In the realm of diesel powertrains, grasping the intricate layout of individual elements is crucial for effective maintenance and repairs. This overview will explore the essential components that ensure optimal performance, offering a clear view of how each part contributes to the engine’s overall functionality.

Every engine is a complex system where various elements work in harmony. From the fuel delivery mechanisms to the cooling systems, each piece plays a pivotal role in driving efficiency and power. By delving into the arrangement and interaction of these crucial components, one can gain valuable insights into the mechanics behind robust engine performance.

Whether you are a seasoned mechanic or an enthusiast looking to enhance your knowledge, understanding the structure of these vital pieces is indispensable. This exploration will not only illuminate the roles of each component but also provide practical guidance for those aiming to troubleshoot or upgrade their diesel machinery.

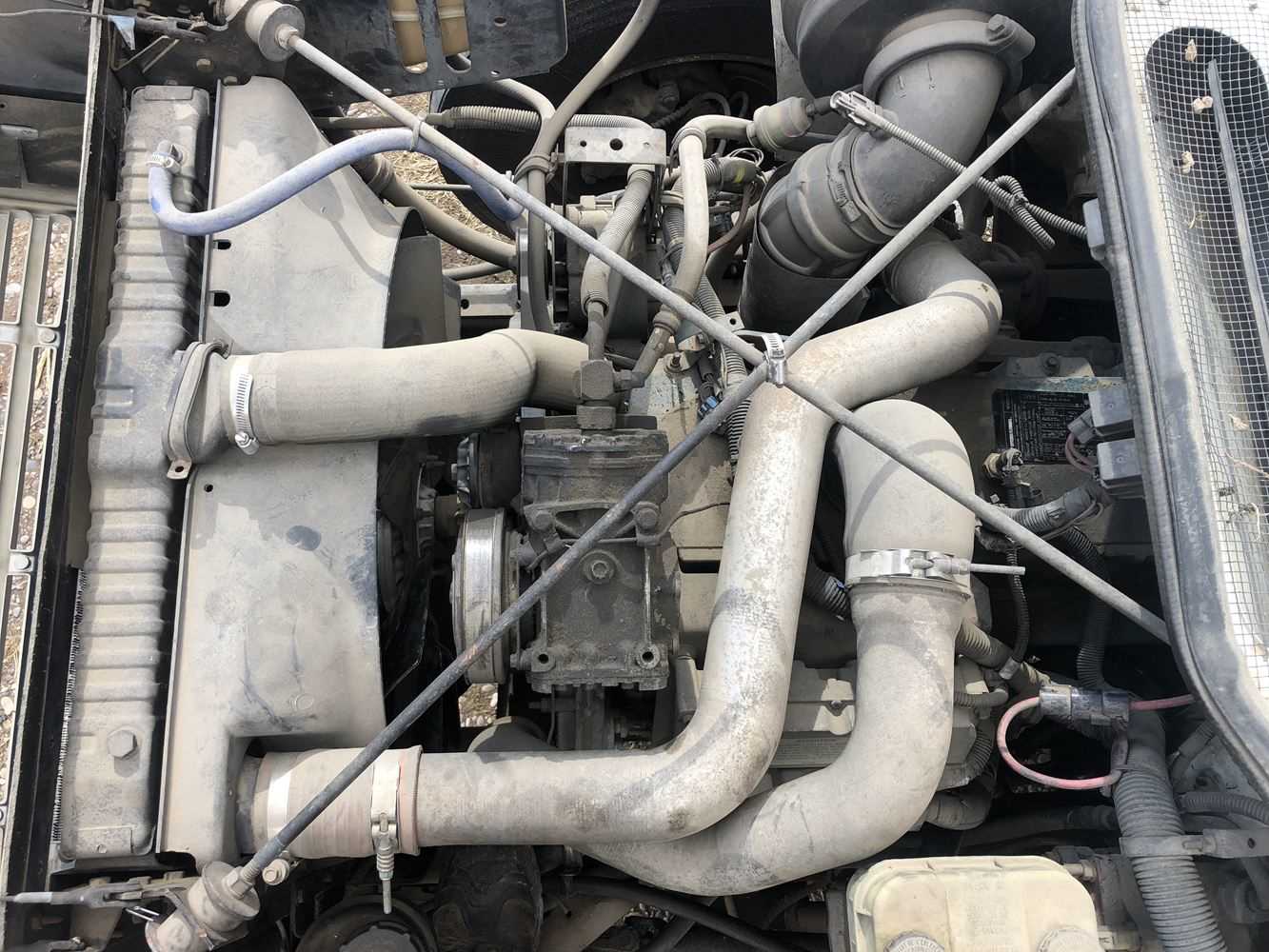

Overview of DT466E Engine Components

The DT466E engine is a robust and versatile power unit known for its reliability and efficiency. Understanding its various elements is essential for maintaining optimal performance and ensuring longevity. Each component plays a crucial role in the engine’s functionality, working together to convert fuel into mechanical energy.

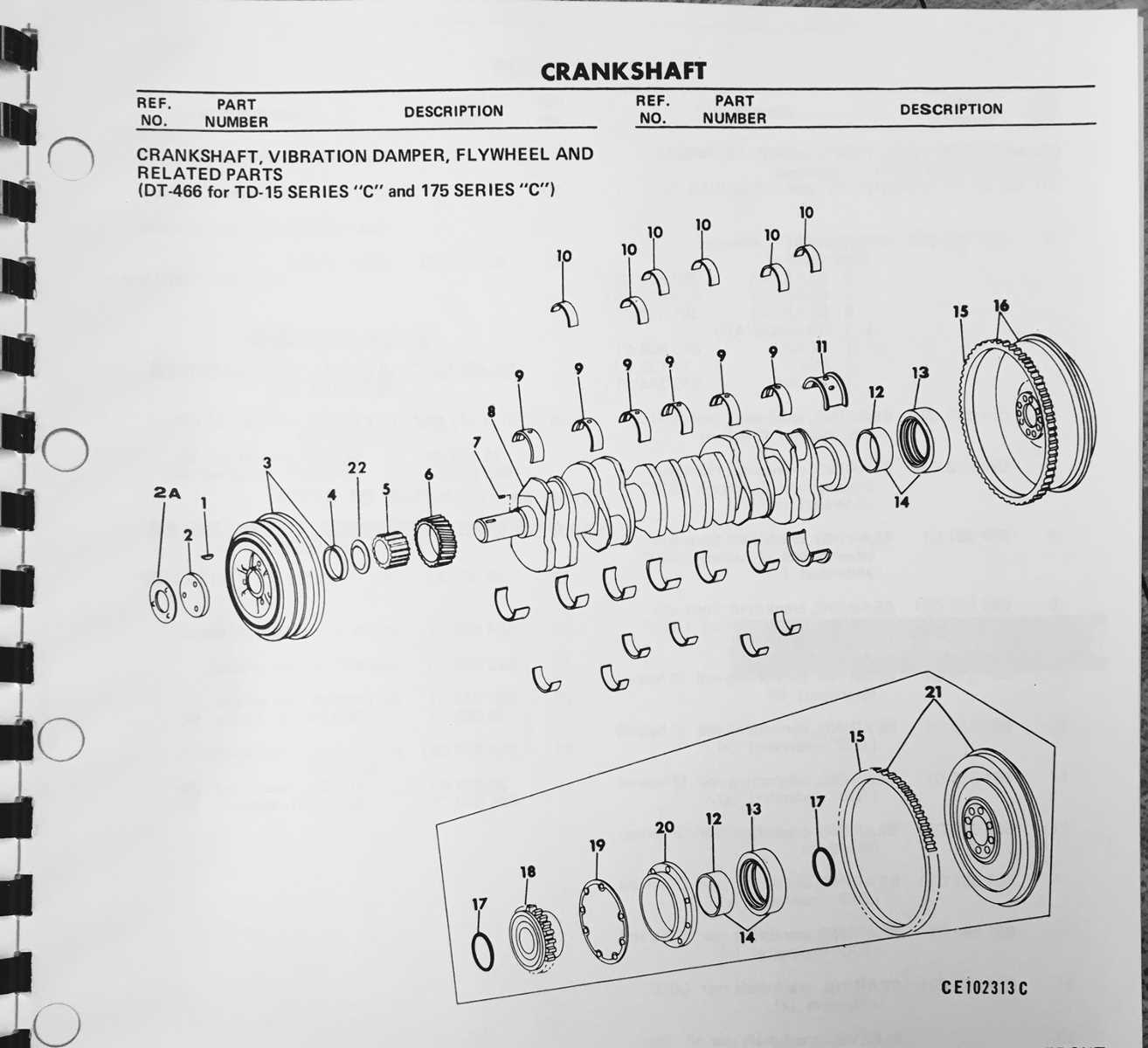

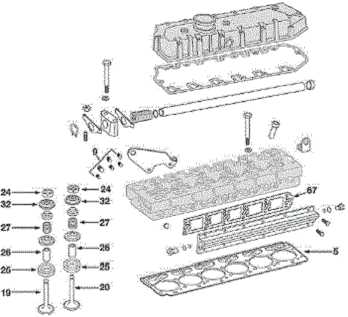

Core Elements: At the heart of this engine lies the block, which houses critical moving parts. The cylinder head, responsible for the intake and exhaust processes, is crucial for efficient combustion. Additionally, the crankshaft and connecting rods facilitate the transfer of energy generated during operation.

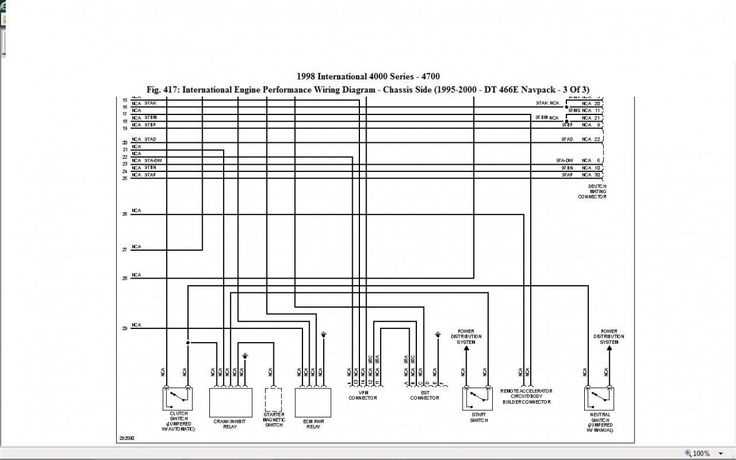

Supporting Components: Auxiliary systems, such as the cooling and lubrication systems, are vital for maintaining safe operating temperatures and minimizing wear. The fuel delivery system ensures the right amount of fuel reaches the combustion chamber, while the electrical system powers essential components, including the starter and ignition system.

Conclusion: A comprehensive understanding of the various elements of this engine enhances maintenance practices and can lead to improved performance. By recognizing the interconnectedness of each part, operators can better address issues and ensure the engine runs smoothly for years to come.

Key Features of the DT466E

The robust engine model is renowned for its reliability and performance, making it a favored choice among various applications. Its design focuses on delivering exceptional power while ensuring efficiency, catering to both heavy-duty and everyday tasks.

Durability is a standout characteristic, with a construction that withstands harsh conditions, extending the lifespan of the engine. This reliability is complemented by a modular design, allowing for straightforward maintenance and repairs, minimizing downtime.

Additionally, the engine boasts an impressive torque output, enhancing its ability to handle demanding loads effortlessly. Coupled with advanced fuel injection technology, it optimizes fuel consumption, striking a balance between performance and economy.

Furthermore, the integration of innovative cooling systems aids in maintaining optimal operating temperatures, ensuring efficient performance under various conditions. These features collectively make this engine a versatile option for many users.

Common Parts and Their Functions

This section delves into various components commonly found in a specific engine type, highlighting their essential roles and contributions to overall functionality. Understanding these elements helps in grasping how the entire system operates effectively, ensuring reliability and performance.

Engine Block

The engine block serves as the core structure where combustion takes place. It houses the cylinders and supports critical components like pistons and crankshafts. Its robust design is crucial for withstanding high pressures and temperatures, contributing to the overall durability of the engine.

Fuel Injector

The fuel injector is responsible for delivering precise amounts of fuel into the combustion chamber. By atomizing the fuel, it ensures optimal mixing with air, leading to efficient combustion. This component plays a vital role in performance, fuel efficiency, and emissions control.

Understanding the Engine Assembly Layout

The configuration of an engine assembly plays a crucial role in its overall performance and efficiency. Each component is meticulously designed to work in harmony, ensuring optimal functionality. Grasping this arrangement allows for better comprehension of how various parts contribute to the engine’s operation.

Key elements of the assembly include the following:

| Component | Description |

|---|---|

| Cylinder Block | The main structure housing the cylinders and providing strength. |

| Pistons | Movable components within the cylinders, converting fuel energy into mechanical motion. |

| Crankshaft | Transforms linear motion from the pistons into rotational force to drive the vehicle. |

| Camshaft | Controls the timing of valve openings and closings for efficient air and fuel intake. |

| Oil Pan | Stores lubricating oil, vital for reducing friction among moving parts. |

Understanding the layout of these components not only aids in maintenance and repair but also enhances the overall appreciation of engine mechanics.

Maintenance Tips for DT466E Components

Regular upkeep of mechanical systems is essential for ensuring long-term functionality and preventing unexpected breakdowns. Proper care helps extend the lifespan of critical elements and optimizes the performance of the overall system.

Regular Inspections

One of the most important steps in maintaining these systems is conducting frequent inspections. Check for signs of wear, loose connections, and any unusual noises. Early detection of potential issues can prevent more serious

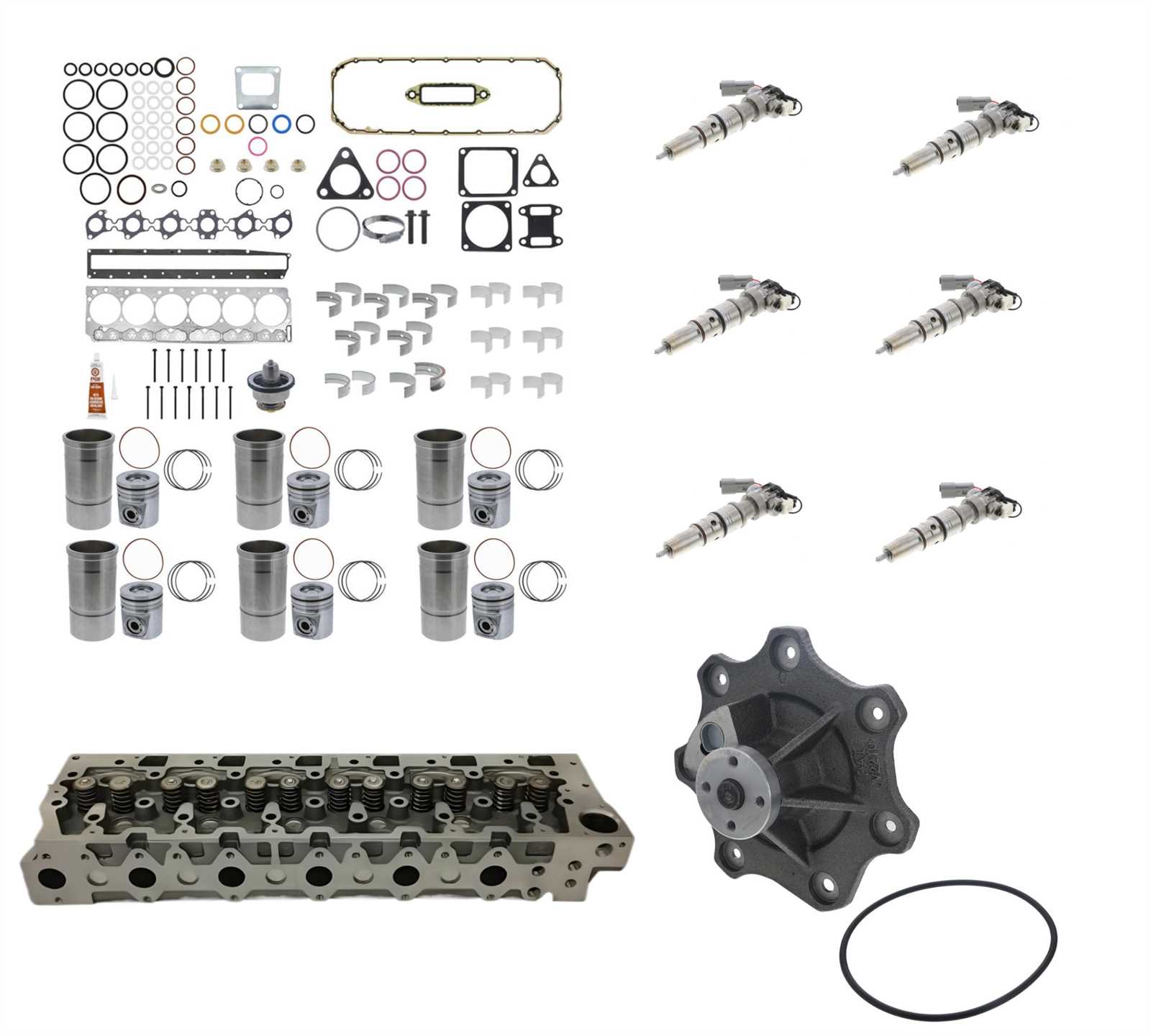

Identifying Essential Replacement Components

Maintaining any mechanical system involves recognizing the key elements that may wear out over time. Understanding which components are critical for smooth operation ensures timely replacements and helps avoid unexpected breakdowns.

Key Mechanical Elements

Several fundamental elements play a vital role in the overall functioning. These include items responsible for power delivery, cooling, and system control. Ensuring these are in good condition is crucial for maintaining reliability.

Replacement Strategies

When it comes to identifying what needs to be replaced, regular inspection is key. It’s important to monitor for signs of wear, such as reduced performance or unusual noises, which may indicate that specific components need to be changed.

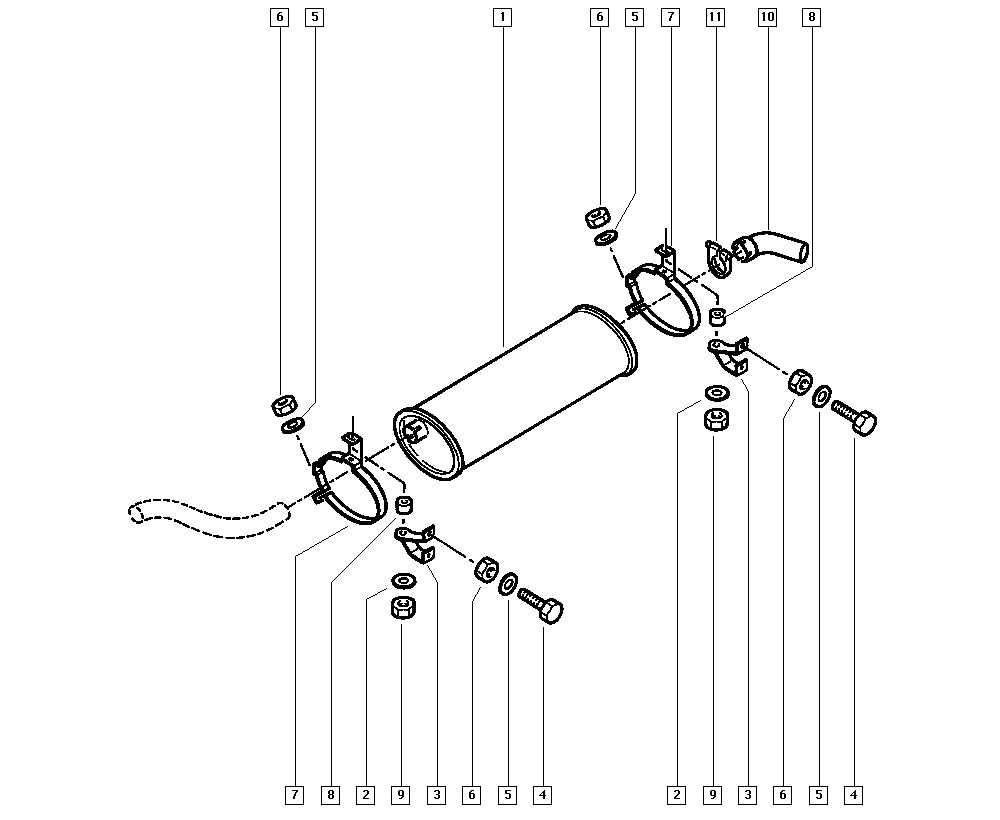

Assembly and Disassembly Guidelines

When working on the reassembly and disassembly of mechanical systems, it’s crucial to follow proper steps to ensure both safety and efficiency. These procedures prevent unnecessary damage and ensure that all components function correctly once reassembled.

- Begin by identifying all necessary tools and making sure they are in good working condition.

- Follow a logical order when removing parts, starting from the outer layers and moving inward, taking care to note the positioning of each component.

- Keep all fasteners organized, preferably labeled, to avoid confusion during reassembly.

- Inspect each element for wear or damage during disassembly and replace any defective pieces before putting everything back together.

- During reassembly, follow the reverse order of disassembly, ensuring that all parts are aligned correctly and fastened to the manufacturer’s specified torque settings.

- Perform a final check after reassembly to ensure smooth operation and functionality of the system.

By carefully following these steps, the

Upgrades for Enhanced Performance

When looking to improve the overall efficiency and power output of an engine, several strategic modifications can be implemented. These improvements focus on optimizing key systems, leading to better durability, fuel economy, and response under heavy loads.

Turbocharger optimization is one of the primary enhancements that can dramatically improve airflow, resulting in better engine performance and power delivery. Upgrading the turbo system can also reduce lag, providing quicker acceleration and higher torque.

Another crucial area of improvement is the fuel delivery system. By refining injectors and upgrading pumps, the fuel mix is more efficiently handled, ensuring a cleaner burn and increased power potential. This modification not only enhances performance but can also contribute to lower emissions.

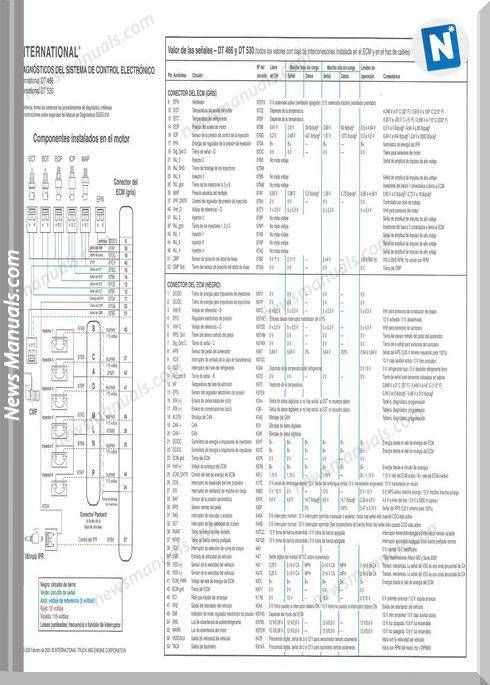

Lastly, advanced ECU tuning allows for better control over engine parameters. Fine-tuning the electronic control unit can optimize power output while ensuring

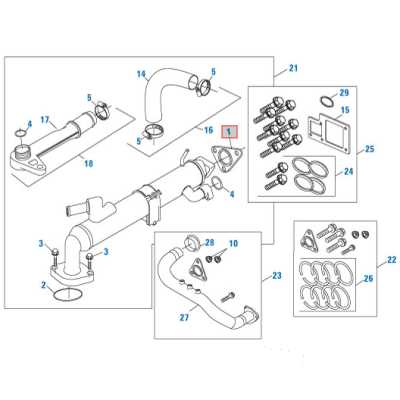

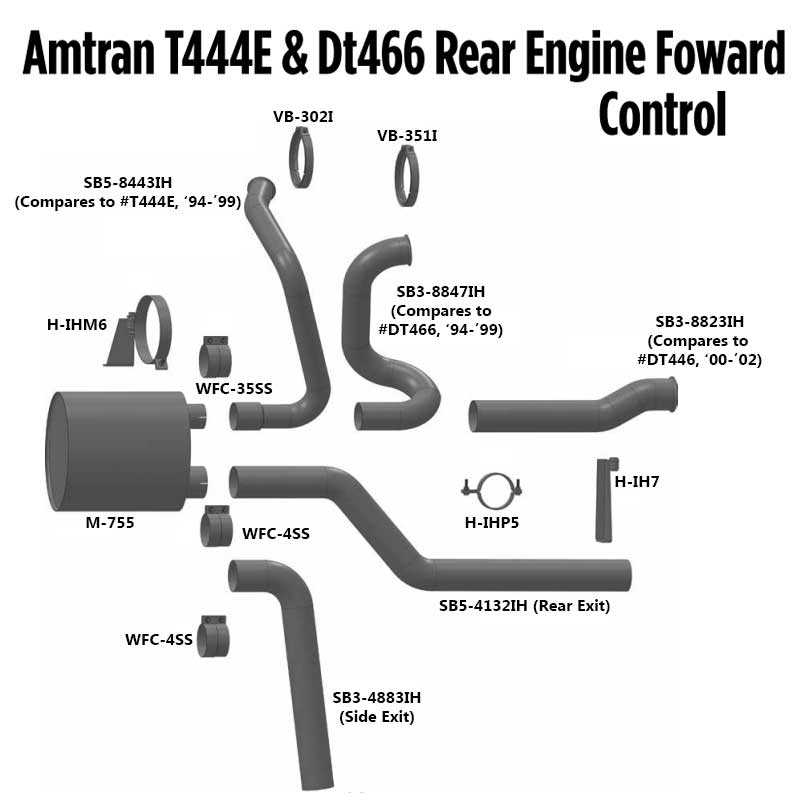

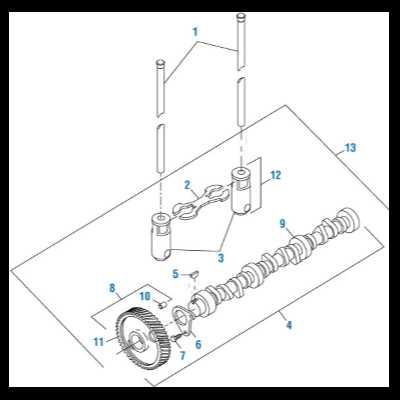

Visual Reference: Parts Diagram Breakdown

This section provides a clear overview of the internal components of the system, helping to understand how each element is interconnected within the overall structure. By examining this breakdown, users can easily identify the location and function of various key elements without needing extensive technical knowledge.

Main Structural Components

Each segment of the assembly is meticulously placed to perform specific roles, ensuring seamless operation. The larger elements typically support the core functions, while smaller ones manage auxiliary tasks, contributing to the overall efficiency and stability of the system.

Key Interaction Points

Understanding how different sections interact is crucial for effective maintenance. The reference highlights areas where components meet, emphasizing potential wear points and connections that require attention during servicing. This visual approach simplifies troubleshooting and ensures a better grasp of

Troubleshooting Common Engine Issues

Identifying and resolving engine problems can significantly enhance performance and extend the lifespan of your equipment. Common issues arise from various components, and understanding their root causes can help minimize downtime and costly repairs.

Unusual Noises and Vibrations

Strange sounds or excessive vibrations often signal underlying mechanical faults. These symptoms could stem from improper alignment, worn-out components, or lack of lubrication. Regular inspections and maintenance can help catch these issues early before they lead to more severe damage.

Overheating Problems

Engines that overheat frequently may be experiencing cooling system malfunctions. Common causes include blocked radiators, low coolant levels, or malfunctioning thermostats. Addressing these problems promptly helps prevent more extensive damage to the engine.

Resources for Parts Procurement

When maintaining or repairing machinery, finding reliable sources for necessary components is critical. Sourcing high-quality materials ensures long-term durability and functionality. Multiple platforms provide access to various mechanical items, making the acquisition process efficient and straightforward.

Online Retailers and Marketplaces

Many digital platforms offer a vast selection of industrial components. These platforms allow easy browsing, comparison, and purchasing. Some websites even provide customer reviews, helping users evaluate the credibility of the vendor and the product’s reliability.

Specialized Suppliers

Specialized stores cater specifically to mechanical maintenance, often offering a range of original and compatible components. Establishing relationships with these suppliers can result in better pricing, more comprehensive support, and access to hard-to-find materials.