The design and arrangement of essential elements play a crucial role in the functionality of various equipment. It’s important to have a clear understanding of how these components are organized and connected to ensure smooth operation and maintenance.

Familiarizing yourself with the layout can significantly improve efficiency when dealing with routine adjustments or troubleshooting. By recognizing the arrangement, you can easily identify the position of critical elements and gain insight into how different sections interact with each other.

Whether you’re dealing with regular upkeep or more extensive modifications, having a solid grasp of the overall structure allows you to approach tasks with confidence. This guide will help you navigate through the essential aspects of the equipment’s configuration, making your tasks more straightforward and informed.

Understanding the Ez Loader System Components

The system consists of several crucial elements working together to ensure smooth and reliable performance. Each element plays a distinct role in maintaining the stability and functionality of the structure, providing balance and support during various operations. This section will explore the key features that contribute to the system’s overall effectiveness without diving into technical definitions.

Key Structural Elements

The structural framework includes various beams and connectors, which form the backbone of the system. These components ensure that the entire setup remains durable under different conditions, offering a secure base for operations. They are designed to withstand significant pressure while maintaining alignment and balance.

Essential Supporting Features

Alongside the main framework, additional elements such as tensioners and fasteners help in maintaining proper operation. These supporting features ensure that all parts remain securely attached and function as intended, reducing the risk of failure or misalignment. They also facilitate easy adjustments when necessary, providing flexibility and ease of use.

Key Features of Trailer Parts

Understanding the essential elements of a trailer’s construction helps ensure safety, durability, and ease of use during transportation. Each component plays a crucial role in maintaining stability, supporting the load, and providing smooth towing experiences.

Durability and Materials

The materials used in building various components significantly impact the trailer’s strength and longevity. Steel and aluminum are commonly employed due to their balance of durability and weight. These materials resist corrosion and handle heavy loads efficiently, ensuring long-term reliability.

Functional Design

The functional aspects of trailer components are designed to optimize performance. From secure couplings to efficient braking systems, each element contributes to smooth operations. Modern designs focus on ease of maintenance and enhancing user experience.

- Hitches: Provide secure connections for safe towing.

- Suspension systems: Ensure stability on uneven roads.

- Lighting: Enhance visibility and improve road safety.

- Brak

Detailed Overview of Axle Assembly

The axle assembly plays a crucial role in the stability and functionality of various types of vehicles and trailers. It ensures that the wheels remain aligned and carry the weight evenly, contributing to smooth and safe movement. Understanding the construction and layout of this component is essential for maintenance and troubleshooting.

Key components of the axle system include the central shaft, which connects the wheels on opposite sides, and other elements designed to manage the load and motion effectively. These parts work in unison to ensure proper balance, handling, and durability over time.

In this section, we will explore the different elements that make up the axle assembly, offering a clear understanding of how each contributes to th

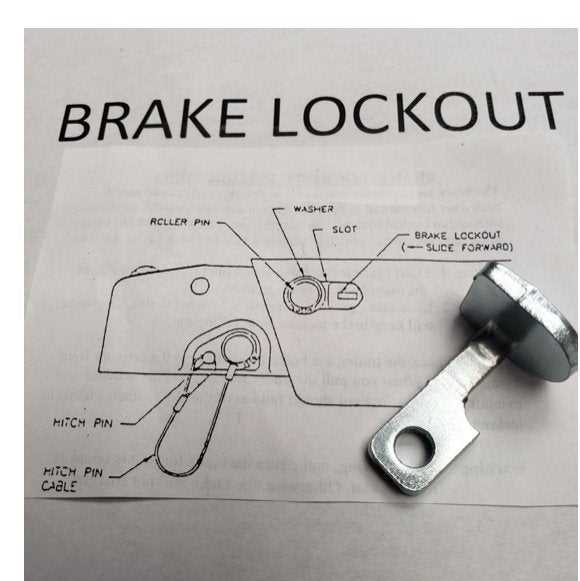

Identifying Brake System Elements

Understanding the components involved in the brake system is essential for ensuring optimal performance and safety. Each element plays a crucial role in controlling the vehicle’s speed and ensuring proper stopping power. By recognizing these key parts, maintenance and troubleshooting become much easier.

- Brake Calipers: These are responsible for applying pressure to the brake pads, forcing them against the rotors.

- Brake Pads: Positioned between the calipers and rotors, these pads create friction that helps to slow down or stop the movement.

- Rotors: These metal discs are attached to the wheels, and they provide a surface for the brake pads to clamp onto.

- Brake Lines: These hoses transfer the hydraulic fluid from the master cylinder to the calipers.

- Master

Exploring Lighting and Wiring Components

The lighting and wiring system plays a crucial role in maintaining the functionality and safety of various equipment. These elements ensure that proper visibility is maintained, both in terms of external illumination and internal electrical flow. Understanding the connections and different fixtures involved in these systems helps enhance operational efficiency, preventing potential failures and improving overall performance.

Types of Lighting Fixtures

Lighting fixtures vary based on their purpose and placement. Exterior lights, such as tail lights and marker lights, help increase visibility during nighttime or in low-light conditions, making them essential for safety. Interior lights, on the other hand, serve to illuminate specific areas where manual work or inspection is needed.

Key Wiring Components

The wiring network is the backbone of the lighting system. It consists of

Fender Construction and Installation Guide

Fenders play a crucial role in protecting essential areas of your vehicle or equipment from damage. Proper construction and installation of these components are key to ensuring durability and safety during use. This guide will provide an overview of the steps involved in assembling and securely attaching fenders, helping you avoid common issues that may arise during the process.

Choosing the Right Materials

When constructing fenders, selecting durable and weather-resistant materials is essential. Common choices include metal or high-strength plastic, both of which offer excellent protection against external impacts. Ensure that the materials are lightweight yet sturdy to enhance performance without adding unnecessary weight.

Installation Process

Proper installation is crucial to maximizing the fender’s functionality. Begin by measuring the mounting area to ensure a precise fit. Secure the fenders using bolts or

Roller and Bunk Configurations Explained

Understanding the difference between roller and bunk setups is essential for ensuring the proper support and smooth operation of your watercraft. Each of these systems has unique characteristics that affect how your boat is handled, making it important to choose the right one based on your specific needs.

Roller Setup

The roller setup is designed for easier launching and retrieving, especially in shallow or steep conditions. It uses multiple rotating supports that help the boat glide effortlessly, reducing friction. This option is ideal for those who frequently launch their vessels solo or in challenging environments.

Bunk Setup

The bunk setup offers a more secure, stable hold during transport. With long, padded support bars, it distributes the weight of the boat evenly, which helps prevent damage. This configuration is well-suited for larger boats and is generally lower maintenance compared to rollers.

Choosing the Right Configuration depends on how often you use your boat, the type

Coupler and Winch Mount Functions

The coupler and winch mount are essential elements in ensuring the secure connection and safe transport of various equipment. They work together to provide a reliable mechanism for holding, guiding, and securing the load during transit. These components play a critical role in maintaining stability and control, especially when transporting heavy items.

Main Functions of the Coupler

The coupler is designed to create a strong link between the towing vehicle and the towed equipment. Its main functions include:

- Ensuring a stable connection during motion

- Allowing smooth articulation while turning

- Providing a secure locking mechanism

Key Roles of the Winch Mount

The winch mount serves as a robust platform for attaching

Suspension System: How It Works

The suspension system plays a critical role in ensuring a smooth and stable ride, absorbing shocks and maintaining balance even on uneven terrain. By controlling the movement between the wheels and the vehicle body, it improves both comfort and control, contributing to overall performance and safety.

The system includes several key components that work together to manage the impact of the road surface and ensure proper handling. Understanding how these components function can help identify issues early and maintain peak efficiency.

- Springs: These absorb the energy from impacts, compressing and expanding to reduce the force felt by the vehicle.

- Shock absorbers: Working alongside the springs, these dampen the motion, preventing excessive bouncing and ensuring the vehicle stays in contact with the road.

- Control arms: These connect the wheels to the frame, allowing for controlled

Tire and Wheel Specifications for Trailers

Tires and wheels are crucial components for any trailer, as they ensure safe and reliable transportation. Choosing the right specifications for your trailer’s tires and wheels is essential for both performance and durability on the road. Proper selection not only affects handling but also the overall load capacity of the trailer. Understanding the key factors involved can help you make informed decisions that will extend the life of your equipment.

Tire Types and Load Ratings

The type of tire used on a trailer plays a significant role in its performance. Trailer tires are often designed with reinforced sidewalls to handle heavy loads. It’s important to match the tire’s load rating with the weight your trailer will be carrying. Overloading tires beyond their rated capacity can lead to premature wear and safety risks. Always check the load rating before making a purchase to ensure it fits your specific needs.

Wheel Size and Material Considerations

Wheels come in various sizes and materials, each influencing the performance and durability of the trailer. Steel wheels offer excellent strength, while aluminum options are lighter and more resistant to rust. Selecting the correct wheel size is just as important, as the wrong size can impact the trailer’s balance

Protective Coating and Rust Prevention Tips

Ensuring durability and longevity of equipment is essential in environments prone to moisture and corrosion. One effective method to achieve this is by applying the right protective coating. Proper surface treatment can significantly slow down the development of rust, keeping metal components intact and operational for a longer time.

Choose the Right Coating: Selecting the appropriate protective layer depends on the material and its exposure to the elements. High-quality coatings provide a barrier between the metal and harmful substances, preventing moisture from seeping through.

Regular Maintenance is also key in rust prevention. Cleaning surfaces and applying anti-corrosion sprays periodically helps maintain the integrity of the protective layer, reducing the chances of rust formation.

By investing time in applying coatings and practicing good maintenance, you can extend the life of metal surfaces and ensure they remain in optimal condition for years to come.

Safety Chain and Hook Mechanisms

The safety chain and hook mechanisms play a crucial role in ensuring the secure attachment and transportation of heavy loads. These components provide stability and security, preventing unintended movements during transit. Proper use of these systems can greatly reduce the risk of accidents, making them indispensable for both light and heavy equipment.

Key Features and Components

Understanding the different features and components of these mechanisms is important for safe operation. Below is a table highlighting essential elements of safety chain and hook mechanisms:

Component Description Safety Chain A durable metal chain designed to withstand heavy tension, ensuring that loads remain securely fastened. Hook A strong metal hook used to latch onto secure points, providing a reliable connection between the chain and the transported load. Locking Mechanism Ensures the hook stays in place, preventing accidental release under stress or vibration. Maintenance Guidelines for Ez Loader Parts Proper upkeep of your equipment is essential for ensuring longevity and efficiency. Routine inspection and timely servicing can prevent unexpected breakdowns and extend the working life of various components. By following a consistent maintenance schedule, you can avoid costly repairs and maintain optimal performance.

Regular Inspections: It is important to conduct visual checks of all key elements to identify any signs of wear, damage, or corrosion. Look for loose connections, unusual noise, or any misalignment, as these can indicate the need for attention. Early detection of issues can save time and prevent more serious problems.

Lubrication: Keeping moving mechanisms well-lubricated is crucial for minimizing friction and reducing wear. Ensure all necessary areas are properly greased according to the manufacturer’s recommendations. Lack of lubrication can lead to premature wear and cause operational issues.

Tightening and Adjustments: Over time, certain fasteners and connections can loosen due to regular use. Periodically