turn the tool on and off.

Importance of Accurate Diagrams

Precise illustrations are crucial for understanding the assembly and functionality of various tools. They provide users with a visual representation that simplifies complex structures, making it easier to identify each component’s role. This clarity helps in both assembly and maintenance processes, ensuring that users can effectively utilize their equipment.

When detailed visuals are available, the risk of errors during reassembly decreases significantly. Users can refer to these representations to confirm that each piece is correctly positioned, which ultimately enhances the tool’s performance and longevity. Moreover, accurate depictions can save time and reduce frustration by guiding individuals through intricate tasks without ambiguity.

Additionally, these illustrations serve as valuable resources for troubleshooting. When issues arise, users can quickly reference the visuals to pinpoint the problem area and determine necessary adjustments or replacements. In essence, high-quality visuals are not just helpful; they are indispensable for anyone seeking to maximize the effectiveness of their tools.

Common Issues with Miter Saw Parts

Tools designed for precise cutting can experience various challenges that affect their performance. Understanding these common complications can help in maintaining efficiency and extending the lifespan of the equipment.

Wear and Tear: Over time, components may show signs of deterioration, leading to decreased accuracy. Regular inspections can identify parts that require replacement.

Alignment Problems: Improper alignment can result in uneven cuts. Ensuring that all elements are correctly positioned is crucial for optimal functionality.

Motor Issues: The motor may encounter problems due to overheating or electrical failures, impacting the overall operation. Proper care and timely servicing can prevent these situations.

Dust Accumulation: Excessive dust buildup can hinder performance and lead to overheating. Keeping the tool clean is essential for smooth operation.

Blade Dullness: A worn blade can compromise cutting efficiency. Regular sharpening or replacement is necessary to maintain sharpness and precision.

How to Identify Miter Saw Components

Understanding the various elements of a cutting tool is essential for effective usage and maintenance. Familiarizing yourself with the key components can enhance your experience and ensure safe operation. Each part plays a specific role in the overall functionality, contributing to precision and efficiency in your projects.

Key Elements to Recognize

When examining a cutting device, focus on the following main components:

- Base: The foundation that provides stability during operation.

- Blade: The essential element responsible for cutting through materials.

- Arm: The mechanism that allows the blade to pivot for angled cuts.

- Fence: The guide that helps align workpieces for accurate cuts.

Tips for Component Identification

To effectively recognize these components, consider the following:

- Refer to the manufacturer’s manual for labeled diagrams that illustrate each part.

- Examine the tool closely, noting any labels or markings that indicate specific functions.

- Practice handling the tool to become more familiar with the layout and operation of its elements.

With this knowledge, you can better navigate the intricacies of your cutting tool, leading to improved performance and safety.

Maintenance Tips for Miter Saw Parts

Proper upkeep of cutting tools is essential for their longevity and optimal performance. Regular attention to various components can enhance efficiency and safety during use. Here are some essential recommendations to maintain these tools effectively.

Regular Cleaning

Keeping the equipment clean is vital. Dust and debris can accumulate, leading to operational issues. After each use, wipe down surfaces with a soft cloth and remove any material buildup.

Lubrication of Moving Components

Ensuring that moving parts are well-lubricated can prevent wear and tear. Use a suitable lubricant to maintain smooth operation, particularly on pivot points and sliding mechanisms.

| Task | Frequency | Notes |

|---|---|---|

| Clean surfaces | After each use | Use a soft cloth and brush |

| Lubricate moving parts | Every month | Choose an appropriate lubricant |

| Check alignment | Every few uses | Ensure precision for accuracy |

Replacing Worn-Out Components

Over time, various elements of cutting tools can degrade, affecting performance and accuracy. Identifying and substituting these worn-out components is crucial for maintaining optimal functionality. Regular maintenance not only enhances efficiency but also prolongs the lifespan of the equipment.

When assessing the tool, start by inspecting areas that experience significant wear, such as the blade and motor. Replacing these critical parts can restore cutting precision and improve overall operation. Additionally, consider checking the alignment of movable sections to ensure they operate smoothly.

Utilizing high-quality replacement components is essential for achieving the best results. By investing in reliable parts, you can ensure your tool remains efficient and effective for various projects.

Safety Features in Miter Saws

Ensuring user protection is paramount in power tools, especially in cutting equipment. Various safety mechanisms are integrated to minimize risks and enhance overall security during operation.

- Blade Guard: A protective cover that shields the user from the rotating blade when not in use.

- Electric Brake: Instantly halts blade rotation after the trigger is released, preventing accidents.

- Safety Switch: Requires two-step activation to avoid unintended start-ups.

- Laser Guide: Projects a line for precise cutting, reducing the likelihood of errors.

These features work together to create a safer working environment, allowing users to focus on their projects with confidence.

Adjusting Miter Saw Settings

Fine-tuning the cutting tool’s settings is essential for achieving precise angles and clean cuts. Proper adjustments can significantly enhance performance and ensure accuracy in various projects.

Here are key adjustments to consider:

- Angle Calibration: Ensure that the angle settings are aligned correctly to achieve the desired cut. Use a square or protractor to verify accuracy.

- Height Adjustment: Set the blade height according to the thickness of the material being cut. This prevents splintering and ensures a smooth finish.

- Bevel Settings: Adjust the bevel to create angled cuts. Confirm the angle using a level for optimal results.

Regularly check these settings to maintain the tool’s performance and longevity. Proper adjustments not only improve the quality of work but also enhance safety during operation.

Choosing the Right Blade

Selecting the appropriate cutting tool is crucial for achieving precise results in woodworking projects. The right blade can significantly affect the quality of the cut and the overall performance of your equipment. Various types of blades are designed for different materials and tasks, making it essential to consider your specific needs before making a choice.

When evaluating options, consider factors such as the material you’ll be cutting, the desired finish, and the type of cuts you plan to make. For instance, blades with finer teeth are ideal for achieving smooth finishes on delicate materials, while those with larger teeth are better suited for quicker, rough cuts. Understanding these differences will help you make an informed decision.

Additionally, pay attention to the diameter and thickness of the blade, as these specifications impact compatibility with your equipment and the type of cuts you can perform. Regular maintenance and periodic replacement of blades are also important to ensure optimal performance and longevity. Investing time in selecting the right cutting tool will ultimately enhance your woodworking experience.

Understanding the Cutting Mechanism

The cutting mechanism is a crucial aspect of precision tools designed for angled and straight cuts. It operates through a series of interconnected components that work in harmony to deliver clean, accurate results. By examining how these elements interact, users can gain insight into the efficiency and effectiveness of their cutting tasks.

Understanding the underlying mechanics can aid users in maintaining their tools, leading to improved performance and longevity. Regular checks on components such as the motor, blade, and support mechanisms are essential to ensure optimal functionality, ultimately enhancing the overall cutting experience.

Assembly Instructions for Miter Saw

Proper assembly of a cutting tool is crucial for optimal performance and safety. Following a systematic approach ensures that all components are correctly positioned and secured, allowing for effective use during tasks.

Begin by laying out all components on a clean, flat surface. Organizing the pieces helps streamline the assembly process and prevents loss of any parts. Refer to the instruction manual for guidance on each component’s role and placement.

Next, assemble the base and frame by aligning the pre-drilled holes. Use the appropriate fasteners to secure them tightly. Ensure that all connections are flush to maintain stability during operation.

Once the frame is set, attach the cutting mechanism. Carefully align it according to the manufacturer’s specifications. It’s essential to check the alignment to prevent uneven cuts. Secure all bolts and screws, ensuring everything is tightened appropriately.

After the main components are in place, connect the power supply. Follow the electrical diagram provided to ensure safe connections. Double-check all wiring before proceeding to the next steps.

| Step | Action |

|---|---|

| 1 | Lay out all components |

| 2 | Assemble base and frame |

| 3 | Attach cutting mechanism |

| 4 | Connect power supply |

Finally, conduct a thorough inspection of the assembled tool. Ensure that all parts are securely fastened and functioning as intended. Once confirmed, proceed to perform a test run to verify that the assembly is successful and safe for use.

Upgrading Miter Saw Accessories

Enhancing the functionality of your cutting tool can significantly improve your woodworking projects. By integrating advanced attachments and components, you can achieve greater precision and efficiency, ultimately elevating your craftsmanship.

Consider adding laser guides to ensure accurate alignment, allowing for cleaner cuts. Another valuable enhancement is a dust collection system, which helps maintain a clean workspace while improving visibility. Additionally, exploring high-quality blades can make a substantial difference in the quality of your results.

Investing in extension arms provides extra support for larger materials, while clamping systems secure your workpieces for added safety during operation. With these upgrades, you’ll not only optimize your tool’s performance but also enhance your overall woodworking experience.