The FS 38 model offers a robust and reliable solution for various outdoor tasks, known for its durability and ease of use. Whether you’re an experienced user or new to the model, familiarizing yourself with its core components can significantly improve maintenance and performance. This section provides an in-depth look at how the different elements are organized, ensuring smooth operation over time.

Each component plays a specific role in the overall functionality of the FS 38. Knowing the arrangement of key elements helps in troubleshooting issues or replacing worn-out sections efficiently. By understanding the inner workings, users can optimize their machine’s longevity and performance.

Maintaining and caring for your FS 38 is essential for long-term use. This guide will highlight the essential elements, providing clear insights into the mechanisms that keep it running smoothly. Through this, users will gain a comprehensive overview of how to manage their tool effectively.

Understanding Key Components of FS 38

The FS 38 is known for its durability and efficiency, built with several crucial mechanisms that work together to ensure smooth operation. By familiarizing yourself with these key elements, you can gain a deeper appreciation of how the machine functions and maintain its optimal performance over time.

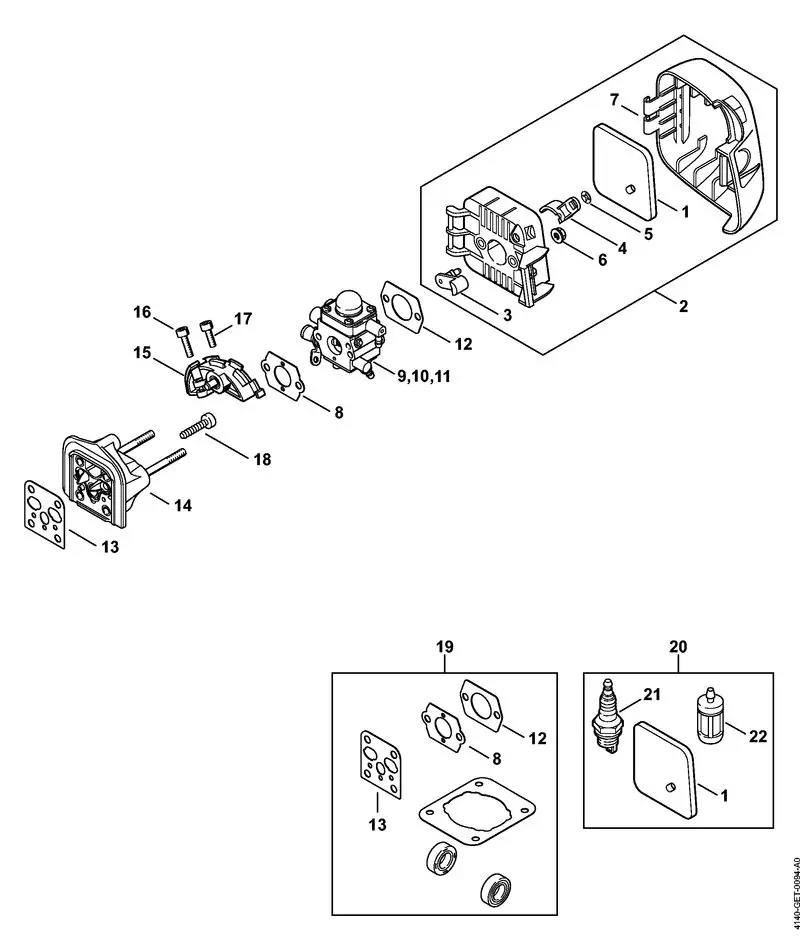

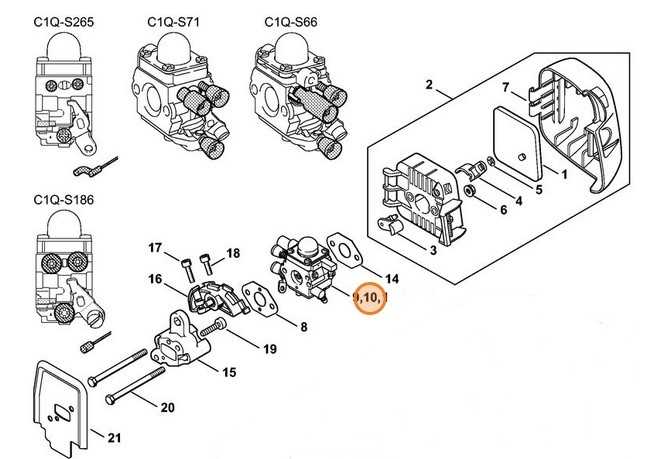

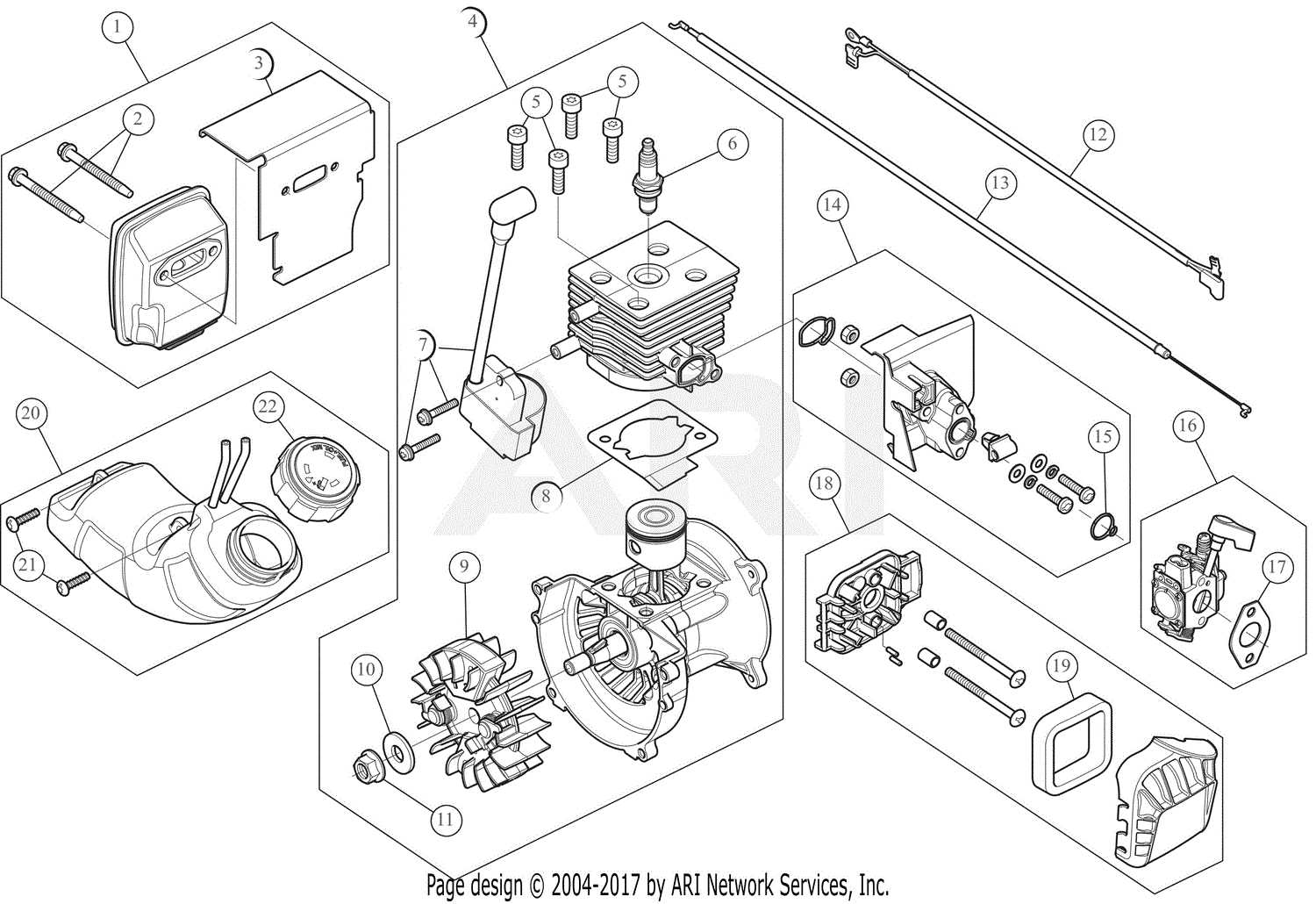

Engine and Fuel System

The heart of the FS 38 is its robust engine, designed to deliver consistent power. It works in tandem with the fuel system, which ensures a steady flow of fuel to keep the device running efficiently. Proper understanding of these features is essential for troubleshooting common operational issues and performing maintenance.

Cutting Mechanism

Another vital section of the FS 38 is its cutting system. This element allows precise trimming and efficient handling of various materials. Regular inspection and care of the cutting components will ensure longevity and reliable performance during use.

| Component | Description |

|---|

| Component | Description |

|---|---|

| Ignition Coil | Transforms battery voltage into a high voltage necessary for spark generation. |

| Spark Plug | Creates a spark that ignites the fuel-air mixture in the combustion chamber. |

| Distributor | Distributes the high voltage from the ignition coil to the correct cylinder at the right time. |

| Ignition Module | Controls the timing of the spark and may incorporate advanced features for improved performance. |

| Battery | Provides the electrical energy needed to power the ignition system. |

Understanding each component’s function helps in troubleshooting ignition-related issues and enhances the overall maintenance process. Regular checks and timely replacements can lead to improved engine performance and longevity.

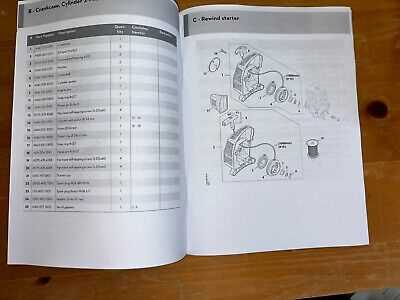

Starter Assembly Functions

The starter assembly plays a crucial role in the operation of a small engine by initiating the ignition process. Its primary function is to engage the engine and enable it to start running smoothly. This component is designed to convert electrical energy into mechanical energy, allowing for the efficient operation of the engine’s ignition system.

When the ignition key is turned, the starter assembly activates, engaging the flywheel and allowing the engine to begin its cycle. This engagement ensures that the engine’s internal components move properly, facilitating a smooth start-up. The assembly also incorporates safety features to prevent damage during operation, ensuring longevity and reliability.

In addition to initiating the engine start, the starter assembly contributes to the overall efficiency of the engine. It helps maintain optimal performance by ensuring that the engine operates at the correct speed and power output. Understanding the functions of the starter assembly is essential for diagnosing potential issues and maintaining the engine’s performance over time.

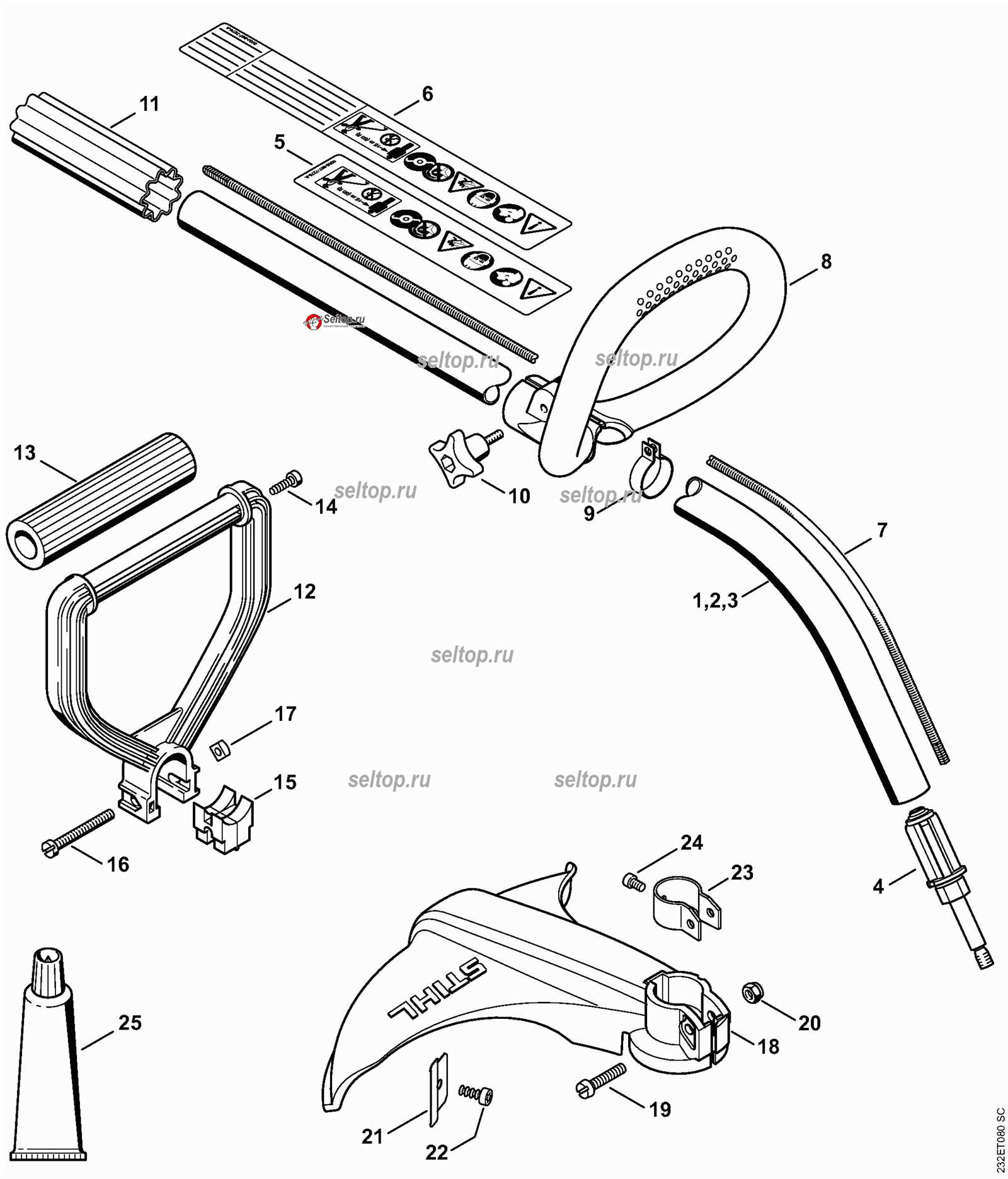

Throttle Control and Adjustments

The proper functioning of throttle control is crucial for optimizing the performance of your equipment. It governs the flow of fuel and air, directly influencing engine power and efficiency. Adjusting this component can enhance responsiveness and ensure smooth operation, making it essential for both novice and experienced users to understand the adjustment process.

When addressing throttle control, it is important to recognize the different elements involved in the system. Below is a summary of the key aspects to consider when making adjustments:

| Component | Function |

|---|---|

| Throttle Lever | Regulates the amount of air and fuel entering the engine. |

| Linkage | Connects the throttle lever to the engine, allowing for precise control. |

| Spring | Ensures the throttle returns to its default position when not engaged. |

| Adjustment Screws | Allow for fine-tuning of the throttle’s position and tension. |

To achieve optimal settings, one should periodically check these components for wear or misalignment. Making small adjustments can significantly impact performance, so careful calibration is recommended. Regular maintenance ensures reliability and prolongs the life of your equipment.

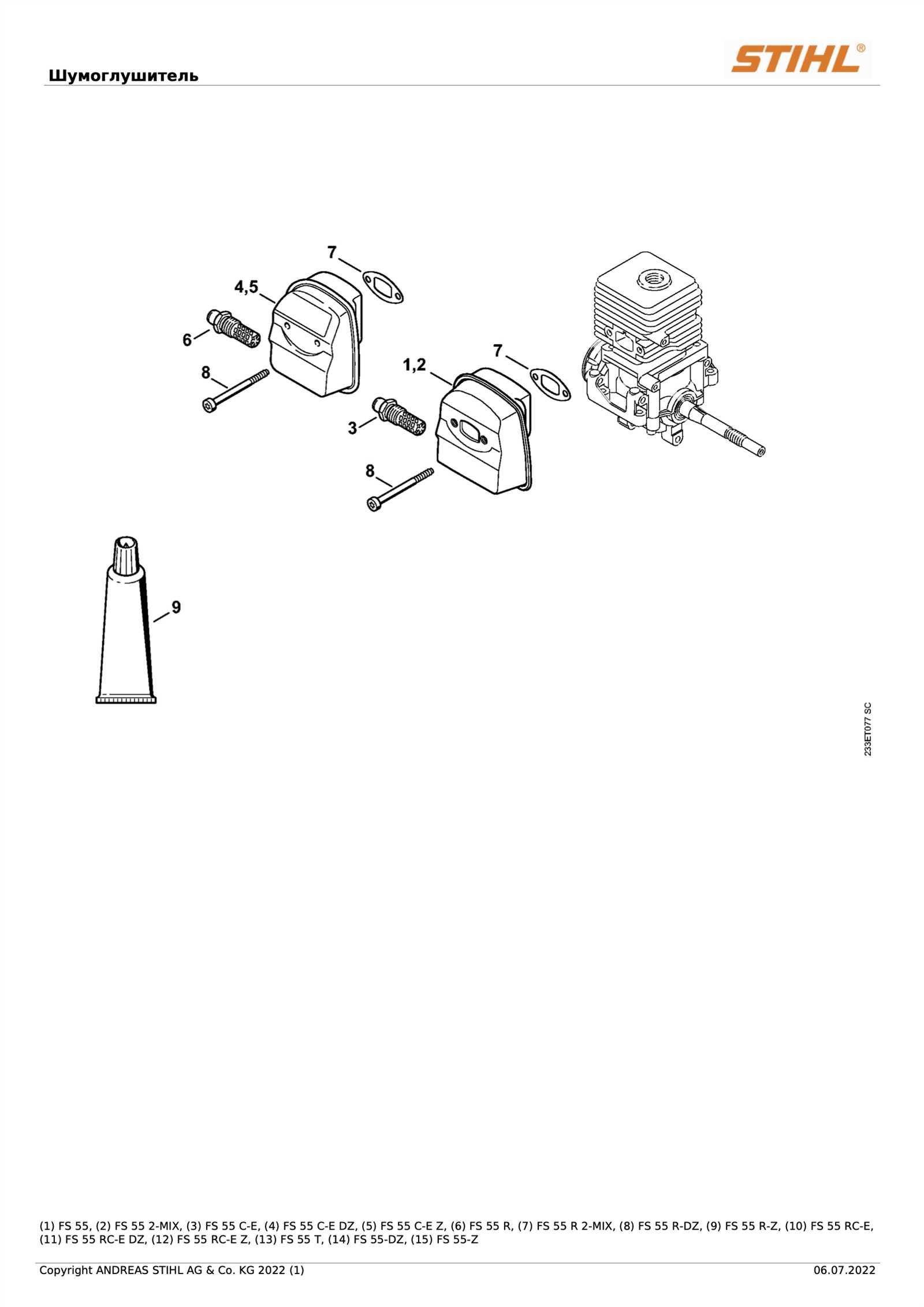

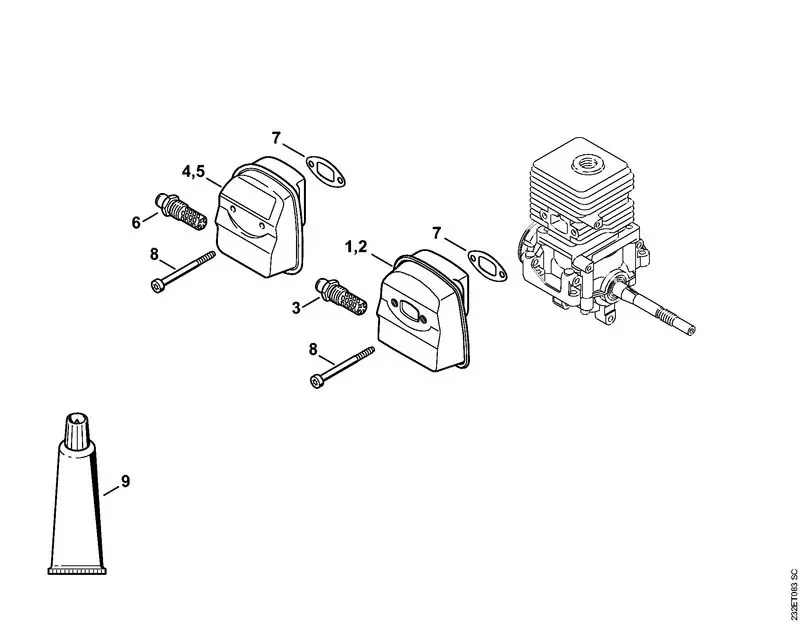

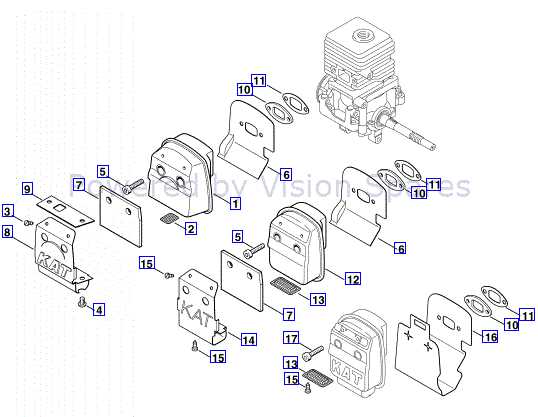

Muffler Assembly and Cleaning Tips

The muffler is a crucial component that contributes to the overall efficiency and performance of your equipment. Proper assembly and maintenance can enhance its functionality and longevity. This section offers insights into ensuring optimal assembly and effective cleaning techniques to keep your muffler in peak condition.

Assembly Guidelines

When assembling the muffler, ensure that all components fit snugly without excessive force. Start by aligning the parts accurately and securing them according to the manufacturer’s recommendations. Use appropriate tools to tighten connections, avoiding overtightening that could lead to damage. Regularly inspect the assembly for any signs of wear or misalignment, addressing issues promptly to maintain efficiency.

Cleaning Techniques

To maintain a clean and efficient muffler, periodic cleaning is essential. Begin by removing any debris or buildup from the exterior using a soft brush or cloth. For deeper cleaning, consider using a mixture of mild soap and water. Rinse thoroughly and ensure all parts are dry before reassembling. Avoid harsh chemicals that could corrode the materials. Regular maintenance will prevent clogs and improve overall performance.

Handlebar and Grip Features

The design of the control section plays a crucial role in the overall functionality and user experience of the device. This area not only facilitates maneuverability but also enhances comfort during prolonged usage. Understanding the various attributes of the handlebars and grips is essential for achieving optimal performance and ease of operation.

Ergonomic Design: The contours of the handlebars are meticulously crafted to provide a natural hand position, reducing strain on the wrists and forearms. This ergonomic feature ensures that users can maintain a comfortable grip, even during extended sessions.

Grip Materials: The materials used for the grips significantly influence the user’s handling experience. High-quality rubber or textured surfaces offer excellent traction, ensuring a secure hold even in challenging conditions. This feature is vital for maintaining control and stability while operating the device.

Adjustability: Some models incorporate adjustable handlebars, allowing users to customize their height and angle. This adaptability caters to individual preferences and body types, promoting a more personalized experience.

Integrated Controls: The inclusion of integrated controls on the handlebars enhances convenience by placing essential functions within easy reach. This feature minimizes the need for users to shift their grip or posture, promoting seamless operation.

Overall, the combination of ergonomic design, quality materials, adjustability, and integrated features contribute to a more enjoyable and efficient user experience, highlighting the significance of this aspect in the overall design of the equipment.

Protective Housing and Its Importance

The protective casing of any device plays a crucial role in ensuring its longevity and efficiency. This outer layer serves as a barrier against environmental factors, mechanical impacts, and various forms of damage that could affect the internal components. A robust housing not only safeguards the inner workings but also contributes to the overall functionality and performance of the equipment.

Enhancing Durability

One of the primary functions of protective housing is to enhance the durability of the machinery. By utilizing high-quality materials and innovative designs, the casing can withstand harsh conditions, preventing wear and tear. This resilience is vital in prolonging the life of the equipment, minimizing the need for frequent repairs or replacements.

Safety and Compliance

Another significant aspect of protective enclosures is ensuring user safety and compliance with industry standards. A well-engineered housing prevents accidental contact with moving parts or electrical components, reducing the risk of injuries. Furthermore, adherence to safety regulations not only protects users but also fosters trust in the brand and its products.

Trimmer Head Parts Explained

The trimmer head is a crucial component of any grass-cutting tool, designed to efficiently manage cutting lines and ensure optimal performance. Understanding the various elements that make up this assembly can enhance your maintenance skills and improve your tool’s longevity.

- Housing: The outer shell that encases the internal components, providing protection and structural integrity.

- Spool: A cylindrical device that holds the cutting line, allowing for easy replacement and adjustment of line length.

- Cutting Line: The flexible filament that extends from the spool, responsible for cutting grass and weeds with precision.

- Retaining Cap: A cover that secures the spool within the housing, preventing it from dislodging during operation.

- Line Feed Mechanism: A system that automatically advances the cutting line as it wears down, ensuring continuous cutting without manual intervention.

Each element plays a vital role in the overall functionality of the trimmer head, contributing to a seamless and effective trimming experience. Regular inspection and maintenance of these components will help in achieving optimal performance and extending the lifespan of your equipment.

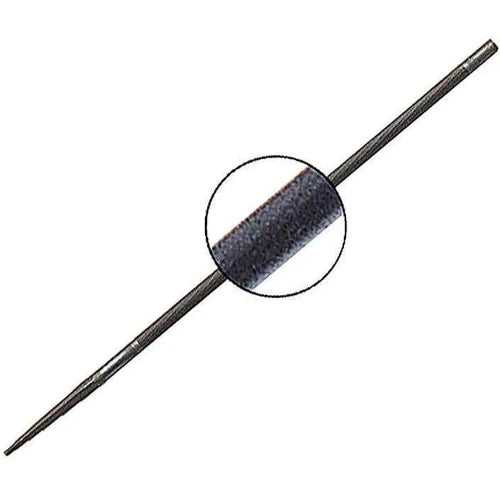

Drive Shaft Components and Care

The drive shaft is a crucial element of many machinery systems, transferring rotational force from the engine to the wheels or other components. Understanding its key components and maintenance practices is essential for ensuring optimal performance and longevity of the equipment.

Key Components: The primary elements of the drive shaft include the main shaft, universal joints, and couplings. The main shaft is responsible for transmitting torque, while universal joints allow for flexibility and movement during operation. Couplings are used to connect various sections of the drive shaft securely, ensuring a seamless transfer of power.

Maintenance Practices: Regular inspection and maintenance are vital to prevent wear and tear. Ensure that all joints are lubricated properly to minimize friction and prolong the life of the assembly. Look for signs of damage, such as cracks or excessive play in the joints, and replace any worn components promptly to avoid more significant issues.

Additionally, keeping the drive shaft clean from dirt and debris will help maintain its efficiency and reduce the risk of failure. Following these care practices will contribute to a more reliable and efficient operation of your equipment.