In the realm of transportation, understanding the intricate assembly of commercial vehicles is crucial for maintenance and repair. Each element plays a vital role in ensuring the efficiency and reliability of these robust machines. A comprehensive overview of these components not only aids in troubleshooting but also enhances overall operational performance.

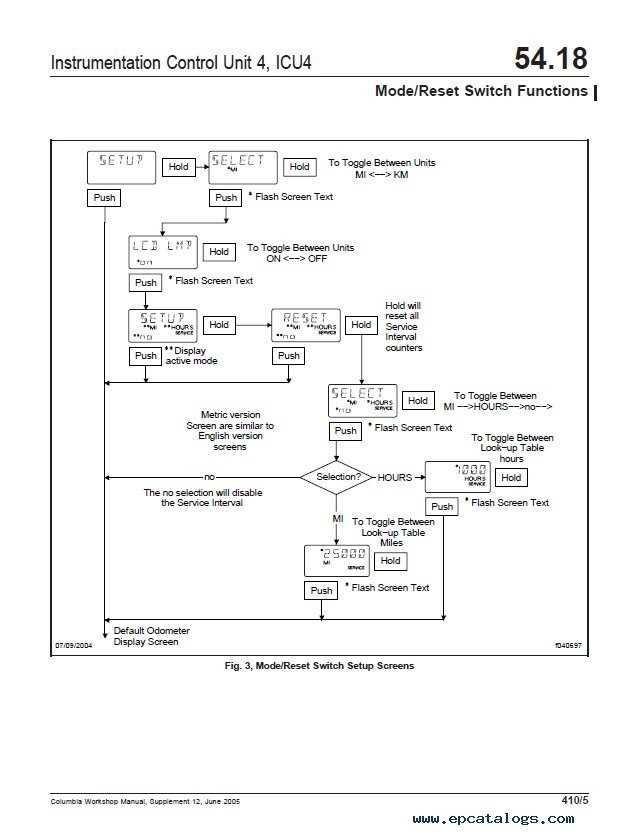

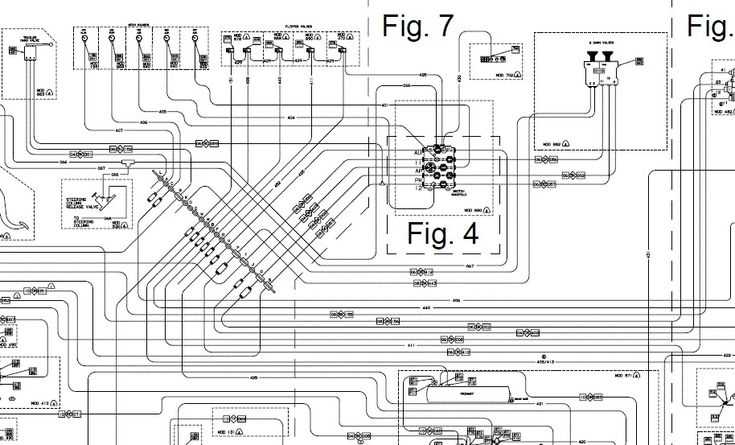

Visual representations of the various segments involved provide invaluable insights. By mapping out the relationships between different parts, one can quickly identify potential issues and streamline the repair process. This systematic approach is essential for both seasoned professionals and those new to the field.

Exploring these illustrations empowers truck operators and mechanics alike to make informed decisions. By familiarizing themselves with the layout and function of each component, they can ensure that their vehicles remain in optimal condition, ultimately contributing to safety and longevity on the road.

Understanding Freightliner Columbia Components

The intricate assembly of a heavy-duty vehicle consists of various elements that work in harmony to ensure optimal performance and durability. Each component plays a vital role, contributing to the overall efficiency and functionality of the machine. A comprehensive grasp of these elements is essential for maintenance and repairs, enabling owners to make informed decisions about their vehicles.

Key elements include the powertrain, suspension system, and braking mechanisms, each engineered to withstand rigorous demands. Understanding these systems helps in identifying potential issues before they escalate, ensuring safety and reliability on the road. Furthermore, familiarity with the layout of these components aids in effective troubleshooting and parts replacement.

Additionally, recognizing the connections between various systems can enhance overall vehicle performance. Regular inspection and maintenance of these critical components will lead to extended service life and improved efficiency, making it crucial for operators to stay informed and proactive.

Overview of Freightliner Columbia Design

The design of this heavy-duty vehicle is characterized by a blend of functionality and aesthetics, ensuring it meets the demands of long-haul transportation. Its aerodynamic shape not only contributes to fuel efficiency but also enhances stability on the road. This truck is engineered to provide optimal performance while prioritizing driver comfort and safety.

Key Features

The vehicle incorporates several essential features that set it apart in the market. The layout and configuration are thoughtfully crafted to facilitate maintenance and ensure longevity. Below is a summary of some of its most notable attributes:

| Feature | Description |

|---|---|

| Cab Design | Spacious interior with ergonomic controls for improved driver experience. |

| Aerodynamics | Sleek contours that minimize air resistance and enhance fuel efficiency. |

| Chassis | Robust framework designed to handle heavy loads and ensure durability. |

| Suspension | Advanced system that provides a smooth ride and better handling. |

Performance and Efficiency

The engineering behind this truck emphasizes both performance and economic operation. Its powerful engine options are coupled with sophisticated transmission systems, allowing for optimal power delivery and responsiveness. Additionally, advancements in fuel technology contribute to reduced emissions and enhanced efficiency, making it a responsible choice for modern transportation needs.

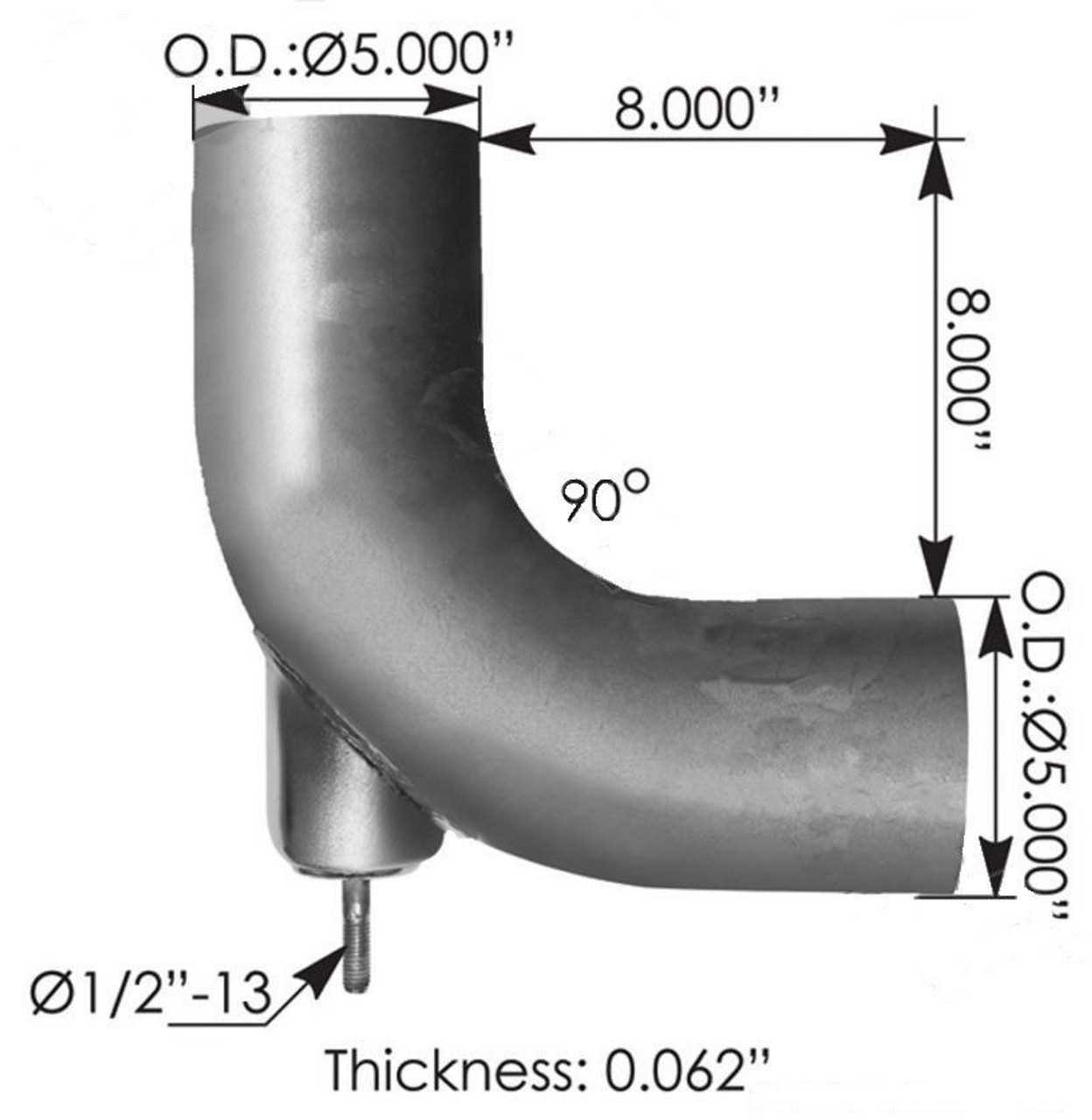

Importance of Accurate Parts Diagrams

In the realm of vehicle maintenance and repair, the precision of visual representations is crucial. These illustrations serve as essential tools, guiding technicians and enthusiasts alike in understanding the complex assembly of components. When dealing with machinery, having a clear, detailed visual reference can significantly streamline the process of troubleshooting and repairing various issues.

Facilitating Efficient Repairs

Accurate visual aids ensure that each element is properly identified, reducing the risk of errors during repairs. When mechanics can easily locate and reference each component, the time taken for maintenance tasks is minimized. This efficiency not only enhances productivity but also helps in avoiding costly mistakes that may arise from misidentification.

Enhancing Knowledge and Skills

In addition to aiding in immediate repair tasks, these representations serve an educational purpose. They provide valuable insights into the function and placement of individual elements, thereby enhancing the overall understanding of the machinery. As users become more familiar with the layout and interconnections, their skills and confidence in handling repairs grow, ultimately leading to a more proficient workforce.

Key Parts of the Freightliner Columbia

Understanding the essential components of a heavy-duty truck is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring the vehicle operates efficiently, offering reliability on the road. Below are some of the critical elements that contribute to the overall functionality of these robust machines.

Engine: The heart of any vehicle, the engine is responsible for powering the truck. It converts fuel into mechanical energy, providing the necessary force to move heavy loads. Regular maintenance and checks can prolong its lifespan and enhance performance.

Transmission: This component transfers power from the engine to the wheels. A well-functioning transmission allows for smooth gear shifts, which is essential for driving under various conditions. It is important to ensure the transmission fluid is at the correct level for optimal operation.

Chassis: The framework that supports the entire structure, the chassis is integral for stability and strength. It houses various systems, including suspension and braking, which are vital for handling and safety.

Suspension System: Designed to absorb shocks and provide comfort, this system ensures that the vehicle can handle rough terrains without compromising on ride quality. Maintaining the suspension components is essential for both comfort and control.

Braking System: A critical safety feature, the braking system allows for effective stopping power. Regular inspections and timely replacements of worn-out components are necessary to ensure reliable braking performance.

Electrical System: This system powers all electronic components, including lights, signals, and onboard technology. A well-maintained electrical system is vital for safety and functionality, particularly during long hauls.

Each of these components is fundamental to the reliable operation of a heavy-duty truck, emphasizing the importance of routine maintenance and timely repairs to ensure longevity and efficiency on the road.

Common Maintenance Issues and Solutions

Regular upkeep is essential for ensuring optimal performance and longevity of heavy-duty vehicles. Addressing frequent problems promptly can prevent costly repairs and enhance reliability on the road.

1. Engine Performance Issues

Engine troubles are a common concern among operators. Symptoms may include poor fuel efficiency or unusual noises.

- Check air filters regularly to prevent clogging.

- Monitor fuel quality to avoid contamination.

- Ensure regular oil changes to maintain lubrication.

2. Brake System Problems

Brake system maintenance is critical for safety. Signs of trouble can manifest as reduced responsiveness or unusual vibrations.

- Inspect brake pads and rotors for wear.

- Monitor fluid levels and check for leaks.

- Regularly test brake performance under various conditions.

Where to Find Parts Diagrams Online

Finding detailed illustrations of vehicle components can greatly assist in maintenance and repairs. Various online resources provide access to these valuable visuals, ensuring you have the necessary information at your fingertips.

- Manufacturer Websites: Official sites often host comprehensive manuals and visual aids for their models.

- Online Marketplaces: Platforms like eBay and Amazon sometimes feature listings that include links to technical documents.

- Forums and Communities: Enthusiast groups can be a treasure trove of shared knowledge and resources.

- Repair Manuals: Websites dedicated to repair guides may offer downloadable manuals with detailed visuals.

- YouTube Tutorials: Video content frequently includes links to diagrams and part locations in the description.

Utilizing these resources can streamline your search for essential visuals, making the repair process more efficient.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that enhance the longevity and performance of your vehicle. These high-quality items are designed specifically to meet the standards set by the manufacturer, ensuring optimal compatibility and reliability.

- Quality Assurance: OEM items are produced to the exact specifications, guaranteeing durability and superior performance.

- Perfect Fit: Designed for seamless integration, these components reduce the risk of installation issues and operational failures.

- Enhanced Performance: Using original parts maintains the vehicle’s efficiency and performance, contributing to better overall functionality.

- Warranty Protection: Many manufacturers offer warranties on OEM items, providing peace of mind and financial protection.

- Resale Value: Vehicles maintained with genuine components often retain higher resale values due to their reliability and condition.

Incorporating original items is a smart investment for maintaining the integrity and performance of your vehicle over time.

Aftermarket Parts: Pros and Cons

When it comes to vehicle maintenance and repairs, many owners consider options beyond original components. Aftermarket solutions offer a wide range of alternatives that can significantly impact both performance and budget. Understanding the advantages and disadvantages of these alternatives is essential for making informed decisions.

Pros: One of the primary benefits of aftermarket solutions is cost-effectiveness. These alternatives often come at a lower price than original manufacturer offerings, allowing owners to save money without sacrificing quality. Additionally, the variety available can lead to enhanced customization, enabling modifications tailored to specific preferences or needs. Furthermore, many aftermarket manufacturers invest in innovation, sometimes providing improved technology or performance compared to standard options.

Cons: On the flip side, quality can be inconsistent among aftermarket offerings. While some manufacturers produce reliable products, others may compromise on durability or performance. This variability can lead to potential issues down the line, necessitating further repairs. Additionally, using non-original components may void warranties or complicate insurance claims, creating long-term considerations for vehicle owners. Lastly, installation may require additional expertise, as not all aftermarket options fit seamlessly into existing systems.

In conclusion, while aftermarket alternatives present opportunities for savings and customization, careful evaluation of quality and potential risks is crucial for maintaining vehicle integrity and performance.

How to Interpret Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations serve as a guide, offering clarity on the relationship between various elements. Familiarity with the layout can significantly enhance your efficiency when working on complex machinery.

Key Elements to Consider

When analyzing these visual aids, focus on the following aspects:

| Element | Description |

|---|---|

| Labels | Each part is typically labeled, indicating its function or identification number. |

| Connections | Arrows or lines show how components are linked or interact with each other. |

| Symbols | Standardized symbols may represent specific types of components or actions. |

Steps to Effective Interpretation

To make the most of these visuals, follow a systematic approach. Start by familiarizing yourself with the overall layout, then identify key parts. Cross-reference with manuals or guides to confirm details, ensuring a comprehensive understanding of the system.

Tools Needed for Parts Replacement

Replacing components in heavy-duty vehicles requires specific instruments to ensure the job is done efficiently and safely. Having the right tools at hand not only streamlines the process but also minimizes the risk of damage to the vehicle.

Here is a list of essential instruments you should gather before starting the replacement:

- Socket Set: A comprehensive socket set will allow you to remove various fasteners easily.

- Wrenches: Both adjustable and fixed wrenches are vital for gripping and turning nuts and bolts.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

- Impact Driver: Useful for loosening stubborn bolts without stripping them.

- Pliers: Essential for gripping, bending, or cutting wires and small components.

- Jack and Jack Stands: Required for safely lifting the vehicle for undercarriage work.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is necessary for various screws.

- Cutting Tools: Wire cutters and utility knives for cutting through cables and other materials.

Having these tools organized and accessible will significantly enhance your efficiency during the replacement process, ensuring a smooth operation from start to finish.

Cost Considerations for Replacement Parts

When it comes to maintaining heavy-duty vehicles, understanding the financial implications of component replacements is crucial. Various factors contribute to the overall expense, from the quality of the items to sourcing methods. Budgeting effectively ensures that operators can keep their vehicles in optimal condition without unexpected financial strain.

One of the primary considerations is the balance between quality and price. Higher-quality components often come at a premium, but they may provide better durability and performance, potentially reducing the need for frequent replacements. Conversely, opting for lower-cost alternatives can lead to savings in the short term, but these items may wear out faster, resulting in increased long-term costs.

Another factor to evaluate is the source of the replacements. Purchasing from authorized dealers typically guarantees authenticity and reliability, but these options may be more expensive. In contrast, aftermarket suppliers can offer competitive pricing, although it’s essential to thoroughly research their reputation and the quality of their products to avoid subpar options.

Labor costs should also be factored into the overall expenditure. Some replacements require specialized knowledge or tools, which can drive up service fees. Therefore, it’s wise to consider whether to perform installations in-house or hire a professional, as this decision can significantly affect the total cost of ownership.

Finally, it’s beneficial to explore warranty options. Some replacements come with guarantees that can safeguard against early failures, providing peace of mind and financial protection. Assessing these warranties can be an important aspect of making informed purchasing decisions.

Repair Tips

Maintaining heavy-duty vehicles requires careful attention to detail and regular upkeep. By following these essential repair tips, you can enhance performance and extend the lifespan of your machinery. Proper diagnostics and timely interventions play a crucial role in preventing larger issues down the line.

Regular Inspections

Conducting frequent checks can help identify problems early. Focus on the following key areas during your inspections:

| Component | Inspection Tips |

|---|---|

| Brakes | Check for wear and fluid levels. |

| Fluids | Monitor oil, coolant, and transmission fluid regularly. |

| Tires | Examine tread depth and pressure. |

Common Fixes

Understanding typical issues can simplify repairs. Here are a few common fixes that can be addressed easily:

| Issue | Solution |

|---|---|

| Overheating | Check coolant levels and radiator condition. |

| Poor Fuel Economy | Inspect air filters and fuel injectors. |

| Electrical Problems | Examine battery and connections for corrosion. |

Resources for DIY Repairs and Maintenance

For those who enjoy tackling their own repairs and upkeep, having access to reliable information and tools is essential. This section provides valuable resources to enhance your skills and ensure your vehicle runs smoothly.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Communities where enthusiasts share tips and troubleshooting advice. | Visit Forum |

| Video Tutorials | Step-by-step guides available on platforms like YouTube for visual learners. | Watch Tutorials |

| Repair Manuals | Detailed documentation offering specifications and repair instructions. | Access Manuals |

| Parts Suppliers | Online stores providing quality components for maintenance and repair. | Shop Parts |