When it comes to efficient winter operations, grasping the intricate elements of a snow clearing mechanism is essential. This guide will help you explore the various components that contribute to the ultimate performance of such systems, ensuring smooth functionality and reliability.

Each segment plays a vital role, working in harmony to tackle challenging weather conditions. By examining the structure and function of these individual elements, operators can optimize their equipment, leading to enhanced productivity and longevity.

Moreover, familiarizing oneself with the layout and relationships between these components allows for effective troubleshooting and maintenance. This knowledge not only empowers users but also ensures a seamless snow management experience.

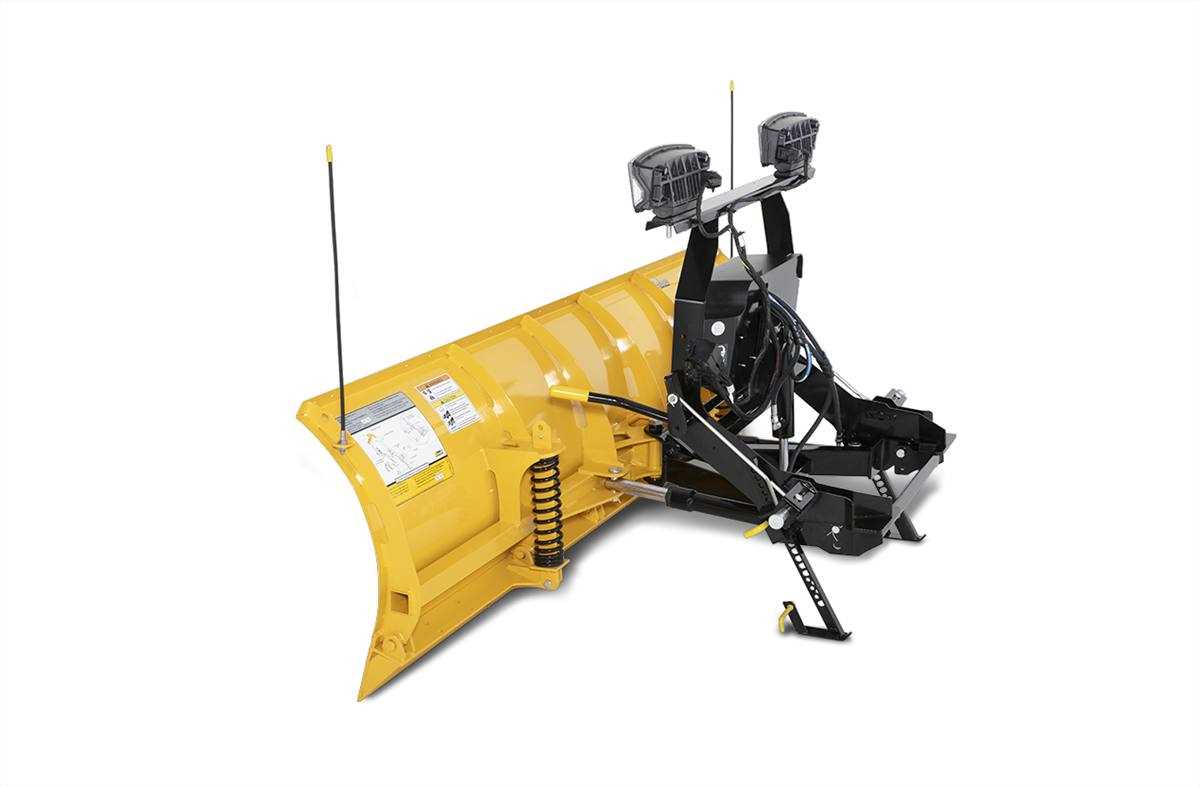

Understanding Fisher Xtreme V Plow

This section provides an in-depth look at a specialized snow removal attachment designed for versatility and efficiency. It is engineered to tackle various winter challenges, ensuring optimal performance in harsh conditions. The structure and functionality of this tool are essential for both professional and residential use.

The design features a unique configuration that allows for multiple positioning options, making it suitable for diverse terrains. Users can benefit from its robust build, which enhances durability and reliability during heavy snowfall. Understanding the key components is crucial for effective operation and maintenance.

| Component | Description |

|---|---|

| Blade | Made from high-strength materials for maximum resistance and efficiency. |

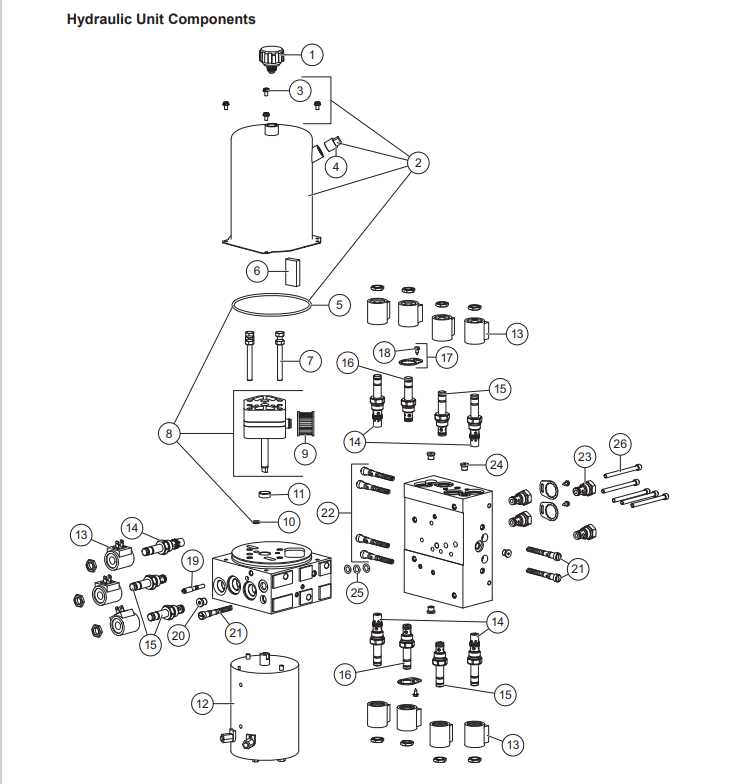

| Hydraulic System | Enables quick adjustments and responsiveness to varying snow conditions. |

| Mounting Frame | Provides secure attachment to the vehicle, ensuring stability during operation. |

| Control Mechanism | Allows the operator to easily maneuver and set the angle of the blade. |

Proper knowledge of these elements can enhance user experience, ensuring that the equipment operates smoothly throughout the winter months. Regular maintenance and understanding of functionality will contribute to longevity and effectiveness, making it a valuable investment for snow management.

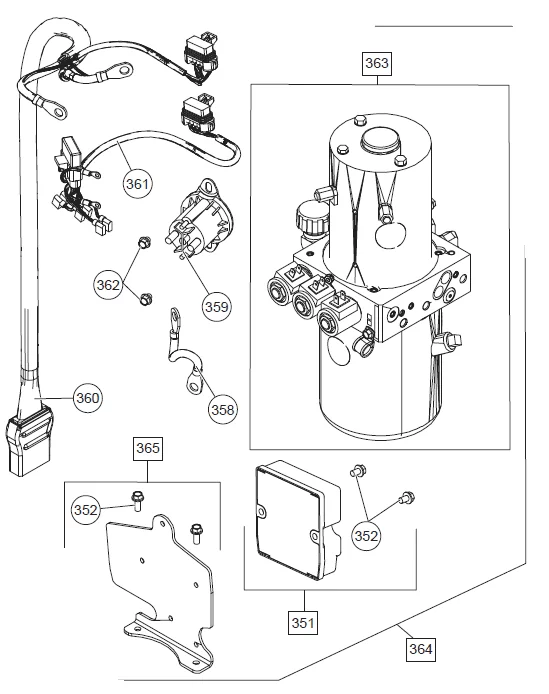

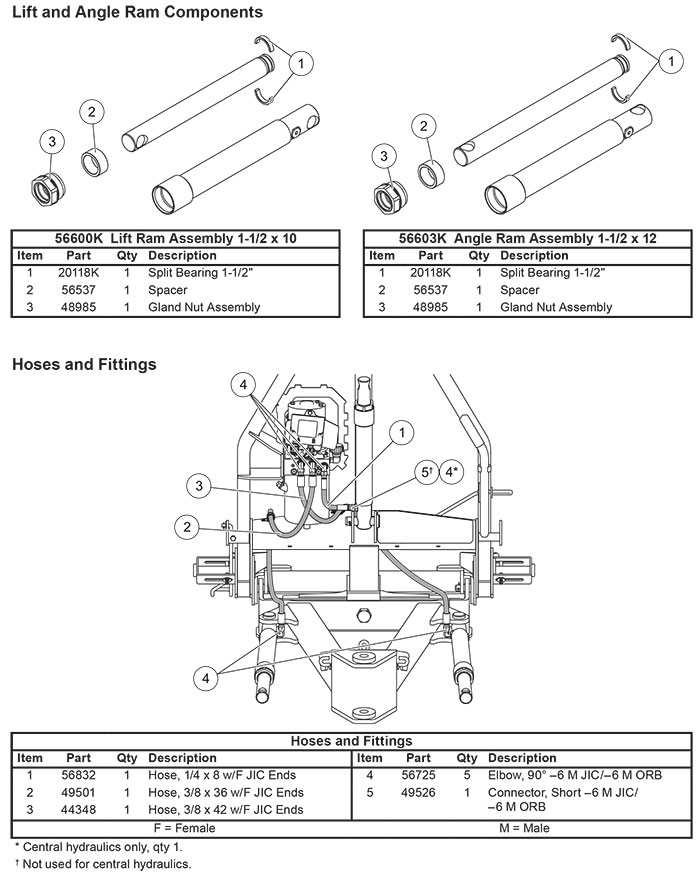

Key Components of the Plow System

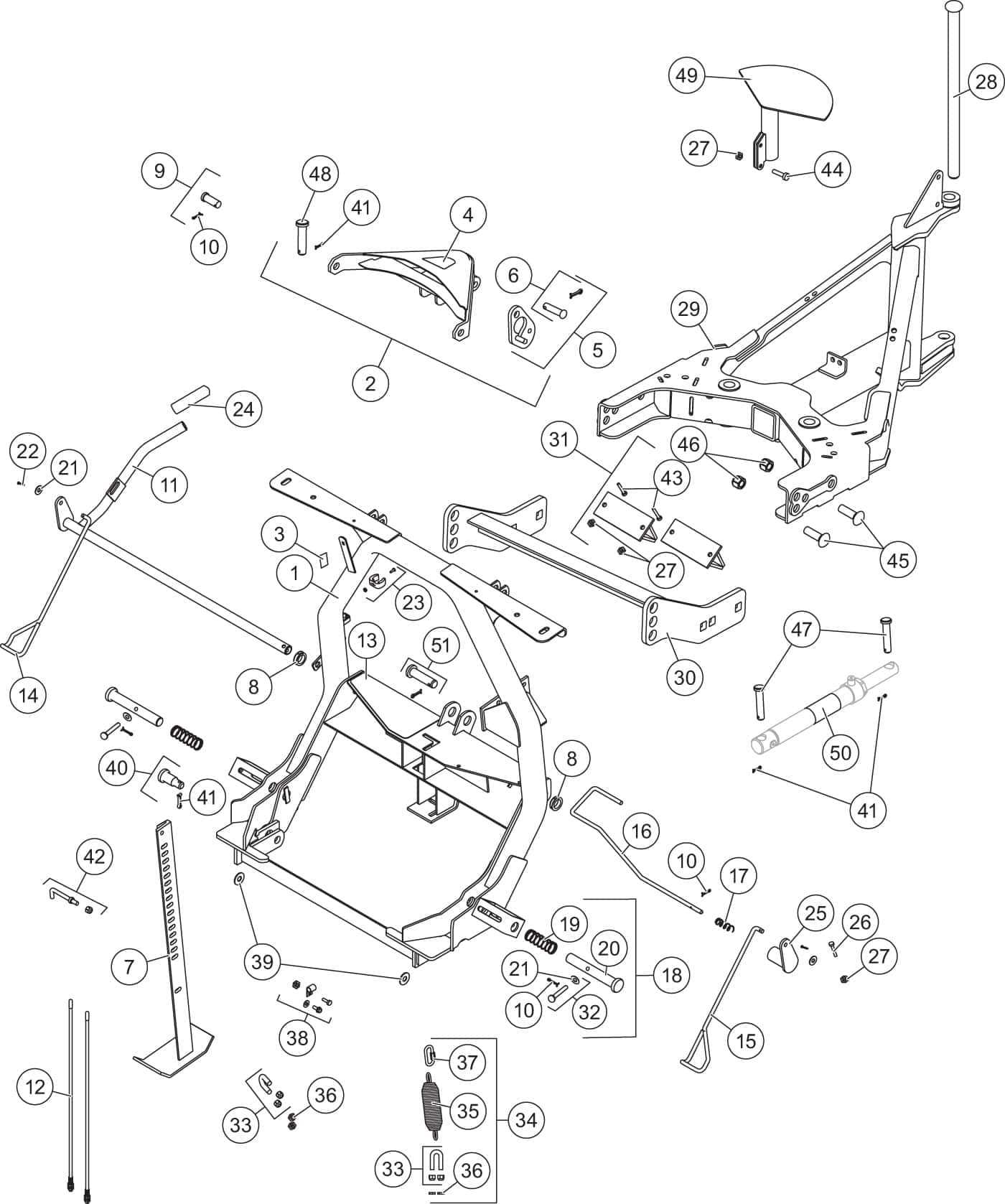

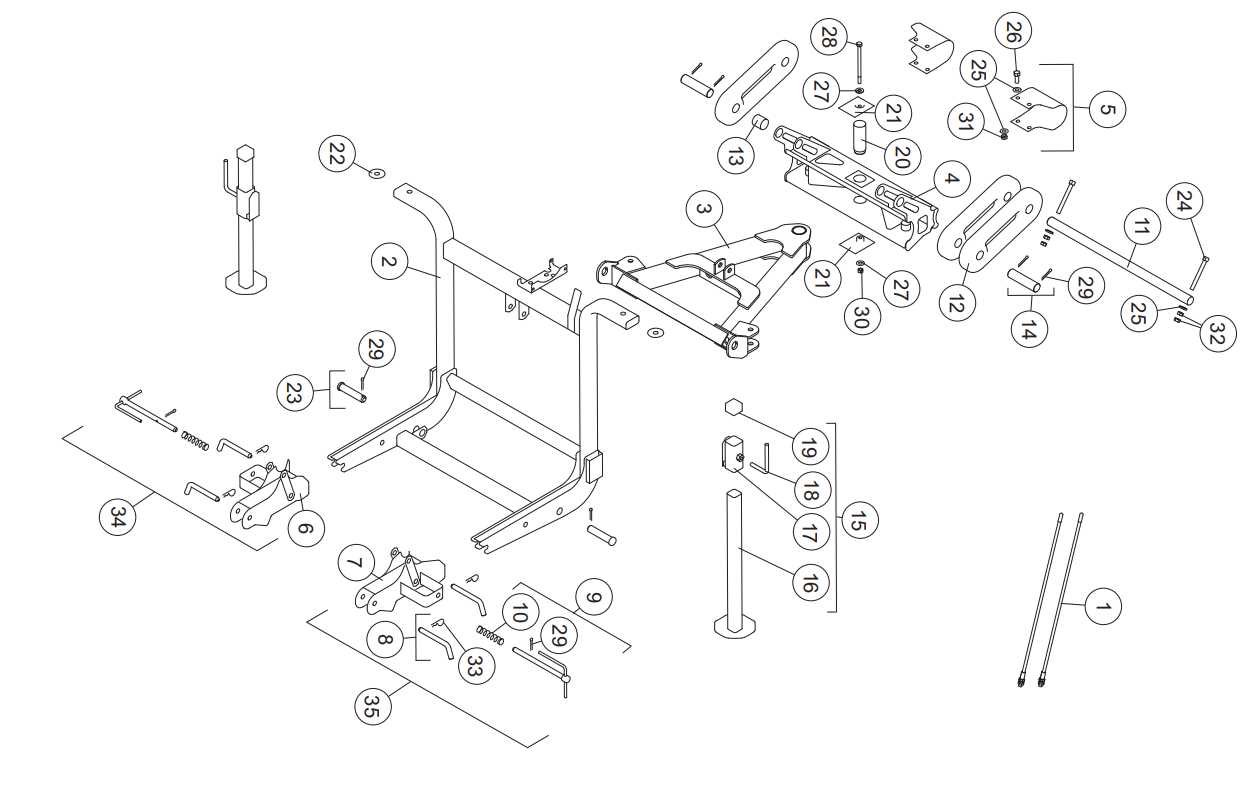

Understanding the essential elements of a snow-clearing mechanism is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance during winter conditions, contributing to the overall efficiency and reliability of the system.

Primary Elements

The core features of this apparatus include the framework, the lifting mechanism, and the blade. Each part interacts seamlessly to facilitate maneuverability and force distribution, making the entire system function smoothly.

Supporting Components

In addition to the main features, there are several auxiliary elements that enhance functionality. These include hydraulic systems, electrical components, and safety mechanisms, all of which ensure the apparatus operates safely and efficiently.

| Component | Description |

|---|---|

| Framework | Provides structural support and stability. |

| Lifting Mechanism | Enables raising and lowering of the blade. |

| Blade | Clears snow and ice from surfaces. |

| Hydraulic System | Controls the movement and positioning of the blade. |

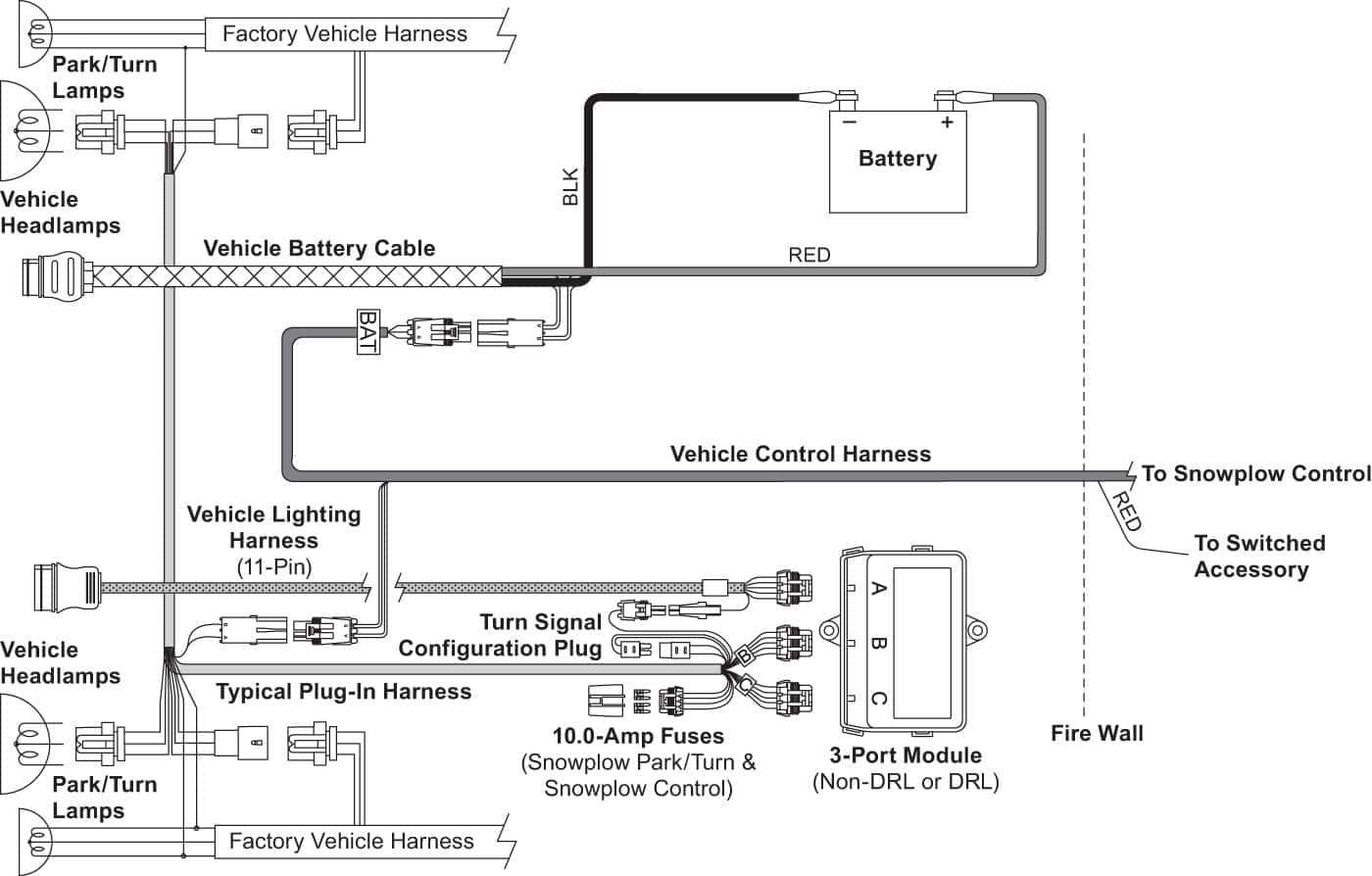

| Electrical Components | Powers lights and controls for operation. |

| Safety Mechanisms | Ensures safe operation under various conditions. |

Benefits of Using Xtreme V Plow

Utilizing a versatile snow removal tool can significantly enhance efficiency and performance during winter weather conditions. Such equipment is designed to tackle various challenges, providing users with effective solutions for clearing snow and ice, ensuring safety and accessibility on roads and driveways.

Enhanced Maneuverability

One of the key advantages of this innovative equipment is its ability to adapt to different environments. The unique shape allows for improved control and flexibility, making it easier to navigate tight spaces and corners. This feature is particularly beneficial for residential areas and commercial lots, where precision is crucial.

Durability and Performance

Constructed from high-quality materials, this tool offers exceptional strength and resilience against harsh winter conditions. Users can rely on its performance season after season, reducing the need for frequent replacements. The robust design ensures that it can handle heavy snow loads, making it an ideal choice for even the most demanding tasks.

In summary, opting for this type of snow-clearing equipment not only boosts operational efficiency but also guarantees longevity and reliable performance, making winter maintenance simpler and more effective.

Common Issues and Troubleshooting Tips

Operating equipment for snow removal can sometimes lead to unexpected challenges. Identifying and resolving these issues efficiently is essential for maintaining performance and safety. Below are some common problems users might encounter and practical solutions to address them.

Frequent Problems

- Inconsistent performance or lack of response

- Hydraulic leaks or irregular fluid levels

- Electrical failures in controls

- Unusual noises during operation

Troubleshooting Steps

- Check Connections: Ensure all electrical connections are secure and free from corrosion.

- Inspect Fluid Levels: Regularly check hydraulic fluid levels and look for signs of leaks.

- Examine Components: Look for wear and tear on critical parts and replace them as needed.

- Test Controls: Confirm that the control mechanisms respond correctly and adjust if necessary.

By staying proactive and attentive to these common issues, operators can enhance reliability and extend the lifespan of their equipment.

Importance of Regular Maintenance

Consistent upkeep of equipment is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to unexpected failures, costly repairs, and reduced efficiency. By prioritizing regular checks and servicing, users can enhance the reliability of their machinery and prevent potential issues before they arise.

Benefits of Preventive Care

Engaging in systematic maintenance practices offers numerous advantages. First, it significantly decreases the likelihood of breakdowns, which can disrupt operations and incur high repair expenses. Additionally, well-maintained equipment often operates more efficiently, consuming less energy and thereby lowering operational costs. Regular inspections also provide opportunities to identify wear and tear early, allowing for timely replacements and adjustments.

Enhanced Safety and Performance

Safety is another vital aspect linked to the maintenance of machinery. Properly serviced equipment reduces the risk of accidents caused by mechanical failures, ensuring a safer working environment for operators. Furthermore, maintaining machinery in peak condition enhances its overall performance, allowing it to meet the demands of various tasks effectively.

In conclusion, dedicating time and resources to regular maintenance is an investment that pays off through improved functionality, safety, and cost savings. Adopting a proactive approach can lead to significant long-term benefits, making it essential for all equipment users.

Choosing the Right Replacement Parts

Selecting the appropriate components for your equipment is essential for optimal performance and longevity. Ensuring compatibility and quality will not only enhance efficiency but also reduce the risk of future issues.

Factors to Consider

- Compatibility with existing machinery

- Quality of materials used

- Manufacturer reputation

- Cost-effectiveness versus quality

Where to Find Reliable Components

- Authorized dealers and suppliers

- Online marketplaces with verified ratings

- Local equipment service centers

- Manufacturer websites for original components

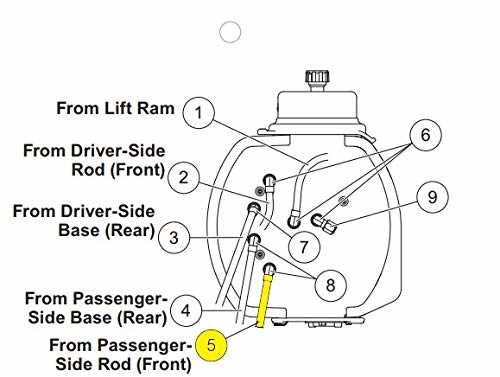

How to Read the Parts Diagram

Understanding a schematic can greatly enhance your ability to maintain and repair equipment. By familiarizing yourself with the visual layout and nomenclature, you can identify components and their relationships, ultimately facilitating smoother operations.

Here are key steps to effectively interpret a schematic:

- Identify the Key: Locate the legend that explains symbols used within the layout.

- Follow the Flow: Observe the connections and flow between various elements to grasp their function.

- Note Annotations: Pay attention to any notes or references that provide additional information on specific components.

By practicing these techniques, you’ll be able to delve deeper into maintenance tasks with confidence.

Installing New Plow Components Safely

Ensuring the safe installation of new equipment is crucial for optimal performance and longevity. Proper procedures and precautions not only protect the user but also enhance the functionality of the gear. Below are key considerations and steps to follow during installation.

Preparation Steps

- Read the manufacturer’s instructions thoroughly before beginning.

- Gather all necessary tools and components to avoid interruptions.

- Ensure you are working in a well-ventilated area, free from distractions.

Safety Precautions

- Wear appropriate personal protective equipment, including gloves and safety goggles.

- Check that the equipment is turned off and disconnected from power sources.

- Use a sturdy workbench or surface to secure components during installation.

By adhering to these guidelines, you can significantly reduce the risk of accidents and ensure a successful assembly process.

Comparing Xtreme V to Other Models

This section explores the differences between a specific multifunctional tool and its competitors in the market. By examining various features, users can determine which option best meets their needs.

Design and Functionality

- Innovative shapes enhance snow management efficiency.

- Versatility allows for multiple applications beyond standard tasks.

- Weight distribution impacts performance and handling.

Performance in Diverse Conditions

- Adaptability to varying terrains and snow types.

- Durability under extreme weather conditions.

- Speed and efficiency in clearing operations.

Ultimately, understanding these differences can help users make informed choices based on their specific requirements and preferences.

Frequently Asked Questions About Plows

This section addresses common inquiries regarding snow removal equipment, offering insights into functionality, maintenance, and usage. Understanding these aspects can help users make informed decisions and enhance their experience with their tools.

Common Inquiries

- What types of equipment are available for snow clearing?

- How do I choose the right model for my needs?

- What maintenance is required for optimal performance?

Maintenance and Care

- Inspect blades regularly for wear and damage.

- Ensure all moving parts are lubricated.

- Store the equipment properly during off-seasons.

These considerations will help ensure longevity and effectiveness, making winter tasks more manageable.

Upgrading Your Plow for Better Performance

Enhancing your equipment can significantly improve its efficiency and effectiveness. By integrating advanced components and technologies, you can achieve superior results in various conditions. This guide will explore the key upgrades that can elevate your system’s performance.

Key Upgrades to Consider

When looking to enhance your setup, consider focusing on the following areas:

| Upgrade | Benefit |

|---|---|

| Improved Blade Material | Increased durability and cutting efficiency. |

| Enhanced Control Systems | Smoother operation and responsiveness. |

| Advanced Hydraulic Components | Faster lifting and angling capabilities. |

| Lighting Solutions | Better visibility during nighttime or low-light conditions. |

Conclusion

Investing in the right enhancements can lead to remarkable improvements in your equipment’s functionality. By carefully selecting upgrades, you will ultimately experience a more productive and reliable operation.

Customer Experiences and Reviews

Understanding user feedback is crucial for evaluating the quality and effectiveness of any equipment. Insights from individuals who have firsthand experience provide invaluable information about performance, reliability, and overall satisfaction. This section explores various customer opinions, highlighting their experiences and key takeaways.

Positive Feedback

- Many users commend the durability and resilience of the equipment, noting that it withstands harsh conditions with ease.

- Several customers appreciate the ease of installation, making the setup process straightforward and hassle-free.

- Users frequently mention the impressive performance in terms of efficiency and speed, especially during heavy-duty tasks.

Areas for Improvement

- Some customers express concerns about the weight, stating that it can be challenging to maneuver in tight spaces.

- A few users suggest that the user manual could be more detailed, as they encountered difficulties during initial assembly.

- Some reviews highlight the need for additional accessories to enhance functionality and versatility.