Understanding the various elements that constitute a specific apparatus is crucial for both users and technicians. Each component plays a vital role in ensuring the overall functionality and efficiency of the device. By familiarizing oneself with these essential features, one can better appreciate the intricacies involved in its operation and maintenance.

In this section, we will explore the intricate layout of the individual sections that come together to form the complete unit. Analyzing how these segments interrelate enhances comprehension of the device’s design and helps identify potential areas for improvement or troubleshooting.

The visual representation of these elements serves as a valuable resource for anyone looking to delve deeper into the mechanics of the apparatus. Whether for repairs, upgrades, or general knowledge, a clear understanding of each component’s role is instrumental in achieving optimal performance and longevity.

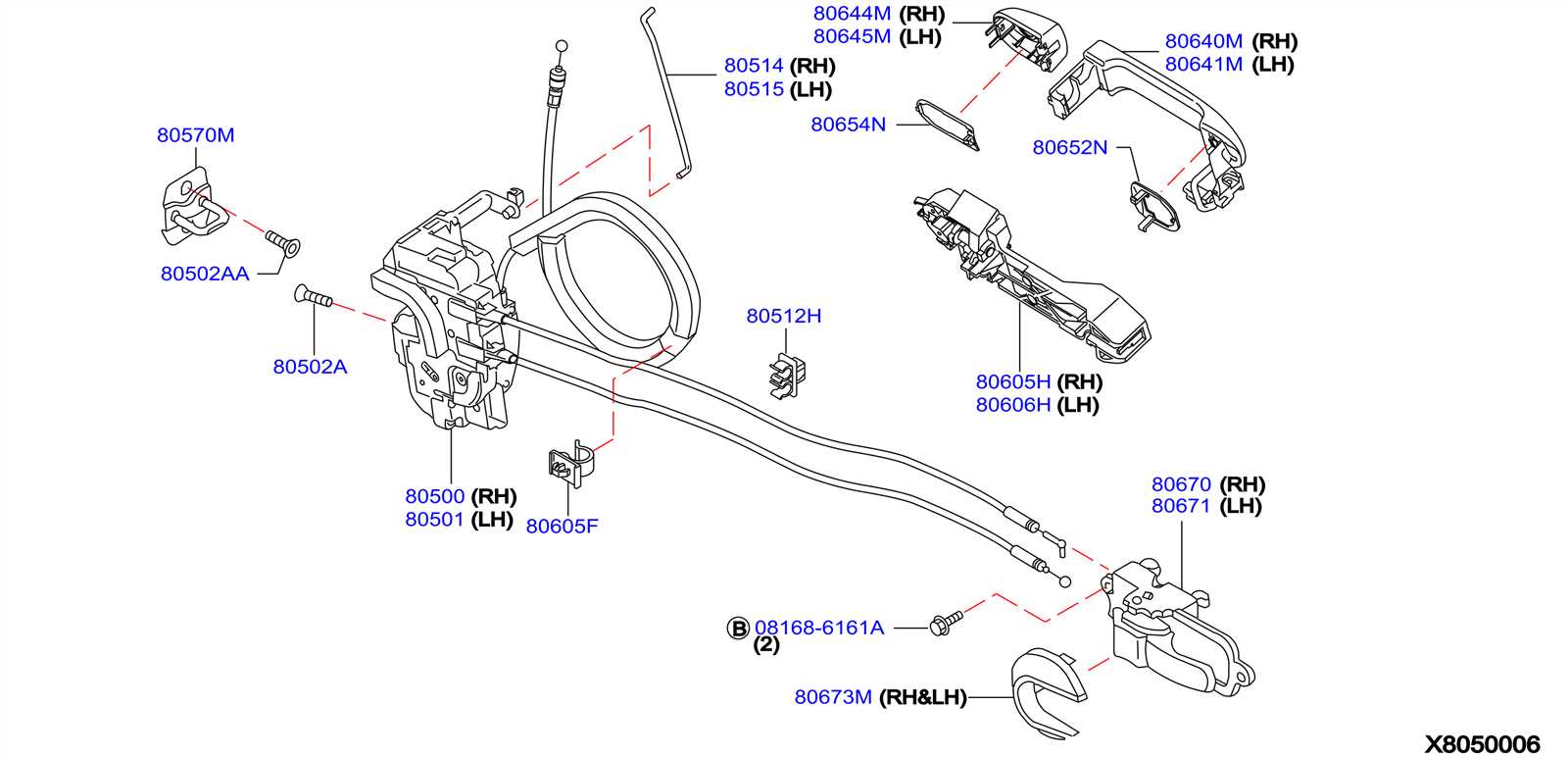

Understanding the Parts Diagram

This section aims to provide insight into the visual representation of various components within a mechanical system. It is essential for users to comprehend how these elements interact and function collectively, enabling effective troubleshooting and maintenance.

Importance of Component Representation

Recognizing the layout of different elements helps in identifying their roles and interconnections. This knowledge is crucial for anyone looking to enhance their understanding of the overall assembly. By studying these illustrations, users can effectively pinpoint specific areas that may require attention or repair.

Interpreting the Visuals

The illustrations typically include labels and codes that correspond to each item, offering clarity on their specifications. Familiarity with these references can significantly aid in the efficient handling of repairs and replacements. Understanding the relationship between various elements is vital for ensuring the system operates smoothly and effectively.

Key Functional Parts Explained

This section delves into the essential components that contribute to the effective operation of the device. Understanding these elements is crucial for optimizing performance and ensuring longevity.

Major Components

- Motor: The driving force behind the device, responsible for converting electrical energy into mechanical motion.

- Control Unit: Acts as the brain, managing the operational settings and ensuring that the motor functions according to user input.

- Chassis: The structural framework that houses and supports various components, providing stability and durability.

Supportive Elements

- Power Supply: Delivers the necessary electrical energy for operation.

- Cooling System: Maintains optimal temperature, preventing overheating during prolonged use.

- Sensor System: Monitors performance parameters, ensuring the device operates efficiently and safely.

Maintenance Tips for El13a

Regular upkeep is essential for ensuring optimal performance and longevity of your device. By following a few simple guidelines, you can maintain its efficiency and reduce the likelihood of malfunctions. Below are practical suggestions for effective maintenance.

Routine Cleaning

- Dust the exterior surfaces regularly to prevent buildup.

- Use a soft, damp cloth to wipe down sensitive areas.

- Avoid using abrasive materials that can scratch or damage components.

Regular Inspections

- Check connections and cables for wear or fraying.

- Inspect moving parts for signs of damage or excessive wear.

- Ensure that all components are securely fastened to avoid operational issues.

Common Issues with El13a Parts

When dealing with machinery components, various challenges can arise that affect functionality and performance. Understanding these potential problems can help in maintaining optimal operation and prolonging the lifespan of the device.

Wear and Tear: Over time, components can experience significant deterioration due to regular usage. This wear may lead to decreased efficiency and increased likelihood of failure.

Improper Installation: Incorrect assembly of elements can result in malfunctions. Ensuring that all pieces are properly aligned and securely fastened is essential for smooth operation.

Incompatibility: Using components that are not designed for specific models can cause serious issues. It is crucial to verify compatibility before making replacements to avoid operational disruptions.

Maintenance Neglect: Regular upkeep is vital for ensuring that every element functions correctly. Failing to perform routine checks can lead to unexpected breakdowns and costly repairs.

Environmental Factors: External conditions such as moisture, dust, and extreme temperatures can adversely affect component performance. Implementing protective measures can mitigate these risks.

How to Identify Replacement Parts

Recognizing suitable components for your equipment is crucial for maintaining its functionality and longevity. Proper identification ensures that you acquire the correct items needed for repair or replacement, preventing potential issues that could arise from using incompatible parts.

Start by examining the device closely. Look for any labels or markings that provide information about the model and specifications. This data will guide you in sourcing the appropriate replacements. It’s also helpful to refer to the original manufacturer’s documentation, which may include illustrations and descriptions of the components.

Additionally, consulting online resources and community forums can be beneficial. Many users share their experiences and provide insights on where to find reliable parts. Below is a simple reference table to aid in your identification process:

| Component Type | Identification Tips | Common Sources |

|---|---|---|

| Motor | Check voltage rating and model number | Manufacturer’s site, electronic suppliers |

| Filter | Measure dimensions, look for serial numbers | Home improvement stores, online retailers |

| Circuit Board | Identify model number and version | Electronics shops, specialized websites |

| Housing | Inspect for cracks, refer to model specs | Local repair shops, online marketplaces |

By following these steps and utilizing available resources, you can effectively identify the correct components needed for your repairs.

Assembly Process of El13a

The assembly process of this specific device involves a series of structured steps that ensure all components are accurately put together. Proper organization and attention to detail are essential for achieving optimal functionality and performance.

Initially, it is crucial to prepare all necessary elements, ensuring that each component is clean and free from any defects. Following this, a systematic approach should be taken, starting with the larger sections and gradually moving to the smaller pieces. This method not only simplifies the task but also reduces the risk of damaging any sensitive parts.

During the assembly, it is important to follow the outlined sequence carefully. Secure connections should be made using appropriate tools, taking care not to overtighten, which could lead to material fatigue or failure. Additionally, checking alignment at each stage can help prevent issues during later stages of operation.

Once the primary assembly is complete, conducting a thorough inspection is necessary. This includes verifying all connections, ensuring that moving parts function smoothly, and confirming that safety features are correctly installed. If any discrepancies are noted, adjustments should be made promptly.

In conclusion, careful adherence to the assembly process not only enhances the durability and efficiency of the device but also contributes to the overall user experience. A well-assembled unit is more likely to perform reliably over time.

Safety Considerations During Repairs

Ensuring a safe working environment is crucial when performing maintenance or fixing equipment. Adhering to specific safety protocols minimizes risks and promotes a secure atmosphere for both the technician and the surrounding individuals.

Always disconnect the power source before beginning any repair work. This step prevents accidental electrical shocks and equipment malfunctions, safeguarding the technician’s well-being. Additionally, it is essential to use appropriate personal protective equipment (PPE), such as gloves and goggles, to shield against potential hazards.

Furthermore, keeping the workspace organized contributes to safety. A clutter-free area reduces the likelihood of accidents and allows for efficient movement while working. Ensure that tools and materials are easily accessible and stored correctly when not in use.

Lastly, familiarizing oneself with the equipment’s manual is imperative. Understanding the operating principles and potential risks involved enables technicians to handle repairs more confidently and effectively.

Where to Source El13a Parts

Finding components for your equipment can be a challenge, but there are various options available to ensure you obtain the necessary items efficiently. From online retailers to local suppliers, understanding where to look can save you time and money.

Online Retailers

The internet offers a plethora of resources for purchasing essential items. Here are some popular platforms:

- eBay: A marketplace with numerous listings for specific components.

- Amazo: Known for a wide range of products, including specialized components.

- AliExpress: Often features affordable options from international sellers.

Local Suppliers

In addition to online options, local suppliers can provide immediate access to necessary components. Consider the following:

- Specialty electronic shops: They may stock specific items or offer special ordering services.

- Hardware stores: Sometimes carry generic components that can be adapted for use.

- Local repair shops: They might have spare parts available or can direct you to reliable sources.

Comparing El13a with Similar Models

This section examines the characteristics and functionalities of a specific model in relation to its counterparts within the same category. By analyzing their features and performance, we can gain insights into their respective strengths and weaknesses.

Key Features Comparison

- Design and Build Quality

- Efficiency and Performance Ratings

- Ease of Use and User Experience

- Maintenance Requirements

Price and Value Assessment

- Initial Purchase Price

- Long-term Operating Costs

- Warranty and Customer Support Services

By considering these aspects, potential buyers can make informed decisions based on their specific needs and preferences.