In the realm of heavy-duty vehicles, a comprehensive overview of their assembly is essential for effective maintenance and repairs. Familiarizing oneself with the layout of various elements within these machines can significantly enhance operational efficiency. Knowledge of each component’s placement aids in identifying potential issues swiftly, ensuring seamless functionality.

Visual representations play a crucial role in grasping the intricate relationships between different parts. By utilizing such illustrations, technicians can better comprehend how each section interacts with others, paving the way for more informed decisions during service tasks. This understanding is vital not only for repairs but also for optimizing overall performance.

Exploring these layouts empowers users to navigate the complexities of vehicle maintenance with confidence. Armed with this information, individuals can approach repairs systematically, reducing downtime and extending the lifespan of their machinery. A solid foundation in component arrangement ultimately leads to improved reliability and productivity in the field.

Precise illustrations are essential in various technical fields, serving as vital tools for understanding complex systems. These visual representations provide clarity and facilitate effective communication among professionals, ensuring that all parties have a shared understanding of the components and their relationships.

Enhancing Understanding

Detailed visual aids significantly improve comprehension. By offering a clear depiction of intricate mechanisms, they allow individuals to grasp how different elements interact within a system. This clarity is particularly beneficial for:

- Training new employees on equipment operation.

- Facilitating troubleshooting and maintenance procedures.

- Assisting in the identification of components and their functions.

Improving Efficiency

Accurate visuals contribute to operational efficiency by minimizing errors. When workers can reference reliable representations, they are less likely to make mistakes during assembly or repair tasks. The benefits include:

- Reduced downtime due to fewer incorrect installations.

- Faster resolution of technical issues.

- Increased productivity and morale among staff.

Common Freightliner Models Overview

This section provides an overview of popular heavy-duty vehicle models from a leading manufacturer, focusing on their distinctive features and applications in various industries. Understanding these models can aid in selecting the appropriate option for specific transportation needs.

Popular Models

- Columbia – Known for its versatility and fuel efficiency, this model is widely used for regional and long-haul trucking.

- Cascadia – Renowned for its aerodynamic design, it offers superior handling and enhanced safety features, making it a preferred choice for long-distance transport.

- Business Class M2 – This model is designed for medium-duty applications, excelling in urban deliveries and service-oriented tasks.

Key Features

- Robust engine options for varying power requirements.

- Advanced safety technologies to protect drivers and cargo.

- Comfortable cab designs that enhance driver productivity.

Key Parts and Their Functions

Understanding the essential components of a vehicle is crucial for effective maintenance and operation. Each element plays a specific role in ensuring the smooth functioning of the entire system. Here, we will explore several critical elements, highlighting their individual functions and importance.

| Component | Function |

|---|---|

| Engine | Converts fuel into mechanical energy, providing the necessary power for movement. |

| Transmission | Transmits power from the engine to the wheels, allowing for speed and torque adjustments. |

| Brakes | Enables the vehicle to slow down or stop by applying friction to the wheels. |

| Suspension | Absorbs shocks from the road, enhancing ride comfort and vehicle stability. |

| Steering System | Allows the driver to control the direction of the vehicle, ensuring precise maneuverability. |

| Electrical System | Provides power to various components, including lights, ignition, and sensors. |

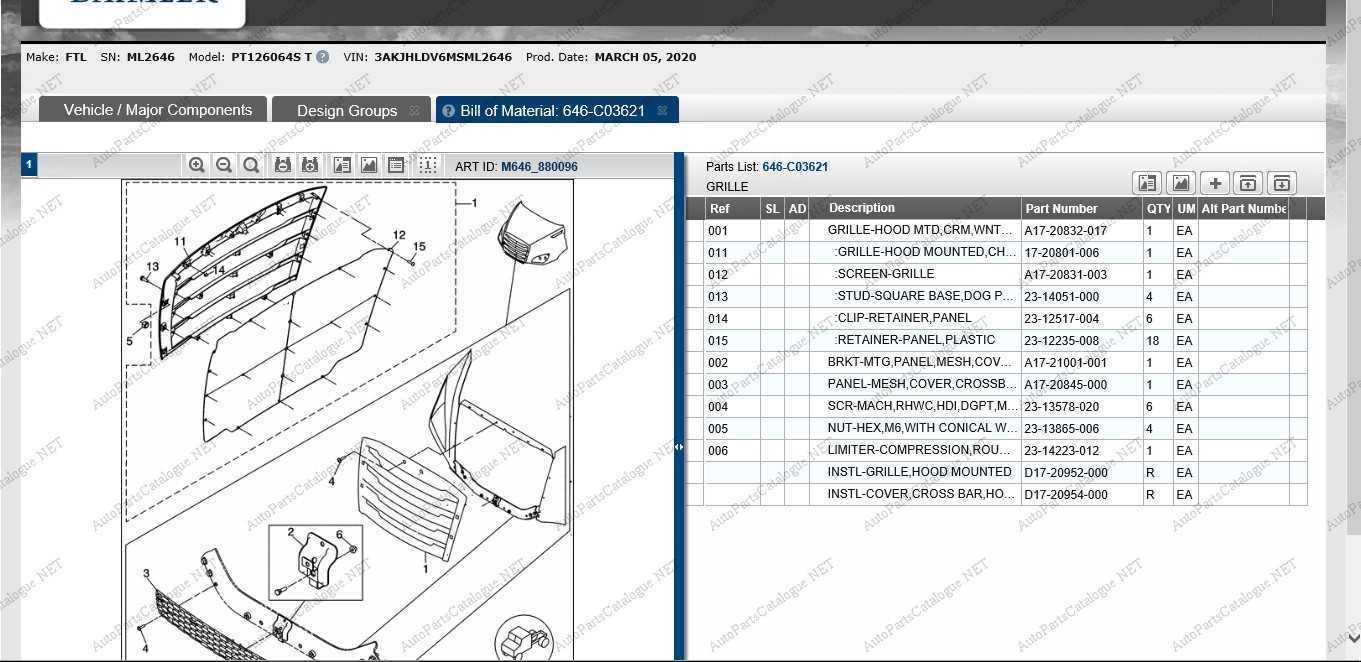

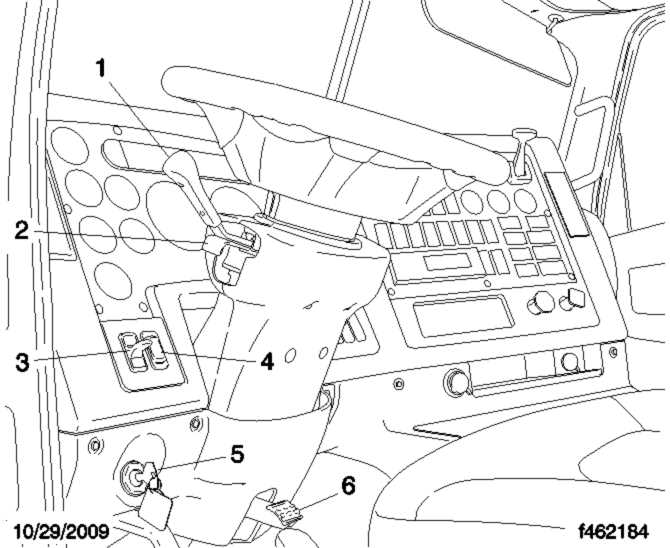

How to Read Parts Diagrams

Understanding technical illustrations is essential for identifying components and their relationships within machinery. These visuals serve as valuable tools for both maintenance and assembly, providing a clear representation of various elements and their functions. Grasping how to interpret these visuals can significantly enhance troubleshooting and repair processes.

When examining these visuals, begin by familiarizing yourself with the symbols used to represent different elements. Each icon typically corresponds to a specific component, and recognizing these symbols will streamline the identification process. Pay attention to accompanying legends or keys, as they offer critical information regarding the meaning of each symbol.

Next, observe the layout of the illustration. Components are often arranged logically, reflecting their physical connections and relationships. Understanding this spatial arrangement helps you visualize how parts interact, making it easier to pinpoint areas requiring attention. Additionally, take note of any annotations or labels, as they provide further context about the components, including part numbers and specifications.

Lastly, practice is crucial. The more you engage with these visuals, the more proficient you will become in deciphering them. Over time, this skill will not only aid in effective repairs but also contribute to a deeper understanding of the overall system.

Using Diagrams for Maintenance

Visual representations play a crucial role in the upkeep of complex machinery. They provide a clear and concise way to understand the various components and their interconnections. By utilizing these visual aids, technicians can enhance their efficiency and accuracy when performing repairs or routine checks.

Understanding Components is significantly simplified through these illustrations. They highlight each element’s location and function, allowing for quicker identification of issues. This clarity helps maintenance personnel to focus on specific areas that require attention without unnecessary guesswork.

Furthermore, utilizing visual tools encourages a systematic approach to maintenance. By following the structured layout of the illustrations, technicians can ensure that no step is overlooked. This methodical practice reduces the risk of errors, ultimately leading to improved performance and longevity of the equipment.

Finding OEM Replacement Parts

Locating original equipment manufacturer (OEM) alternatives is essential for ensuring your vehicle operates at its best. These components are designed to meet the specific requirements set by the manufacturer, providing reliability and optimal performance. When searching for these items, consider a few key factors to facilitate the process.

Researching Reliable Sources

Start by identifying trustworthy suppliers that specialize in OEM alternatives. Here are some methods to find these vendors:

- Check online marketplaces that are well-known for offering high-quality automotive components.

- Consult forums and community groups focused on vehicle maintenance, where experienced users often share their recommendations.

- Visit authorized dealerships, as they typically stock a comprehensive range of OEM items.

Verifying Compatibility

Once you have identified potential sources, it is crucial to ensure the compatibility of the selected components with your vehicle. Follow these steps:

- Consult the vehicle’s manual for specific details regarding the required components.

- Cross-reference the part numbers provided by the suppliers with those listed in your vehicle’s documentation.

- Reach out to customer service representatives for assistance in confirming compatibility.

Aftermarket Parts vs. OEM

The decision between purchasing replacement components from independent suppliers or original manufacturers can significantly impact vehicle performance and longevity. Both options offer distinct advantages and disadvantages, making it essential to evaluate them based on specific needs and preferences.

Aftermarket components are often designed to meet or exceed the specifications of their original counterparts. They may provide cost savings and a wider variety of choices, which can be appealing for many vehicle owners. However, there are potential risks associated with quality and compatibility. On the other hand, original manufacturer components are crafted to the exact standards set by the vehicle’s maker, ensuring reliability and perfect fitment.

| Criteria | Aftermarket Components | OEM Components |

|---|---|---|

| Cost | Generally lower | Typically higher |

| Variety | Wide selection available | Limited to original offerings |

| Quality | Variable; depends on the manufacturer | Consistent; meets original specifications |

| Warranty | May vary by supplier | Usually comes with a manufacturer warranty |

| Availability | Easily accessible | Available through authorized dealers |

Ultimately, the choice between aftermarket and original components depends on individual requirements, budget, and the importance of quality assurance. Making an informed decision can lead to optimal performance and maintenance of the vehicle over time.

Frequently Asked Questions

This section aims to address common inquiries regarding the components and assembly of heavy-duty vehicles. Understanding these elements is essential for maintenance, repairs, and overall vehicle efficiency.

What should I do if I can’t find a specific component?

If a particular element is not available, consider consulting the manufacturer’s resources or authorized dealers for alternatives or replacements. Online forums and communities can also provide valuable insights.

How can I identify the right components for my vehicle?

Identification can typically be achieved through reference manuals, which include detailed information about specifications and compatibility. It’s advisable to check vehicle identification numbers (VIN) when seeking components.

Is it necessary to use original components for repairs?

While original components are often recommended for optimal performance and longevity, high-quality aftermarket options may also be viable. Assessing warranty implications is crucial before making a decision.

How often should I perform maintenance on my vehicle?

Regular maintenance should align with the manufacturer’s guidelines, typically performed every few thousand miles or as indicated by the vehicle’s monitoring system. Adhering to these schedules helps ensure reliability.

Resources for Further Learning

Acquiring in-depth knowledge about vehicle components is essential for both enthusiasts and professionals in the automotive industry. There are numerous avenues available for individuals seeking to enhance their understanding of these intricate systems. Engaging with reputable sources can significantly improve your expertise and confidence in working with various vehicle mechanisms.

Books and Manuals

Investing in well-regarded literature can provide foundational knowledge and advanced insights into vehicle systems. Look for technical manuals and reference guides that cover a wide range of topics.

Online Courses and Tutorials

Digital platforms offer a plethora of educational courses tailored to different skill levels. These resources often include video tutorials, interactive quizzes, and community forums for discussion.

| Resource Type | Examples |

|---|---|

| Books | Automotive Technology: A Systems Approach, Haynes Repair Manuals |

| Online Courses | Coursera, Udemy, LinkedIn Learning |

| Websites | HowStuffWorks, AutoZone, Car and Driver |

Tips for Effective Parts Management

Efficient management of components is crucial for maintaining operational effectiveness in any industry. Implementing organized strategies can lead to improved productivity and reduced downtime. Here are some practical suggestions to enhance the management of your inventory.

Establish a Comprehensive Inventory System

Creating a detailed inventory system helps in tracking components efficiently. Consider the following:

- Utilize inventory management software to automate tracking and ordering.

- Maintain accurate records of stock levels to avoid shortages and overstocking.

- Implement barcoding or RFID technology for real-time inventory updates.

Optimize Storage and Accessibility

Efficient storage solutions can significantly improve retrieval times and minimize errors. Focus on these aspects:

- Organize components logically based on usage frequency.

- Label storage areas clearly to enhance visibility and ease of access.

- Regularly assess storage methods to identify opportunities for improvement.