Maintaining the proper equipment is essential for effective snow clearing. Knowing how different elements come together ensures that your setup operates smoothly, allowing you to manage even the heaviest conditions with ease. The importance of understanding each section of your system cannot be overstated.

Each mechanical system relies on a series of interconnected elements, and ensuring these are in top condition is vital for optimal performance. Familiarity with how these components fit together provides valuable insight into addressing potential issues before they become significant problems.

In this guide, we’ll break down the essential elements, explaining their function and how to ensure their proper alignment for the best performance. Keeping each part well-maintained can prevent wear and tear, saving time and resources during critical moments.

Fisher Homesteader Plow Overview

This equipment is designed to handle various outdoor tasks efficiently, providing reliable performance in demanding environments. It combines robust materials with an intuitive structure, ensuring ease of use and durability. The device is suitable for clearing surfaces of different sizes and types, with its versatile design allowing for effective operation in both residential and commercial settings.

Key features include a straightforward mechanism for quick setup and minimal maintenance, making it a popular choice for users seeking a balance between functionality and practicality. Its compact size and adaptable components contribute to its overall versatility, enabling smooth and controlled usage in a wide range of conditions.

Key Components of Fisher Plow

Understanding the essential elements of this snow-moving equipment helps to ensure optimal performance and durability. Each component is carefully designed to function harmoniously, ensuring smooth and efficient operation in demanding winter conditions.

Main Structural Elements

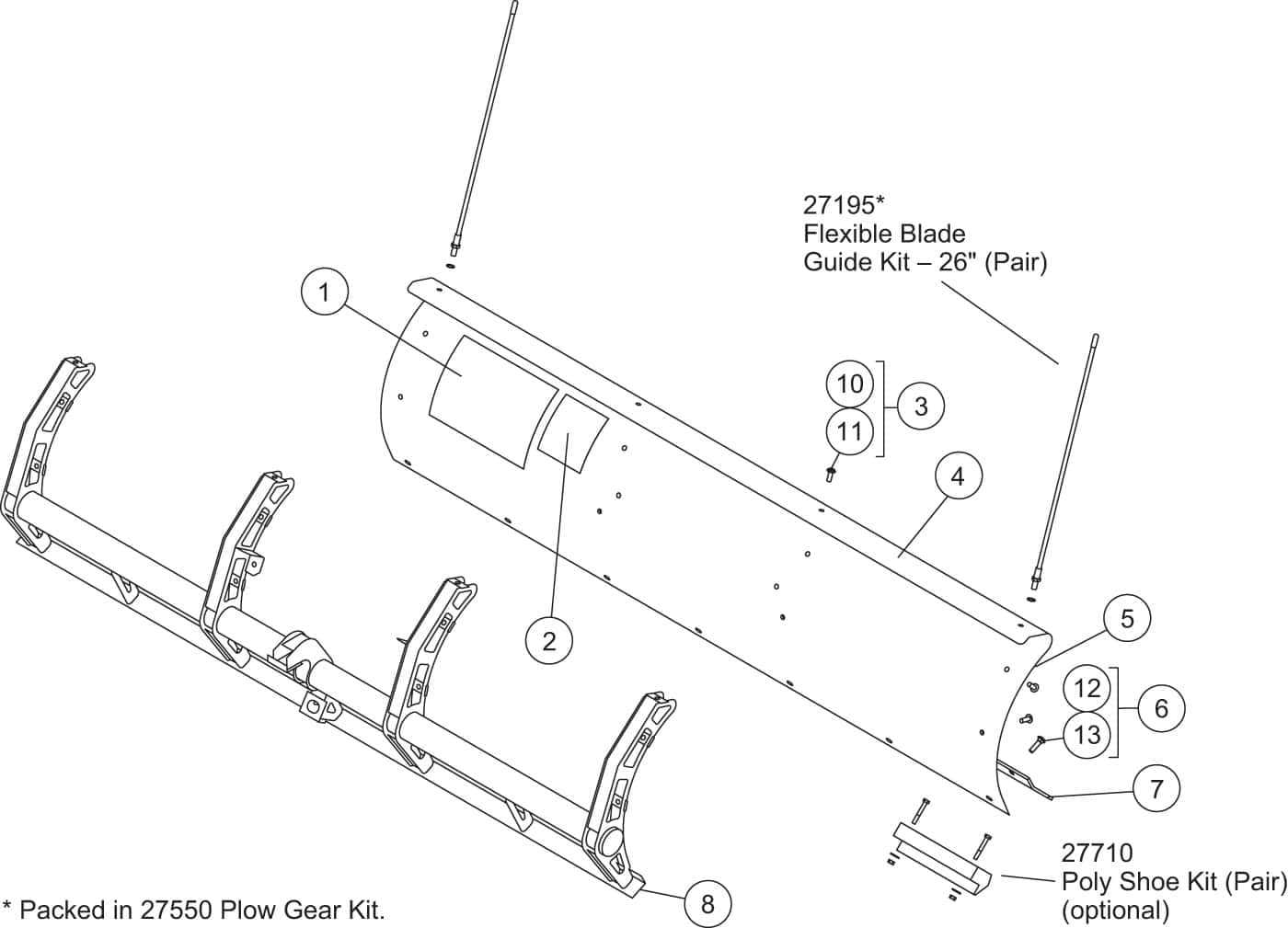

- Blade: The wide, curved structure designed to push and clear large amounts of snow. Its shape and material are crucial for durability and effectiveness in harsh environments.

- Mounting Frame: Provides a secure connection between the vehicle and the equipment, ensuring stability during operation.

- Cutting Edge: Positioned at the bottom of the blade, this replaceable part is responsible for scraping snow and ice off the surface, maintaining consistent contact with the ground.

Hydraulic and Control Systems

- Pump: Powers the movement, allowing for lifting and angling adjustments while clearing snow.

- Cylinders: Responsible for controlling the up and down, as well as side-to-side movements, offering flexibility and precise control.

- Control Module: This interface enables the driver to manage

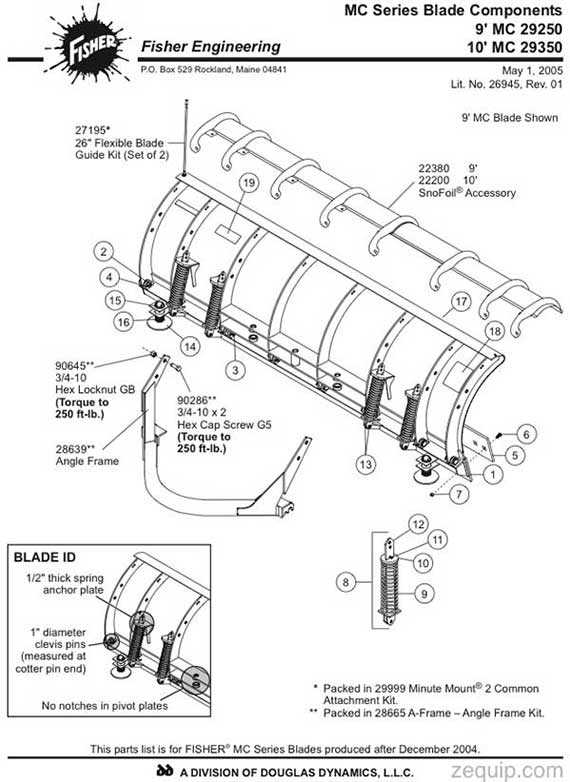

Blade Types and Attachments

Different blade designs and their respective attachments are essential for ensuring optimal performance across a variety of terrain and tasks. Understanding the unique characteristics of each blade type and how they connect to equipment is critical for efficient operation.

Blade Type Features Common Uses Straight Blade Simpler design, effective for basic tasks, easy to install. Ideal for light snow removal and flat surfaces. V-Shaped Blade Two angled sections that form a “V,” providing more versatile clearing options. Perfect for cutting through deep snow and ice buildup. Box Blade Enclosed sides for efficient containment and pushing material. Best for moving large amounts of snow or debris in one pass. Understanding the Hydraulic System

The hydraulic system is crucial for the efficient operation of heavy machinery, allowing for smooth and controlled movement of various components. By harnessing fluid power, the system ensures that tasks requiring significant force can be accomplished with precision and reliability.

Key elements in any hydraulic setup work together to create the necessary pressure and flow. Understanding how these parts interact is essential for maintaining optimal performance. Below is an overview of the main components and their roles:

- Pump: The pump is responsible for generating the flow of hydraulic fluid, which is essential for creating pressure in the system.

- Valves: Valves control the direction and amount of fluid flow, allowing for precise operation of machinery.

- Cylinders: Hydraulic cylinders convert the fluid pressure into mechanical force, enabling the movement of different components.

- Reservoir: The reservoir stores the hydraulic fluid, ensuring a consistent supply for the system.

- Hoses and Fittings: These components transport the fluid between various parts of the system, ensuring an uninterrupted flow.

Each of these components plays a vital role in ensuring that the system functions correctly, and understanding how they work together can help in troubleshooting and maintaining efficiency.

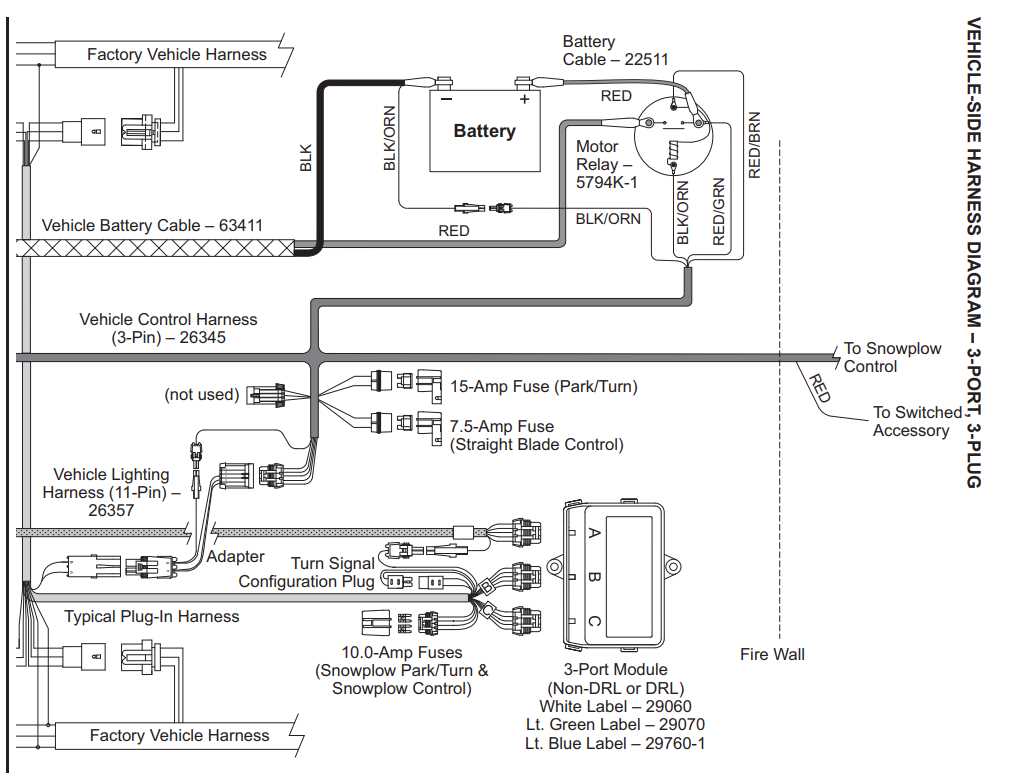

Wiring and Electrical Diagram Details

The electrical system is essential for ensuring the proper functionality of various components, connecting all critical elements through wiring. Understanding how the system is structured and how the different sections interact allows for efficient troubleshooting and repairs.

- Power distribution: Outlines how electricity is delivered to key systems.

- Grounding connections: Ensures safety by preventing electrical overloads.

- Control circuits: Provides control over mechanical and electronic elements.

- Lighting setup: Details the integration of lights and their power sources.

A clear understanding of these areas is crucial for maintaining and diagnosing electrical issues effectively.

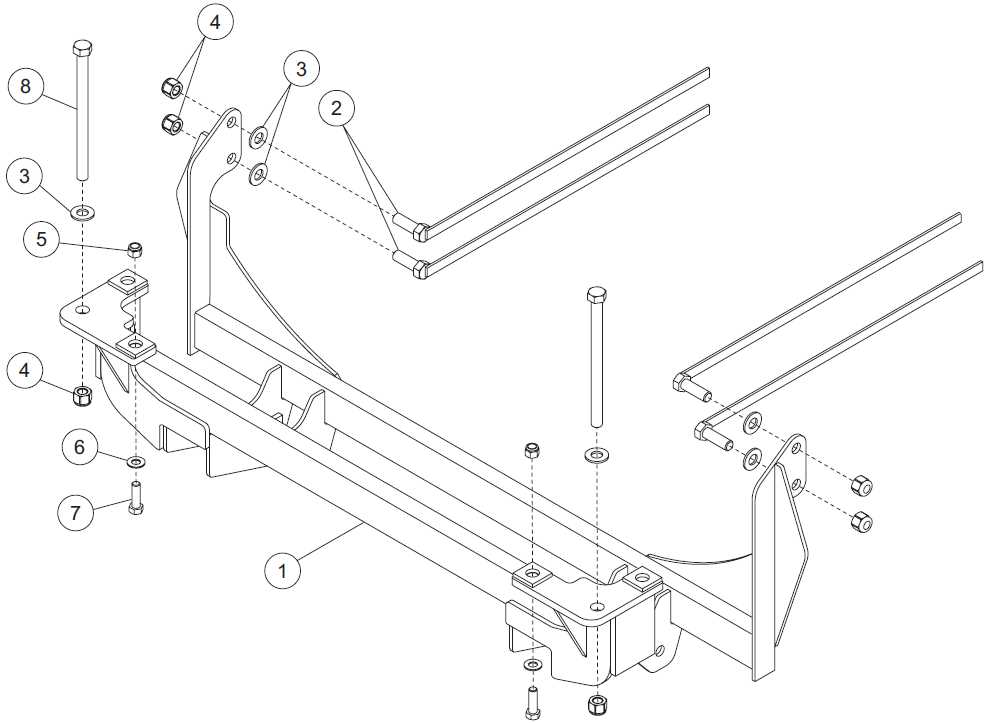

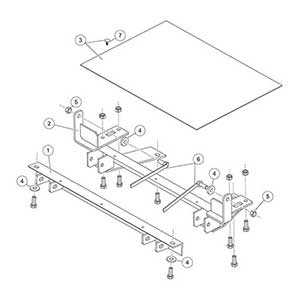

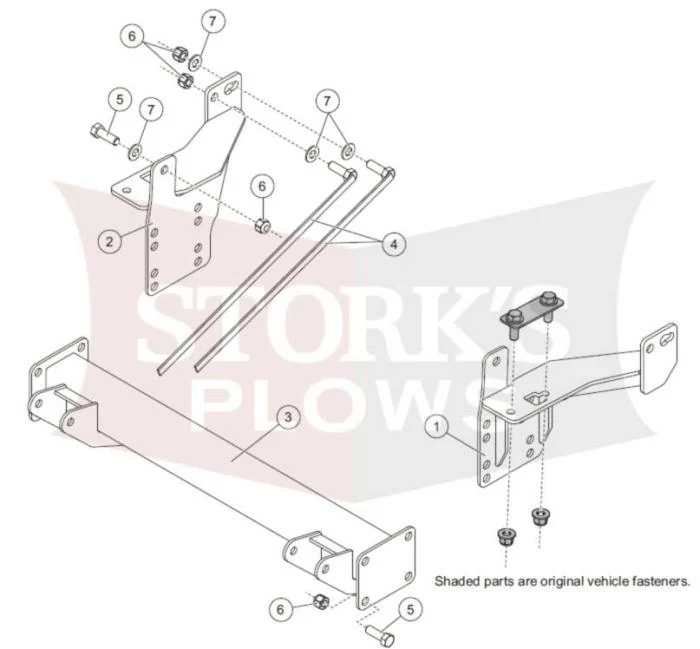

Frame Assembly and Mounting Parts

The structure of the assembly is crucial for ensuring stability and functionality during operation. This section outlines the various components that contribute to the overall integrity of the system, highlighting their roles and interconnections.

Frame Components consist of robust materials designed to withstand harsh conditions. Each element must be securely attached to maintain balance and prevent wear over time.

Mounting Elements play a vital role in connecting the assembly to the vehicle. Proper alignment and secure fastening are essential to ensure efficient performance and safety. Regular checks and maintenance of these components are recommended to avoid any operational issues.

Understanding the assembly’s structure and its components allows for better maintenance and troubleshooting. A thorough knowledge of these aspects enhances the overall performance and longevity of the system.

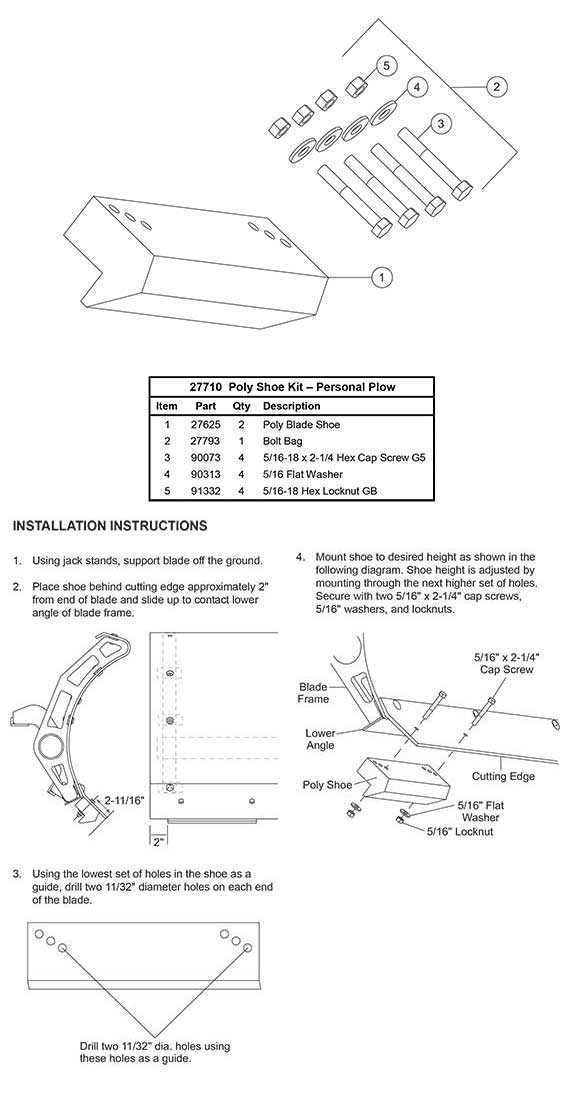

Cutting Edge Replacement Guide

Replacing the cutting edge of a snow removal tool is essential for maintaining optimal performance and efficiency. This guide outlines the steps and considerations necessary for a successful replacement, ensuring your equipment operates smoothly during winter conditions.

Understanding Wear and Tear

The cutting edge is subjected to significant wear over time due to constant contact with hard surfaces. Identifying signs of wear, such as uneven surfaces or decreased effectiveness in clearing snow, is crucial for timely replacement.

Gathering Necessary Tools

Before beginning the replacement process, gather the required tools, including wrenches, sockets, and a sturdy work surface. Ensuring you have everything on hand will streamline the replacement and minimize downtime.

Steps for Replacement

- Lift the Equipment: Elevate the tool using a jack or similar device to access the cutting edge safely.

- Remove the Old Edge: Carefully unscrew the worn cutting edge, taking note of the configuration for proper reinstallation.

- Install the New Edge: Align the new cutting edge in the same position as the old one and secure it firmly.

- Test the Installation: Lower the equipment and perform a test run to ensure everything is functioning correctly.

Regular Maintenance

To prolong the lifespan of the new cutting edge, regular maintenance is essential. Inspect the edge frequently and perform adjustments or replacements as needed, ensuring consistent performance throughout the season.

Snow Deflector and Guard Options

When preparing for winter conditions, having the right accessories can significantly enhance performance and efficiency. Various options exist to optimize the effectiveness of equipment, ensuring that snow is managed effectively. Among these options, deflectors and guards play a crucial role in directing snowfall and minimizing debris buildup.

Snow Deflectors are designed to redirect snow away from the operator and machinery. These accessories can be adjustable, allowing users to modify their angle based on specific weather conditions. By directing snow further from the equipment, they help maintain visibility and improve overall handling during operation.

Guard systems provide additional protection for critical components, reducing wear and tear caused by harsh elements. These installations can prevent snow and ice from accumulating on sensitive areas, ensuring optimal functionality and extending the lifespan of the equipment. Choosing the right guard option depends on the environment and specific needs of the user.

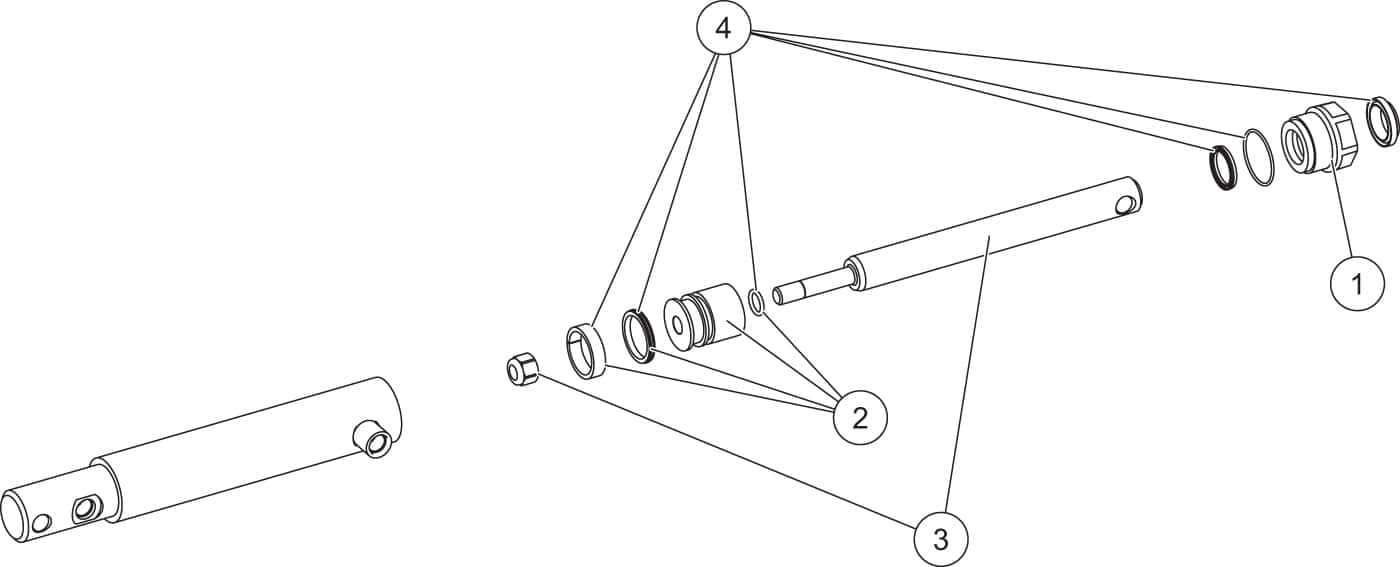

Angle Cylinders and Control Mechanisms

The effective operation of various agricultural equipment relies on the precision and reliability of their hydraulic systems. Key components, including specific angle actuators and associated control systems, play a significant role in ensuring optimal functionality. These elements work together to facilitate smooth adjustments and enhance overall performance, allowing operators to achieve desired results with ease.

Components of Angle Actuators

Angle actuators are crucial for adjusting the positioning of attachments and implements. Understanding their structure is essential for maintenance and troubleshooting. Common features include:

Component Description Hydraulic Cylinder Converts hydraulic pressure into mechanical force for movement. Piston Moves within the cylinder, driving the actuator’s action. Seals Prevent fluid leaks, ensuring efficient operation. Mounting Brackets Securely attach the actuator to the main structure. Control Mechanisms Overview

Control mechanisms allow the operator to manipulate the angle actuators effectively. These systems can vary based on the equipment type but typically include manual and automated options. Key aspects are:

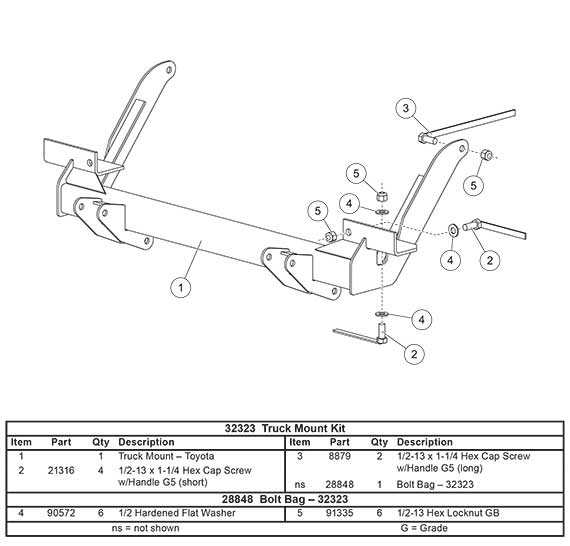

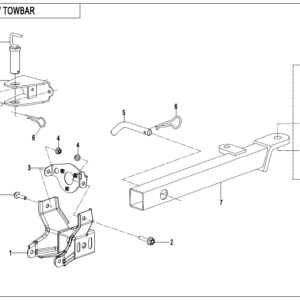

Control Type Function Manual Levers Enable direct operator control over adjustments. Electronic Controls Provide precision and automation for enhanced accuracy. Feedback Sensors Monitor and relay position information for adjustments. Hydraulic Valves Regulate fluid flow to the actuators for movement control. Hitch Assembly and Installation Tips

Understanding the assembly and proper installation of a towing mechanism is crucial for ensuring safe and efficient operation. This section provides guidance on assembling the hitch and tips for a successful installation, enhancing the overall functionality of your equipment.

- Gather Necessary Tools: Before starting, ensure you have all the required tools at hand. Common tools include wrenches, sockets, and pliers.

- Read the Instructions: Always consult the manufacturer’s instructions for specific assembly steps and recommendations. This can prevent mistakes and ensure compliance with safety standards.

- Check Components: Inspect all components for damage or wear. Replace any parts that show signs of deterioration to ensure optimal performance.

- Follow Assembly Order: Adhere to the recommended assembly order outlined in the instructions. This helps maintain the integrity and alignment of the hitch.

- Secure Fasteners: Make sure all bolts and fasteners are tightened properly. A loose connection can lead to instability during operation.

- Test the Assembly: After installation, perform a thorough test of the hitch to confirm it is secure and functions as intended. Look for any unusual movements or noises.

Following these tips will help ensure that your towing mechanism is assembled and installed correctly, providing reliability and safety during use.

Maintenance Tips for Longevity

To ensure the prolonged functionality of your equipment, regular upkeep is essential. Implementing effective maintenance practices not only enhances performance but also extends the lifespan of your machinery.

Here are some key maintenance strategies to consider:

- Regular Inspections: Routinely check components for wear and tear. Look for signs of damage, rust, or misalignment.

- Cleaning: Keep surfaces free from debris and dirt. Regular cleaning prevents corrosion and mechanical issues.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent wear.

- Proper Storage: Store equipment in a sheltered environment to protect it from harsh weather conditions.

- Timely Repairs: Address any issues immediately to avoid further damage. Replace worn-out parts without delay.

By following these maintenance tips, you can ensure that your equipment operates efficiently and lasts for many seasons to come.

Where to Find Replacement Parts

Locating suitable components for your agricultural equipment can enhance its functionality and lifespan. Various avenues exist for sourcing these essential items, ensuring that you can maintain optimal performance during your tasks.

One of the most reliable options is to explore local retailers specializing in farming supplies. These stores often carry a range of inventory tailored to specific machinery. Additionally, you may consider visiting authorized dealers who provide original components, guaranteeing compatibility and quality.

Online marketplaces are another valuable resource. Websites dedicated to farming equipment or general e-commerce platforms offer a wide selection of items, often at competitive prices. When purchasing online, it is advisable to check customer reviews to ensure the reliability of the seller.

Moreover, connecting with local agricultural communities can lead to useful recommendations. Fellow farmers often share their experiences and may know of reliable sources for obtaining necessary items. Joining online forums or social media groups dedicated to farming can also facilitate valuable discussions.

Lastly, do not overlook salvage yards that specialize in agricultural machinery. These locations can be treasure troves for second-hand components that are still in excellent condition, providing an affordable alternative for those on a budget.