When examining the internal construction of advanced cleaning devices, it becomes crucial to have a clear view of how various elements work together. This intricate system is composed of many interconnected elements, each playing a specific role to ensure smooth and efficient operation.

In the next sections, we will delve deeper into the individual sections of the assembly. From the electrical framework to the mechanical structures, each aspect is vital for the optimal functionality of the device. Proper knowledge of the key connections within this system allows for easier troubleshooting and maintenance.

Whether you’re interested in gaining a broader understanding or focusing on specific internal elements, this guide will provide a comprehensive overview to assist you in your exploration. You’ll discover the vital mechanisms that keep the device running seamlessly.

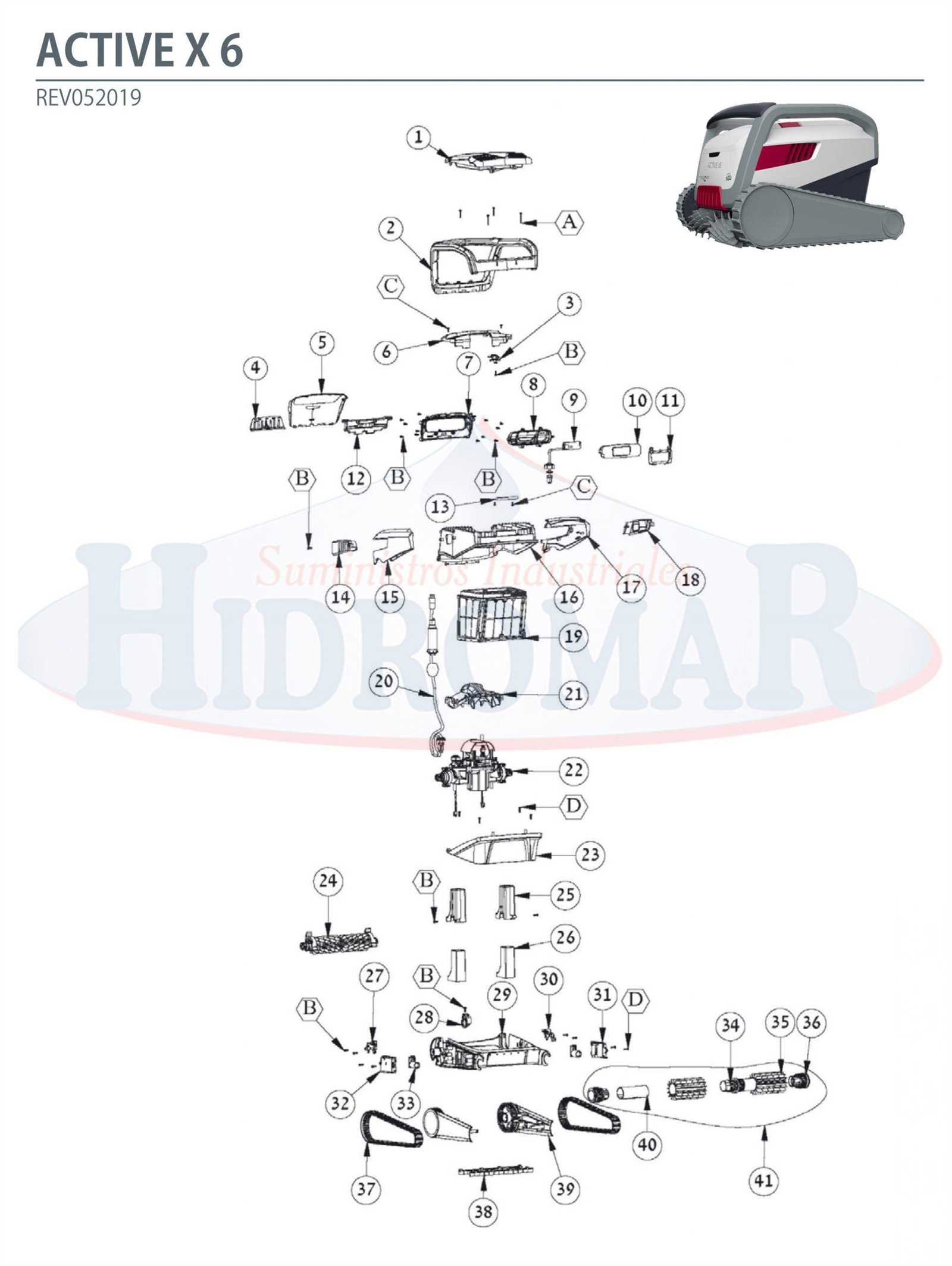

Component Breakdown

Exploring the inner workings of this advanced device reveals a collection of critical elements that collaborate to ensure smooth operation. Each individual piece plays a distinct role, contributing to the overall functionality of the system.

Key Structural Elements

At the heart of this machine is a sturdy frame that houses the primary mechanisms. This includes a propulsion unit that drives movement and a filtration system designed to maintain optimal performance. These fundamental elements work together to handle different tasks with precision.

Supporting Components

A variety of supplementary parts, such as the power unit and control board, ensure the device operates efficiently. The control board oversees essential processes, while the power unit delivers the necessary energy to keep the system running smoothly. These components guarantee reliability and effectiveness throughout each cycle.

Exploring Key Internal Elements

When examining the inner workings of any complex system, understanding its primary components is crucial. Each element plays a specific role in ensuring the overall functionality and efficiency of the unit. The harmonious interaction between these core elements allows for seamless operation and maintenance, while the structure itself guarantees long-term reliability.

Core Mechanical Components

- Motor Assembly: This element is responsible for driving the main functions, ensuring consistent performance across different conditions.

- Propulsion Unit: The propulsion unit aids in navigation, adjusting direction and speed to adapt to varying circumstances.

- Filtration System: Designed to filter debris efficiently, this part keeps the system clear and functional.

Electronic Control Elements

- Processing Unit: This acts as the brain, managing various operations and ensuring all tasks are performed in the correct sequence.

- Power Module: Distributing energy across components, it ensures each part receives the necessary power for optimal functioning.

- Connectivity Interfaces: These allow for communication with external control systems, offering adaptability and ease of control.

Understanding the Electrical System

The electrical network plays a crucial role in ensuring smooth and efficient operation of the entire mechanism. It consists of various components that interact to manage power distribution and regulate functionality. A thorough understanding of how these elements work together allows for better maintenance and troubleshooting, ensuring long-term efficiency and reliability.

Each element within the system contributes to the overall stability, and careful attention to the flow of currents is essential. Key components such as conductors, connectors, and control units need to be well-aligned to achieve seamless integration. This coordination helps in avoiding potential disruptions, ensuring that energy flows smoothly throughout the circuitry.

Main Structural Parts Overview

The core framework of the device is composed of several essential components that ensure its functionality and stability. Each element plays a crucial role in maintaining the overall structure, allowing smooth and efficient operation in various environments.

Key Components of the Framework

At the heart of the structure are several interconnected segments that form a durable and reliable body. These include the outer shell, which protects internal mechanisms, and the base, which provides support. Additionally, the operational core houses the moving elements, ensuring continuous motion.

Additional Supportive Elements

Various supplementary pieces are integrated into the design to enhance performance. The control unit, for example, manages the overall coordination, while protective seals safeguard delicate internal sections from external factors. Together, these elements create a seamless and efficient operational system.

Motor Unit and Its Functions

The motor unit plays a vital role in ensuring the efficiency and performance of any automated system. It acts as the core element responsible for driving various mechanical components, enabling movement and precision in operation. By converting electrical energy into motion, it allows seamless coordination within the system.

Key responsibilities of the motor unit include:

- Powering the main drive mechanism to control motion

- Ensuring the accurate synchronization of internal components

- Maintaining stability and operational reliability under different conditions

These functions contribute to the overall performance and longevity of the system, making the motor unit a critical element in any automated operation.

Filtration System Components

The filtration mechanism in robotic aquatic cleaners is crucial for maintaining water clarity and health. This system employs various elements that work in harmony to remove impurities, debris, and contaminants, ensuring optimal performance and longevity of the device.

Key components of the filtration system include:

- Filters: These elements capture dirt, algae, and other particles, providing clean water as it cycles through the system.

- Skimmers: Essential for gathering larger debris from the surface, skimmers prevent clogging and enhance filtration efficiency.

- Impellers: They help in circulating water through the filtration system, ensuring even distribution and effective cleaning.

- Hoses: Flexible tubes that facilitate the movement of water between the various components, maintaining smooth operation.

- Collection Baskets: Designed to hold captured debris, these containers can be easily removed and cleaned for convenience.

Understanding these components allows users to better maintain their cleaning devices and optimize performance over time.

Examining the Outer Shell Design

The outer casing of any device plays a crucial role in its overall functionality and aesthetics. This component not only provides structural integrity but also influences the user experience through its ergonomic design and visual appeal. Understanding the nuances of this protective layer is essential for both manufacturers and users alike.

In many instances, the shell is crafted from durable materials that withstand wear and tear, ensuring longevity. Moreover, the design may incorporate features that facilitate ease of use, such as textured surfaces for better grip. This thoughtful consideration enhances the interaction between the user and the device, promoting efficiency in operation.

Furthermore, the outer structure often houses various internal mechanisms, making it imperative for the design to balance both functionality and aesthetics. A well-engineered outer shell not only protects vital components but also contributes to the overall branding of the product. By prioritizing both form and function, manufacturers can create a compelling and effective design that meets user needs.

Control Unit Connections

The connections associated with the control module are crucial for ensuring seamless communication and functionality within the system. Understanding how these connections work can enhance troubleshooting and maintenance efforts, leading to improved performance and reliability of the overall apparatus.

Overview of Connectivity

At the core of the system lies a network of interfaces that facilitate the transfer of signals between various components. Each connection plays a vital role, as it determines how efficiently data is relayed, impacting the operational effectiveness of the entire setup. By mapping out these connections, technicians can identify potential issues and optimize functionality.

Importance of Proper Wiring

Proper wiring practices are essential in maintaining the integrity of the connections. Faulty connections can lead to malfunctions, reduced efficiency, and even damage to the components involved. It is imperative to follow the recommended specifications and guidelines when establishing these links to ensure long-lasting performance.

Wheels and Mobility Mechanism

The efficient movement of equipment relies heavily on its wheel system and mobility components. These elements work together to facilitate smooth navigation across various terrains, ensuring both stability and ease of use. A well-designed mechanism not only enhances functionality but also contributes to the overall user experience.

Understanding Wheel Design

The wheel configuration is crucial in determining the performance of mobility devices. Different designs can offer unique advantages, such as improved traction or maneuverability. Materials used in wheel construction also play a significant role in durability and responsiveness, impacting how the device interacts with its environment.

Mobility Mechanism Insights

In addition to wheels, the mobility mechanism encompasses various components that facilitate movement. These include axles, bearings, and drive systems, all of which must be engineered to work in harmony. Effective integration of these parts can significantly enhance the device’s ability to traverse obstacles and provide a comfortable ride.

Detailed View of the Pump Assembly

The pump assembly plays a crucial role in the overall functionality of the cleaning device, serving as the heart that circulates water efficiently. This intricate system comprises various components that work in harmony to ensure optimal performance and reliability.

Key Components

Among the essential elements are the motor, which powers the pump, and the impeller, responsible for generating flow. Additionally, the casing protects these internal parts while directing the movement of water. Each component must be precisely engineered to function seamlessly within the assembly.

Assembly Overview

Proper assembly and alignment of these components are vital for preventing leaks and ensuring durability. Regular maintenance and inspections can enhance the longevity of the pump assembly, reducing the likelihood of malfunctions and improving the overall effectiveness of the cleaning apparatus.

Power Supply and Cable Connections

The effective functioning of aquatic devices heavily relies on their power source and the integrity of their wiring. A thorough understanding of the electrical provisions and cable setups ensures seamless operation and longevity of the equipment. Proper connections are essential to prevent malfunctions and to maintain optimal performance in various conditions.

To facilitate efficient operation, the following table outlines the critical components associated with the electrical supply and connections:

| Component | Description |

|---|---|

| Power Adapter | Transforms AC voltage to the required DC voltage for operation. |

| Cable Connectors | Ensure secure and reliable connections between different components. |

| Fuse | Provides protection against overcurrent by breaking the circuit if necessary. |

| Battery | Stores energy to power the device when not connected to an external supply. |

| Ground Connection | Ensures safety by preventing electrical shock and maintaining stability. |