Understanding the structure of a modern filtration system is crucial for maintaining optimal performance and longevity. The combination of various elements within the device ensures efficient water circulation, debris removal, and overall aquatic health. Knowing the arrangement and purpose of each element can significantly simplify both maintenance and troubleshooting.

Each section of the system plays a vital role in ensuring smooth operation, from the mechanical filters to the intricate network of seals and valves. Proper alignment of these components is essential for achieving a reliable and long-lasting setup. Whether you are conducting regular maintenance or replacing specific elements, a clear understanding of the assembly is key.

Detailed knowledge about the individual segments of the filtration system also helps in ensuring proper care. By identifying the purpose and function of each component, you can ensure that your setup continues to operate at peak efficiency.

Filter Components Overview

The filtration system is designed with multiple elements that work together to ensure efficient water cleaning. These components are engineered to provide both mechanical and biological filtration, maintaining optimal water quality in aquariums of various sizes.

Main Structural Elements

The core of the system includes a powerful motor and impeller that drive the water through various layers of media. The outer casing provides a secure housing for all internal mechanisms, ensuring durability and ease of use during setup and maintenance.

Filtration Media and Circulation

Inside the unit, several trays hold different types of media, each responsible for a specific filtration task. Water passes through these trays, where debris is trapped, and beneficial bacteria can thrive, helping to maintain a balanced environment for aquatic life.

Key Parts of the Fluval FX6 System

The advanced filtration setup is built around several crucial elements that ensure efficient water circulation and thorough cleaning. These components work together to provide optimal performance, supporting the health of aquatic environments. Each element has a specific role in maintaining water clarity, debris removal, and biological balance.

Main Components of the Filtration System

The system includes various elements designed to maximize water flow and filtration efficiency. Each of these plays a unique part in the process of water purification.

| Component | Function |

|---|---|

| Canister | Holds the filtration media and facilitates the movement of water through the system. |

| Impeller | Drives water circulation, ensuring a consistent flow rate within the system. |

| Valves | Control the direction and flow of water, enabling easy maintenance and regulation. |

Additional Elements for Optimal Performance

Other supporting components contribute to the overall efficiency, including various hoses, clamps, and seals that prevent leaks and maintain proper water flow.

Understanding the Motor Function in FX6

The motor is the core of any filtration system, driving the movement of water through the device. It ensures the constant circulation necessary for efficient cleaning and oxygenation of the tank. By maintaining a steady flow, the motor helps to keep the aquatic environment balanced and healthy.

One of the key aspects of motor functionality is its ability to operate continuously without interruptions. This is crucial for avoiding the buildup of debris and ensuring that all parts of the system function properly. Regular maintenance and monitoring of the motor’s performance are important to prevent any issues that could affect the system’s overall efficiency.

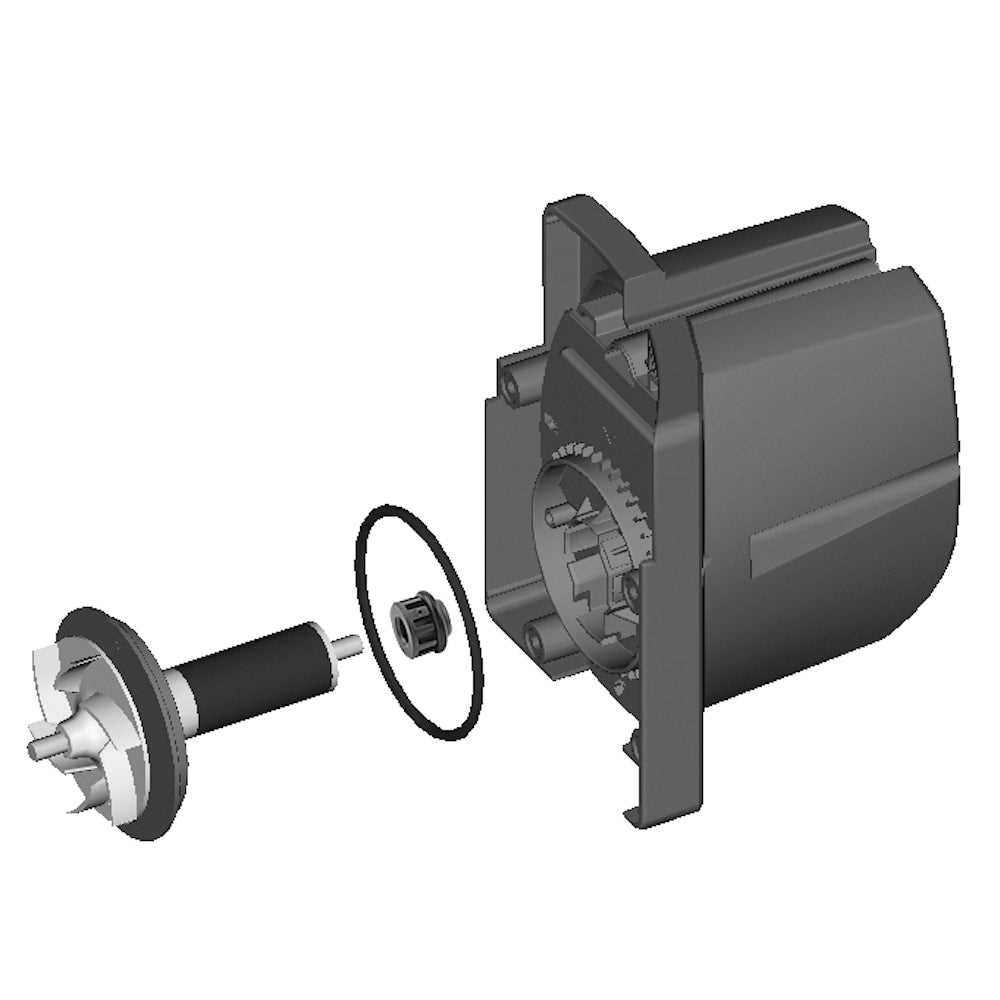

How to Replace the FX6 Impeller

Over time, the rotating element of the filtration system may experience wear and require replacement. Ensuring the smooth operation of your water filter is essential for maintaining a healthy aquatic environment. Below is a step-by-step guide to help you replace this crucial component efficiently.

Step 1: Power Down and Disassemble

Before beginning the replacement, disconnect the device from its power source. Carefully remove the top section of the unit, exposing the internal components. Ensure the system is free of water to avoid any spills during the process.

Step 2: Remove the Old Impeller

Locate the impeller within the system. Gently detach the cover securing it and slide the old piece out of its chamber. Take note of how the component is positioned to ensure proper installation of the new one.

- Ensure the impeller chamber is clean and free of debris.

- Inspect other nearby parts for wear and tear.

- Insert the new impeller carefully into the chamber.

- Secure the cover back in place, ensuring a snug fit.

- Reassemble the top section of the unit and check all connections.

Once reassembled, power up the device and monitor for any unusual noises or malfunctions. If everything operates smoothly, the replacement was successful.

Examining the Canister Structure

The canister system is designed to provide efficient water filtration by housing various components in an organized and compact unit. Understanding the layout and how each element fits together is crucial for maintaining optimal performance. This section explores the key elements and the overall structure of the canister unit.

- The main body serves as the central container for water flow and filtration processes.

- Several trays or baskets are stacked within the canister to hold different types of filtration media.

- Seals and gaskets are used around the lid to prevent leaks and ensure a secure connection.

- The intake and output valves are positioned strategically to control water movement in and out of the unit.

- A motor or pump is located at the base or side to power the water flow through the system.

By understanding the structure and how these components interact, users can effectively manage the canister system for consistent and efficient water filtration.

Filter Media Options for the FX6

Choosing the right filtration materials is crucial for maintaining a healthy aquatic environment. Various types of media cater to different needs, ensuring effective water purification and clarity. This section explores the available options to optimize filtration performance.

- Mechanical Media: This type captures large particles and debris from the water. It is essential for pre-filtering and maintaining clarity.

- Chemical Media: Designed to remove impurities and unwanted substances, chemical media can enhance water quality significantly. Options include activated carbon and specialty resins.

- Biological Media: Supporting beneficial bacteria, this media facilitates the breakdown of harmful substances. It is vital for establishing a balanced ecosystem.

Using a combination of these media types allows for a more comprehensive filtration process, ultimately promoting a healthier environment for aquatic life.

Tubing and Valve Setup Guide

This section aims to provide a comprehensive overview of the proper arrangement and installation of flexible hoses and control mechanisms for optimal functionality. Understanding how to effectively connect these components can enhance the overall performance and reliability of your aquatic system.

To begin, ensure that you have the appropriate length of tubing to reach from the filtration unit to the desired outlet or intake. Measure carefully to avoid excess slack or tension, which can lead to inefficiencies. Once the correct lengths are determined, securely attach the tubing to the corresponding valves. This ensures a snug fit that prevents leaks.

When setting up the valves, position them strategically to allow for easy access and adjustment. Proper alignment is crucial; any misalignment can hinder the water flow and affect the performance of your setup. Additionally, regularly check for any signs of wear or damage in both the tubing and valves to maintain optimal operation.

Maintenance of Fluval FX6 O-Rings

Proper upkeep of sealing components is crucial for ensuring the longevity and efficiency of any filtration system. These elements are essential in preventing leaks and maintaining optimal performance, thus enhancing the overall functionality of the aquarium setup.

Regular inspection and maintenance of these seals can help in identifying wear and tear early on, allowing for timely replacements. Here are some best practices to consider:

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect O-rings for cracks or wear | Monthly | Replace if damaged. |

| Clean O-rings with a damp cloth | Monthly | Avoid harsh chemicals. |

| Lubricate with silicone grease | Every 6 months | Use a thin layer for best results. |

| Replace O-rings | As needed | Consider the manufacturer’s guidelines. |

By following these simple maintenance tasks, users can ensure that their sealing components remain in top condition, ultimately enhancing the reliability of their filtration systems.

Proper Installation of Intake Strainers

Correct placement of intake filters is crucial for maintaining optimal performance in water filtration systems. These components are designed to prevent debris from entering the pump, ensuring a smooth operation and longevity of the equipment. Proper installation helps enhance water flow and efficiency.

To begin, ensure that the strainers are clean and free from any obstructions before installation. Position them securely at the designated locations within the tank. It is important to check that they fit snugly to avoid any gaps that could allow larger particles to pass through. Regularly inspecting and cleaning these filters will further aid in their effective functioning.

Maintenance Tips:

- Inspect regularly: Check the strainers for blockages or wear.

- Clean thoroughly: Remove any buildup that may hinder performance.

- Replace when necessary: If strainers show signs of damage, consider replacing them to ensure optimal filtration.

Water Flow Control Components in FX6

Effective management of water circulation is crucial for maintaining a healthy aquatic environment. This section explores the various elements involved in regulating the flow of water within an advanced filtration system. Understanding these components allows users to optimize performance and enhance the overall functionality of their setup.

Adjustable Flow Rate Mechanisms

One of the key features of modern filtration systems is the ability to adjust the flow rate. These mechanisms enable users to customize water movement according to the needs of their aquarium inhabitants. By fine-tuning the flow, aquarists can ensure that sensitive species are not subjected to excessive currents, promoting a balanced ecosystem.

Intake and Output Valves

Intake and output valves play a vital role in directing water into and out of the filtration unit. These components are designed to create a seamless flow, preventing clogs and ensuring optimal filtration efficiency. Regular maintenance of these valves is essential to avoid disruptions in water circulation and to maintain a healthy habitat for aquatic life.

Gasket Seals and Their Importance

Gasket seals play a crucial role in ensuring the efficiency and reliability of various mechanical systems. These components are designed to create a tight barrier between surfaces, preventing the leakage of fluids and gases. Their effectiveness directly influences the overall performance and longevity of the equipment they are a part of.

Functionality of Gasket Seals

The primary function of gasket seals is to maintain a secure connection between components. By filling the microscopic gaps between mating surfaces, they minimize the risk of leaks. This not only helps in maintaining optimal pressure but also reduces the chances of contamination, ensuring that the internal environment remains stable.

Materials and Durability

Gasket seals are made from various materials, each selected based on the specific requirements of the application. Common materials include rubber, silicone, and metal, each offering different levels of resistance to temperature and pressure. Choosing the right material is essential for ensuring the longevity and effectiveness of the seal in its intended environment.

Fluval FX6 Replacement Part Guide

This section offers a comprehensive overview of essential components for a popular aquarium filtration system. Understanding the different elements that may require attention ensures optimal performance and longevity. Whether you are looking to replace a specific item or simply want to familiarize yourself with the system’s design, this guide provides valuable insights.

When maintaining an aquarium filtration setup, it’s crucial to identify which parts can wear out over time. Common items that may need replacement include seals, impellers, and media baskets. Each of these components plays a vital role in ensuring that the filtration process runs smoothly, thereby keeping the aquatic environment healthy.

Regularly inspecting and replacing worn parts not only enhances efficiency but also prolongs the lifespan of the entire system. It’s advisable to have a list of replacement options on hand to facilitate timely maintenance and prevent potential issues from arising.

Troubleshooting Common FX6 Issues

When maintaining an aquarium filtration system, various challenges can arise that affect performance. Identifying and resolving these common problems is essential for ensuring a healthy aquatic environment. This section offers insights into typical issues users may encounter and provides guidance on how to address them effectively.

Below are some frequent concerns along with their potential solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Weak water flow | Clogged filter media | Clean or replace the filter media to restore proper flow. |

| Unusual noise | Air trapped in the system | Purge the system to remove air bubbles; check for proper assembly. |

| Water leaks | Loose connections or damaged seals | Tighten connections and inspect seals; replace if damaged. |

| Filter not starting | Power supply issues | Ensure the power source is functioning; check for damaged cables. |

Addressing these concerns promptly can prevent further complications and maintain the efficiency of your filtration setup.