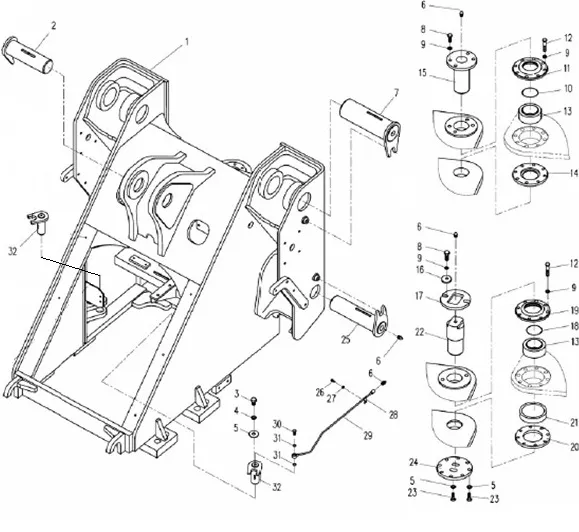

When it comes to maintaining machinery, one of the key aspects is having a clear and accurate understanding of the internal setup. This knowledge ensures that repairs and replacements are carried out with precision, preventing further issues down the line. A detailed breakdown of individual elements plays a crucial role in streamlining this process, offering a roadmap for effective servicing.

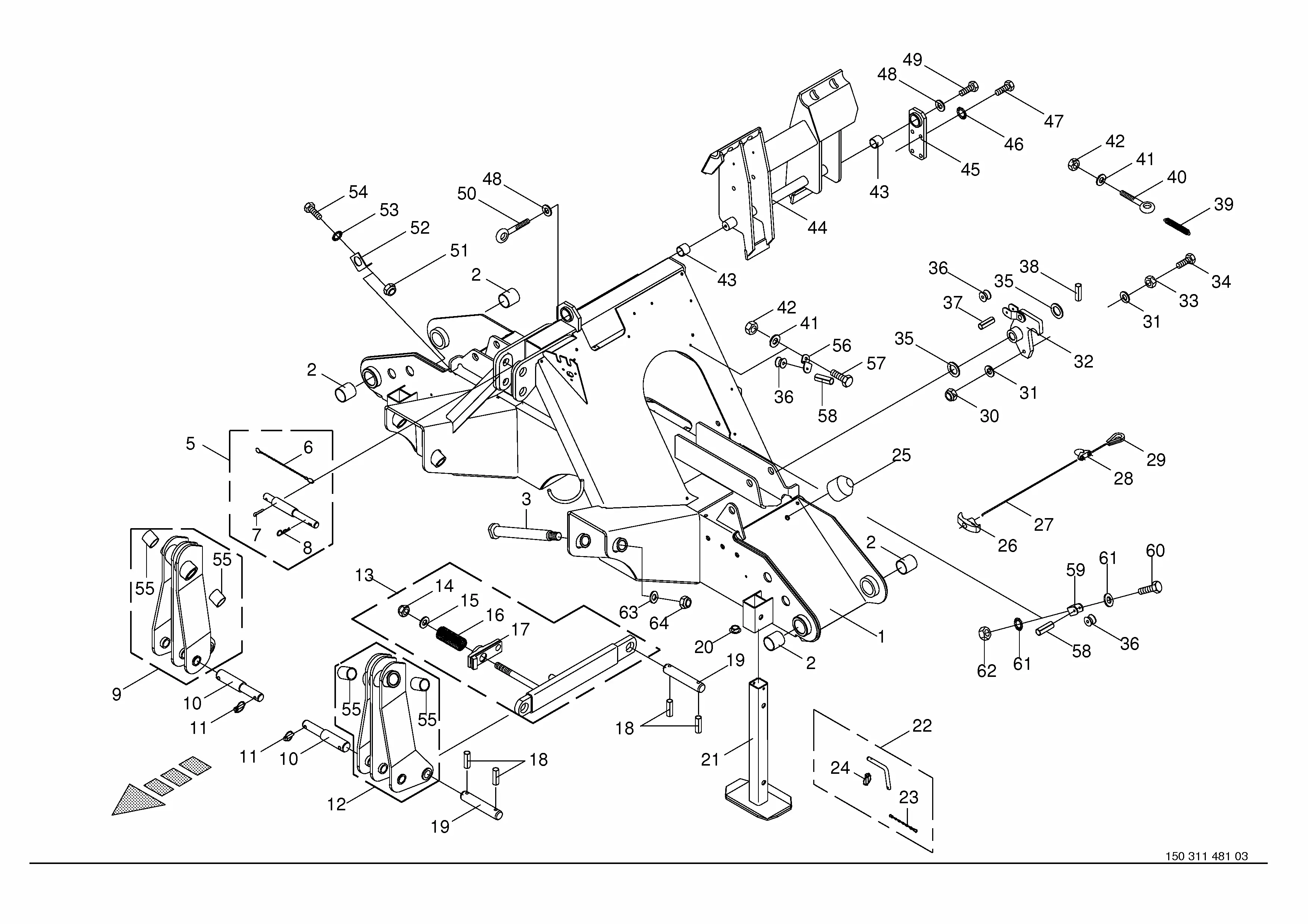

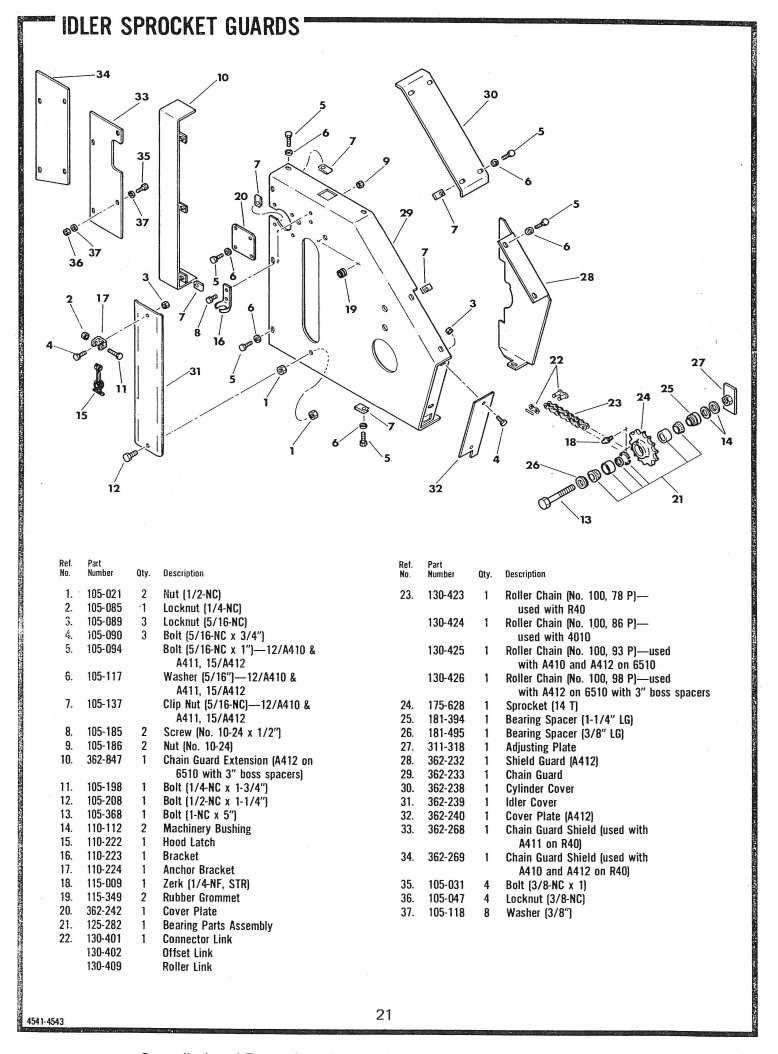

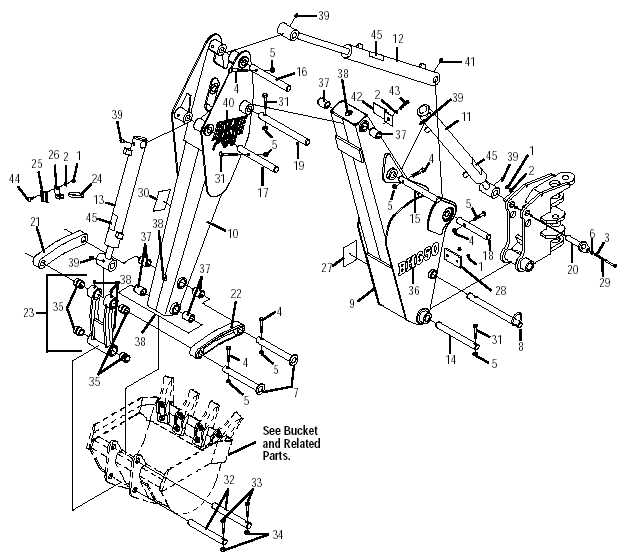

Accurate schematics allow technicians to visualize each element in relation to the whole structure. This helps identify potential wear points and facilitates smoother replacements. By understanding how each component interacts with others, the overall longevity and performance of the equipment can be significantly enhanced.

Components Overview

This section provides a detailed insight into the main mechanical elements and functional units of the equipment. Understanding these components ensures effective use, maintenance, and troubleshooting, helping to keep the machinery in optimal working condition.

Key Mechanical Units

- Engine Assembly – Powers the equipment and drives various mechanisms.

- Transmission System – Transfers power from the engine to the working parts, ensuring smooth operation.

- Hydraulic Components – Controls the movement and functionality of various arms and attachments.

Additional Functional Elements

- Control Panel – Allows the operator to manage speed, direction, and other operational parameters.

- Safety Mechanisms – Includes systems to ensure operator protection and prevent malfunctions.

- Attachment Points – Connects additional tools or components, enhancing versatility.

Key Features of Ditch Witch 1030

This equipment is designed for efficient and reliable performance in challenging environments. It is well-known for its versatility, durability, and ability to tackle various ground conditions, making it a valuable tool for different types of projects.

Efficient Performance

The machine delivers exceptional efficiency, allowing operators to complete tasks quickly and with minimal effort. Its powerful engine and optimized design ensure smooth operation, even in demanding conditions.

Durable Construction

Built with high-quality materials, the device offers long-lasting durability. Its robust construction enables it to withstand harsh environments, ensuring consistent performance over time. Reliability is one of its standout characteristics, making it a go-to option for professionals seeking long-term value.

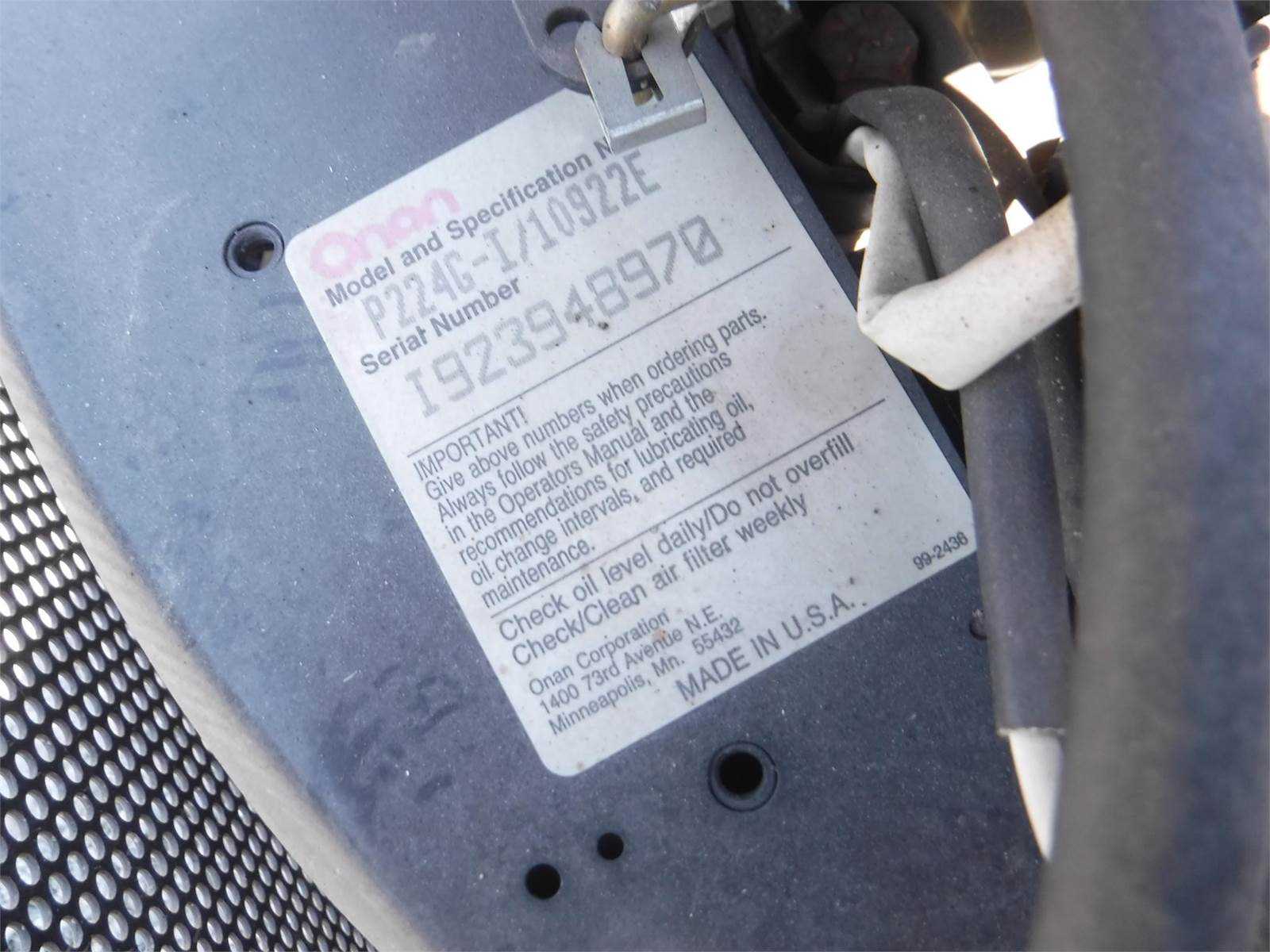

Understanding the Function of Engine Parts

The core of any mechanical system is its engine, a complex assembly of components that work together to convert energy into motion. Each element of the engine has a specific role, ensuring smooth performance and optimal efficiency. Comprehending how these components interact helps in maintaining and troubleshooting the engine effectively.

Main Components and Their Roles

- Pistons: These are responsible for transferring the force generated by combustion to the crankshaft, enabling movement.

- Crankshaft: This key component converts the linear motion of the pistons into rotational movement, driving the machinery.

- Valves: They control the flow of air and fuel into the engine and allow exhaust gases to exit after combustion.

Combustion Process and Its Importance

At the

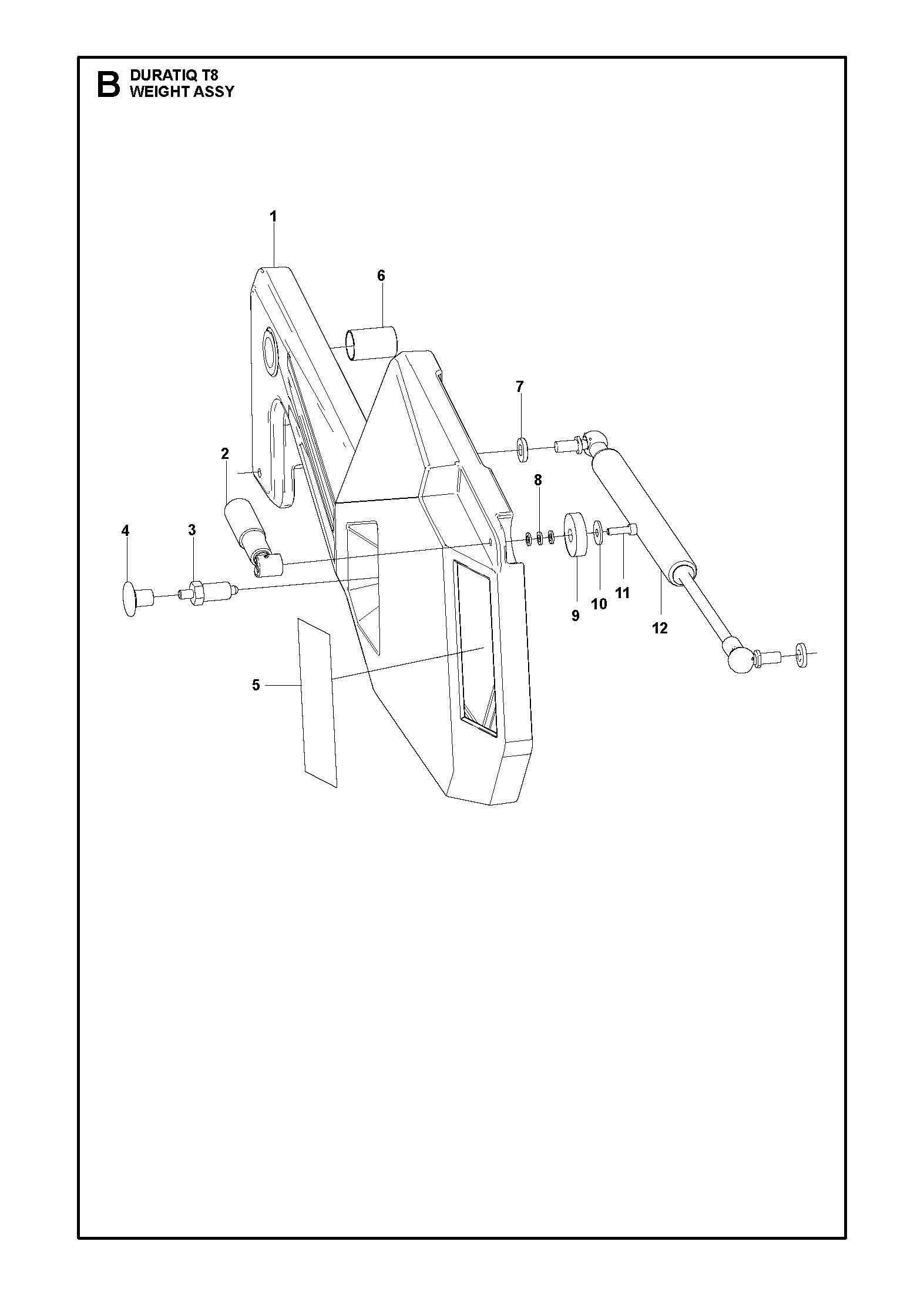

Blade Mechanism and Maintenance Tips

The cutting system plays a critical role in ensuring efficient performance. Keeping the blade assembly in proper condition not only enhances the overall function but also prolongs the lifespan of the equipment. Below are essential recommendations on how to maintain this mechanism effectively.

Key Components Overview

Understanding the individual parts of the blade assembly is crucial for smooth operation. The cutting edge, pivot points, and attachment hardware all require routine checks to prevent wear and damage. Make sure to inspect these areas frequently to ensure they are free from obstructions and securely fastened.

Maintenance Guidelines

Regular maintenance is key to ensuring longevity. Clean the blade and its surrounding components after each use, removing dirt and debris that could hinder performance. Additionally, sharpen the blade as needed and lubricate all moving parts. Always tighten any loose connections to avoid malfunctions during operation.

Pro Tip:

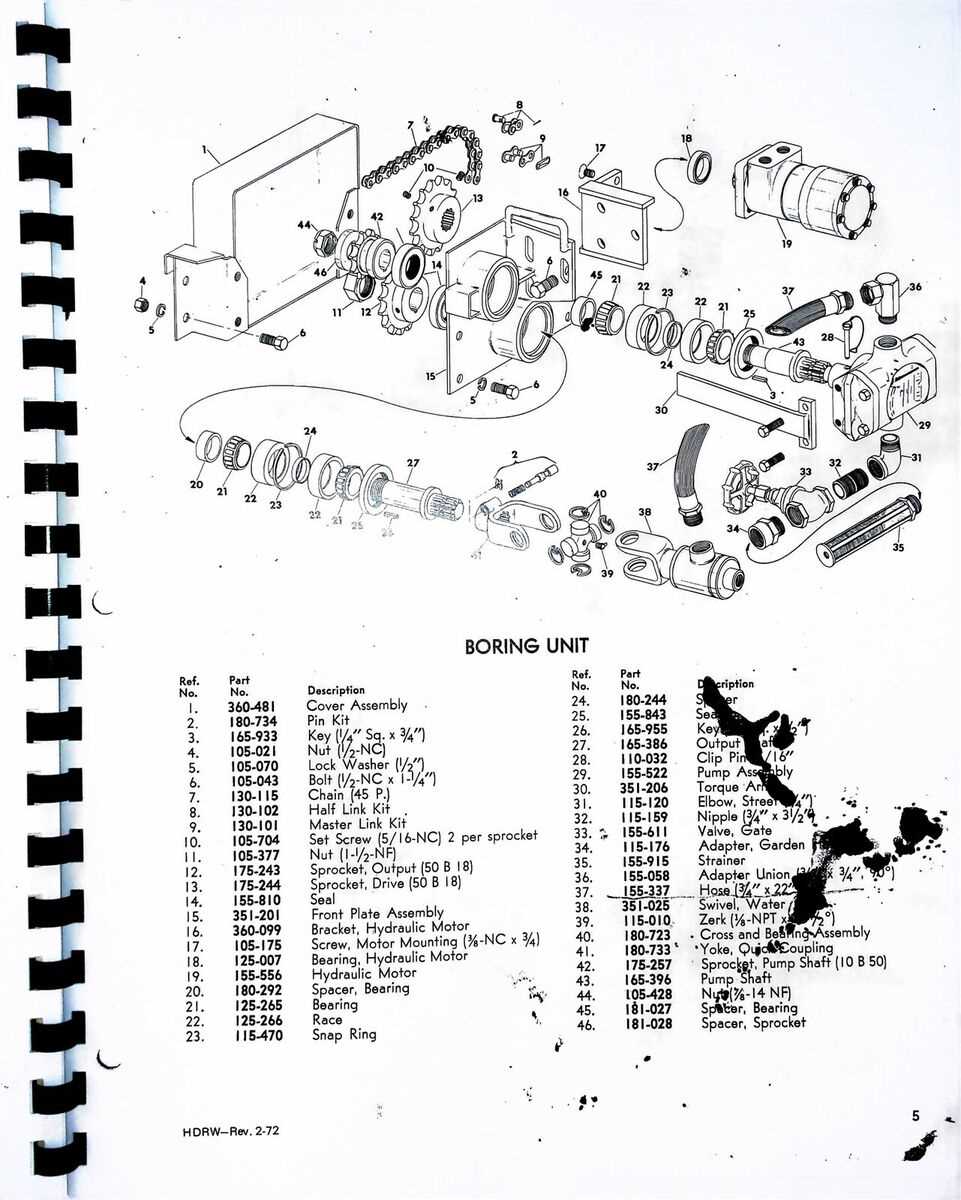

Hydraulic System Components Explained

The hydraulic system plays a crucial role in ensuring efficient operation by utilizing pressurized fluid to transfer power. Understanding the key components involved in this system is essential for maintaining optimal performance and addressing any potential issues. Below, we break down the main elements that make up a standard hydraulic mechanism.

| Component | Description | |||||||

|---|---|---|---|---|---|---|---|---|

| Pump | This device is responsible for converting mechanical energy into hydraulic energy by pressurizing the fluid, initiating the power flow. | |||||||

| Hydraulic Cylinders | These are used to convert hydraulic energy back into mechanical force, providing the necessary movement or lifting actions. | |||||||

| Valves | Valves regulate the flow and pressure within the system, controlling how and when hydraulic fluid moves through the circuit. | |||||||

| Reservoir |

| Feature | Description |

|---|---|

| Emergency Shutdown | Instantly stops all operations in case of an emergency. |

| Protective Barriers | Physical shields that prevent accidental contact with moving parts. |

| Warning Indicators | Visual alerts that signal potential hazards during operation. |