In modern electric and gasoline-powered transport, understanding the layout of various mechanical and electrical elements is crucial for efficient maintenance and repairs. Whether you’re troubleshooting or simply looking to improve the performance of your vehicle, having a clear grasp of its internal design can help streamline the process. This overview provides a fundamental understanding of how different modules are interconnected, aiding in a smoother upkeep experience.

With a detailed overview of how different systems are connected, users can identify potential issues more efficiently and replace faulty elements with ease. Knowing how critical systems are organized allows for targeted repairs, saving both time and effort. By analyzing the structure of these elements, users can improve their understanding of the vehicle’s overall functionality.

Essential Components of the Ezgo RXV

Understanding the fundamental elements of this vehicle model is key to ensuring its proper function and maintenance. Each part plays a vital role in supporting efficient performance, and knowing how these pieces work together helps in troubleshooting and upkeep.

Power and Control Systems

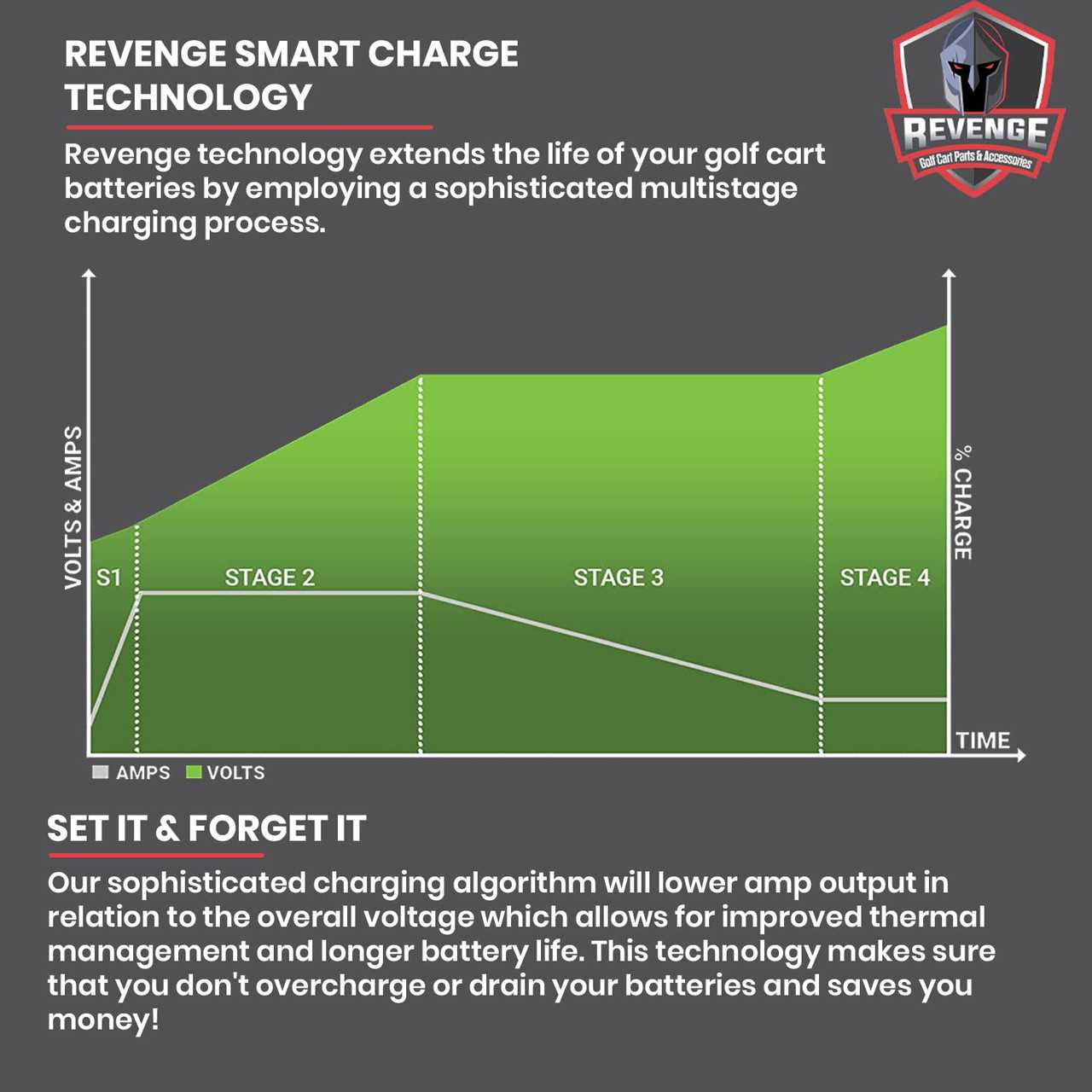

The driving mechanism relies heavily on the energy source and control modules. The battery pack supplies the necessary power, while the control unit manages acceleration, braking, and overall operation. Proper functioning of these systems is critical to the smooth operation of the vehicle.

Structural and Mechanical Elements

The structural integrity of the vehicle is supported by its chassis, steering system, and suspension components. These mechanical parts ensure both stability and maneuverability. Regular inspections of these elements can help maintain optimal performance and longevity.

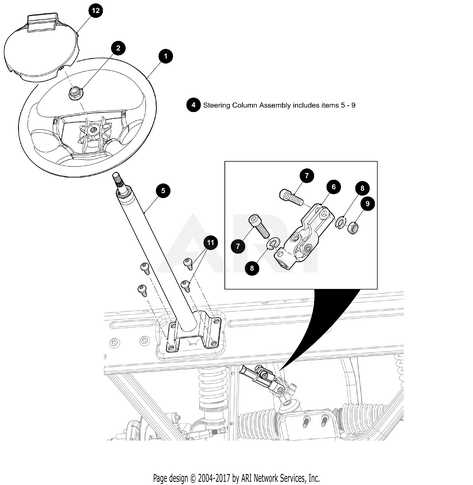

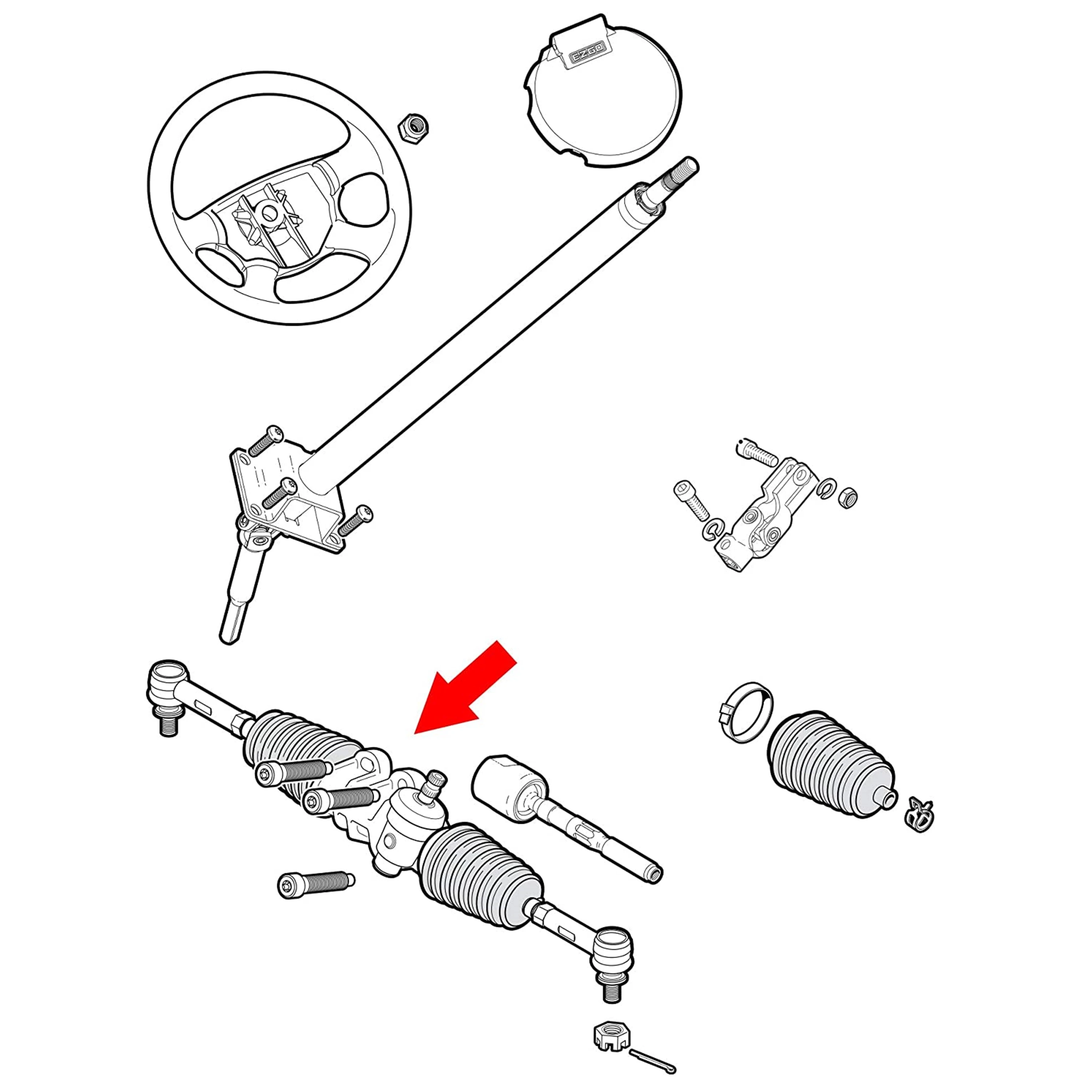

Understanding the Steering Mechanism

The steering system in electric vehicles ensures safe and precise control, allowing the driver to navigate effectively. Its structure involves interconnected components that work together to translate the driver’s movements into directional changes. Each part is essential for maintaining balance and accurate movement during turns and maneuvers.

| Component | Function | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steering Wheel | Initiates directional input from the driver | ||||||||||||||||||||||||||||||

| Steering Column | Transfers motion from the wheel to other mechanisms | ||||||||||||||||||||||||||||||

| Rack and Pinion | Converts rotational motion into linear movement | ||||||||||||||||||||||||||||||

| Steering Linkage |

| Component | Function | |

|---|---|---|

| Brake Pedal | Initiates the braking process by applying pressure to the system. | |

| Hydraulic Lines | Transmit force from the pedal to the brake components. |

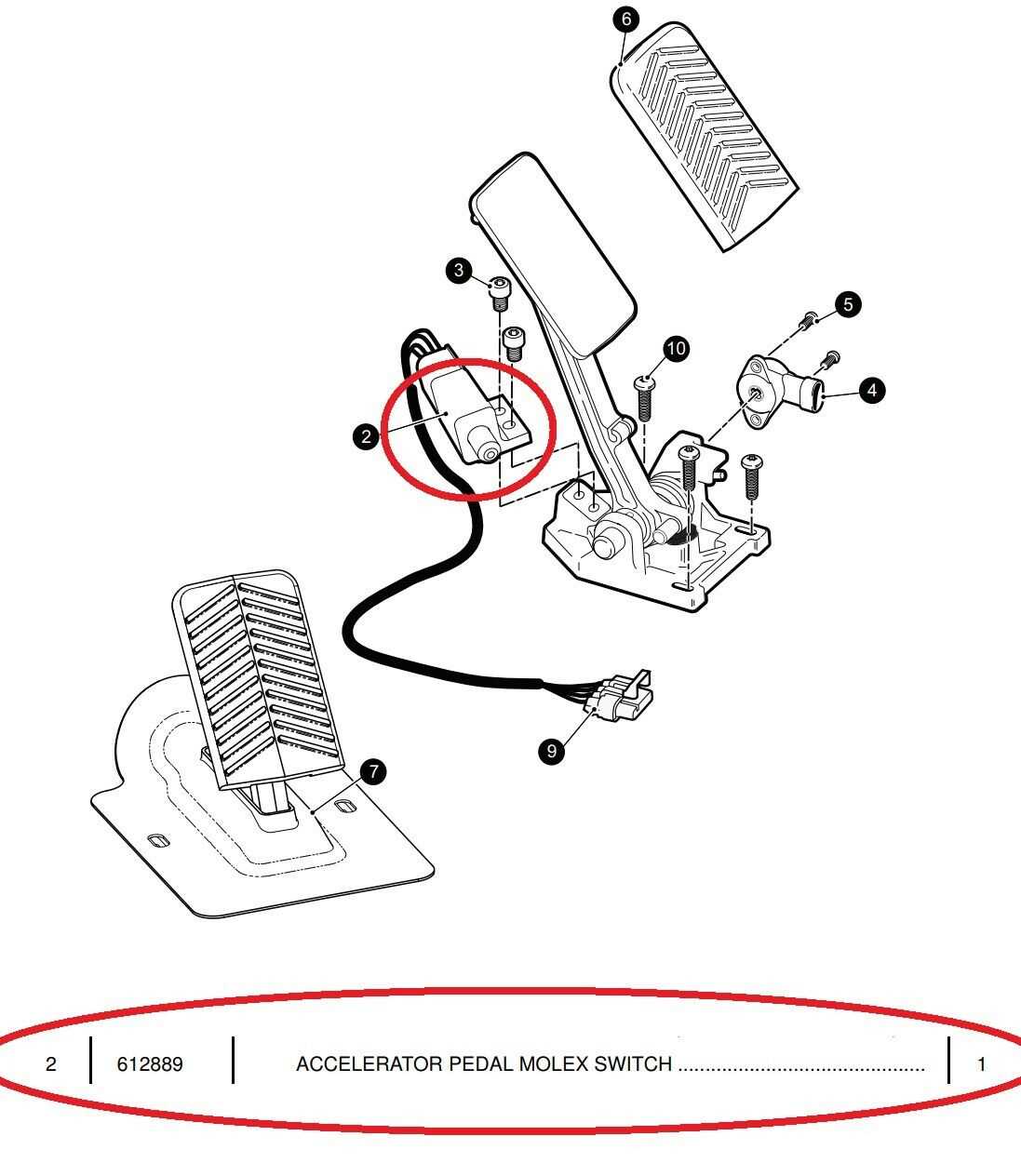

| Component | Description |

|---|---|

| Throttle Pedal | The primary interface used by the driver to control speed. |

| Linkage Mechanism | Connects the pedal to the electronic control system, translating pedal movement into speed adjustments. |

| Position Sensor | Monitors the pedal’s position and relays this information to the vehicle’s controller. |

| Mounting Bracket | Secures the assembly to the vehicle’s chassis, providing stability and support. |

Maintenance Considerations

Regular inspection and maintenance of the accelerator and pedal assembly are vital for ensuring reliable performance. Pay attention to any signs of wear or malfunction, as these can affect driving safety and efficiency. Proper lubrication and adjustment of components can help prolong the lifespan of this critical system.

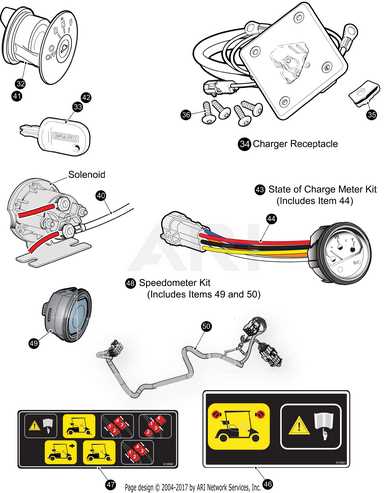

Key Wiring Connections and Configurations

Understanding the essential wiring links and layouts is crucial for effective maintenance and troubleshooting of electric vehicles. Proper configurations ensure that electrical systems function seamlessly, preventing potential issues that can arise from incorrect connections.

Here are the main wiring connections to consider:

- Battery Connections: Ensure that positive and negative terminals are correctly connected to avoid short circuits.

- Controller Wiring: Connect the controller securely to manage power distribution efficiently.

- Motor Links: Check the connections between the motor and controller to guarantee smooth operation.

When setting up these connections, follow these guidelines:

- Always disconnect the power supply before making any changes.

- Use appropriate gauges of wire to handle the current load.

- Regularly inspect connections for signs of wear or corrosion.

By adhering to these recommendations, one can maintain optimal performance and longevity of the electrical system.

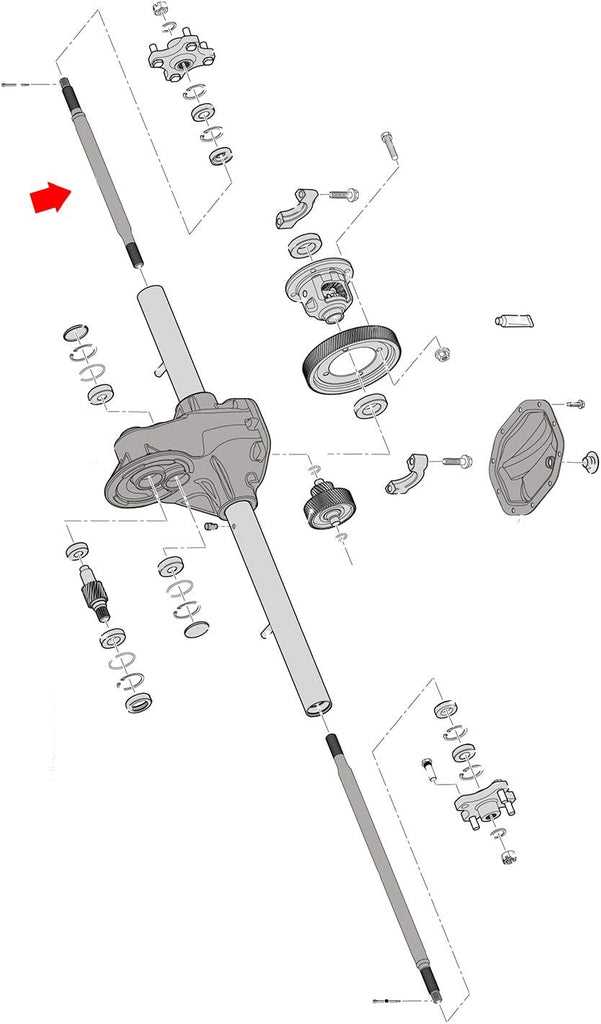

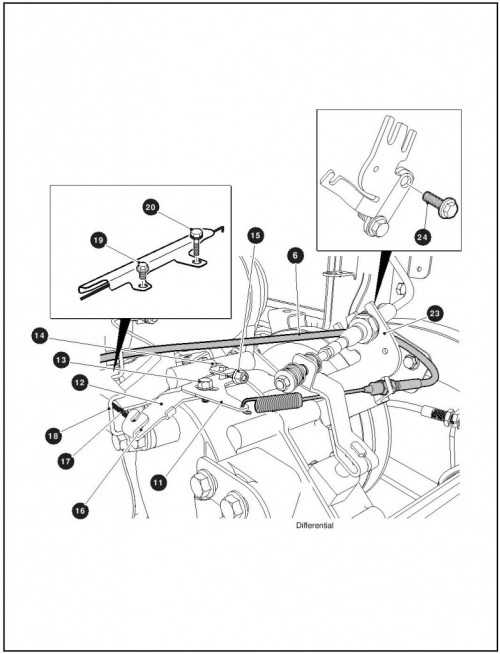

Rear Axle and Differential Components

The rear axle and differential assembly play a crucial role in the overall functionality of a vehicle’s drivetrain. This system is designed to transfer power from the engine to the wheels, ensuring smooth motion and effective handling. Understanding the components involved is essential for maintenance and troubleshooting, as they contribute significantly to the vehicle’s performance and stability.

The rear axle consists of several key elements, including the axle shafts, housing, and bearings. The axle shafts are responsible for transmitting torque from the differential to the wheels, while the housing provides structural support and houses the lubricant. Bearings facilitate smooth rotation and reduce friction between moving parts. The differential, on the other hand, allows the wheels to rotate at different speeds, particularly during turns, ensuring optimal traction and control.

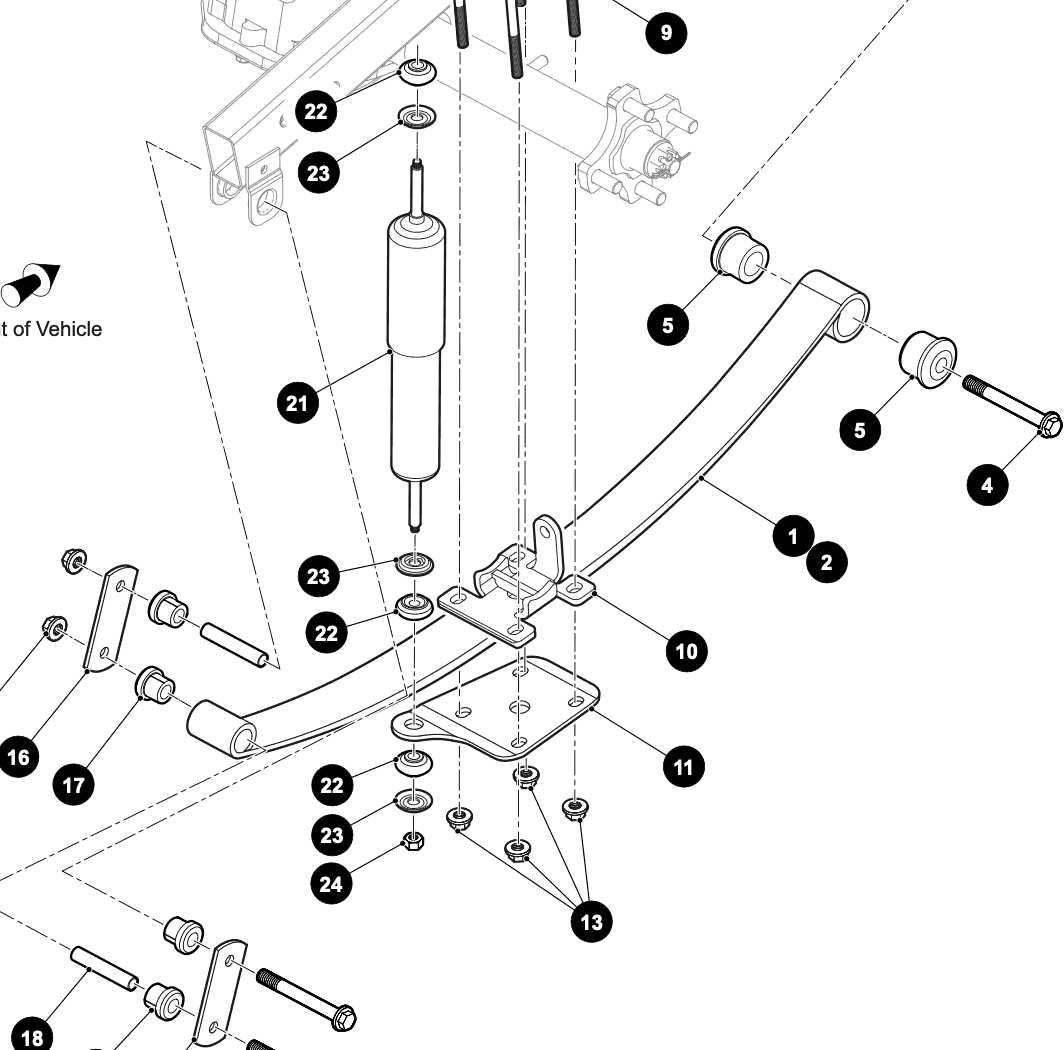

Front End Assembly Breakdown

The front assembly of a vehicle is crucial for ensuring stability, control, and overall performance. This section delves into the various components that comprise this essential area, highlighting their functions and interrelations. Understanding each part’s role can aid in maintenance and troubleshooting, enhancing the longevity of the vehicle.

The assembly typically includes elements such as the steering mechanism, suspension system, and wheel attachments. Each of these components works in harmony to provide a smooth and responsive driving experience. For instance, the suspension system absorbs shocks and ensures that the vehicle remains level during operation, while the steering mechanism allows for precise navigation.

Regular inspection and maintenance of the front assembly are vital. Identifying wear and tear on these components can prevent more significant issues down the line. By familiarizing oneself with the assembly’s structure and functionality, owners can make informed decisions about repairs and upgrades, ultimately improving the vehicle’s performance and safety.

Troubleshooting Common Issues with Ezgo RXV

Addressing frequent problems with electric vehicles can enhance performance and extend their lifespan. Understanding potential malfunctions and their symptoms is essential for effective resolution. By recognizing common challenges, users can take proactive measures to maintain functionality and prevent future disruptions.

The following table outlines typical issues encountered with electric models, their possible causes, and recommended solutions:

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| No Power | Dead battery, faulty wiring | Charge or replace the battery, check connections |

| Slow Speed | Low battery charge, worn components | Recharge battery, inspect and replace worn parts |

| Unusual Noises | Loose components, damaged motor | Inspect for loose parts, service or replace motor |

| Braking Issues | Worn brake pads, hydraulic fluid leak | Replace pads, check and refill hydraulic fluid |