When it comes to maintaining garden equipment, having a clear view of how its mechanisms are structured is crucial for both regular upkeep and potential repairs. Knowing the layout of various elements ensures efficient work, reducing the chance of mistakes. This guide will help you get familiar with the arrangement of key components used in soil preparation devices, offering a clear overview of their assembly.

By breaking down the complex systems into understandable sections, this resource aims to simplify any maintenance task. With well-organized visuals and explanations, you can confidently address any issue, ensuring smooth operation of your machinery season after season. Familiarity with each piece in the system makes troubleshooting and servicing more manageable.

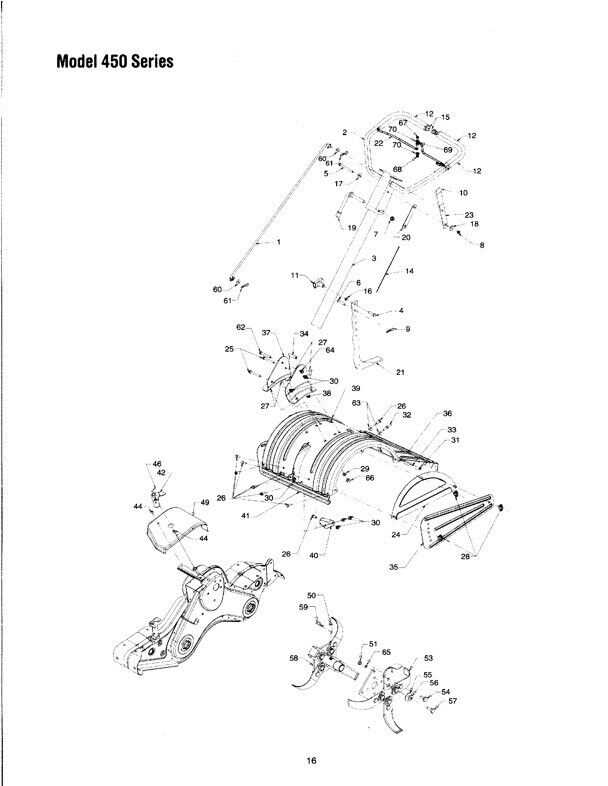

Understanding the Components of a Garden Tiller

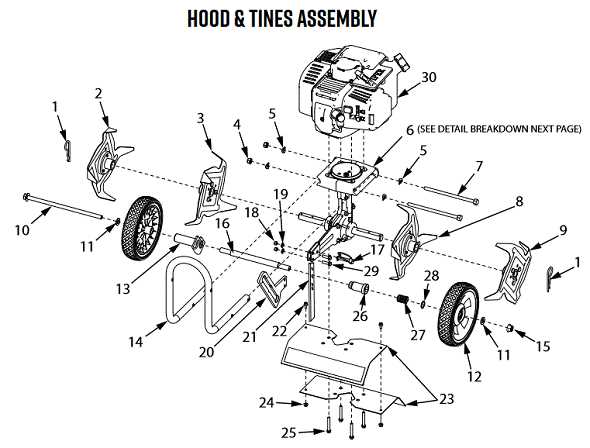

A garden cultivator is a powerful tool designed to simplify the process of soil preparation, turning and mixing the ground to create ideal growing conditions. It is composed of various essential elements that work together to break up compacted earth, aerate soil, and incorporate organic matter. Understanding these components can help in maintaining the device and ensuring its efficiency during gardening tasks.

Key Elements of the Soil Cultivating Machine

The machine comprises multiple parts, each serving a specific function. Below is an overview of some of the most critical elements:

| Component | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | Provides the power needed to operate the machine. It drives the movement of blades and controls the depth and intensity of soil cultivation. | ||||||||||||

| Blades | Also known as tines, these metal blades rotate to churn the soil, making it loose and ready for planting. The design and number of tines can vary depending on the model. |

| Type of Tool | Description | Best Use |

|---|---|---|

| Spade | A flat-bladed tool for digging and turning soil. | Breaking up hard ground |

| Hoe | A tool with a long handle and a flat blade, used for shaping soil. | Weeding and aerating |

| Rotary Blade | Designed to spin and cut through the earth, ideal for larger areas. | Large-scale tillage |

By selecting the appropriate cutting tool, cultivators can significantly enhance soil health and improve the overall yield of their crops. Understanding the unique characteristics and uses of each implement ensures that soil preparation is both efficient and effective.

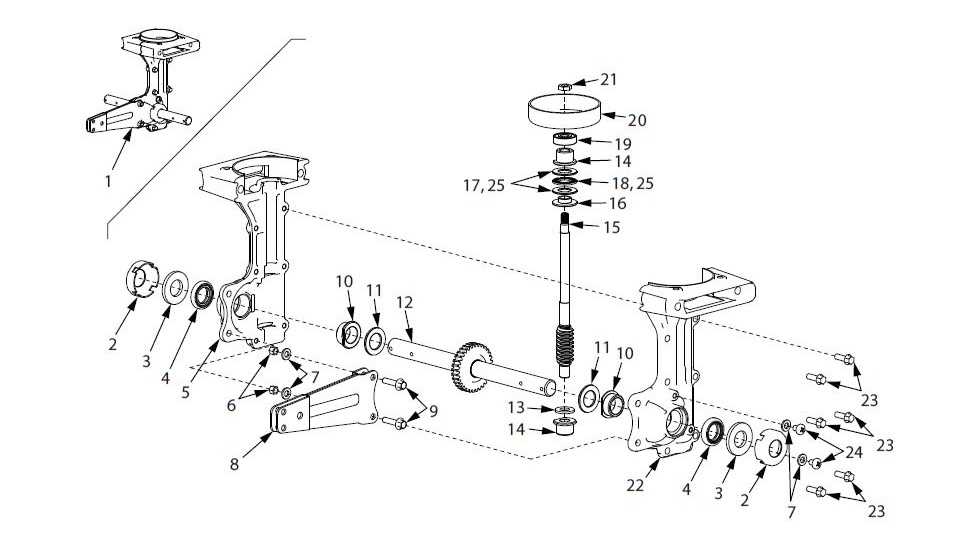

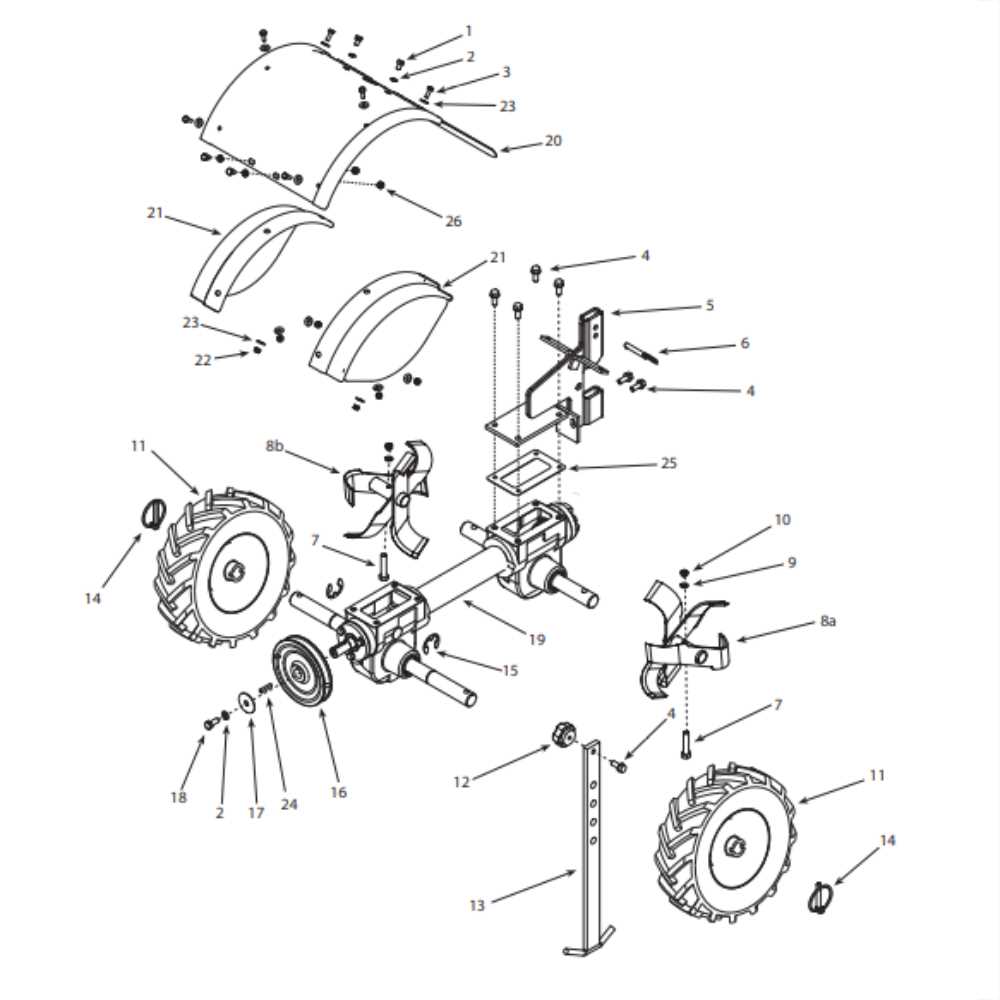

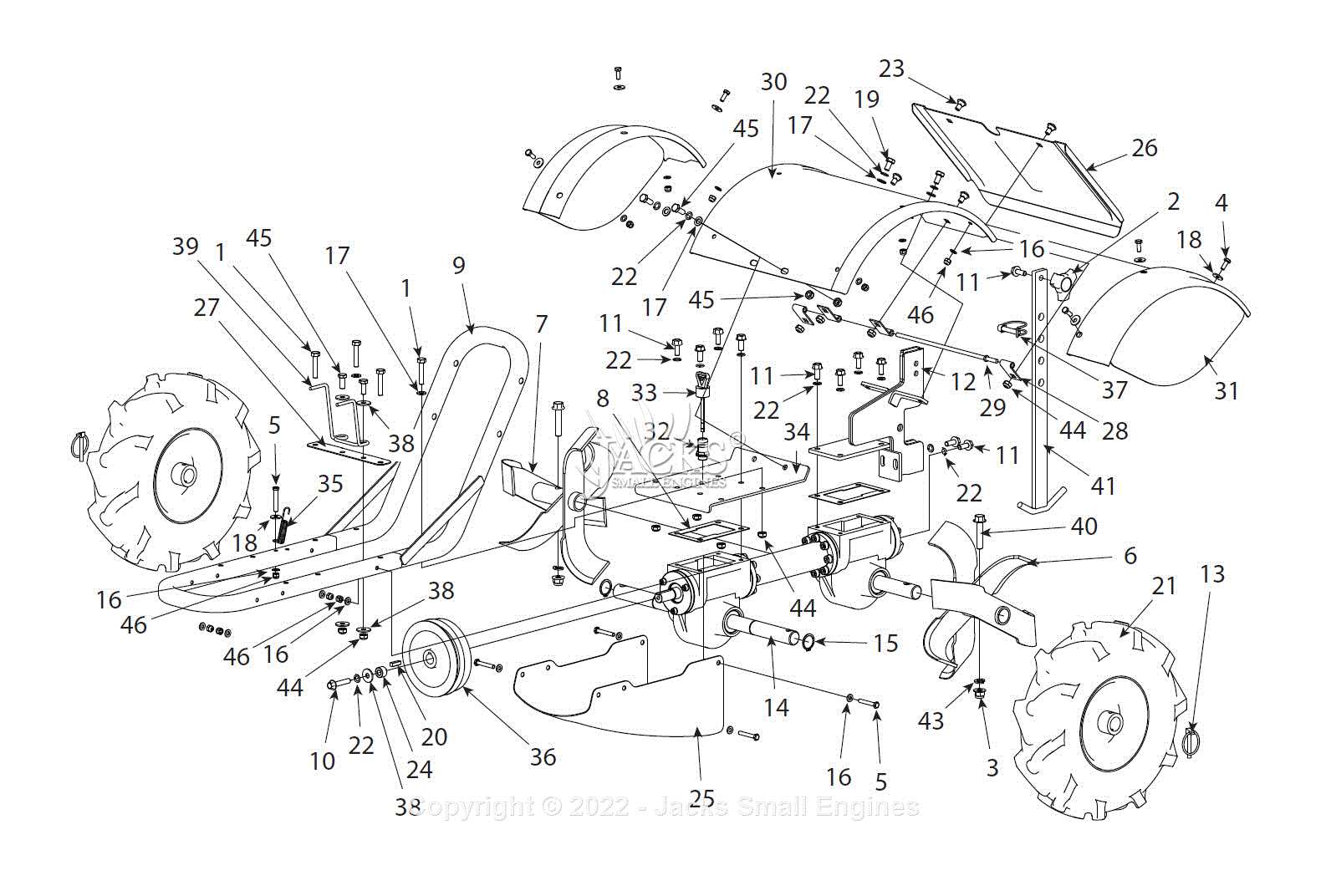

Drive System Breakdown for Earthquake Tillers

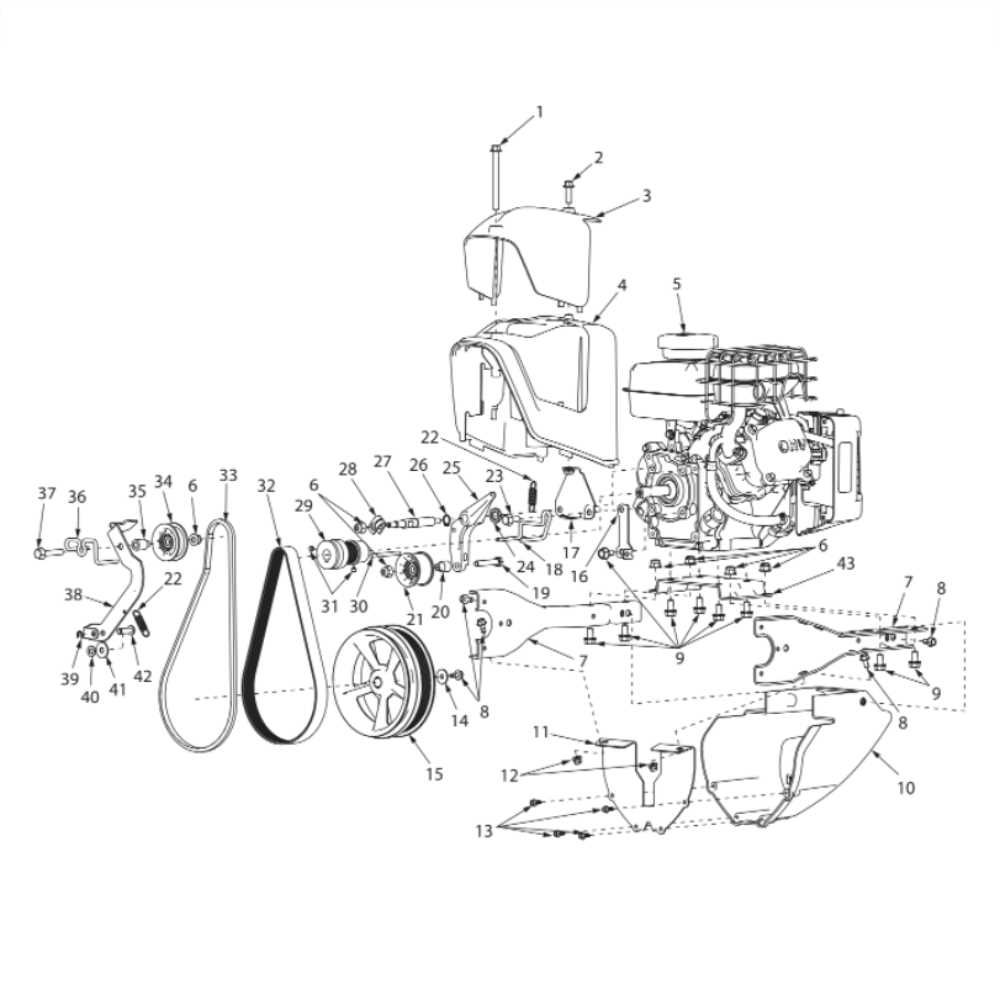

The drive mechanism of a cultivation implement is essential for its efficient operation. This system transforms the power generated by the engine into rotational force, enabling the equipment to function effectively in soil preparation tasks. Understanding the components and their interactions is crucial for maintenance and optimal performance.

Key Components of the Drive Mechanism

At the heart of the drive system is the engine, which provides the necessary power. This power is transmitted through a series of gears and belts, ensuring that the rotational force is directed to the necessary parts. Sprockets play a vital role in this process, allowing for adjustments in speed and torque, while clutches ensure smooth engagement and disengagement of power to the working components.

Maintenance and Troubleshooting

Regular inspection of the drive components is essential for longevity and reliability. Check for wear on the belts and sprockets, as well as ensuring proper tension. Lubrication of moving parts is crucial to reduce friction and prevent overheating. Understanding these elements will help in troubleshooting any issues that may arise during operation.

Common Replacement Parts for Garden Tillers

Maintaining optimal performance of your gardening equipment is essential for effective soil preparation. Over time, certain components may wear out or become damaged, necessitating their replacement to ensure the machine operates smoothly and efficiently.

Here are some frequently needed components for your gardening tools:

- Blades: These are crucial for breaking up soil. Sharp, well-maintained blades ensure efficient digging and mixing of soil.

- Drive Belts: Essential for transferring power from the engine to the working parts, worn belts can cause a decrease in performance.

- Spark Plugs: These components ignite the fuel-air mixture in the engine. Regularly replacing spark plugs can improve engine efficiency and starting reliability.

- Air Filters: Keeping the air intake clean is vital for engine performance. Dirty filters can restrict airflow and reduce power output.

- Fuel Filters: These prevent contaminants from entering the engine, ensuring smooth operation and longevity of the machinery.

Regularly checking and replacing these components will not only prolong the lifespan of your gardening equipment but also enhance its efficiency, leading to better gardening results.

Maintaining Engine and Performance

Proper upkeep of your gardening equipment’s motor is essential for ensuring optimal functionality and longevity. Regular maintenance can enhance efficiency, prevent breakdowns, and improve overall performance, allowing you to achieve better results in your outdoor tasks.

Routine Checks: Conduct frequent inspections of the engine to identify any signs of wear or damage. Look for leaks, loose components, or unusual noises that may indicate underlying issues.

Fuel System Maintenance: Ensure that the fuel system is clean and free from contaminants. Replace old fuel with fresh gasoline and consider using a fuel stabilizer to prevent degradation during periods of inactivity.

Air Filter Care: A clean air filter is vital for optimal airflow to the engine. Check and replace the air filter regularly to maintain engine efficiency and prevent dirt from entering the combustion chamber.

Oil Changes: Regular oil changes are crucial for lubricating engine components and reducing friction. Follow the manufacturer’s recommendations for oil type and change intervals to keep the engine running smoothly.

Spark Plug Inspection: Check the spark plug periodically for signs of wear or buildup. Replacing a worn or dirty spark plug can significantly improve starting and overall engine performance.

Storage Considerations: When not in use, store the equipment in a dry, sheltered location to protect it from the elements. Consider draining the fuel system if storing for an extended period to prevent deterioration.

By adhering to these maintenance practices, you can enhance the performance and durability of your gardening equipment, ensuring that it remains a reliable tool for your outdoor endeavors.

How to Replace a Tiller Transmission

Replacing the drive mechanism of your gardening machine can significantly enhance its performance and efficiency. Whether due to wear and tear or damage, understanding the steps involved will help you carry out this task effectively. This guide will walk you through the essential procedures to successfully perform the replacement.

Required Tools and Materials

Before starting the replacement process, gather the necessary tools and materials. You will need a socket set, wrenches, screwdrivers, and a replacement drive mechanism. Having these items ready will streamline your work and ensure a smooth operation.

Step-by-Step Replacement Process

1. Disconnect the Power Source: Ensure the machine is turned off and unplugged. This precaution will prevent any accidental starts during the replacement process.

2. Remove the Old Mechanism: Locate the mounting bolts and carefully detach the existing drive unit from the frame. Keep track of all components as you take them apart.

3. Install the New Mechanism: Position the new drive unit in place and secure it with the previously removed bolts. Ensure that all connections are tight and correctly aligned.

4. Reconnect the Power: After securing the new component, reconnect the power source. Check that everything is functioning correctly by testing the machine.

Following these steps will help ensure a successful replacement of the drive system, restoring your equipment to optimal working condition.

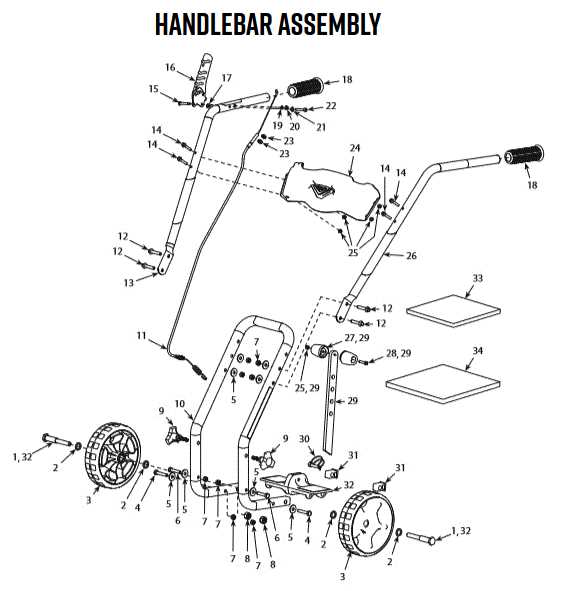

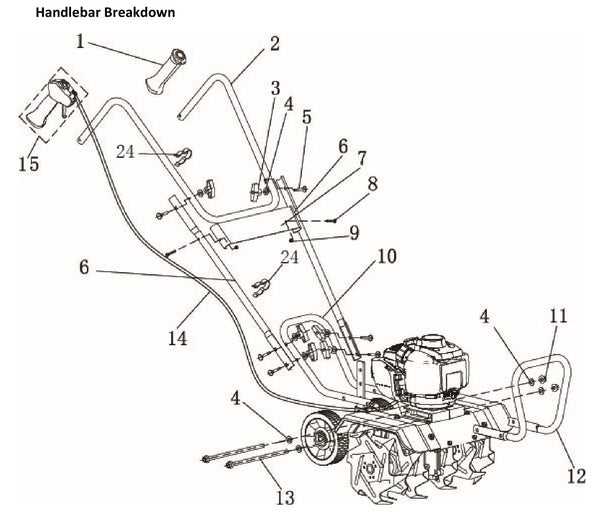

Troubleshooting Tiller Handle and Control Issues

When operating a ground cultivation machine, users may encounter various challenges related to the handle and control mechanisms. Identifying and resolving these issues is crucial for ensuring smooth operation and enhancing overall efficiency. This section will explore common problems and offer practical solutions to help maintain optimal performance.

Common Handle Malfunctions

One frequent concern involves the handle becoming stiff or unresponsive. This can often be attributed to dirt or debris buildup in the pivot points. To address this, inspect the handle assembly for any foreign material and clean it thoroughly. If the issue persists, check for any signs of wear or damage, as these may require replacement. Regular maintenance can prevent such complications and ensure the handle remains functional.

Control Mechanism Failures

Control failures may manifest as erratic behavior or complete loss of functionality. First, examine the control cables for any signs of fraying or detachment. If found, these cables should be replaced immediately to restore proper functionality. Additionally, inspect the connection points and ensure all fasteners are tight. Lubricating moving parts can also help mitigate friction-related problems and enhance responsiveness.

Keeping the Wheels and Tires in Optimal Condition

Maintaining the integrity of wheels and tires is essential for ensuring smooth operation and longevity of outdoor equipment. Regular checks and proper care can enhance performance and reduce the risk of mechanical failures during use. Understanding key maintenance practices will contribute to overall efficiency.

Regular Inspections

Conducting frequent examinations of wheels and tires helps identify any signs of wear or damage. Look for cracks, bulges, or uneven wear patterns that may indicate underlying issues. Addressing these concerns promptly can prevent further complications and extend the lifespan of the components.

Proper Inflation and Alignment

Ensuring that tires are adequately inflated is crucial for optimal performance. Under-inflated tires can lead to increased resistance and reduced efficiency, while over-inflation may result in a harsh ride and premature wear. Additionally, maintaining correct alignment helps prevent uneven wear and enhances stability during operation.

Ensuring Longevity with Proper Tiller Maintenance

Maintaining agricultural equipment is crucial for its performance and lifespan. Regular care and attention can prevent wear and tear, ensuring that the machine operates efficiently over time. By following a structured maintenance routine, users can avoid costly repairs and enhance the reliability of their machinery.

Regular Inspections

Conducting routine checks is essential for identifying potential issues before they escalate. Inspecting components such as belts, filters, and tines can help in detecting any signs of damage or wear. Make it a habit to review these elements periodically, as early intervention can significantly extend the life of your equipment.

Proper Cleaning and Storage

After use, it is vital to thoroughly clean the equipment to remove dirt and debris. Residue can cause corrosion and affect performance. Additionally, storing the machinery in a dry, sheltered location protects it from environmental factors that could lead to deterioration. Using protective covers can also provide an extra layer of defense against dust and moisture.