When working with complex mechanical systems, it is essential to have a clear understanding of how each element fits and functions together. Knowing how to identify various elements and their roles can greatly improve maintenance efficiency and overall performance.

Efficient organization of various components is key to ensuring smooth operation and simplifying the process of repairs or replacements. With a thorough overview, users can better navigate through the intricate connections between elements.

Whether you are handling regular upkeep or solving unexpected issues, having a reliable reference helps in making informed decisions. A well-structured approach to understanding how each element interacts guarantees that all ta

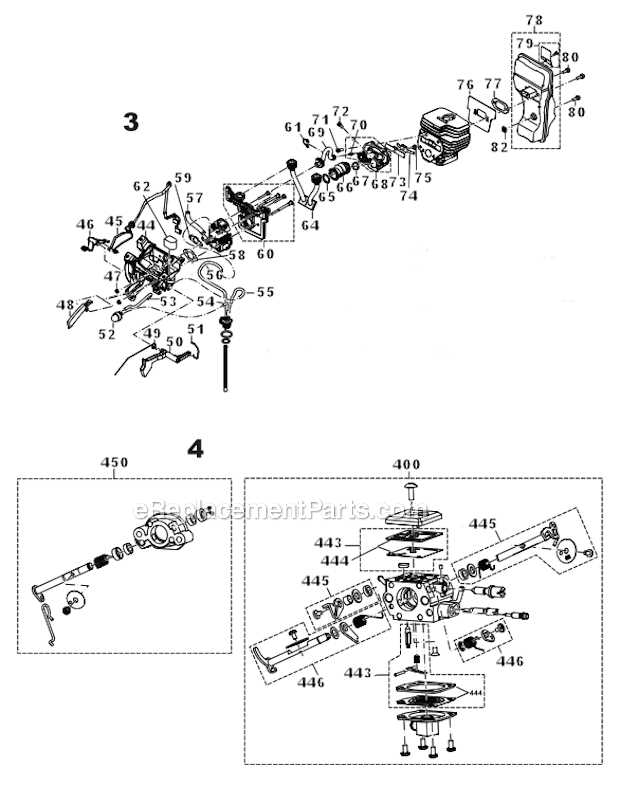

Ek6101 Parts Diagram

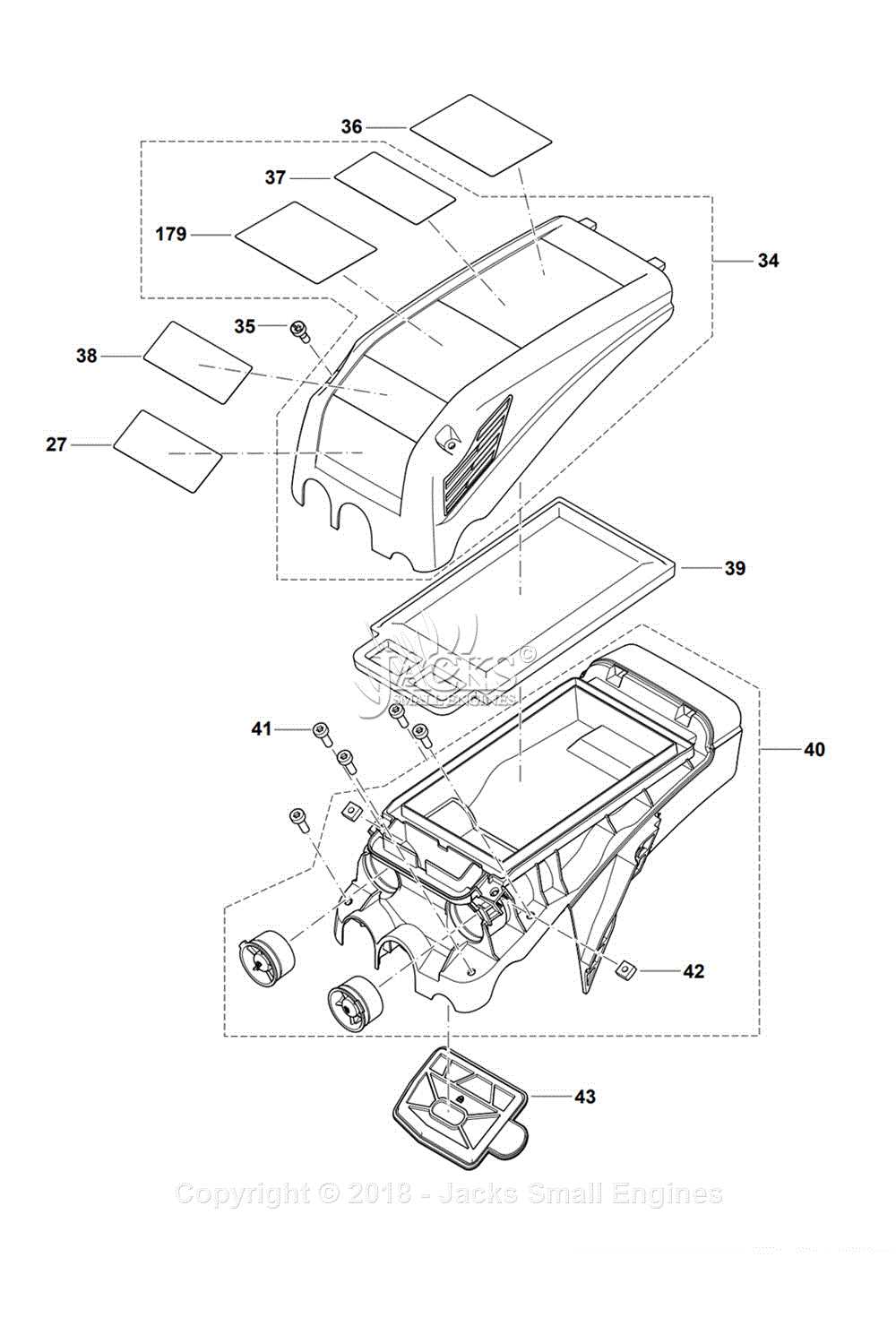

The detailed layout of various components plays a crucial role in understanding how different elements work together. This layout helps in identifying key sections, ensuring proper assembly, and maintaining functionality over time. It serves as a reference for both beginners and experienced users, offering insight into the proper positioning and structure of each element.

Component Overview

Every essential element is carefully positioned, contributing to the overall efficiency of the system. Identifying these elements allows for smoother operation and easier maintenance, ensuring longevity and reliability.

Overview of Component Structure

The assembly of mechanical elements is designed with precision, ensuring that each piece works in harmony with others. These individual elements are interconnected in a way that allows for smooth operation and reliable performance, forming a cohesive structure. Understanding this layout helps in grasping how the system functions as a whole.

Main Elements and Their Functions

Each unit plays a critical role in the overall operation. Whether it’s providing support, facilitating movement, or ensuring safety, the structure is composed of several key components:

- Framework for stability

- Movement facilitators like joints and connectors

- Safety mechanisms

Connection and Interaction

These components do not function in isolation

Detailed Breakdown of Key Parts

The internal structure of the device consists of several crucial elements, each playing a significant role in ensuring proper functionality. Understanding the individual components and their roles can help with maintenance and troubleshooting, providing insight into how the system operates as a whole.

Main Components: The core units form the foundation, working together to deliver the expected performance. These elements, although varied in their design, share the goal of keeping the device running smoothly and efficiently.

Supporting Elements: Smaller yet equally important pieces complement the primary units, offering stability and enhancing performance. These assist in the smooth operation and are designed

Main Sections and Their Functions

This section provides an overview of the primary components of the system and their respective roles. Understanding these elements is crucial for effective operation and maintenance, ensuring that each part contributes to the overall functionality and efficiency.

Core Components

The core components serve as the backbone of the system, responsible for its essential operations. Each element works in harmony to facilitate seamless functionality, enhancing the user experience. Key features include:

- Power Supply: Ensures that the entire system receives adequate energy.

- Control Unit: Manages the various processes, allowing for efficient operation.

- Transmission System: Facilitates the transfer of energy and information between components.

Supportive Elements

Supportive elements enhance the overall performance and reliability of the system. These parts work together to maintain stability and effectiveness, often providing additional safety features. Notable functions include:

- Cooling System: Prevents overheating, ensuring the longevity of the components.

- Feedback Mechanism: Monitors performance and provides necessary adjustments for optimal efficiency.

- Protective Housing: Shields internal components from external damage and contaminants.

Essential Elements and Their Roles

Understanding the fundamental components of a system is crucial for effective functionality and maintenance. Each element plays a distinct role, contributing to the overall efficiency and performance. Recognizing how these pieces interact allows for better management and troubleshooting, ensuring that everything operates smoothly.

Key Components and Functions

Every system comprises various integral parts, each with specific responsibilities that facilitate seamless operation. Here is a summary of the primary elements and their respective functions:

| Component | Function |

|---|---|

| Controller | Manages and regulates operations based on input and feedback. |

| Sensor | Monitors conditions and provides data for decision-making. |

| Actuator | Performs actions to alter the state of the system based on commands. |

| Power Supply | Delivers the necessary energy for the system to function. |

Importance of Each Element

Each component’s reliability and performance directly influence the system’s overall effectiveness. A failure in one part can lead to inefficiencies or malfunctions. Therefore, regular inspection and maintenance are essential to ensure all elements function harmoniously.

How the System Components Interact

This section explores the interaction among various elements within the framework. Understanding these relationships is essential for optimizing functionality and ensuring seamless operation. Each component plays a specific role, contributing to the overall performance and efficiency of the system.

The components function together in a harmonious manner, where the output of one element often serves as the input for another. This interconnectedness allows for efficient processing and smooth transitions between different phases of operation.

| Component | Function | Interaction |

|---|---|---|

| Element A | Provides initial processing | Feeds data to Element B |

| Element B | Conducts analysis | Outputs results to Element C |

| Element C | Finalizes output | Delivers completed information to users |

Locating Specific Parts in the Diagram

Identifying particular components within a schematic can be a straightforward process when approached methodically. Understanding the layout and organization of the visual representation is essential for effective navigation. This section aims to guide users in pinpointing the elements they need efficiently.

To facilitate the search for specific items, consider the following steps:

- Familiarize yourself with the overall layout.

- Look for labels and legends that indicate various sections.

- Use a systematic approach by following a grid or a sequential pattern.

In addition, utilizing the following tips can enhance your efficiency:

- Cross-reference with a list of components if available.

- Highlight or note down key areas of interest for quicker access.

- Take advantage of color codes or symbols, which can aid in differentiation.

By adopting these strategies, navigating through the schematic will become a more manageable and less daunting task.

Explaining the Role of Minor Parts

The functionality of any device often hinges on the various components that may seem insignificant at first glance. These smaller elements play crucial roles in ensuring the overall performance and efficiency of the system. While they may not attract much attention, their contributions are essential for the seamless operation of the equipment.

Each of these elements is designed to perform a specific function, often enhancing the efficiency and reliability of the entire mechanism. For example, certain components may aid in stability, while others might facilitate movement or connectivity between larger pieces. Understanding their significance helps in appreciating how each part interacts within the whole, ultimately contributing to the device’s success.

Neglecting these minor components can lead to operational issues, emphasizing the importance of maintenance and awareness of all elements involved. Proper care and replacement of these parts can prevent larger malfunctions and extend the lifespan of the device. In summary, recognizing the value of even the smallest elements fosters a greater understanding of the equipment and its workings.

Connections Between Major Components

This section explores the essential linkages between significant elements within the assembly, highlighting how their interactions contribute to the overall functionality. Understanding these connections is crucial for effective maintenance and troubleshooting.

Overview of Key Relationships

The interplay among the primary units ensures optimal performance. Each part serves a specific role, and their cooperation is vital for seamless operation. Recognizing how these components are interconnected allows for better insights into system behavior.

Importance of Proper Assembly

Correct assembly of the critical components is essential for achieving desired outcomes. Misalignments or faulty connections can lead to inefficiencies or failures in operation. It is advisable to consult the appropriate guides for ensuring accurate configurations.

| Component | Function | Connection Type |

|---|---|---|

| Unit A | Drives the main operation | Mechanical |

| Unit B | Regulates the flow | Electrical |

| Unit C | Provides structural support | Supportive |

| Unit D | Facilitates control functions | Data link |

Identifying Critical Functional Areas

In the realm of machinery and equipment, pinpointing essential operational zones is crucial for ensuring efficiency and reliability. These areas play a significant role in the overall performance, impacting both functionality and maintenance. Understanding these vital sections allows for better management and troubleshooting.

Operational Zones encompass various components that must work harmoniously to achieve optimal results. Recognizing the significance of each zone aids in addressing potential issues before they escalate. Furthermore, having a clear understanding of these segments enhances the effectiveness of maintenance protocols.

Systematic Analysis of critical areas can reveal insights into their interdependencies and how they influence the entire setup. This knowledge not only supports efficient operation but also informs future upgrades or modifications, ultimately contributing to a more robust and resilient system.

Visual Guide to Key Assemblies

This section offers a comprehensive overview of essential components and their configurations, facilitating a better understanding of the overall structure. By examining these crucial assemblies, users can gain insights into the functionality and interconnections of various elements, enhancing maintenance and repair efforts.

| Component Name | Description | Function |

|---|---|---|

| Main Frame | The core structure that supports all other parts. | Provides stability and durability. |

| Control Module | Central unit that manages operations. | Ensures proper functioning and control. |

| Power Supply | Source of energy for the system. | Powers all electronic components. |

| Drive Assembly | Mechanism that converts energy into motion. | Facilitates movement and operational capability. |

| Sensor Unit | Device that detects changes in the environment. | Provides feedback for adjustments and safety. |

Understanding the Layout of Components

The arrangement of elements within a system plays a crucial role in its functionality and maintenance. By comprehending how these components are positioned and interact, users can enhance their operational efficiency and troubleshooting processes. This section will explore the significance of a well-organized setup and its impact on performance.

Importance of Clear Organization

A well-structured arrangement of parts provides several advantages:

- Ease of Access: Clearly defined placements allow for quick identification and reachability of essential components.

- Streamlined Maintenance: When elements are logically organized, routine checks and repairs become more efficient.

- Enhanced Performance: Optimal placement can lead to improved overall system functionality.

Key Considerations for Layout

When evaluating the configuration of components, consider the following:

- Functional Relationships: Assess how each element interacts with others to ensure a harmonious operation.

- Accessibility: Ensure that critical parts are easily reachable for quick adjustments or replacements.

- Space Utilization: Maximize the use of available space without overcrowding, promoting airflow and cooling.