Specifically de

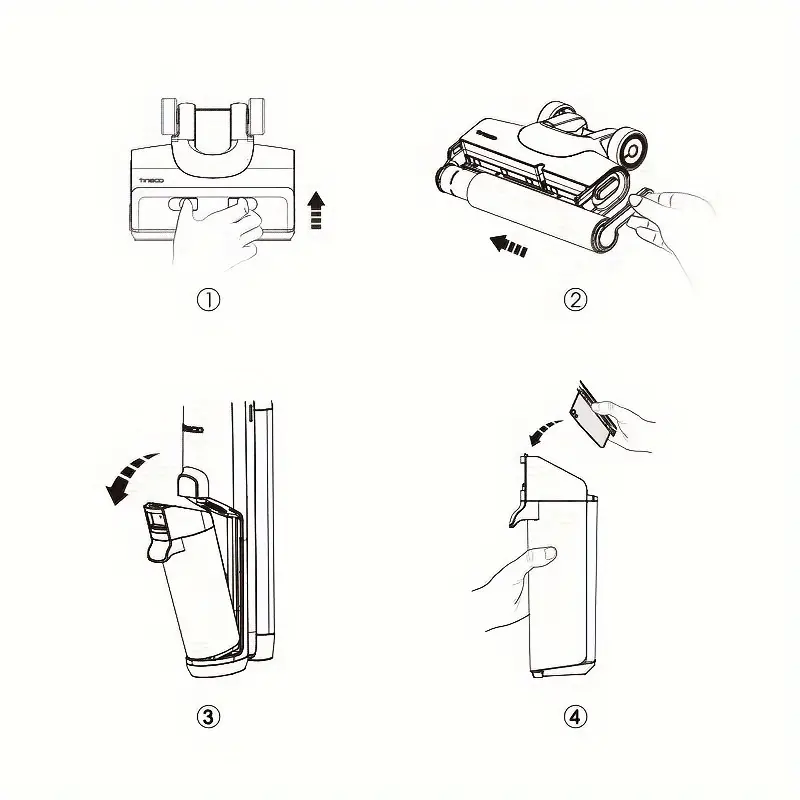

Battery Assembly and Power Supply

The power system is a crucial component that ensures the effective functioning of the entire device. A well-assembled and maintained energy unit allows for extended use and consistent performance. Proper understanding of how the charging mechanism operates helps in achieving the best results from the equipment.

During the assembly process, ensuring the secure connection between the battery module and the main body is vital for optimal energy transfer. Misalignment or improper attachment can lead to reduced operational time or even sudden shutdowns. Regular checks of the charging port and contacts will prevent issues related to poor power supply.

Additionally, the charging cycle plays a significant role in the longevity of the power source. It is recommended to fully charge the device after every use and avoid partial recharges to maintain the battery’s health over time.

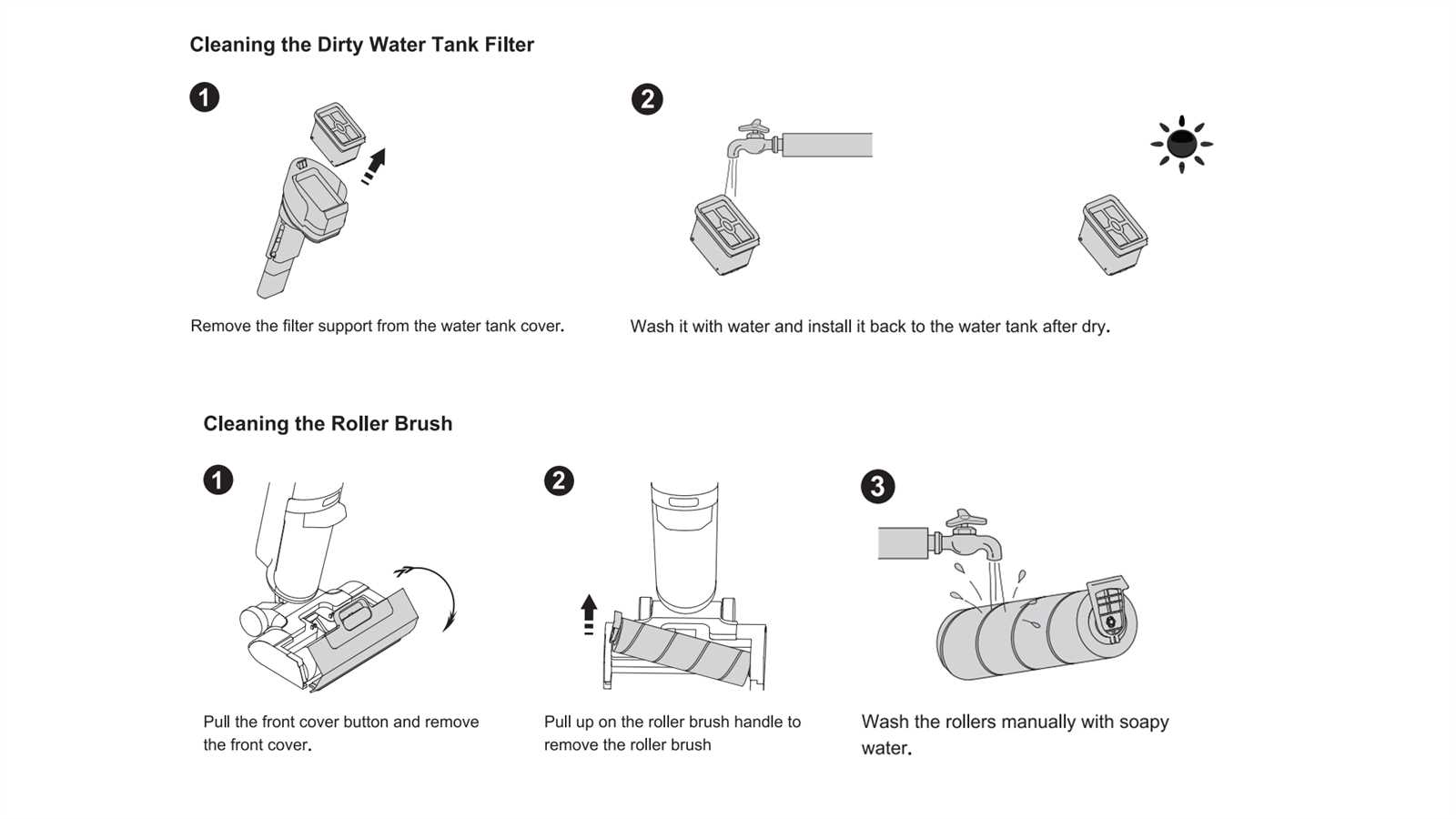

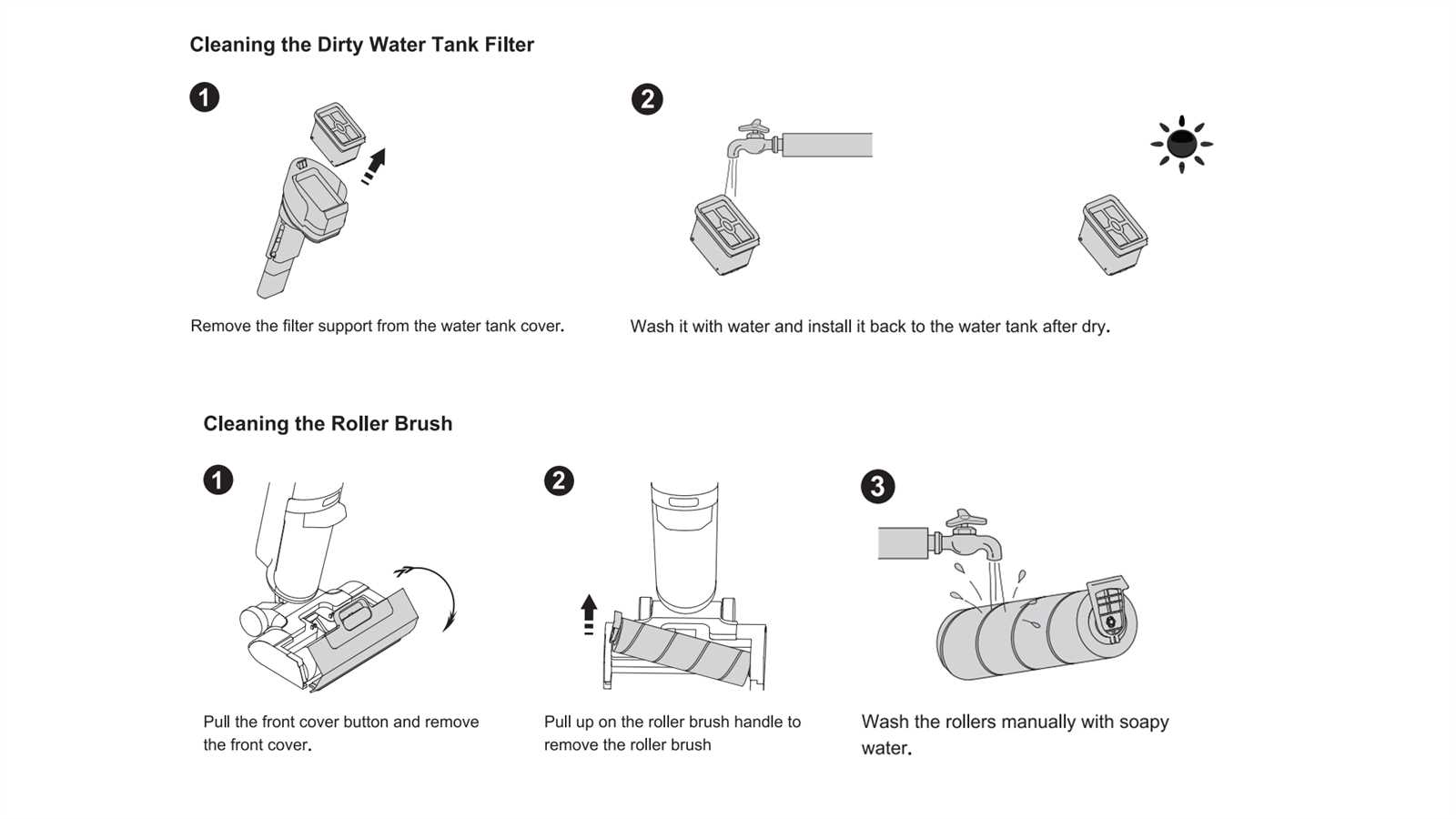

Filters: Placement and Maintenance

Proper filter positioning and care are essential for maintaining optimal performance and longevity of your vacuum. Ensuring the correct placement of the filtration units and following regular maintenance routines will help in keeping the device functioning effectively over time.

Filters play a crucial role in trapping dust and debris, which can impact the suction and efficiency of the vacuum. Regular cleaning and periodic replacement are necessary to avoid buildup that could hinder air circulation.

| Filter Type |

Placement |

Maintenance Frequency |

| Pre-motor filter |

Near the motor unit |

Rinse every 1-3 months |

| Post-motor filter |

Behind the motor assembly |

Replace annually |

To maintain

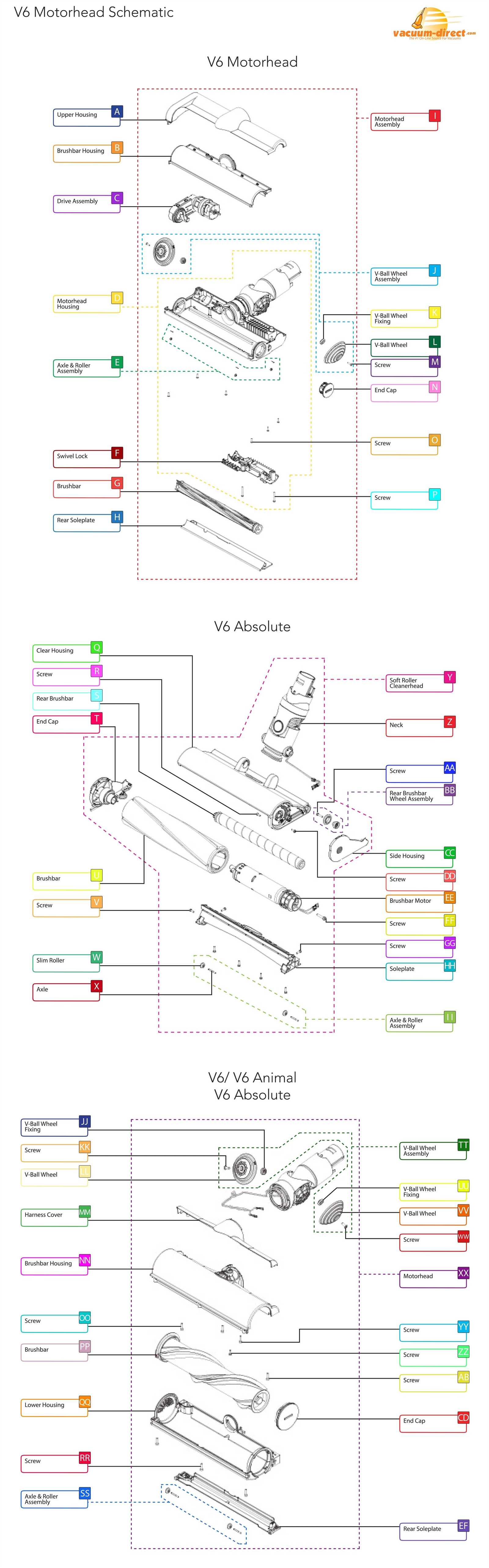

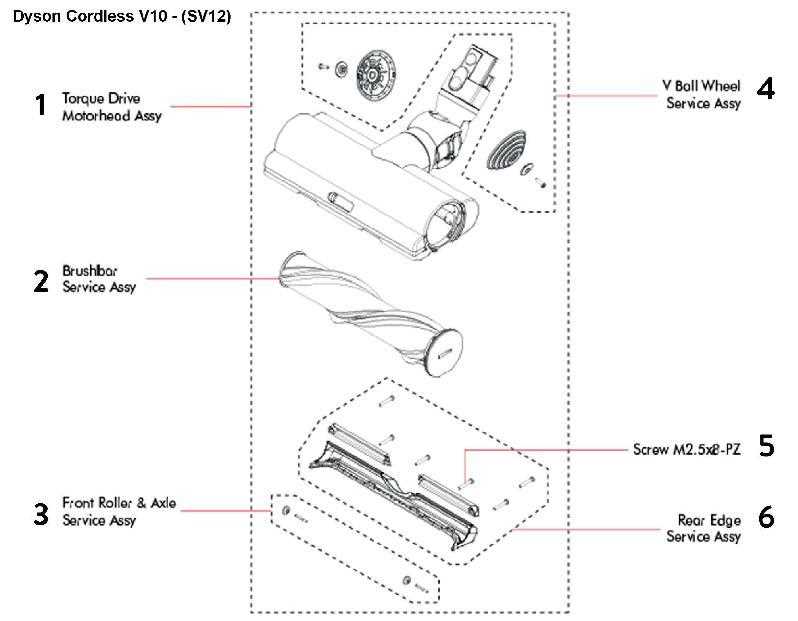

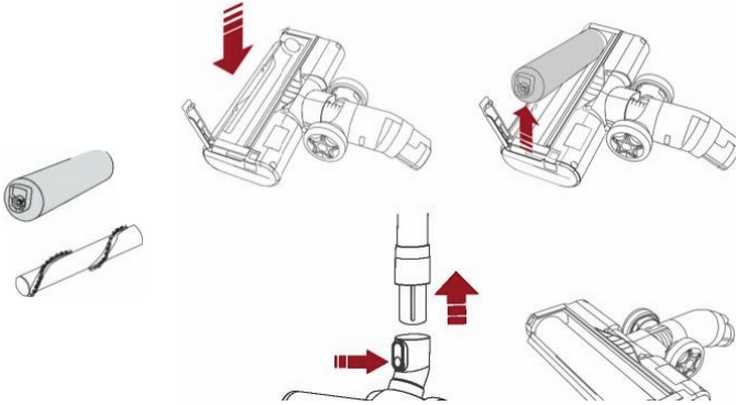

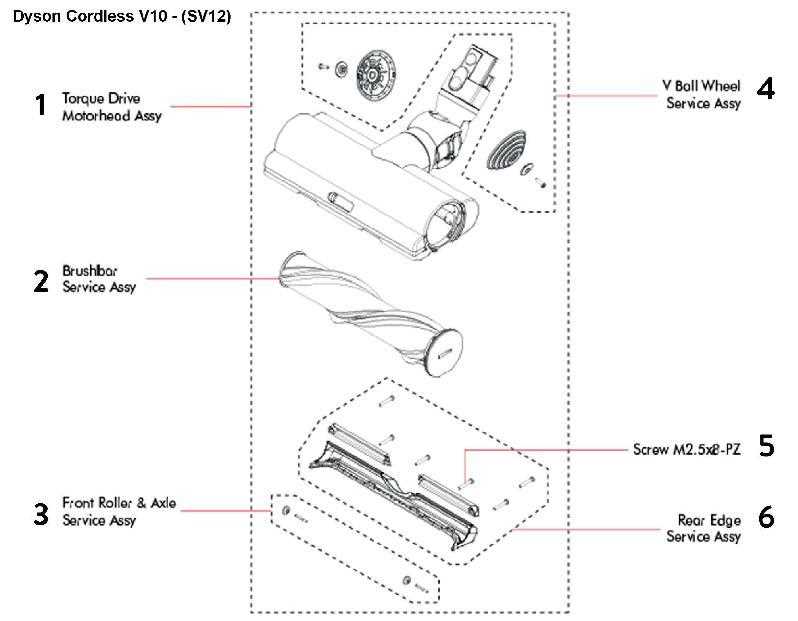

Motorized Head Construction

The motorized head of a vacuum cleaner is a crucial component that enhances its cleaning capabilities. This assembly is designed to provide efficient and powerful suction, allowing for thorough removal of dirt and debris from various surfaces. Its construction typically incorporates advanced technology to optimize performance and ensure durability.

At the core of this unit is a high-speed motor that drives the brush bar, enabling it to agitate carpets and lift away stubborn particles. The brush bar is strategically designed with bristles that penetrate deep into fibers, enhancing cleaning efficiency. Additionally, the housing of the motorized head is constructed from robust materials that withstand wear and tear while maintaining a lightweight profile for ease of use.

The assembly often features a flexible neck that allows for better maneuverability around furniture and into tight spaces. Integrated sensors may also be present to automatically adjust the brush height based on the surface type, ensuring optimal performance on both carpets and hard floors. Overall, the motorized head is engineered to deliver superior cleaning results while providing a seamless user experience.

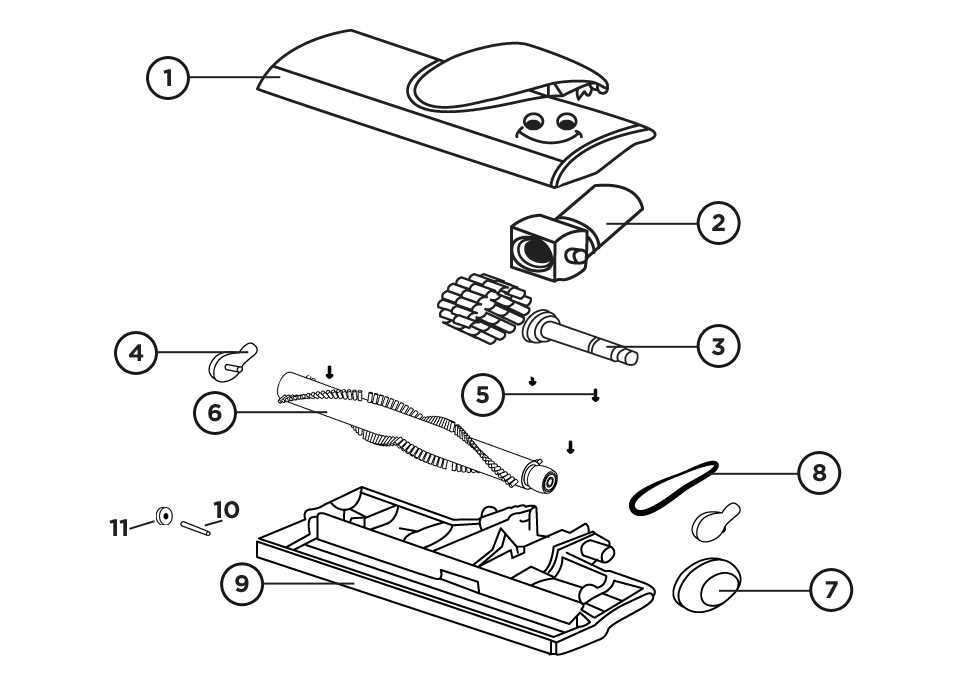

Canister Design and Capacity

The construction and size of the collection unit play a vital role in the efficiency and usability of a vacuum system. This section explores the various aspects of the container’s design and its ability to hold debris, which are crucial for maintaining optimal performance during cleaning tasks.

The design typically incorporates a streamlined shape that allows for easy handling and maneuverability. Additionally, the materials used contribute to the overall durability, ensuring that the unit can withstand regular use without wear or damage. A well-thought-out container design also facilitates easy emptying, minimizing mess and maintaining hygiene.

| Feature |

Description |

| Material |

High-strength plastics or composites that resist wear and tear. |

| Capacity |

Ample space to accommodate various types of debris while minimizing the frequency of emptying. |

| Shape |

Ergonomic design that enhances grip and control during operation. |

| Filtration |

Integrated systems that prevent dust from escaping, ensuring a cleaner environment. |

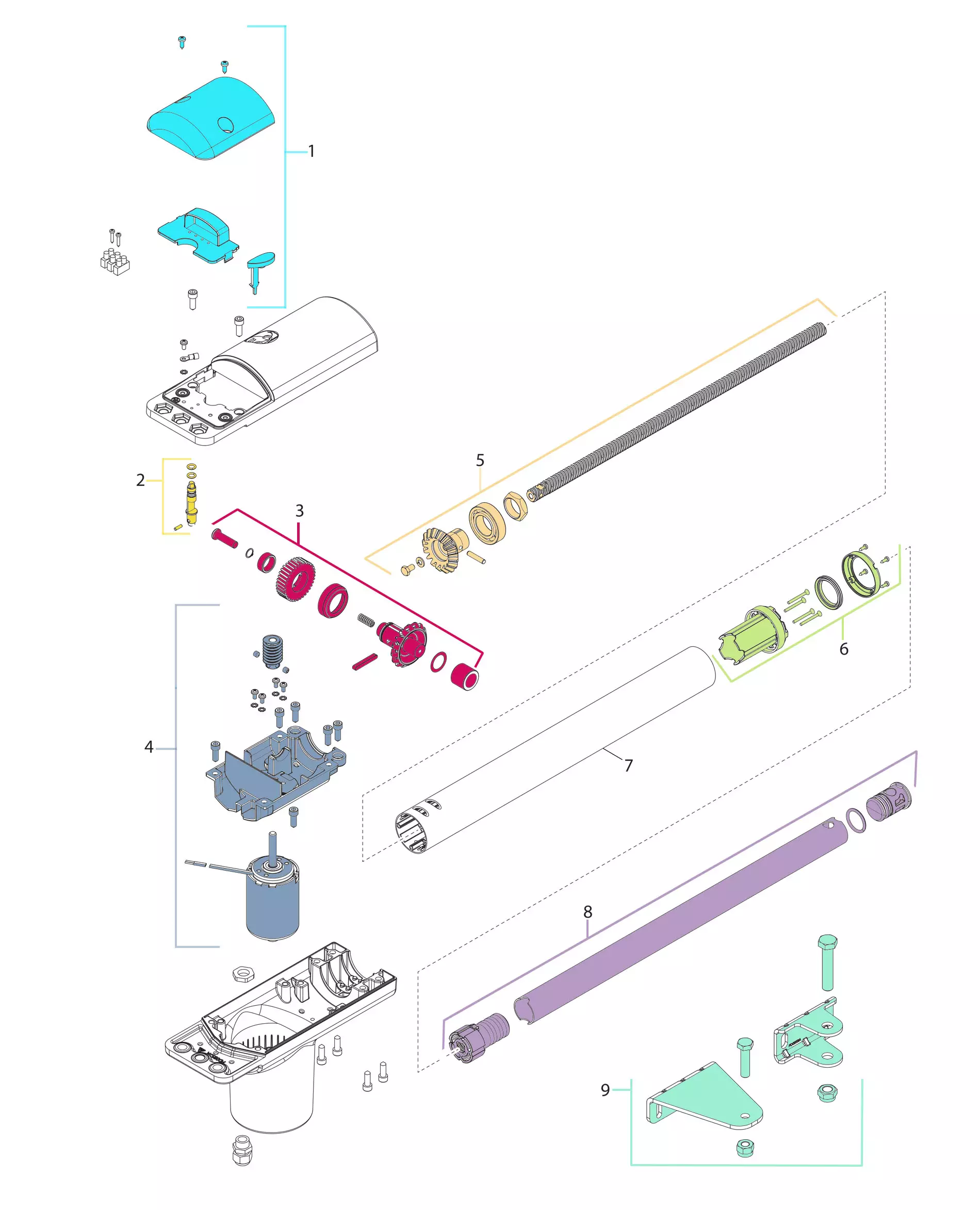

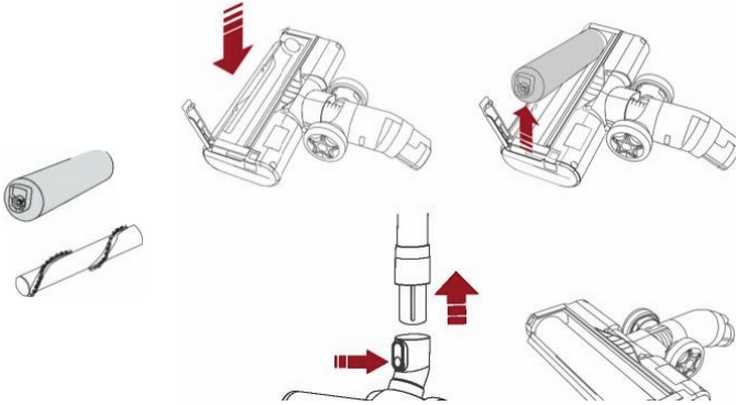

Connection Points and Attachments

This section focuses on the various junctions and fittings found within a vacuum cleaner model. Understanding these elements is essential for efficient assembly and maintenance, ensuring that each component functions optimally.

Typically, the main connection points include:

- Power supply entry

- Brush head attachment

- Dust bin lock mechanism

- Extension wand connection

Each of these points serves a specific purpose and is designed for ease of use:

- Power supply entry: This is where the charger plugs in to recharge the unit.

- Brush head attachment: This point allows users to swap out different cleaning heads based on the surface being cleaned.

- Dust bin lock mechanism: Ensures the dust container is securely fastened while in use, preventing accidental detachment.

- Extension wand connection: Facilitates the addition of longer attachments for reaching high or tight spaces.

Each connection point plays a crucial role in the overall performance and versatility of the cleaning device, making them integral to the user’s experience.

Wand Structure and Usage

The wand serves as an essential component in the functionality of various cleaning devices, allowing users to navigate and access hard-to-reach areas with ease. Its design often emphasizes a lightweight yet durable construction, facilitating optimal maneuverability during cleaning tasks.

Design Features

Typically, the wand incorporates an ergonomic handle that enhances user comfort while minimizing fatigue during extended use. Additionally, the telescoping feature enables adjustments to various lengths, accommodating different cleaning scenarios and preferences.

Operational Benefits

Utilizing the wand effectively can significantly improve cleaning efficiency. With its reach, users can tackle elevated surfaces, corners, and crevices that may be difficult to clean with standard attachments. This versatility ensures a thorough clean, making it a valuable tool in maintaining a pristine environment.

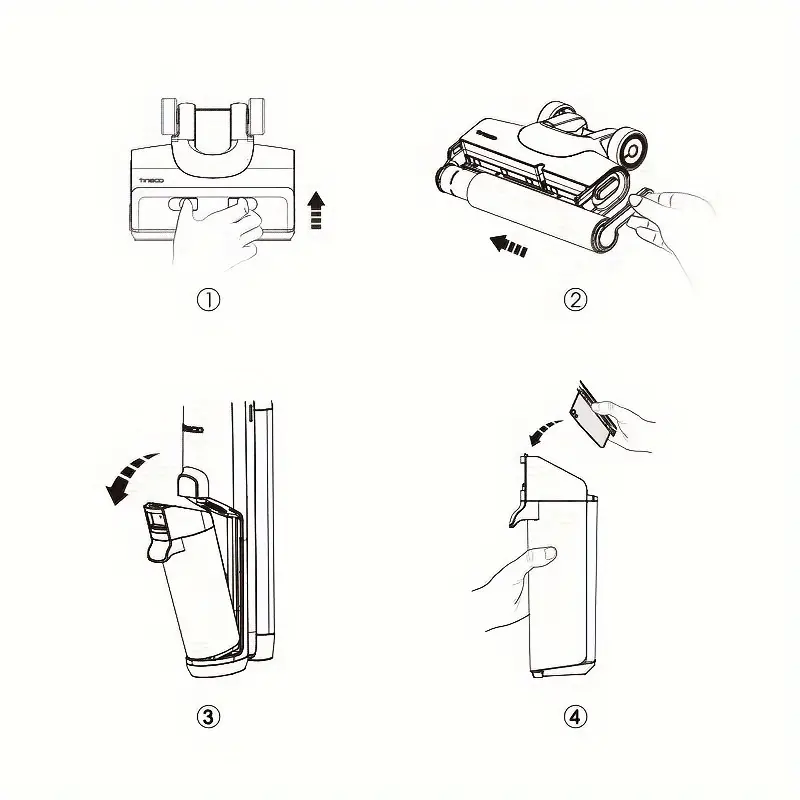

Charging Dock and Accessories

This section provides an overview of the charging station and supplementary components designed for optimal functionality and convenience. Understanding these elements is essential for maintaining the performance of your device and ensuring it operates efficiently when needed.

Charging Station Features

The charging station serves as the primary hub for re-energizing the device. It is designed for easy access, allowing the unit to be securely placed for charging when not in use. Key features include:

| Feature |

Description |

| Compact Design |

Space-saving and suitable for various environments. |

| Indicator Light |

Displays charging status to inform users when the device is fully charged. |

| Non-slip Base |

Ensures stability and prevents movement during charging. |

Additional Components

In addition to the charging station, various accessories enhance the functionality and versatility of the device. These components include:

| Accessory |

Purpose |

| Wall Mount |

Facilitates storage and accessibility, keeping the unit off the floor. |

| Extension Wand |

Extends reach for cleaning high or hard-to-reach areas. |

| Brush Attachments |

Designed for specific surfaces, enhancing cleaning efficiency. |

Understanding the Cyclone System

The cyclone mechanism is an innovative feature designed to enhance suction performance and improve dirt separation in cleaning devices. By utilizing a combination of centrifugal force and airflow, this system efficiently captures particles, preventing them from clogging filters and maintaining optimal functionality.

How the Cyclone Mechanism Works

This advanced design operates by creating a whirlwind effect within the collection chamber. As air enters the chamber, it spirals around the interior walls, forcing larger debris to the outer edges while finer particles are drawn towards the center. This separation allows for effective dirt removal and reduces the frequency of filter maintenance.

Benefits of Cyclonic Technology

The benefits of using this technology are significant. By minimizing filter blockage, users can experience sustained suction power over longer periods. Additionally, the need for regular filter replacements is reduced, leading to lower maintenance costs and an overall more efficient cleaning experience.

| Feature |

Advantage |

| Efficient Dirt Separation |

Improved suction power and performance |

| Minimized Clogging |

Longer operational time without loss of suction |

| Reduced Filter Maintenance |

Lower costs and less frequent replacements |

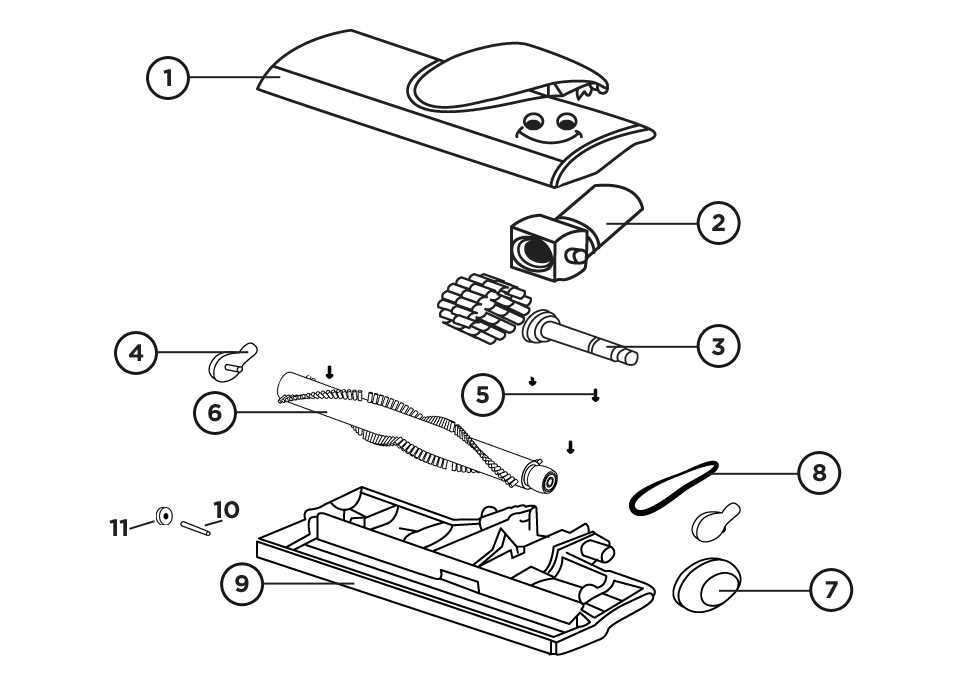

Common Replacement Parts Guide

This section provides insights into essential components that may require periodic replacement for optimal performance. Understanding these key elements can help maintain functionality and extend the lifespan of your cleaning device.

Essential Components

Among the most crucial elements are filters, which play a vital role in trapping dust and allergens, ensuring cleaner air. Regularly changing these components is essential for maintaining efficiency and preventing clogging. Additionally, batteries are significant for the overall performance, and replacing them when they show signs of wear can restore the device’s power and longevity.

Other Important Elements

Brush rolls are also noteworthy, as they directly impact the cleaning capability on various surfaces. If they become damaged or worn, replacing them can significantly improve cleaning results. Furthermore, seals and gaskets are essential for maintaining proper airflow and suction, so checking and replacing these when necessary is advisable for peak performance.

|